Trucks

There is nothing more aggravating than having a dead battery, and it always occurs at the least opportune times. Our street rods are often stored or sit for periods of time. How many times have you decided the weather was perfect for an afternoon cruise and had a problem cranking the car?

Today’s 4x4s have become extremely specialized. At one end of the spectrum are one-off, purpose-built, non-street-legal rock buggies. These are the cream of the rock crop. Most have tube chassis with what seems like nearly 360 degrees of axle articulation. Often the transfer cases are doubled up to produce crawl ratios way beyond the once magical 100:1. They’re obviously awesome, and capable of handling boulders as if they were speed bumps.

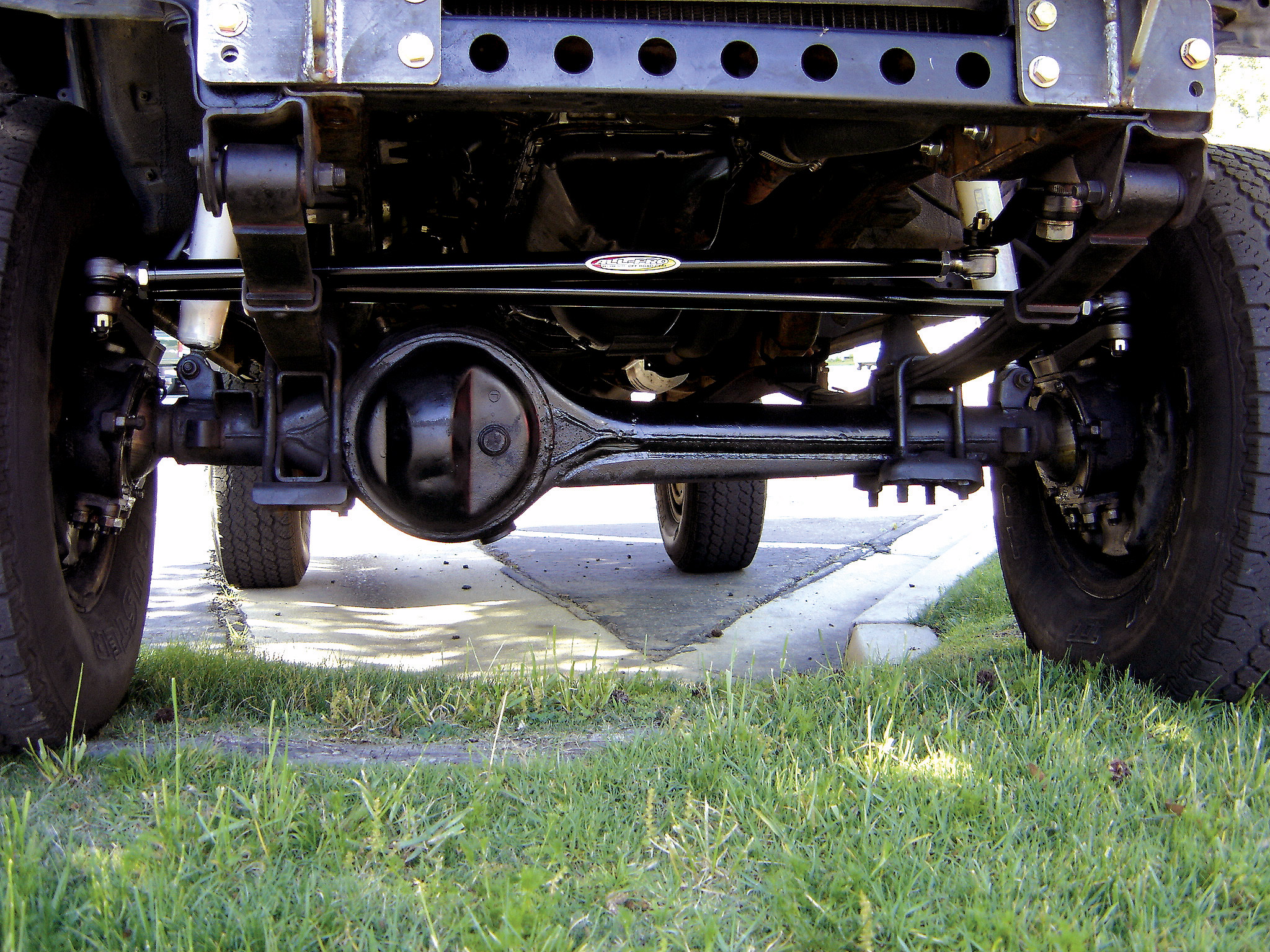

While early Toyota trucks are a great foundation, they do require a few modifications to make them capable of serious off-road use. Sure, you’ll need the basics, such as larger tires, lower gears and some kind of traction-aiding device in the differentials, but first there is a more important issue at hand. The steering on these early Toyota trucks was not designed with hardcore off-road use in mind.

Poison Spyder has a reputation for building some of the most extreme crawler rigs out there, and when it comes to advice, Clifton is usually at the top of our list of guys to ask. We were looking for a bumper that would be able to hold up to any rock we could slide into, as well as a well placed winch mount. A good looking bumper would be an added bonus, but we were willing to compromise on that last option. As it turned out, Poison Spyder had recently released their Brawler Bumper for XJ Cherokee’s. Not only did it have everything we were looking for, it’s a lot easier on the eyes than you would think for a hardcore bumper.

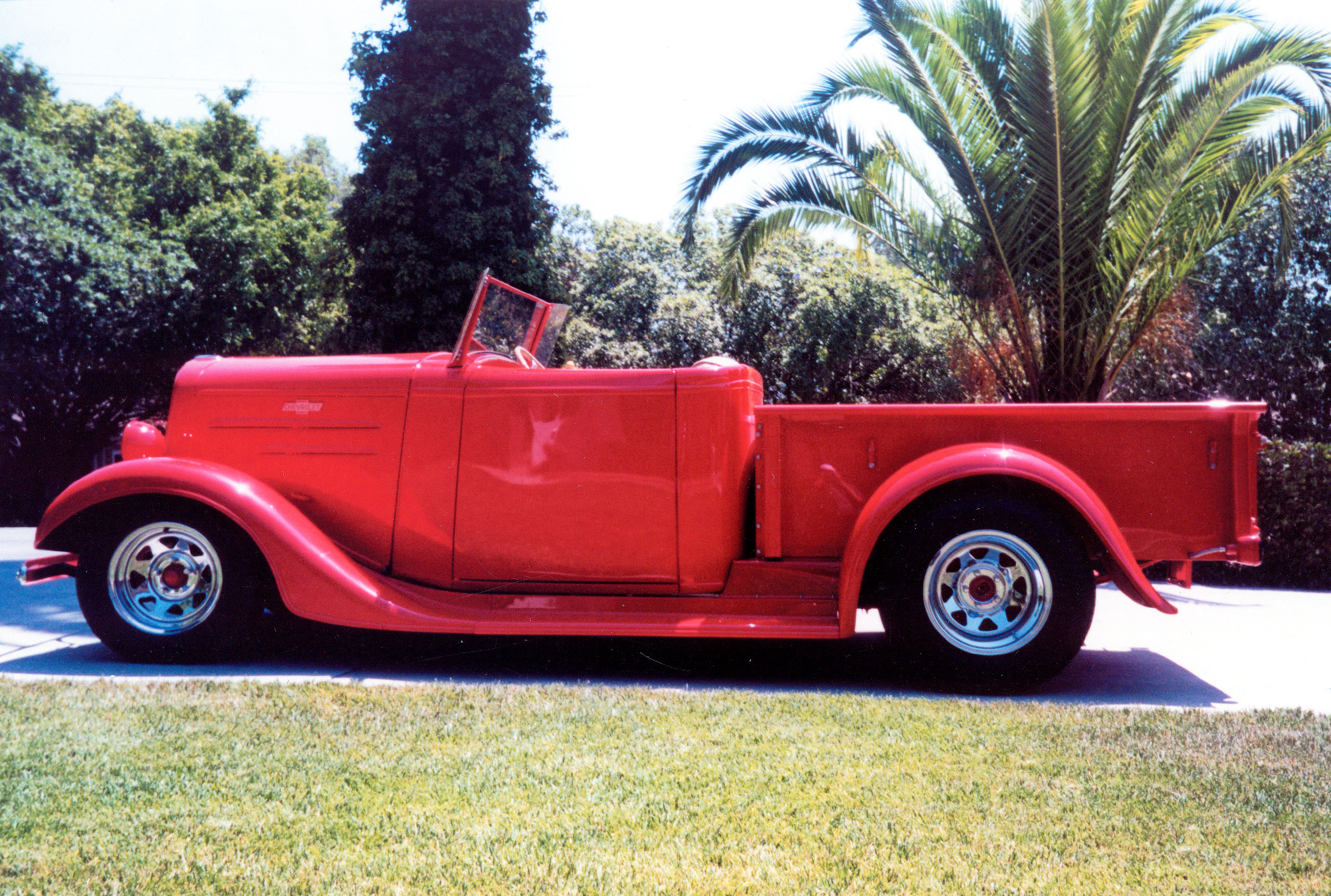

Let’s face it, most of us are working within the confines of a set of unwritten, yet clearly defined, rules of hot rodding. Stance, engine choice and wheels are for the most part selected from a menu of items that come “pre-approved” by our peers. Sure these rules work most of the time, and they provide a degree of certain acceptance when you’re building a traditional pre-’49 hot rod. But all in all, it also makes us a group of conforming nonconformists. However, for some hot rodders (and they are in the minority) building hot rods is about pure ingenuity, a total lack of peer pressure and joy of mixing parts from various sources and making it all work.

Ford fans will always have a soft spot in their blue-oval hearts for the Windsor, the Cleveland and the big 460 FE engines—and deservedly so. If you’ve ever crawled a junkyard for one of these engines, you’ve likely passed over more than a few 351M and 400 engines to find what you are looking for. Poor factory numbers and bad word-of-mouth have made these cousins to the mighty Cleveland about as wanted as poison ivy at a nudist colony, but there is power to be found in those engines—and cheap, too.

“I started building this car a little over 15 years ago after completing a Pro Street ’70 Camaro RS for my then-16-year-old son, Brad,” says overhead door installation specialist Jim Meltzer of Ventura, California. “I always had the urge to build a ’59 Pro Street Chevrolet El Camino (hence the nickname “U.S. Pro-1”), having owned one of those cars when I was just 21 years old,” he says. “Forty years later, the ’60 came along, and I figured that was close enough. The El Camino project was a joint collaboration with my sons Brad and Rod, and it got off to a great start. We made plans for a big motor and even built a full rollcage for that huge hunk of steel with the intentions of actually racing it.”

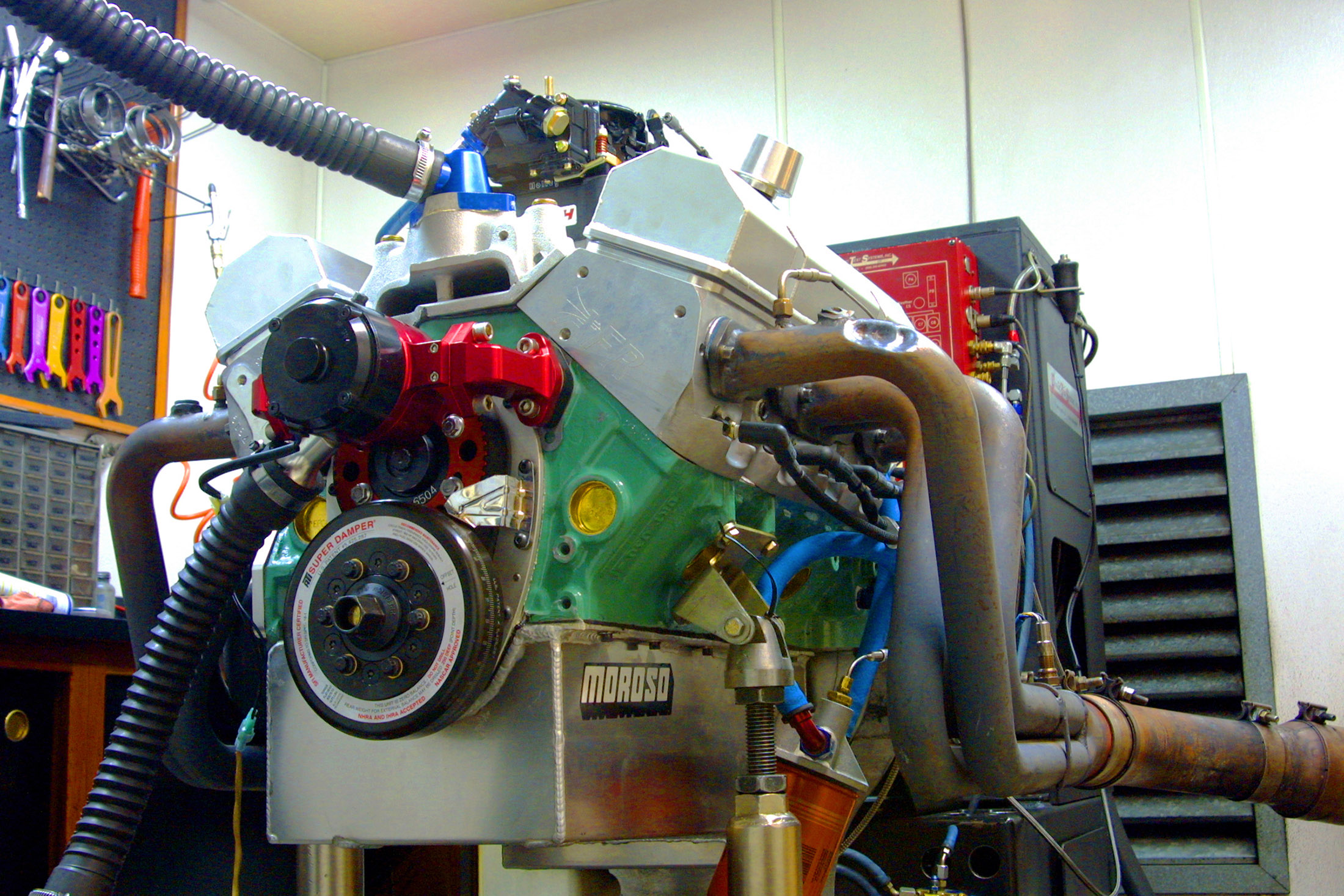

We showed you how to build a small-block engine that could make over 500 hp and 500 lb-ft of torque on 87-octane gas. It was a motor that could be driven just about every day with a hydraulic-roller cam and a good carburetor, making acquisition and maintenance almost nonexistent. Like many things we do in the engine world, the results we enjoyed—while good—just weren’t satisfying anymore. We wanted more.

When starting any project that requires bodywork, rebuilding or even repainting, the first question is always, “What could possibly be lurking under the old paint that could come back and haunt us later?”

There’s nothing like an impending event inspection to motivate an install. Lorne Pearson was looking forward to the PNW4WDA Trail Jamboree in Naches, Washington where he was planning to run the challenging Rimrock Trail. This often-off-camber route required front & rear lockers, CB and winch along with some wheel base and tire specifications – all of which Pearson had. What his YJ lacked, however, was the mandatory full roll cage.