Manufacturers

Tom Lawson was attending the Goodguys West Coast Nationals with his family and friends when a friend of his father-in-law, Bill, also a street rodder, walked up and started talking to everyone in the group.

We learned that Underground Motorsports in Little Rock, Arkansas, was going to build one fast daily driver, so we thought we’d take a peek and drop some knowledge for you. We were looking for any tech procedures that may illustrate for readers how a car of this sort is built from scratch.

If you own a Ford or Chevy, most of the parts you will need to build a street rod are readily available, and from a variety of suppliers. We have written numerous stories about kits for these cars in our family of rodding magazines, and some of them were a direct replacement for the original. By and large, they worked perfectly and bolted right in, as designed. These types of kits are convenient for many street rod builders, as well as street rod shops, and they are part of what has helped grow our hobby into such a broad special-interest group. But in addition to the “normal” and most popular rods, there were many other great cars made in the pre-war era, and some of them can be a real challenge to street rodders because there are no pre-manufactured parts, and no kits that make them easy to build. Sounds like the old days, right? Well, that’s the modern world for you–even our hobbies have become targets of convenience.

The new E46 BMW M3 comes equipped with some serious OE HID headlights, but what if you’re still not happy? You want something different; you want to add some spice to your headlight setup. Well, this story is just for you.

When a B16A-equipped CRX EF came into the Rage Performance shop for a Skunk2 intake manifold install, the crew dove into the job with a fury. With cameras at hand to document the swap (’88-’91 CRX) for your personal pleasure, the job took no time at all and the owner of this Honda is deliriously happy with the results.

Advanced Fuel Dynamics has developed kits for many makes and models, and our focus today is installing a PROFLEX DX Adaptive Flex Fuel System on a 2022 Ford Mustang GT Premium.

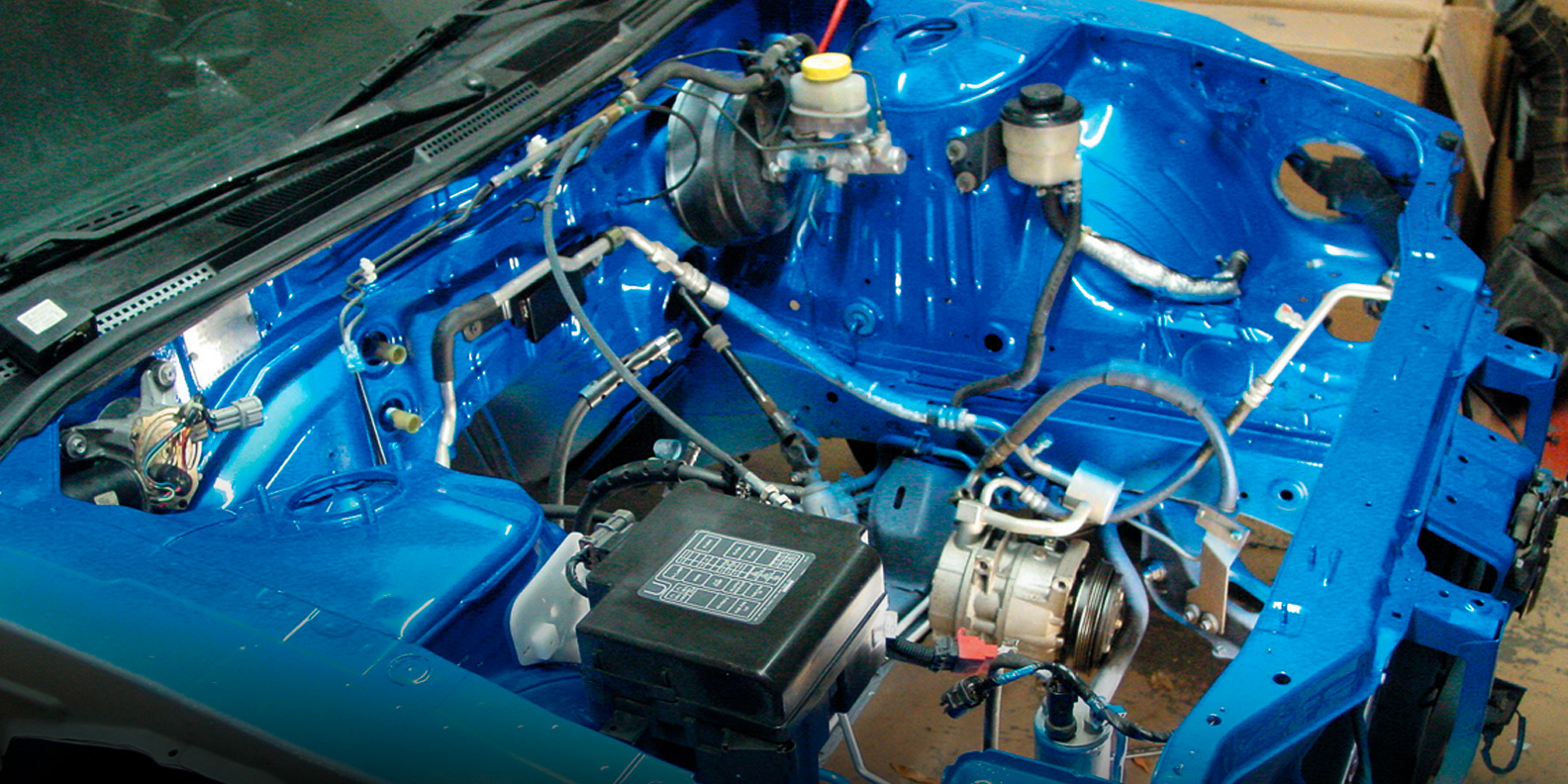

In the long continuation of our Project ’67, the 1967 Chevrolet C10 buildup, several major components and systems have been previously addressed, most notably the Goodwrench LQ4 6.0-liter 366ci Escalade engine buildup by Arizona Speed & Marine. This included the versatile Magnuson Radix supercharger, 4L60E transmission and numerous performance parts and accessories. Continuing along those performance lines and all-out fashion, we would need to contend with the great amount of power this engine package would deliver. Initially, we can’t say that the stock brakes on the C10 were ever designed for the shear torque that would be applied to these assemblies, so it would eventually be necessary to address the stopping performance as well as the go performance. And, after all, brake upgrading was a part of this project plan from the beginning.

Nissan is hoping that the Altima finds a niche with the tuner crowd and makes a huge splash with the younger generation that is far more car-conscious than those who buy mere transportation. It priced the car competitively at $17,900, but it’s hard to consider that $18,000 is reasonable—until you compare the Altima to what little you get out there for $17,900 nowadays.

In the case of a new Honda Civic Si (EP3), this owner wanted to enhance high-rpm power. The K20 engine with the new i-VTEC 2-liter powerplant has considerably more torque available in the lower part of the power band in comparison to the older B- and H-series VTEC engines. While the EP3 used here is primarily a street-driven machine, the owner plans on taking the car to the weekend dragstrip on occasion.

You have to admit that the thought of injecting water into your engine sounds crazy. We all know that water doesn’t burn and it can’t be compressed. Those unfortunate souls who have tried to do this now have engines that are the equivalent of ship anchors. In this installation, we aren’t going to be injecting huge amounts of water into an engine, but rather a fine mist that’s proportionate to the fuel flow (10 percent to 20 percent), using a high-pressure pump. This will help lower the chances of detonation by reducing the intake charge temperature.