Chevrolet

If you’re like many of us, vacillating between the car you’ve always dreamed of owning and what you really can afford, be sure you know what you need before you shell out more money than sense. Check around, ask your friends, read magazines on the subject, surf the Internet, get connected, and you’re likely to find your dream car, even if it is not everything you think it is.

Experience the thrill of Project Tin Can, a neighborhood sensation turned adrenaline-pumping amusement ride! With its roaring 283 engine and close-ratio Muncie four-speed, this car is a showstopper. Hear the laughter, witness the stares, and feel the excitement as Tin Can leaves a trail of awe wherever it goes. Discover how a modest 283 engine transformed into a powerhouse, making this car a 13-second wonder. Join us as we bid farewell to Project Tin Can, but stay tuned for occasional updates and adventures. Thank you to all who contributed to this unforgettable journey. Old-school enthusiasts, rejoice!

If you’re in the planning stages of building your car, or even if you have finished and are driving it, there are lots of free or inexpensive things you can do to make your ride faster and/or more efficient. This month, The Auto Builder gives you 25 of those ideas. Most of these free tips simply involve putting your car on a diet. Every 100 pounds of weight removed from your car equals dropping 1/10th of a second at the strip. Even though you may not be racing, the same theory applies to the street, and also to the extra weight you must lug around.

Eyes wide open, with faces up against the glass, kids on a passing school bus wondered what it could be. Amazed by the size of this land yacht, some must have wondered what it was like to pilot such a gas-guzzler, while a few couldn’t help but smile at the resounding roar of the mighty L72 427 underneath it all.

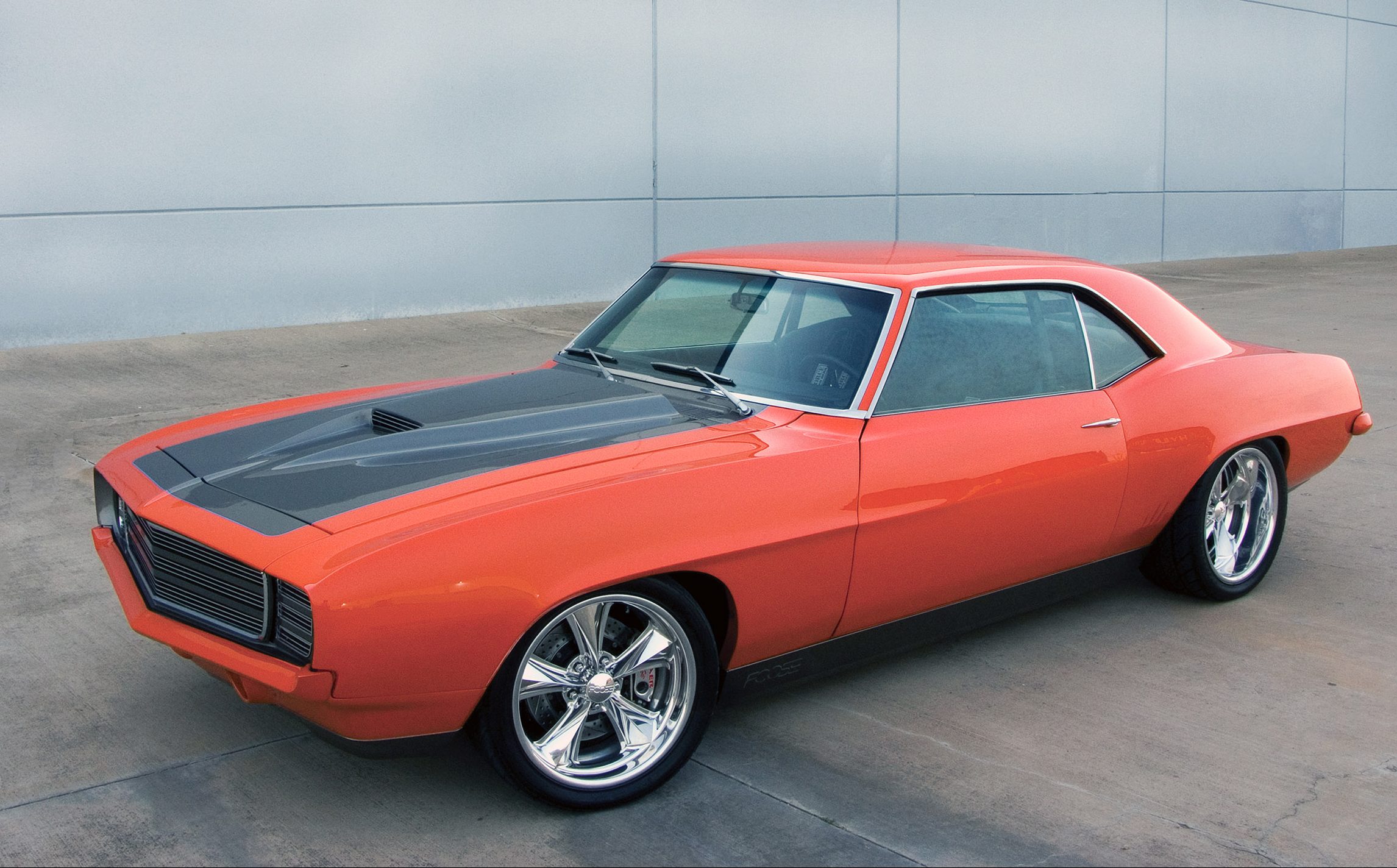

we learned that three important players in the hot rod industry—Chip Foose, Unique Performance and Year One—were coming together for a unique collaboration. Their combined goal was to build a limited-production-built car. Unique Performance already has just such a business, as it builds and sells its continuation Shelby Mustangs.

Is a love for fast cars—specifically those that are Chevrolet-powered—hereditary? If you were to ask C.A.T. Operations Engineer Kevin Christensen of Castaic, California, he would definitely say that it is.

Sitting slightly nose-high and looking that much more restrained with dog dish hubcaps framed in bias-ply blackwalls, this ’62 Chevy bubbletop is as sinister as it is subdued. In fact, as smooth as these panels are, one has to wonder if this car has ever broken a sweat or even turned a wheel with aggression since it rolled off the showroom floor.

“I started building this car a little over 15 years ago after completing a Pro Street ’70 Camaro RS for my then-16-year-old son, Brad,” says overhead door installation specialist Jim Meltzer of Ventura, California. “I always had the urge to build a ’59 Pro Street Chevrolet El Camino (hence the nickname “U.S. Pro-1”), having owned one of those cars when I was just 21 years old,” he says. “Forty years later, the ’60 came along, and I figured that was close enough. The El Camino project was a joint collaboration with my sons Brad and Rod, and it got off to a great start. We made plans for a big motor and even built a full rollcage for that huge hunk of steel with the intentions of actually racing it.”

“I shouldn’t have sold that car.” How many times have you heard an enthusiast make that statement? It seems that a great many of us regret selling our favorite rides over the years, whatever the reasons.

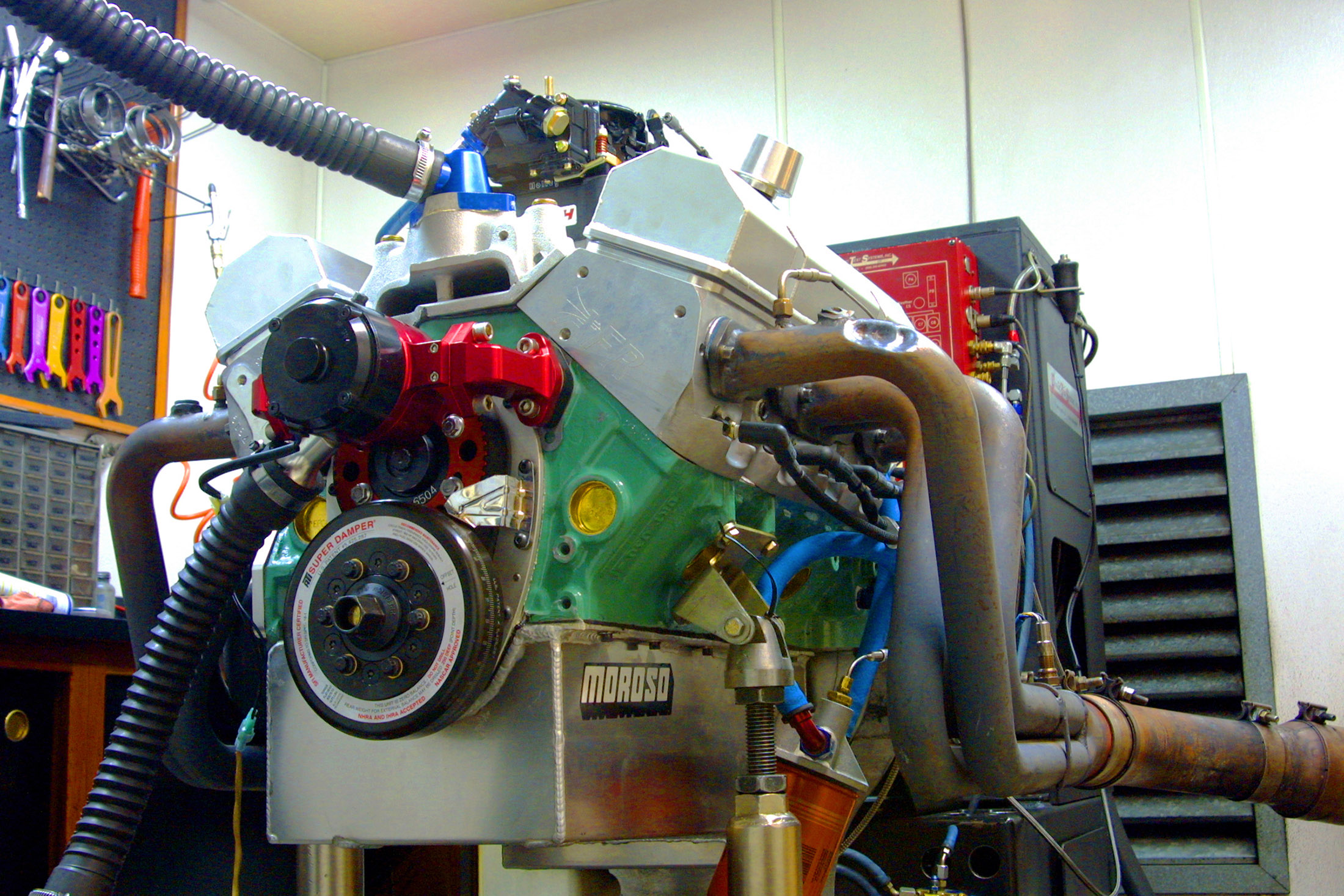

We showed you how to build a small-block engine that could make over 500 hp and 500 lb-ft of torque on 87-octane gas. It was a motor that could be driven just about every day with a hydraulic-roller cam and a good carburetor, making acquisition and maintenance almost nonexistent. Like many things we do in the engine world, the results we enjoyed—while good—just weren’t satisfying anymore. We wanted more.