Street Trucks

After recently purchasing a ’62 Thunderbird, it became obvious very quickly that the car needed a new engine. Our plan was to turn the car into a daily driver, and so, as long as we needed a new engine, we figured we’d add air conditioning to the car while we were at it. And if you really know your Ford history, you also know that the ’62 was the last model T-bird to come with a generator rather than an alternator—one more reason to consider an upgrade.

This is a story about two tensioners, one fabricated with machine tools and the second fabricated in a garage with a minimum of tools. In fact, the only power tool you will need is a drill motor, yet the finished products will be almost identical.

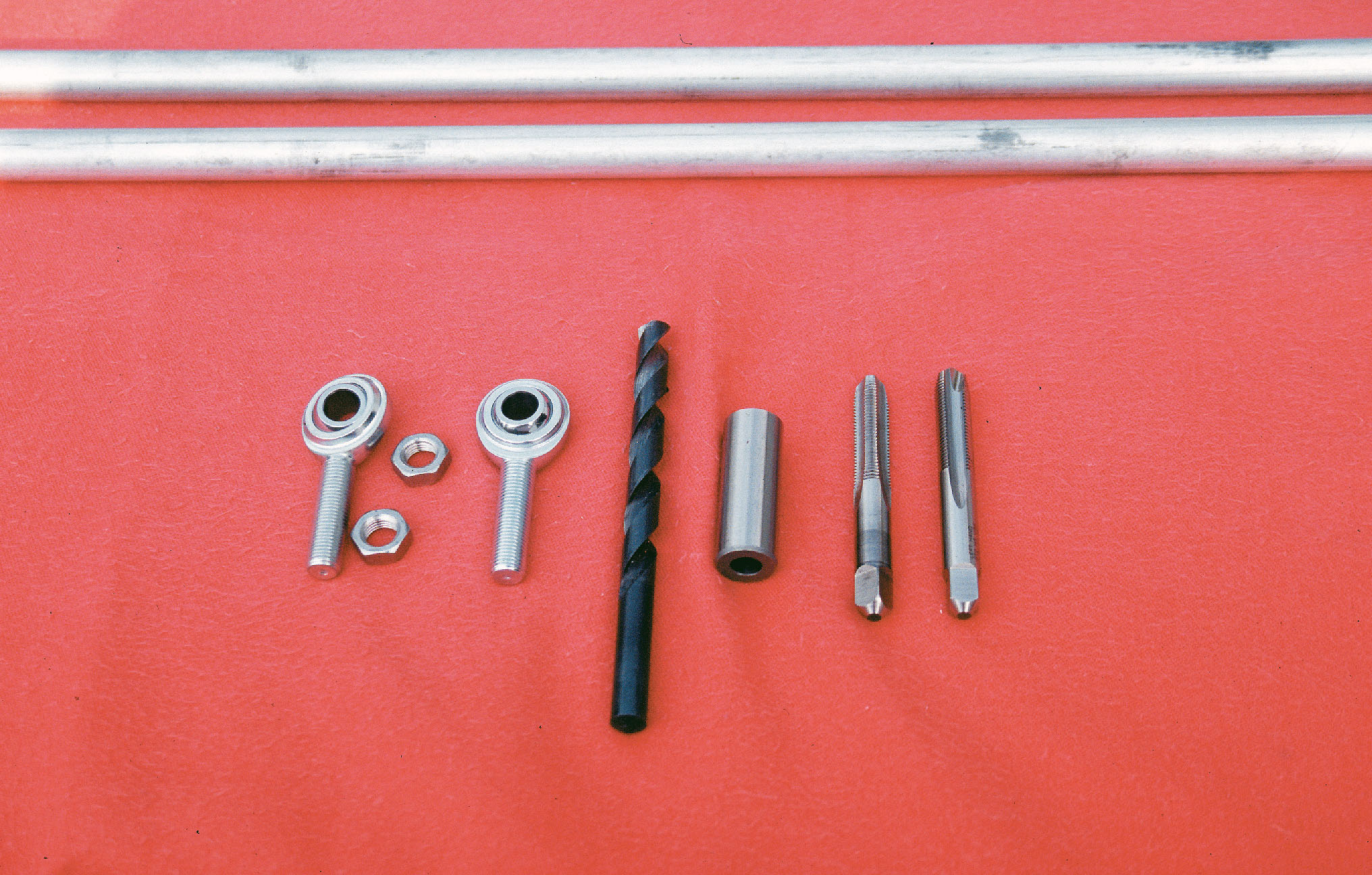

Your first response to fabricating something may be, “I don’t have the necessary tools; I don’t have any way to get the materials I will need.” If you have a door number so the UPS man can find you, you have everything you need. The materials list at the end of this story contains everything you will need. The rod-end bearings and lock nuts were purchased from AFCO Hot Rod Parts. The aluminum round stock and cutting tools were purchased from MSC.

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

Kinney Lazarus has owned several Jeeps over the years, and he had an interest in owning one of these vintage Willys pickups. While searching the Internet one day, he came across a running ’52 Willys 4WD pickup in Arkansas. He purchased the pickup online and had it shipped to his home in Georgia. Once he had possession of the truck, he quickly found that the performance of the original flathead four-cylinder engine left a lot to be desired by today’s standards. Also, being accustomed to a more modern ride, he found that the outdated suspension was less than desirable. In general, this classic Jeep was no fun to drive.

Even though we all dream of blasting through the desert at 130-MPH like Robby Gordon, most of our 4×4 adventures take place at a much more reasonable pace. Unfortunately for our engines crawling along a boulder strewn dry river bed or climbing a goat trail through a mountain pass does not always allow enough airflow to keep our engines cool with a belt driven mechanical fan. Belt driven fans are designed to keep your engine cool when traveling down a street or highway not while crushing boulders at 3-MPH and 1,500-RPM. So what can we do to keep our rigs from boiling over this summer? Follow along with us as we install a pair of 11-inch electronic cooling fans along with a programmable fan controller both from SPAL USA.

OK, we all know that it is easy to ignore automatic transmission maintenance—its messy and time consuming and no one really thinks about it until the trans starts to slip. Most transmission pans are simple stamped steel and do not have a drain plug so draining the fluid makes a big mess on your garage or shop floor. If maintaining your automatic trans was easier and less messy you would probably stay on top of the maintenance wouldn’t you?

Steering is one of the two most important systems on any vehicle, along with the brakes. Unfortunately, steering is often neglected for modifications that yield more visual impact, such as suspension lifts and larger tires. These are the exact modifications, however, that make attention to steering so important. Suspension lifts can alter steering geometry while big, heavy tires may cause increased wear to steering components, particularly if the tires are out of balance.

After a springover conversion was performed on the Dana 44 front axle in our ’67 Toyota Land Cruiser, the new spring location interfered with the steering geometry. The draglink was then bent as a temporary fix, but this sacrificed strength and resulted in poor steering angles.

Auto manufacturers are constantly working to develop trucks that safely tow and haul more weight. However, the byproduct of high load capabilities is a rough unloaded ride. On a recent visit to J&D Performance, we found the crew beginning work on an Air Ride system for the owner of a 1999 F-350 two-wheel-drive dually. The owner of the truck was happy with its ability to tow and haul, thanks to Part-1’s addition of a full Banks Power Pack, but extremely unhappy with the truck’s ride when unloaded.

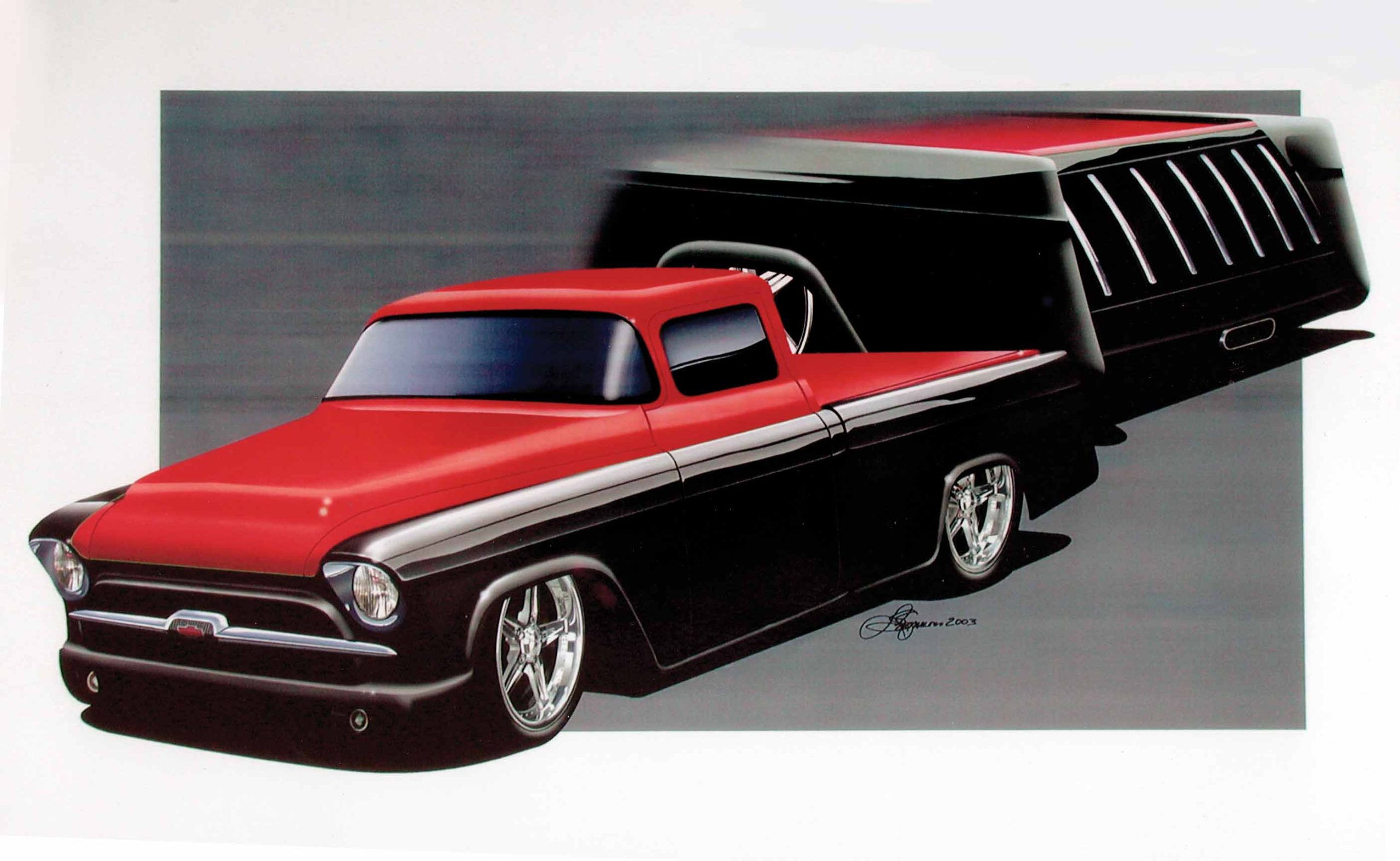

In part nine of our Cimtex Rods Super Cameo Buildup Series, we covered the installation of the Classic Industries Parts and Accessories reproduction ’55-’59 Chevrolet/GMC lower door hinge panels, doorsill rocker panels, upper and lower door hinges, new right- and left-side front floor pans, inner and outer lower cab patch panels, and right- and left-side truck cab supports. To put it in a nutshell, the crew at Cimtex Rods in Jarrell, Texas, basically rebuilt the whole bottom end of our Super Cameo ’56 Chevrolet big window truck cab from stem to stern. Now, with a rock-solid truck cab firmly bolted onto our Cameo’s highly modified C4 Corvette-suspended truck chassis, we closed with the promise that we would be installing a new set of Dynacorn International Inc. ’55-’59 Chevrolet/GMC reproduction truck doors, followed by angle-chopping the top on our ’56 big-window a total of 3-1/2 inches in the front and 3 inches in the rear. Unfortunately, things didn’t exactly go according to plan.

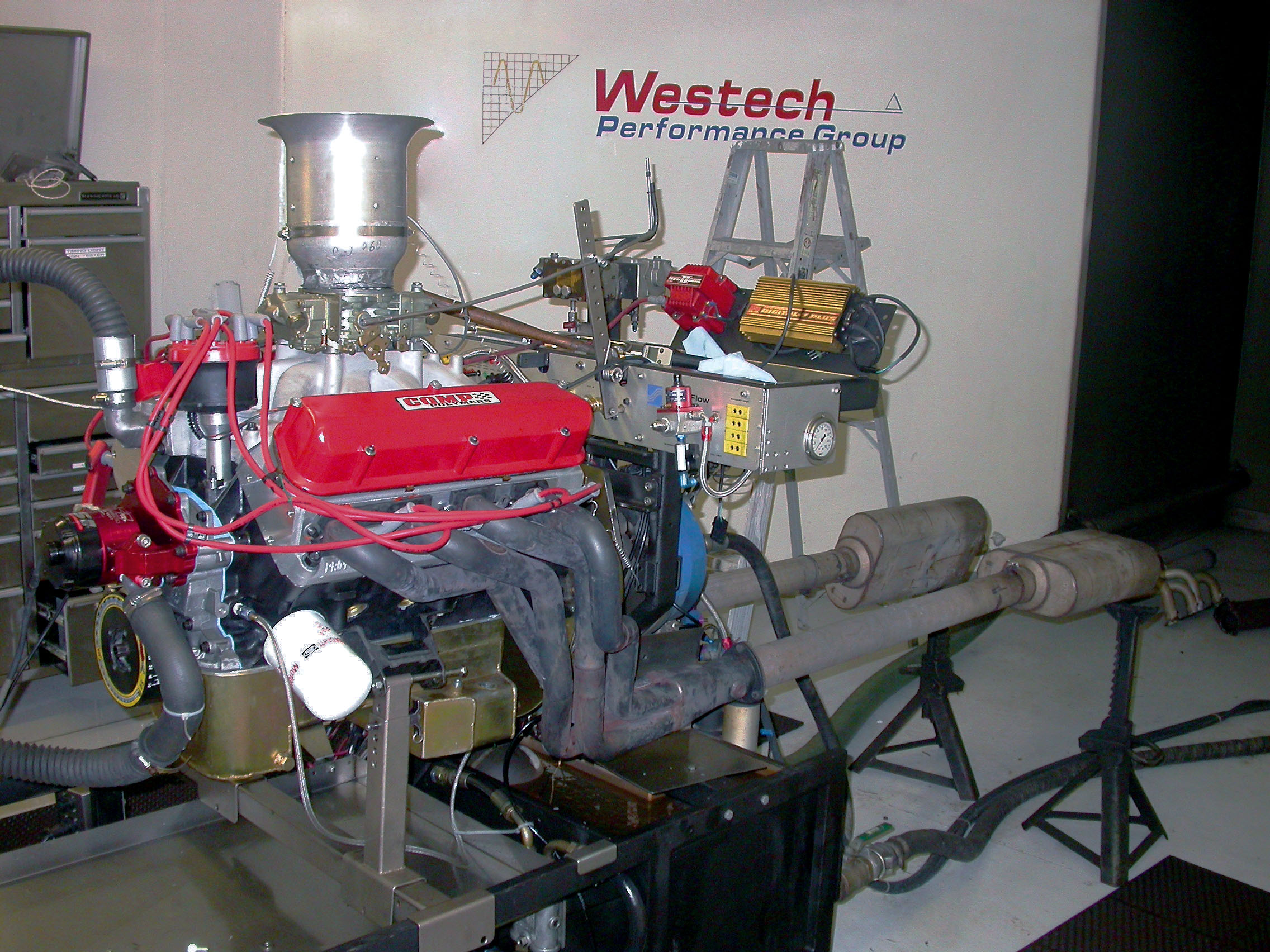

In part seven of our Cimtex Rods Super Cameo Buildup series, we covered the installation of our Stainless Works four-tube ZR1 headers and Cimtex Rods-fabricated 3-inch custom exhaust system, as well as the fabrication and installation of our Cimtex Rods-constructed 22-gallon fuel tank and the accompanying MagnaFuel fuel system. Now we’re going to cover the mockup of our Powerdyne BD-11A SilentDrive twin supercharger system. But first let’s digress and take a look at the big picture. One of the key criterion in our Cimtex Rods Super Cameo buildup was to elicit that all-important “wow” factor throughout the entire series. When it came to the engine, we didn’t want to install just any old run-of-the-mill, multi-carbureted GM small or big block, much less a late-model GM crate engine straight out of the catalog. Going in we figured that the Cimtex Super Cameo powerplant should be something special.