Engine

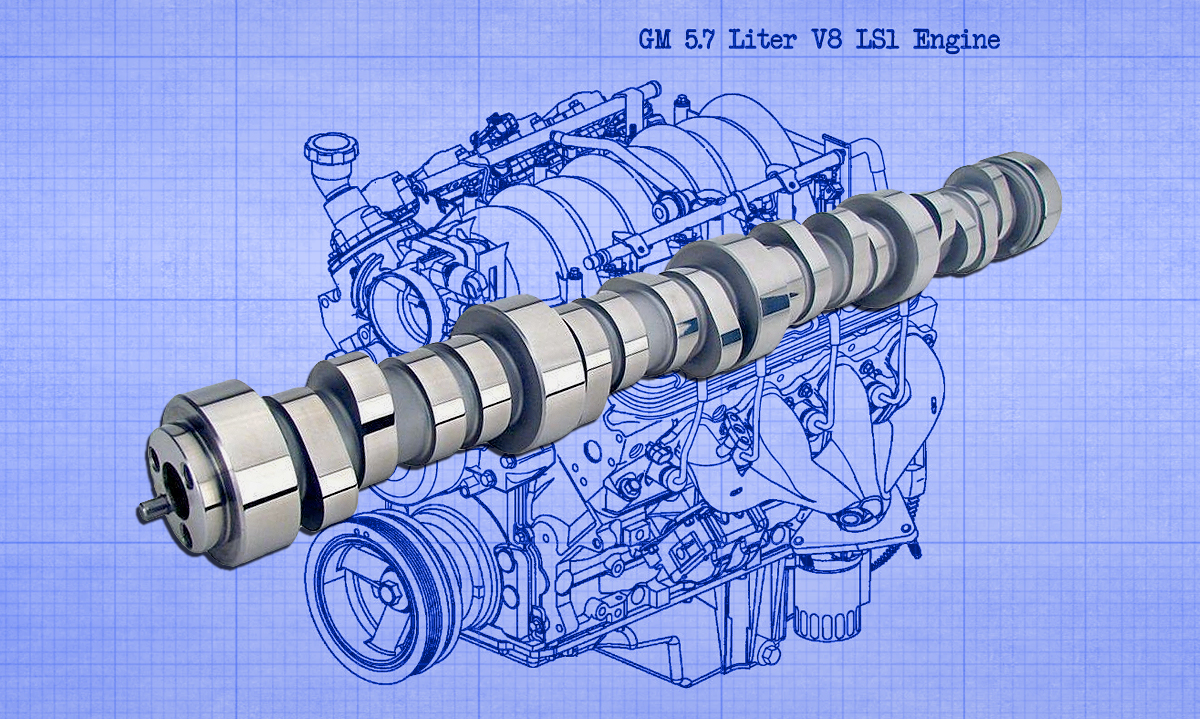

When it comes to adding power to your small-block Chevy, the camshaft is an integral part of the performance equation. Luckily for owners of Chevy’s latest iteration (Gen III) of the famous small block, the modern fuel-injected LS1 responds just as well to camshaft upgrades as the LT1s, L79s and L48s of old. Naturally, cam technology has come a long way since the days of the Duntov 30-30 profile. The improvements in cam technology are important, as the new LS1 is head and shoulders above any of the old ’60s and ’70s muscle-car small blocks, regardless of the advertised power ratings.

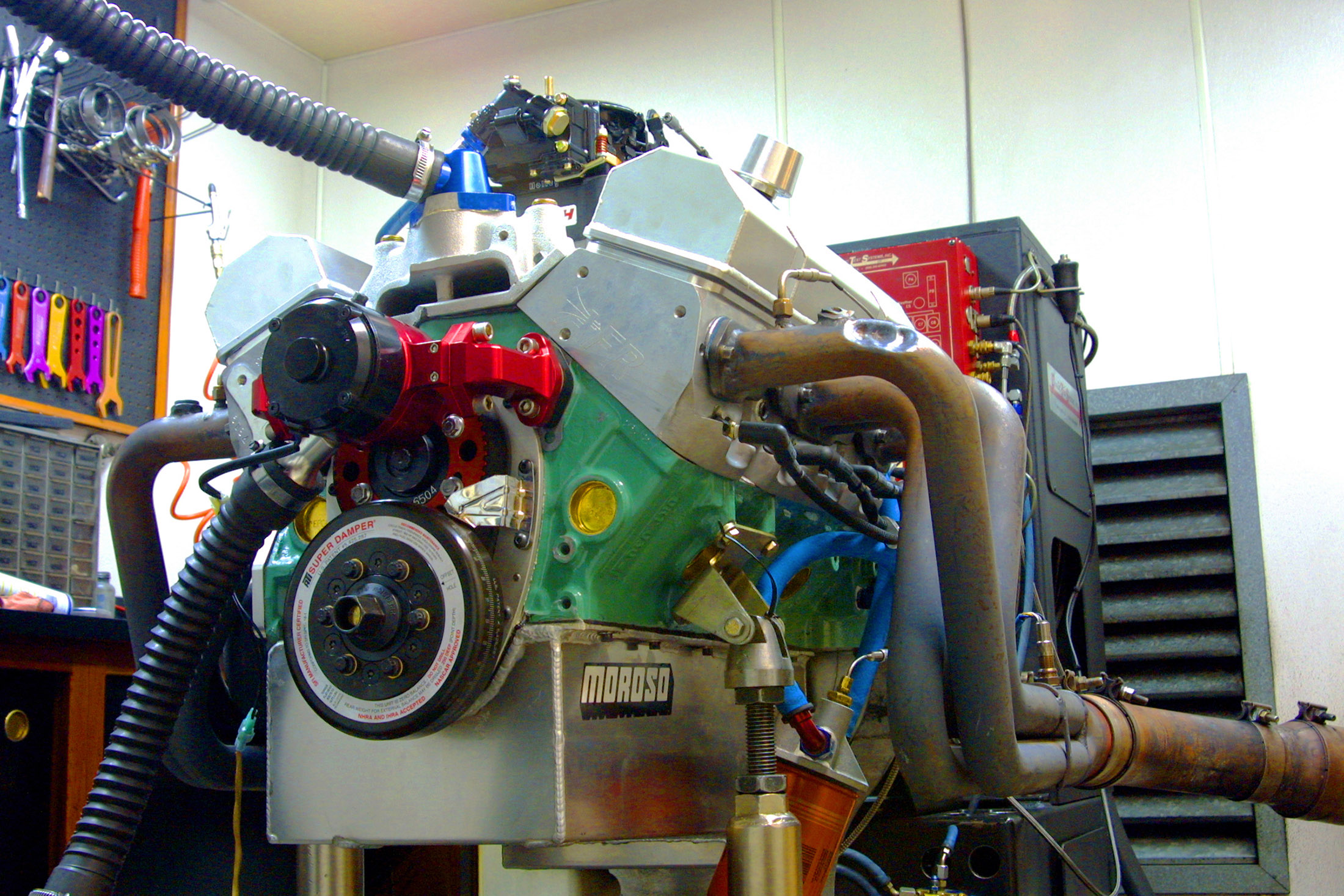

If you’ve ever imagined a time when you could simply pick up the phone or send an e-mail to General Motors and order the engine of your dreams, pull it out of a box delivered to your door and plug it into the car of your dreams, then stop dreaming as that time has come. While it’s not new information that GM Performance Parts provides an assortment of engines to choose from, it’s never been easier to select the one that is best for your budget and the intended purpose of your car.

Low in its architecture and functionally beautiful, the LS2 engine is an ideal replacement for a previous generation of Chevy powerplants. It offers good

performance, greatly improved economy and plenty of support from an industry leaders.

When GM introduced the Gen III small block in the F-body, it rekindled a dying performance flame with its new-generation small block. While the Gen I small block actually kick-started the hobby and got it into gear, it’s the latest family of small-block engines that has grabbed the attention of enthusiasts everywhere—and for good reason.

Honda did the right thing in refreshing the looks of the aging DC2 Integra platform, but somewhere along the retooling process, the terrific driving experience for which the Integra was known was lost somewhere. The Integra Type-R was a no-frills, high-performance sport compact that bordered on being a street-legal racecar, but without the loud exhaust or kidney-bruising ride; the RSX Type-S just doesn’t have the feel that the older Integra had—instead of being razor sharp and agile, the RSX feels numbed and subdued by comparison.

Ford fans will always have a soft spot in their blue-oval hearts for the Windsor, the Cleveland and the big 460 FE engines—and deservedly so. If you’ve ever crawled a junkyard for one of these engines, you’ve likely passed over more than a few 351M and 400 engines to find what you are looking for. Poor factory numbers and bad word-of-mouth have made these cousins to the mighty Cleveland about as wanted as poison ivy at a nudist colony, but there is power to be found in those engines—and cheap, too.

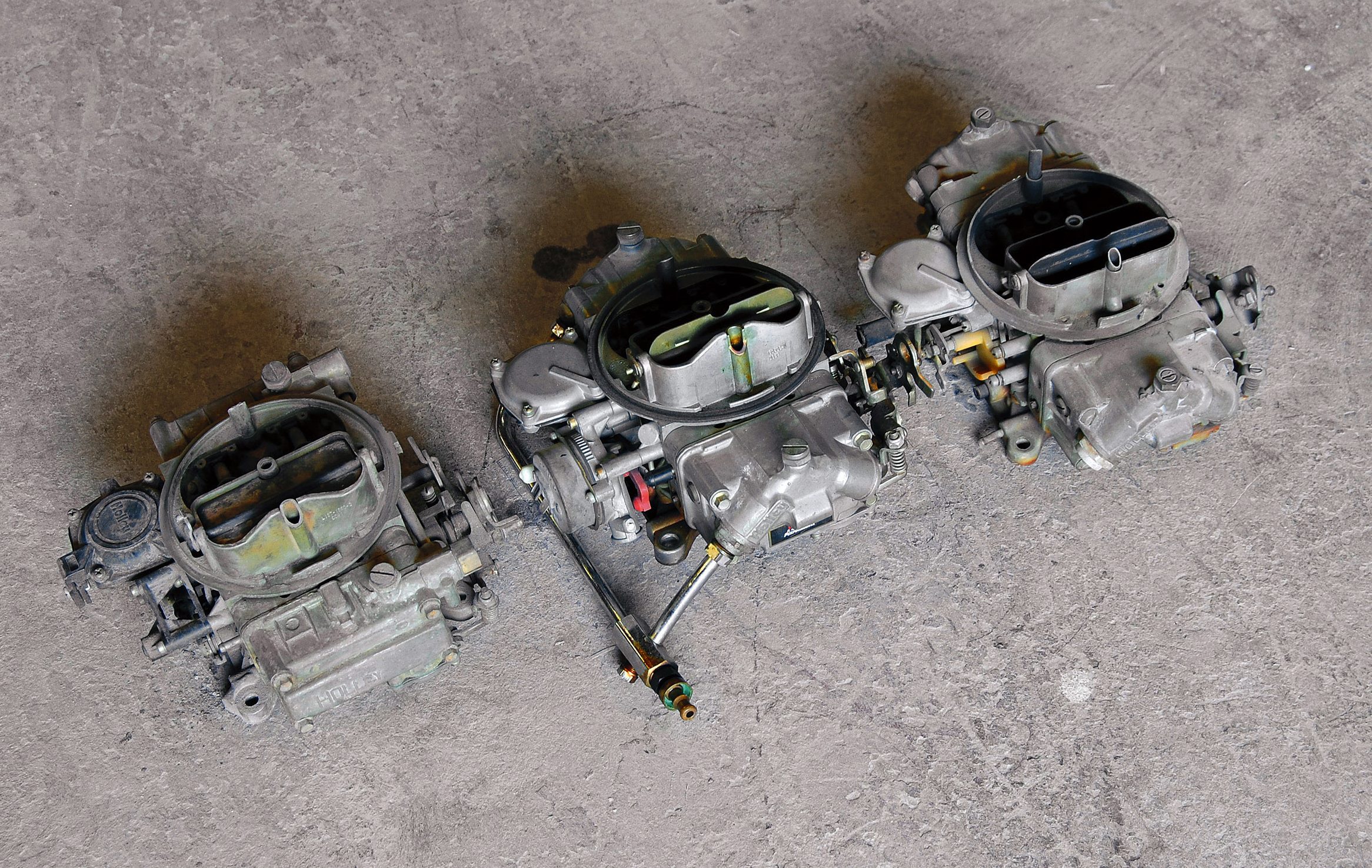

We showed you how to build a small-block engine that could make over 500 hp and 500 lb-ft of torque on 87-octane gas. It was a motor that could be driven just about every day with a hydraulic-roller cam and a good carburetor, making acquisition and maintenance almost nonexistent. Like many things we do in the engine world, the results we enjoyed—while good—just weren’t satisfying anymore. We wanted more.

Holley carburetors have long been a staple in the go-fast world of high-performance motoring, whether it’s NASCAR, drag racing or on the street. Much like other performance-oriented products—perhaps even more so with a carburetor—a carburetor requires a fundamental setup and a degree of maintenance, and that’s considering you have chosen the correct-size carburetor for your application, at least to get it in the ballpark. Knowing how to adjust, maintain and even repair your Holley carburetor goes a long way toward helping to ensure that your carburetor will make optimum horsepower for a long time. Because of this, we decided to compile a few troubleshooting and repair tips for the popular 4150-series Holley carburetor, which is the series designation for Holley’s street/strip and racing carburetors.

Alternative-fuel sources and hybrid cars are all the rage today. Everyone from major automakers to backyard inventors is pursuing alternative fuels and energy sources. While the ultimate goal is generally to eliminate dependence on foreign oil, for hot rodders there is also the desire to invent and create a better-performing engine.

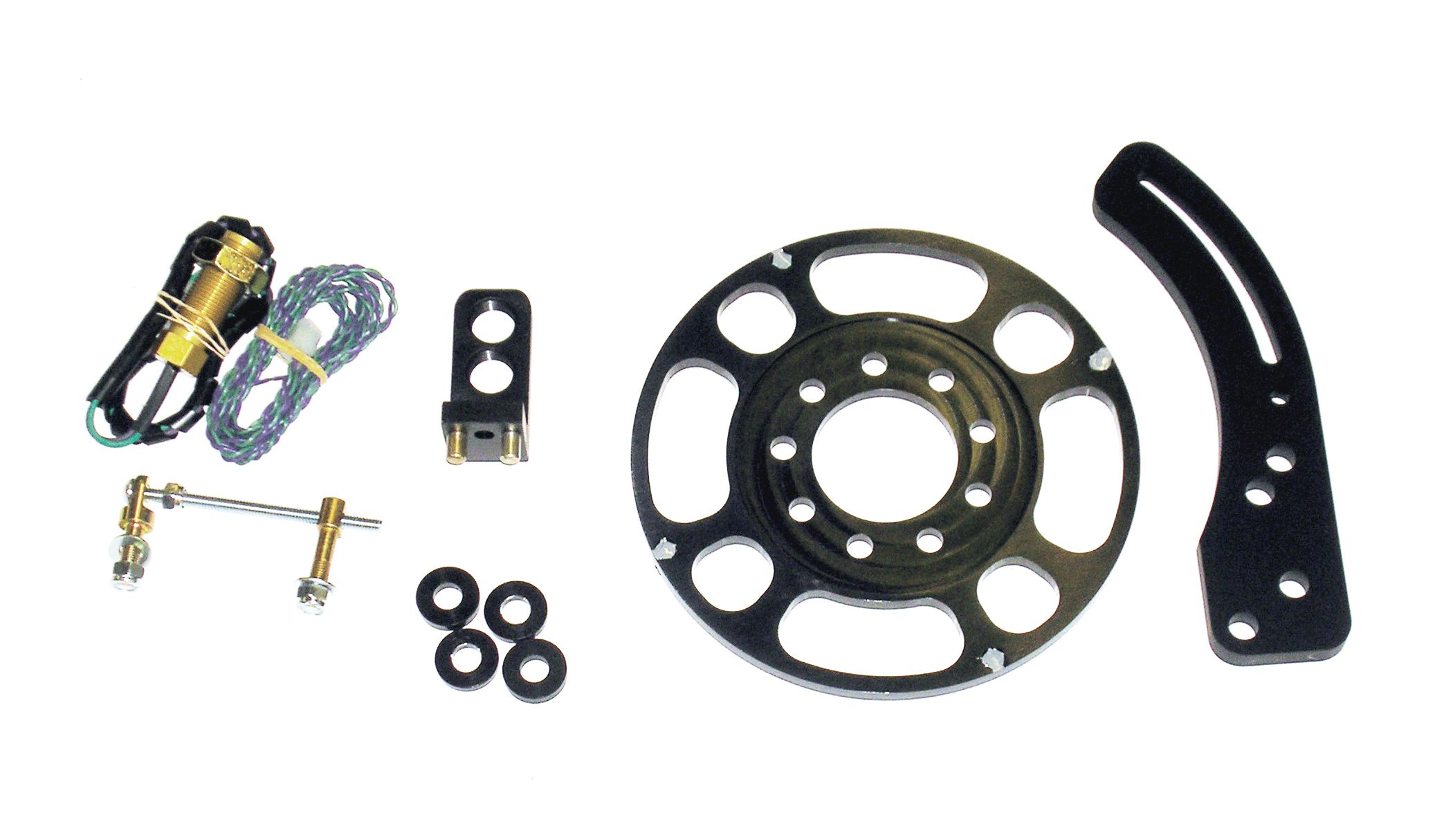

Crankshaft trigger mechanisms have been used in racing applications for a considerable length of time. In truth, they’ve actually been in service for decades. It’s a simple known fact that one of the best ways to improve engine performance is to ensure that the ignition timing is stable. That’s the whole purpose behind such a system, and that’s why racers regularly use them.