Handling

The gear driven RF1A Toyota transfer case found in 1979-1995 4 cylinder pickups and 4Runners fits the needs of many wheelers. It offers a strong, lightweight package with growing aftermarket support. These transfer cases have been used in numerous pickups, 4Runners, buggies, and even Jeeps! Everything from dual transfer case adapters, low range gear sets, twin sticks, and low profile crossmembers are available for Toyota transfer cases from a bevy of aftermarket sources. The RF1A is lighter and less expensive than a Dana 300, though they are not as easy to “clock” and do not allow front wheel drive operation.

Artec Industries, specializing in designing and manufacturing high-quality off-road components for Jeep, Toyota, Chevy, Ford, Dodge, Scout, or Custom vehicles, is known for its innovative designs, quality reputation, fast shipping, and exceptional customer service. Founded in 2003 by Artie Nuttall, the company has a mission to provide world-class aftermarket automotive parts to off-road enthusiasts and to break the mold on what has been done in the industry. Artec’s relentless dedication ensures that it consistently exceeds customer expectations and earns their trust through unparalleled service.

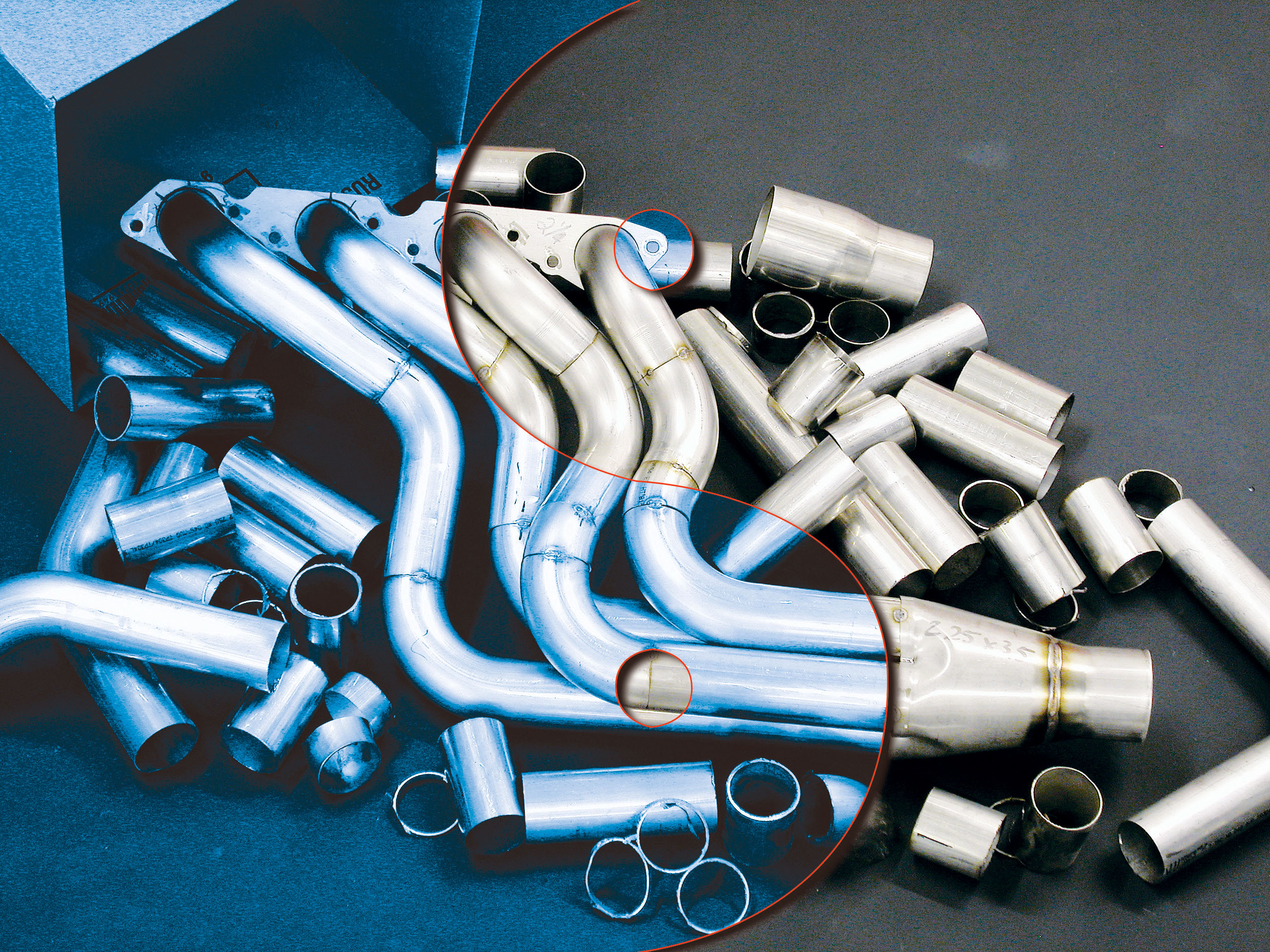

Dive into the world of header fabrication as we demystify the process and equip you with the knowledge and skills to create custom headers for your vehicle. Follow along step-by-step as we break down the intimidating task into manageable steps, offering valuable insights and practical advice along the way.

Crafted with precision and expertise, this cutting-edge column is set to revolutionize your driving experience. Rad Rides engineers focused on maximizing space, ensuring comfort during entry and exit, and offering customizable steering wheel positioning. Compact yet powerful, the Tilt Steering Column boasts a total unit length of just 5 1/8 inches. With five different tilt positions and approximately 40 degrees of total tilt, you’ll find the perfect angle for your comfort and convenience.

“The Grand Daddy of Them All,” The Grand National Roadster Show just took place this last weekend. Held annually in Pomona, California, is a premier event celebrating the artistry and craftsmanship of custom automobiles. Established in 1949, it has earned a reputation as one of the longest-running and most prestigious car shows in the world. Spanning multiple days, the show features an eclectic mix of meticulously restored classic cars, innovative hot rods, and custom-built vehicles, showcasing the creativity and passion of automotive enthusiasts. Attendees can marvel at the intricate details of each vehicle, from flawless paint jobs to finely tuned engines, and interact with passionate owners and builders.

If a hot rodder were to have built an EV charging station, we think it would have looked like the heavy-duty version Lincoln Electric has built. Now for the nuts and bolts information from Lincoln Electric themselves on the new single and dual Velion™ Chargers. Like ourselves most people reading this article may have a hard time comprehending all the abbreviated terminology listed below but here it is to inform you on the knowledge of Lincoln Electric’s EV chargers.

Though clutches rank below power-adders on the desirability scale, they are every bit as important. In fact, you’d be better off not spending the time and money on a trick blower or turbo kit if you do not plan on upgrading the stock clutch assembly. Sure, it is possible on some applications to improve the performance of your motor without a clutch and pressure plate upgrade, but you can only take things so far. Eventually, the engine will let you know by racing to the moon when you least expect it. Your clutch will likely slip under full throttle, and most probably at the highest load. Better hope you have a rev limiter or things can really get ugly. But have no fear … Advanced Clutch Technology (ACT) has come up with a variety of effective combinations to cater to the needs of performance enthusiasts and racers.

In order to thrive in the exhaust market, a company must have products with a zing factor. For Corsa, the difference begins with its materials, production techniques and efficiency of its designs. Corsa uses T-304 stainless steel, which makes each exhaust system effective, durable, attractive and easy to clean. A good grade of stainless steel makes the process of cleaning pipes about as easy as scrubbing with a Scotch-Brite pad. However, other companies also offer T-304 stainless construction, so what really sets Corsa exhausts apart? The answer is Reflective Sound Cancellation technology…

Lowering a truck usually involved cutting coils and shaving bump stops. Out back, the rear end was treated to lowering blocks, a few pulled leaf springs or heated coil springs. Over the years, manufacturers began to address these demands, as lowering coils, spring leaf blocks, dropped spindles and flip kits were offered. Times changed with the introduction of airbags, as owners were able to slam their pickups with full ride height adjustability. Air Ride Technologies (ART) is one of those companies offering quality suspension solutions for truck owners, with kits that fit specific applications.

Adding power windows is a popular aftermarket option for classic vehicles these days. Worn-out window regulators have given people problems for years, and as replacement parts have become increasingly more expensive and harder to find, it’s simply easier and often cheaper to replace the old regulators with new electric ones. In the past we had to raid wrecking yards for parts that would adapt into our vehicles, and as expected there were generally a few problems associated with doing this. First, you don’t always know the condition of the parts being used, even though they look good; and second, you would need some background in window geometry to get the job done correctly. Finally, you need a certain level of basic fabrication skill and tools, which would be more than basic hand tools. With today’s technology and the availability of well-engineered aftermarket power window kits this has all changed, as it’s commonplace for most people to go straight to a kit designed for their vehicle.