Trucks

GP-1 Conventional 80W-90 GL-5 Gear Oil is a conventional limited-slip gear oil for use as recommended by high performance gear and differential manufacturers. Designed for racing and high-performance differentials and transaxles, it’s formulated from USA made Pennsylvania Grade base oils that provide natural film strength, tack, and tenacious cling without relying on polymers that shear causing viscosity loss.

Pickup trucks from the ’30s were never meant to be high-quality hot rods, but several builders, including Jeff Lilly Restorations, are ready to change that theory. Lots of beater trucks are being built and driven frequently, and it’s great to see some of the cool ideas that come from these old farm or service trucks. Pickups are hot right now, and while some rodders are using low-gloss paint for their final coatings, many opt for a super-slick appearance with precision gaps and laser-straight panels.

If you are going to connect anything automatic to your car, especially when dealing with electricity, lead and acid, you owe it to yourself to do a bit more research rather than pulling just any super-discounted, off-the-shelf item and connecting it to something as potentially volatile as a lead-acid battery. But we have, haven’t we?

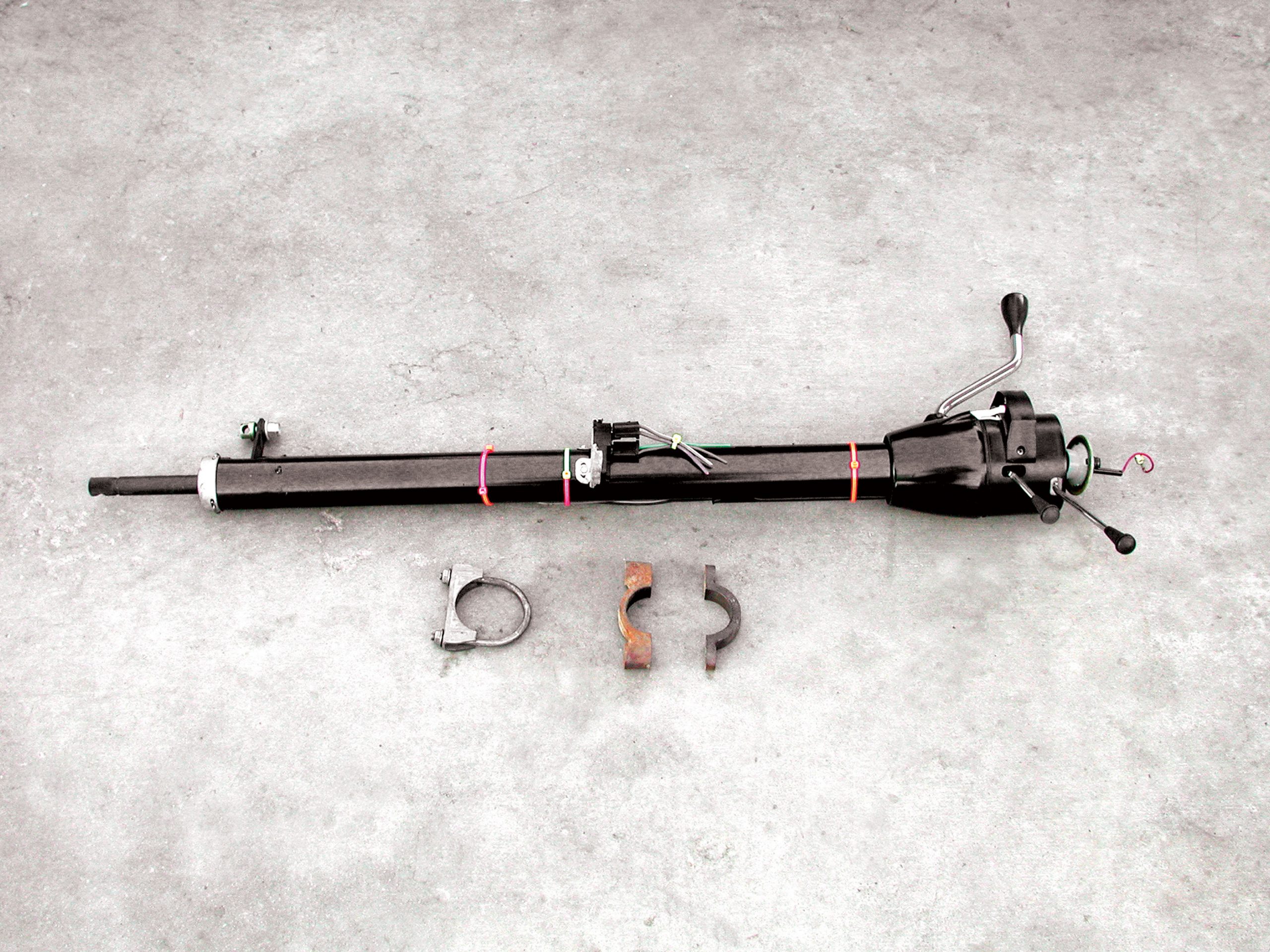

In the long continuation of our Project ’67, the 1967 Chevrolet C10 buildup, several major components and systems have been previously addressed, most notably the Goodwrench LQ4 6.0-liter 366ci Escalade engine buildup by Arizona Speed & Marine. This included the versatile Magnuson Radix supercharger, 4L60E transmission and numerous performance parts and accessories. Continuing along those performance lines and all-out fashion, we would need to contend with the great amount of power this engine package would deliver. Initially, we can’t say that the stock brakes on the C10 were ever designed for the shear torque that would be applied to these assemblies, so it would eventually be necessary to address the stopping performance as well as the go performance. And, after all, brake upgrading was a part of this project plan from the beginning.

When dismantling your project car, you probably ran across the crumbling remnants of the original insulation. Old cars are notoriously “leaky” when it comes to heat and sound barriers, making them louder and hotter than the typical daily driver. Sometimes a loud exhaust system overrides the road noise, but you’ll always notice when your air conditioning system never seems to keep the cabin cool. If you’re in the midst of an interior refresh, or a full restoration, it’s a great time to consider new insulation.

There are many ways to add flash to your truck, but some of them are time consuming, expensive or overpowering. Then there’s a product such as Grippin’ Billet door handles. Grippin’ Billet handles will not only add a little sparkle to an otherwise bland part, but they will do so in an easy way without breaking your budget.

Rearview mirrors with LED turn-signal indicators are relatively new, but you will be seeing more and more of them, especially on luxury SUVs and pickups. They are already standard equipment on some models, and probably part of an upgrade premium package on others. They are also now available in the aftermarket.

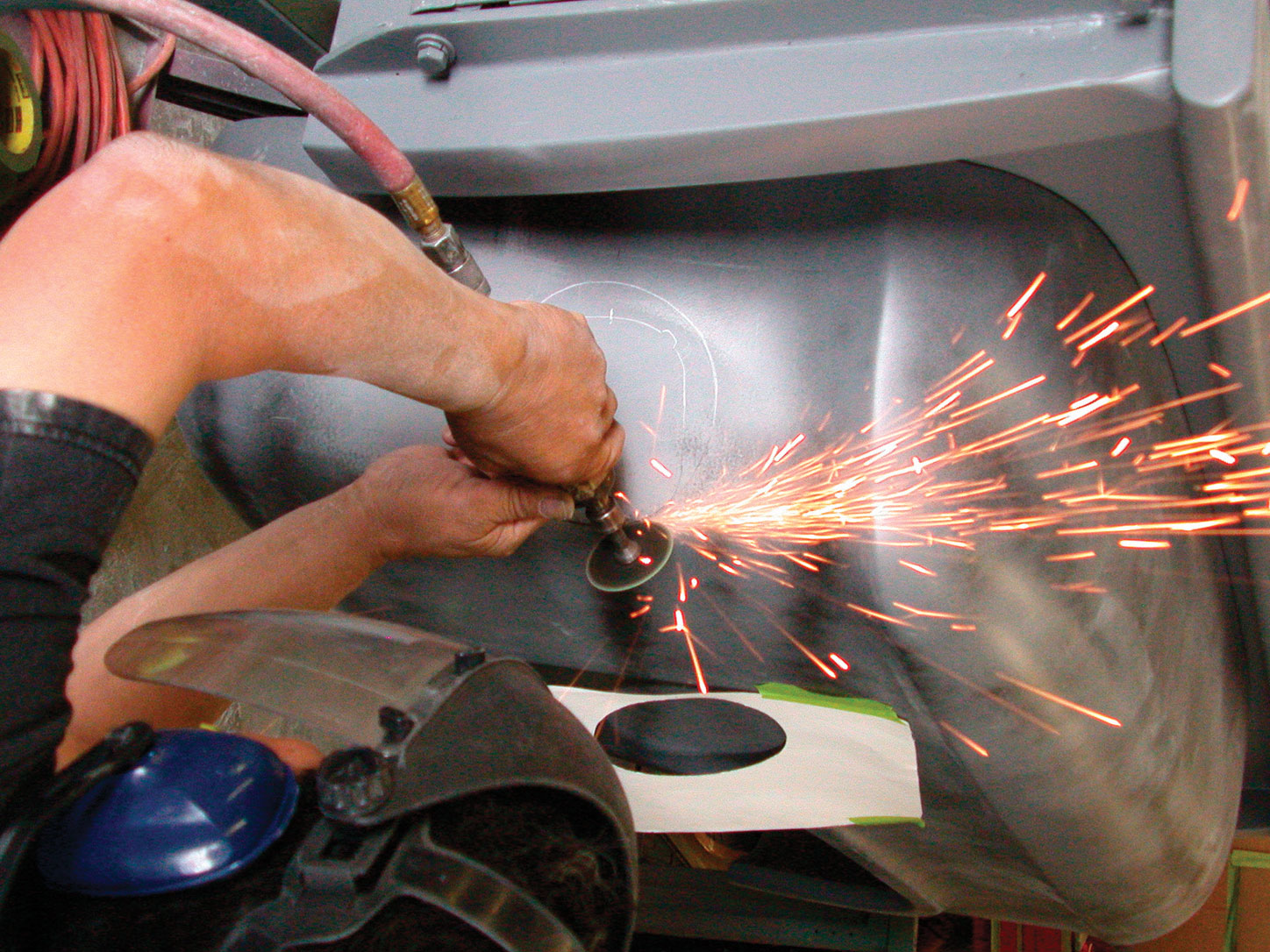

Always hard at work in the never-ending pursuit to do something just a little different, Darryl Nance and the crew at D&P Classic Chevrolet in Huntington Beach, California, recently added a pair of Chevy Cobalt taillights to one of the mid-’50s pickups that they have been working on. The Chevy is a frame-off project that was completed to exhibit all of the tricks that the D&P team can throw at it, and we were on hand when they installed the late-model lights to the old-time treasure.

Dean Brown was looking for another street rod to build after selling his ’40 pickup truck when he heard about a ’52 Chevy panel delivery for sale. As he’d always been fond of these trucks, he decided to take a look. When he saw the panel delivery he found that it was in reasonable condition and was still running fine with the original six-cylinder engine. The truck’s history showed that it was a Helms Bakery truck in the ’50s and had never been modified.

Most enthusiasts drive a newer car or truck for daily transportation, and we would dare say that most of them are equipped with power steering, power brakes and air conditioning. These are conveniences that most people take for granted and enthusiasts believe their street rods should have the same features.