Engine

After recently purchasing a ’62 Thunderbird, it became obvious very quickly that the car needed a new engine. Our plan was to turn the car into a daily driver, and so, as long as we needed a new engine, we figured we’d add air conditioning to the car while we were at it. And if you really know your Ford history, you also know that the ’62 was the last model T-bird to come with a generator rather than an alternator—one more reason to consider an upgrade.

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

Even though we all dream of blasting through the desert at 130-MPH like Robby Gordon, most of our 4×4 adventures take place at a much more reasonable pace. Unfortunately for our engines crawling along a boulder strewn dry river bed or climbing a goat trail through a mountain pass does not always allow enough airflow to keep our engines cool with a belt driven mechanical fan. Belt driven fans are designed to keep your engine cool when traveling down a street or highway not while crushing boulders at 3-MPH and 1,500-RPM. So what can we do to keep our rigs from boiling over this summer? Follow along with us as we install a pair of 11-inch electronic cooling fans along with a programmable fan controller both from SPAL USA.

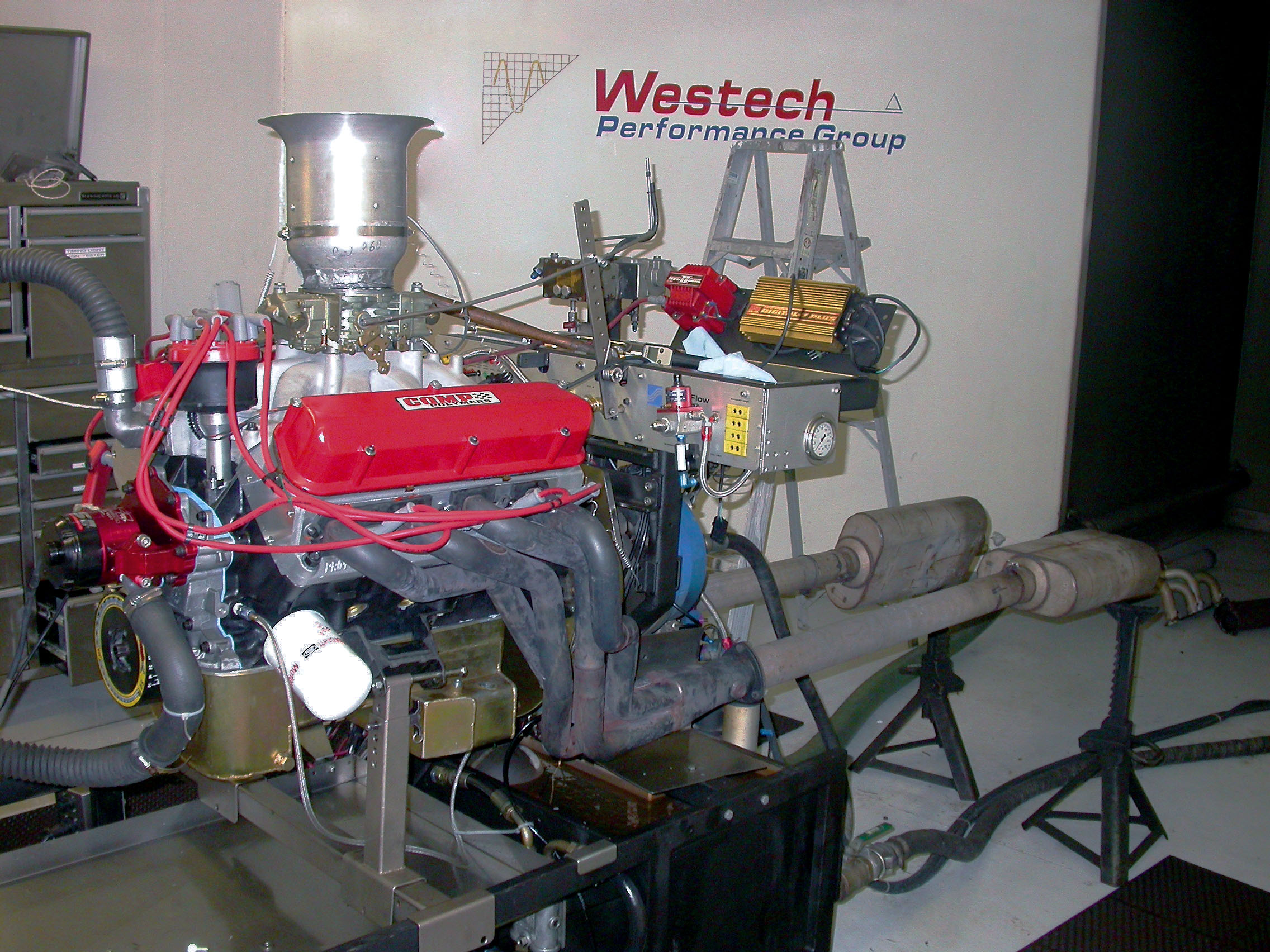

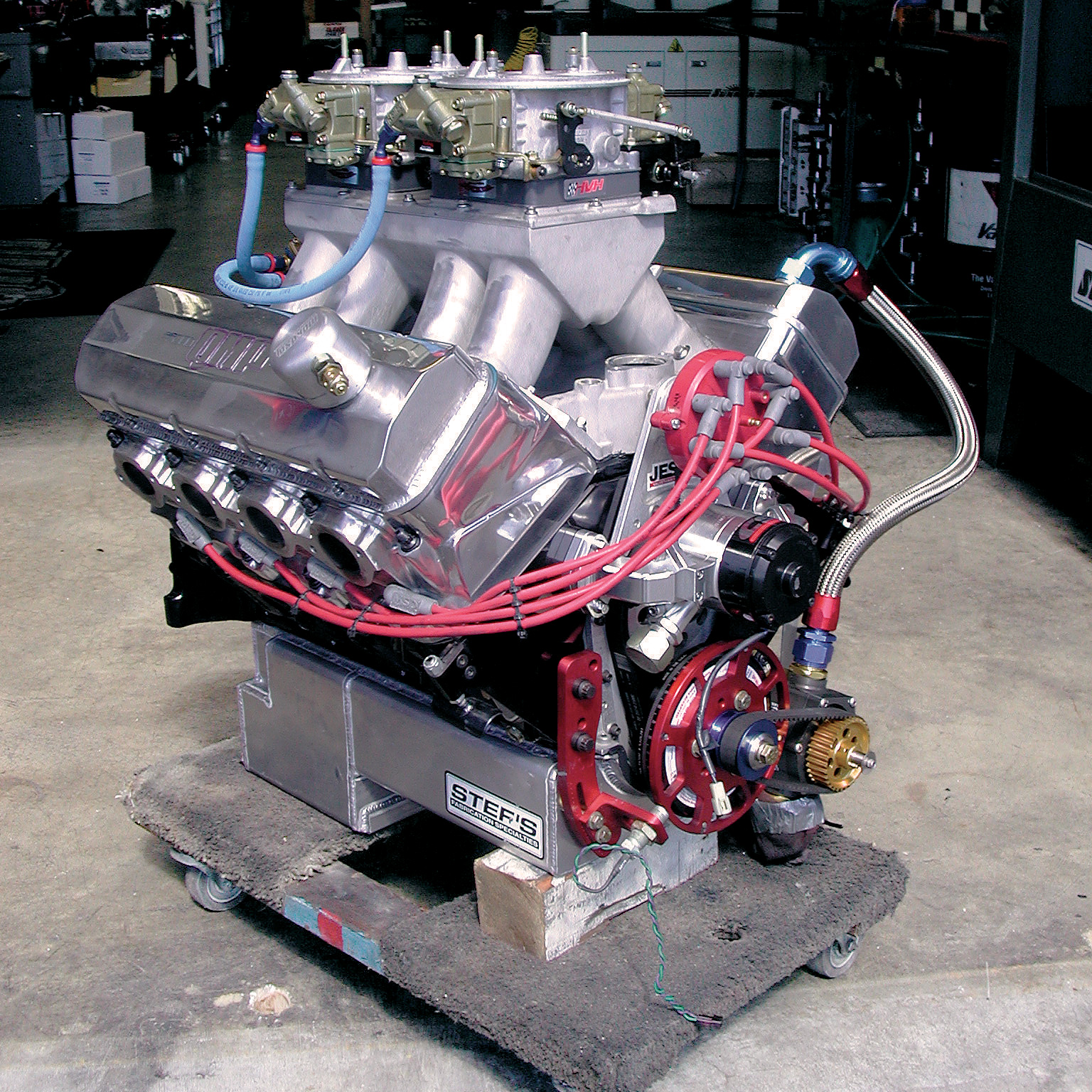

This engine, and others like it, has opened up a brand-new chapter in the ever-evolving, wild world of Chevrolet power. By design it has a bore and stroke of 4.60 inches by 4.25 inches and Big Chief II heads, which are about 2 inches taller, that feature oval-shaped intake ports. This, they say, is for maximum cylinder filling. Years ago, creative racers would angle-mill heads to arrive at the desired combustion chamber size and to improve the valve angle in combination with the incoming intake flow. These heads are nicknamed “11-degree” heads, as they have been designed with a built-in 11-degree angle right out of the box. There’s no angle milling needed here. A special valvetrain is necessary, along with longer stem valves. Quarter Mile Performance feels that these heads are worth 200 additional horsepower over the very best “shorter” heads.

Be Cool is no newcomer to cooling heavy metal. For years it has provided cooling solutions for some of the most impressive high-performance engines to rumble down the streets and dragstrips of America. The folks at Be Cool understand that having the proper cooling components in any car or truck is vital to keep an engine safely within its operating temperature range. They also understand that to make cooling and installation easier, they had to design a full bolt-in system, a system that would fit hundreds of applications for classic cars and trucks, as well as more modern vehicles that also need cooling help.

It can be argued that one of the best mods you can make to an LS-based or Gen III motor is a camshaft change. With the number of aftermarket companies making many different types, a good cam can be found for anywhere from $300 to $1,000, depending upon what type of power you want to make and how sophisticated the cam package is. Because 99.99 percent of all vehicles on the road today are computer controlled, most aftermarket companies are able to suggest whether a new tune will be necessary or if the stock one will suffice. But with so many different options out there, it can be quite confusing as to which is the right one for you.

Those who longed for their engines to look as they did back in the old days of multiple-carb setups were out of luck. Cool as they were to look at, there are lots of reasons why the multi-carb setup fell out of favor, and most of them had to do with the fact that they were a bear to sync. The advent of the four-barrel carb was the death for these systems, though the purists among us prayed for a breakthrough. Thanks to Ken Farrell and his company, Retro Tek, those prayers have been answered. Farrell started off converting old mechanical fuel injection systems (Hilborn & Enderle) when the first aftermarket EFI systems became available. His new system, which uses the latest in EFI mated together with the classic Stromburg 97 design, came about when Farrell saw that there was interest in the benefits of EFI, but he also knew that they were lacking in the looks department. The idea was simple take the best aspects of both and add them together.

Driven Racing Oil developed the original high zinc, petroleum and low detergent break-in oil over twenty years ago. Break in oil is a specialty oil that reduces wear and contaminates when breaking in a new high-performance engine. It provides controlled friction for your piston rings and incredible protection that helps your camshafts break in properly.

Adding a nitrous spray bar to an intercooler is a proven way to lower the intake air temps and consequently give a more dense charge to the combustion chamber for more horsepower. We’ve been seeing more and more intercooler spray bars popping up on both performance and show-n-go cars.

By now, we all certainly know that nitrous oxide is a performance enthusiast’s best friend. Nothing can wake up a sleepy motor like a quick shot of nitrous.