Engine

Some of the greatest feelings in life come with a rise in rpm, a dropped clutch and tests of traction stretching the boundaries of our physiology. These are the emotions many of us cherish, and while many factors can evoke such emotions, the single most influential force behind these kinetic kicks is torque (which is then equated into horsepower).

Building an engine that produces more horsepower than its stock configuration can be done in many ways. However, supercharging has proven to be one of the best ways to make the most horsepower over stock. Superchargers are air pumps that force a “super” charge of air into an engine, which in turn allows the engine to make more power. A Roots supercharger or blower is a sealed case with two rotors inside. It is driven through the crankshaft by belts and pulleys, causing the spinning rotors to force compressed air into an engine.

For diesel enthusiasts and Power Stroke purists alike, performance and reliability are more than features—they’re expectations. For nearly 15 years, the Adrenaline™ High-Volume High-Pressure Oil Pump from DIESELSITE has been meeting and exceeding those expectations, earning a reputation as a trusted upgrade in the 6.0L Power Stroke community.

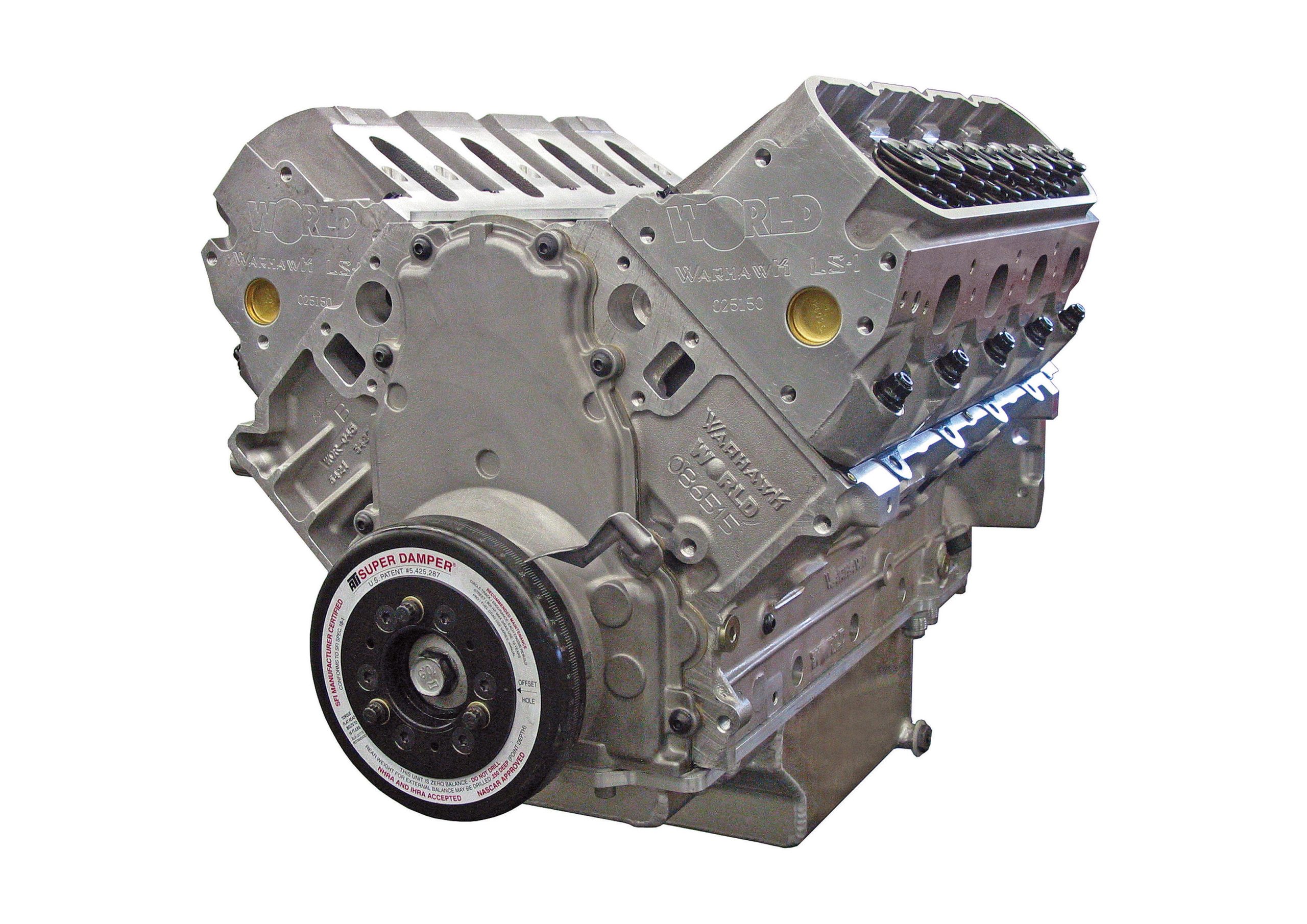

Whether you’re in the driver’s seat or looking underneath the hood, it’s the first place enthusiasts come to find out what a car is all about. After all, without the right engine package, everything we long for in our cars would be nothing more than static displays of creative artistry.

We here at The Auto Builder understand that when it comes to performance, every component counts. That’s why the Canton Racing Products GM LS1/LS6 Front Sump Road Race and Drift Pan has earned a top spot on our must-have list for any serious gearhead looking to elevate their game.

If there’s one thing we can’t stress enough, it’s the importance of keeping your engine cool. That’s why we’re pumped about the Canton Racing Products Universal Aluminum Coolant Expansion Fill Tank. This baby is an absolute game-changer for anyone looking to optimize their vehicle’s cooling system.

Here’s the deal: if you’ve got a V-8 or a high-horsepower V-6 or 4-banger and you’re not running an Accusump, you’re gambling with your engine’s life. The 24-006 Accusump 3 Qt No Valve is one of those pieces of gear you slap on and immediately wonder why you didn’t do it sooner. It’s been saving engines—and wallets—for over 30 years. Let’s break it down.

Let’s talk about something that doesn’t always get the glory it deserves but is crucial for any high-performance build—pushrods. And who better to get the job done right than Brian Tooley Racing (BTR)? These guys know their stuff, and their pushrods are proof.

Alright, gearheads, if you’ve been chasing that extra performance edge for your LS engine, it’s time to step up your game. The BTR Platinum LS Dual Spring Kit – .660 Lift (SK001) from Brian Tooley Racing is the go-to upgrade when you’re running a high-lift cam and want to keep things dialed in tight. Let me tell you, this kit is more than just parts in a box—it’s the insurance policy your high-performance build demands.

Are you ready to give your GM truck the performance boost it deserves? Look no further than the BTR Gen III/IV Truck Norris Camshaft from Brian Tooley Racing. Designed specifically for 1999-2013 Chevrolet Silverado and GMC Sierra trucks, this camshaft is engineered to deliver a significant increase in horsepower and torque, transforming your daily driver into a powerhouse.