Builds

While several different rod builders have created limited-production vehicles, few handled every aspect of the construction in-house, mainly because they thought it best to team up with other craftsmen to create certain aspects of their cars. While this takes nothing away from the quality or beauty of the cars they created, it does say a good deal about SAR. By keeping every aspect of the construction process in-house, SAR has been able to maintain personally set tolerances and control the design theme at every juncture, yet still build each car as if it were the only one. And because each of the Double Dozens is offered simply as a “roller,” the final results of each still depend heavily on the imagination, talent and individuality of their owners. In the end, each of these cars will be special in its own right, and we’ll be showing them to you in the months and years to come.

Ok, you’ve lifted your rig so you can put those big tires on, and you take it out on it’s maiden wheelin’ trip. The first thing you notice is how the terrain seems to guide the tires while fighting your biceps. If this sounds familiar then you probably have manual steering. Many of the older rigs on the trail only came from the factory with a manual steering box. There are several options to remedy the manual steering blues. Upgrading to a power steering setup is the most basic route, then there are a number of companies specializing in hydraulic ram setups. There are also many combinations using common power steering boxes in addition to a hydraulic ram assist. With the vast variety of power steering system components available, the possibilities are quite endless.

Kinney Lazarus has owned several Jeeps over the years, and he had an interest in owning one of these vintage Willys pickups. While searching the Internet one day, he came across a running ’52 Willys 4WD pickup in Arkansas. He purchased the pickup online and had it shipped to his home in Georgia. Once he had possession of the truck, he quickly found that the performance of the original flathead four-cylinder engine left a lot to be desired by today’s standards. Also, being accustomed to a more modern ride, he found that the outdated suspension was less than desirable. In general, this classic Jeep was no fun to drive.

“I built this Jeep to handle a variety of terrain,” Todd Tice told us. “The coilover five-link rear and three-link front suspension provide excellent articulation for rockcrawling, and it is stable enough for hammering the desert at higher speeds. I wanted the Jeep to be able to handle most off-road challenges and still be able to cruise down the highway. This is an everyday driver,” he added.

Even though we all dream of blasting through the desert at 130-MPH like Robby Gordon, most of our 4×4 adventures take place at a much more reasonable pace. Unfortunately for our engines crawling along a boulder strewn dry river bed or climbing a goat trail through a mountain pass does not always allow enough airflow to keep our engines cool with a belt driven mechanical fan. Belt driven fans are designed to keep your engine cool when traveling down a street or highway not while crushing boulders at 3-MPH and 1,500-RPM. So what can we do to keep our rigs from boiling over this summer? Follow along with us as we install a pair of 11-inch electronic cooling fans along with a programmable fan controller both from SPAL USA.

Upgrading your Jeep for better off-road adventures sounds awesome, but sometimes it can cause unexpected problems. For example, when you install a Skyjacker Rock Ready-Double Flex Suspension Kit, you might notice your Jeep vibrating more than usual. That’s because the lift can mess with how the transfer case and rear axle line up. Luckily, Skyjacker has a solution called the Slip Yoke Eliminator (SYE) kit. It not only stops the vibrations but also makes your Jeep’s drive shaft stronger. In this guide, we’ll walk you through installing the NP 231 Short Shaft “Fixed Yoke” Kit. We’ll cover everything from the tools you need to important things to think about before you start. So, if you’re eager to boost your Jeep’s performance, keep reading to learn how Skyjacker can help.

OK, we all know that it is easy to ignore automatic transmission maintenance—its messy and time consuming and no one really thinks about it until the trans starts to slip. Most transmission pans are simple stamped steel and do not have a drain plug so draining the fluid makes a big mess on your garage or shop floor. If maintaining your automatic trans was easier and less messy you would probably stay on top of the maintenance wouldn’t you?

Off road racing in the desert Southwest has been around for almost forty years now and we’ve never gotten tired of looking at vehicles and hardware associated with going off-road. Off-roading–racing or just having fun presents problems. We’re always intrigued by some of the solutions.Here’s what we found on a recent trip to Baja.

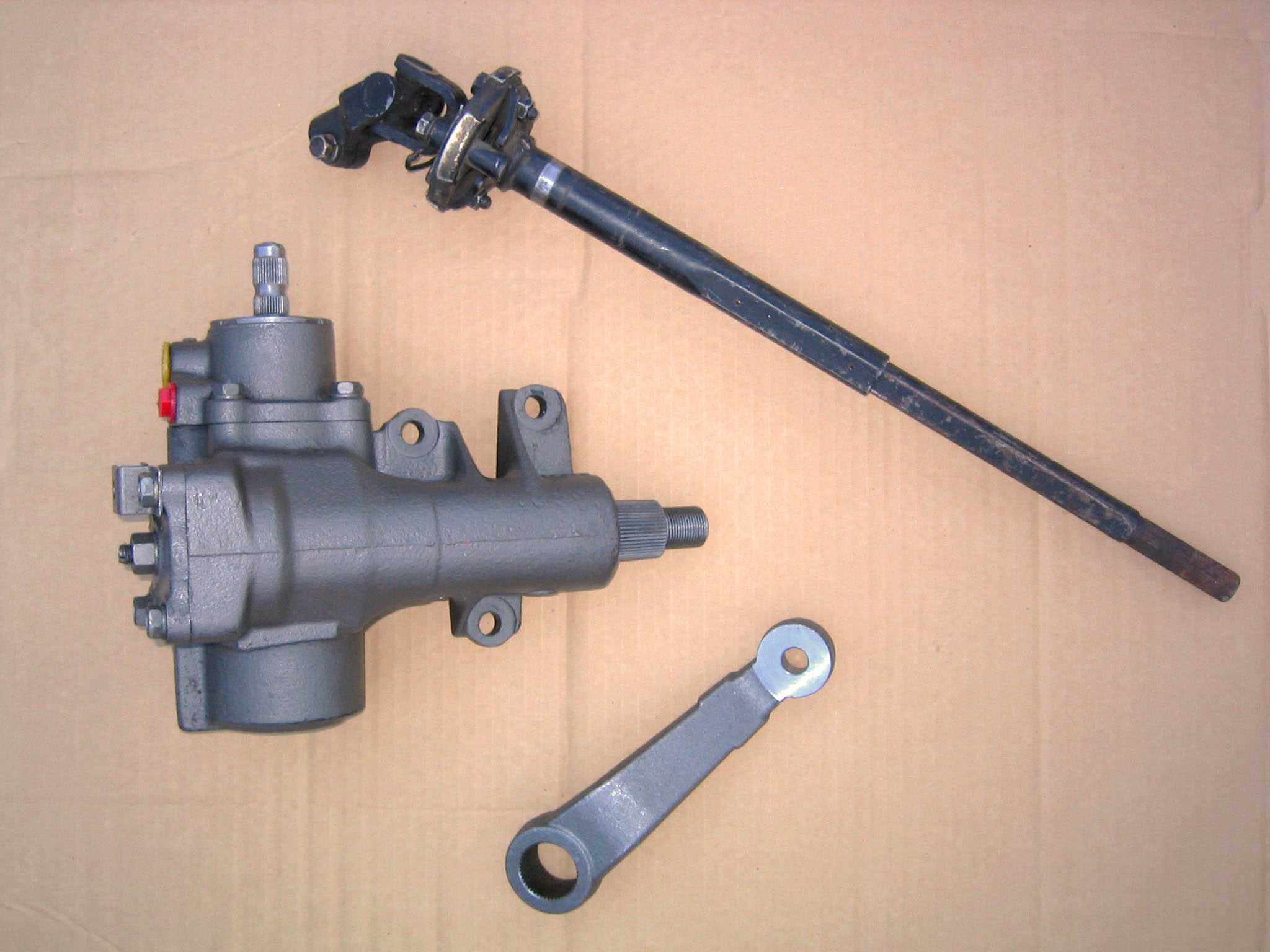

Steering is one of the two most important systems on any vehicle, along with the brakes. Unfortunately, steering is often neglected for modifications that yield more visual impact, such as suspension lifts and larger tires. These are the exact modifications, however, that make attention to steering so important. Suspension lifts can alter steering geometry while big, heavy tires may cause increased wear to steering components, particularly if the tires are out of balance.

After a springover conversion was performed on the Dana 44 front axle in our ’67 Toyota Land Cruiser, the new spring location interfered with the steering geometry. The draglink was then bent as a temporary fix, but this sacrificed strength and resulted in poor steering angles.

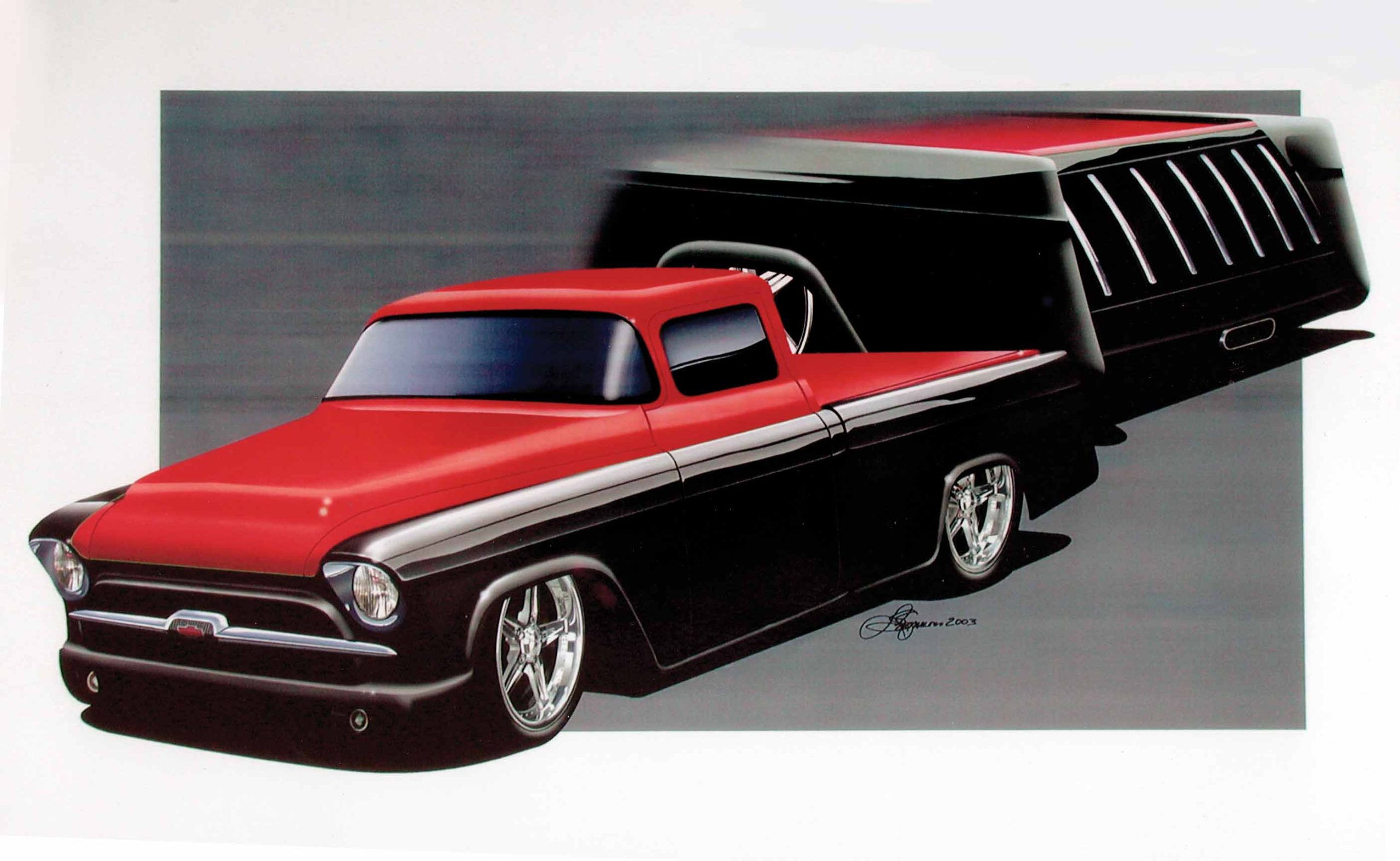

In part nine of our Cimtex Rods Super Cameo Buildup Series, we covered the installation of the Classic Industries Parts and Accessories reproduction ’55-’59 Chevrolet/GMC lower door hinge panels, doorsill rocker panels, upper and lower door hinges, new right- and left-side front floor pans, inner and outer lower cab patch panels, and right- and left-side truck cab supports. To put it in a nutshell, the crew at Cimtex Rods in Jarrell, Texas, basically rebuilt the whole bottom end of our Super Cameo ’56 Chevrolet big window truck cab from stem to stern. Now, with a rock-solid truck cab firmly bolted onto our Cameo’s highly modified C4 Corvette-suspended truck chassis, we closed with the promise that we would be installing a new set of Dynacorn International Inc. ’55-’59 Chevrolet/GMC reproduction truck doors, followed by angle-chopping the top on our ’56 big-window a total of 3-1/2 inches in the front and 3 inches in the rear. Unfortunately, things didn’t exactly go according to plan.