July 16, 2023

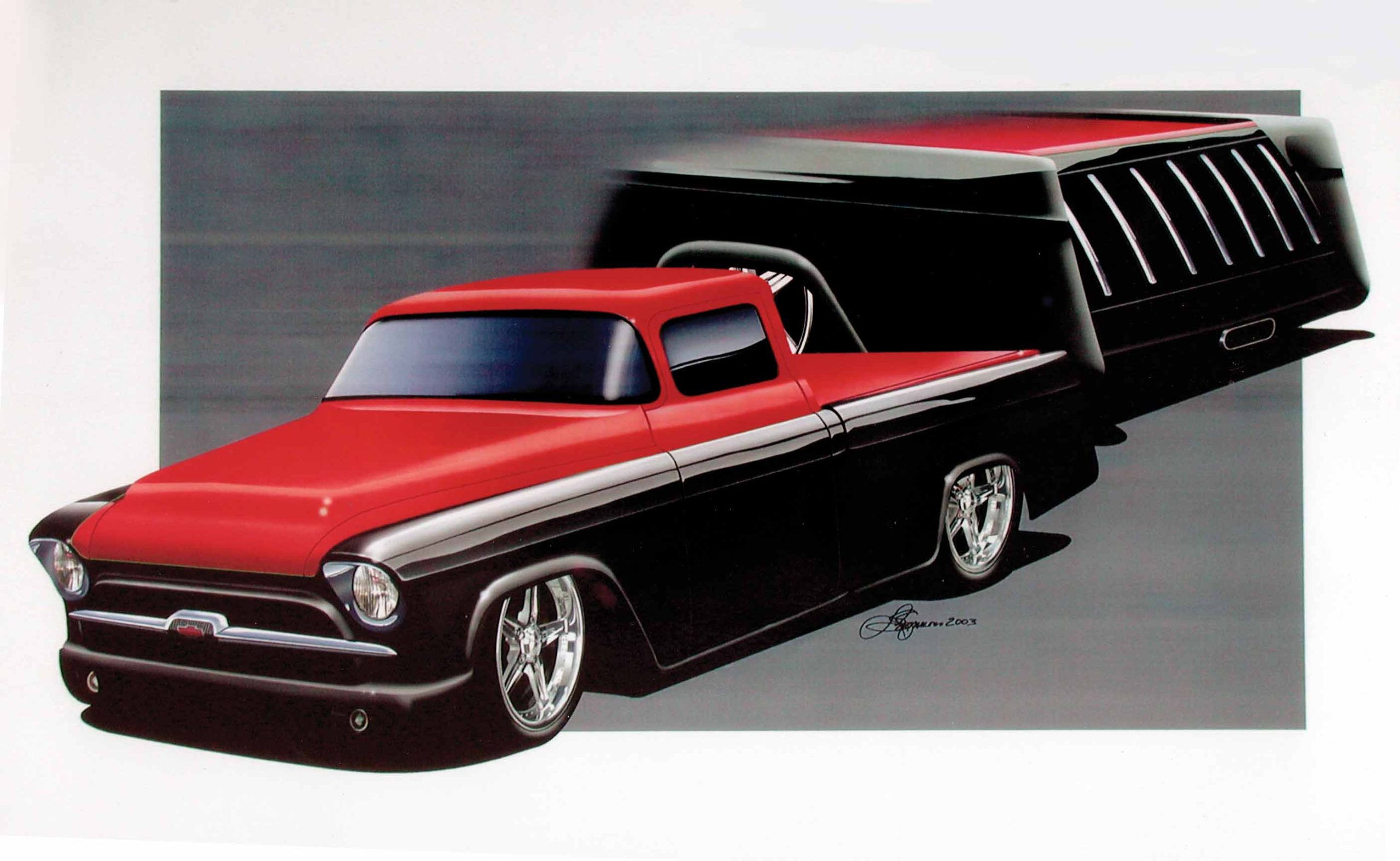

Builders Joe Keenum and Dan Ehle are best friends and business partners. Initially drawn together by their love for classic cars and trucks, the two have created a number of super rods and classic trucks over the years out of their shop in Leighton, Alabama. Keenum and Company has built trucks that compete with the best of the top-name builders in the country. Producing upwards of a dozen custom vehicles a year, the duo decided it was time to go it a bit further and build a radical shop truck that would showcase the expert craftsmanship the shop is capable of producing.

After running across this 1972 Chevrolet 1/2-ton pickup in early 2006, they felt this was the classic truck that would make the ideal candidate for the project they had in mind. 0nce Keenum and Ehle acquired the truck, they began the extensive build. The truck was a nice driver, and the previous owner performed a rather simple hot rod restoration, leaving the truck on the frame and updating a few of the components here and there. However, Keenum and Company had other plans for this classic.

Lowering a truck usually involved cutting coils and shaving bump stops. Out back, the rear end was treated to lowering blocks, a few pulled leaf springs or heated coil springs. Over the years, manufacturers began to address these demands, as lowering coils, spring leaf blocks, dropped spindles and flip kits were offered. Times changed with the introduction of airbags, as owners were able to slam their pickups with full ride height adjustability. Air Ride Technologies (ART) is one of those companies offering quality suspension solutions for truck owners, with kits that fit specific applications.

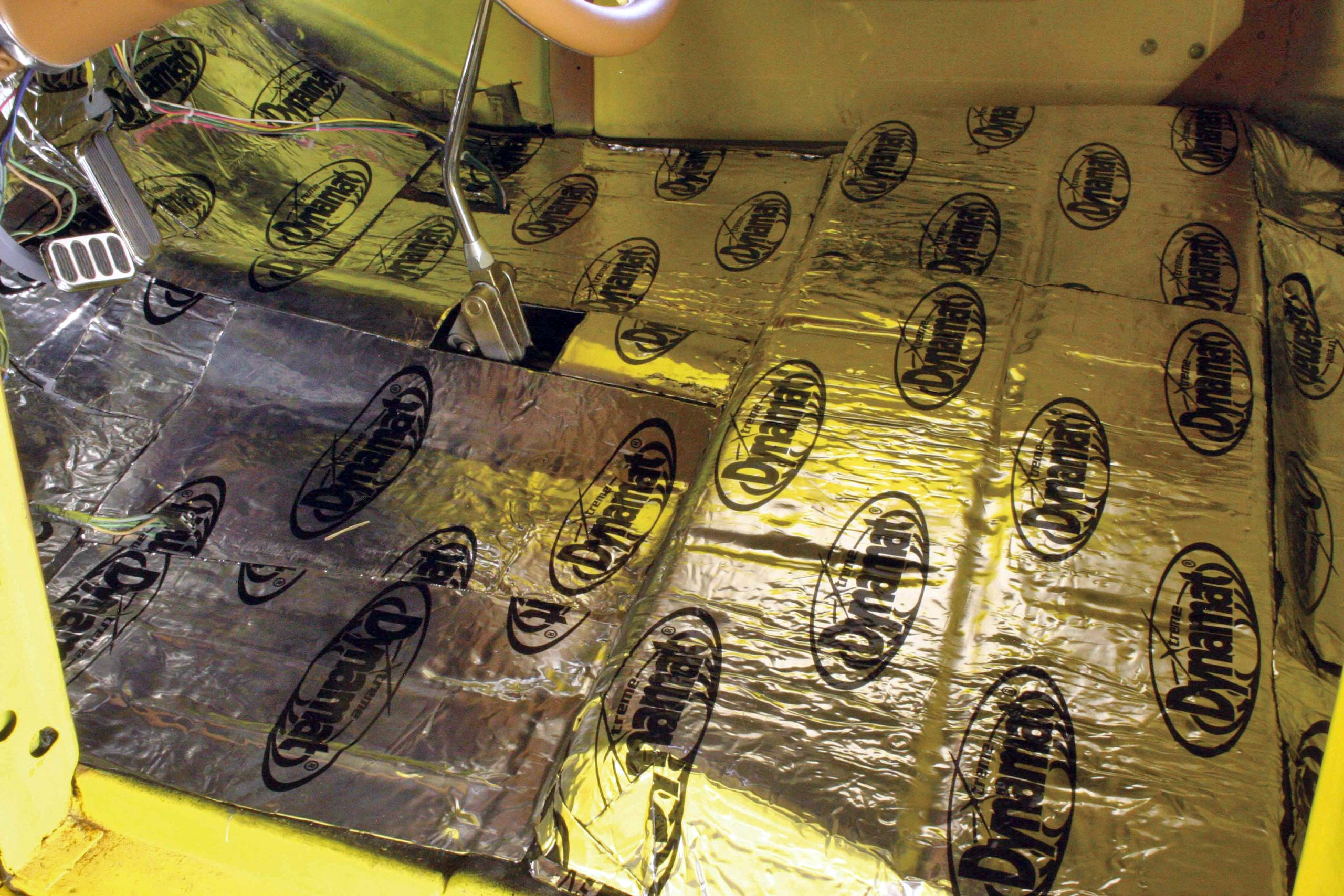

If you’ve ever hopped out of a classic pickup into a modern daily driver pickup, you have probably noticed the startling difference in noise and heat levels within and throughout the interior. This is because some time in the mid-’80s, pickups began receiving the same noise and heat control attention as auto manufacturers spent on cars, as they filled every nook and cranny with noise cancellation foam, sealant and padding. These insulations greatly helped cancel out noises and improved temperature control, as well as help dampen vibrations.

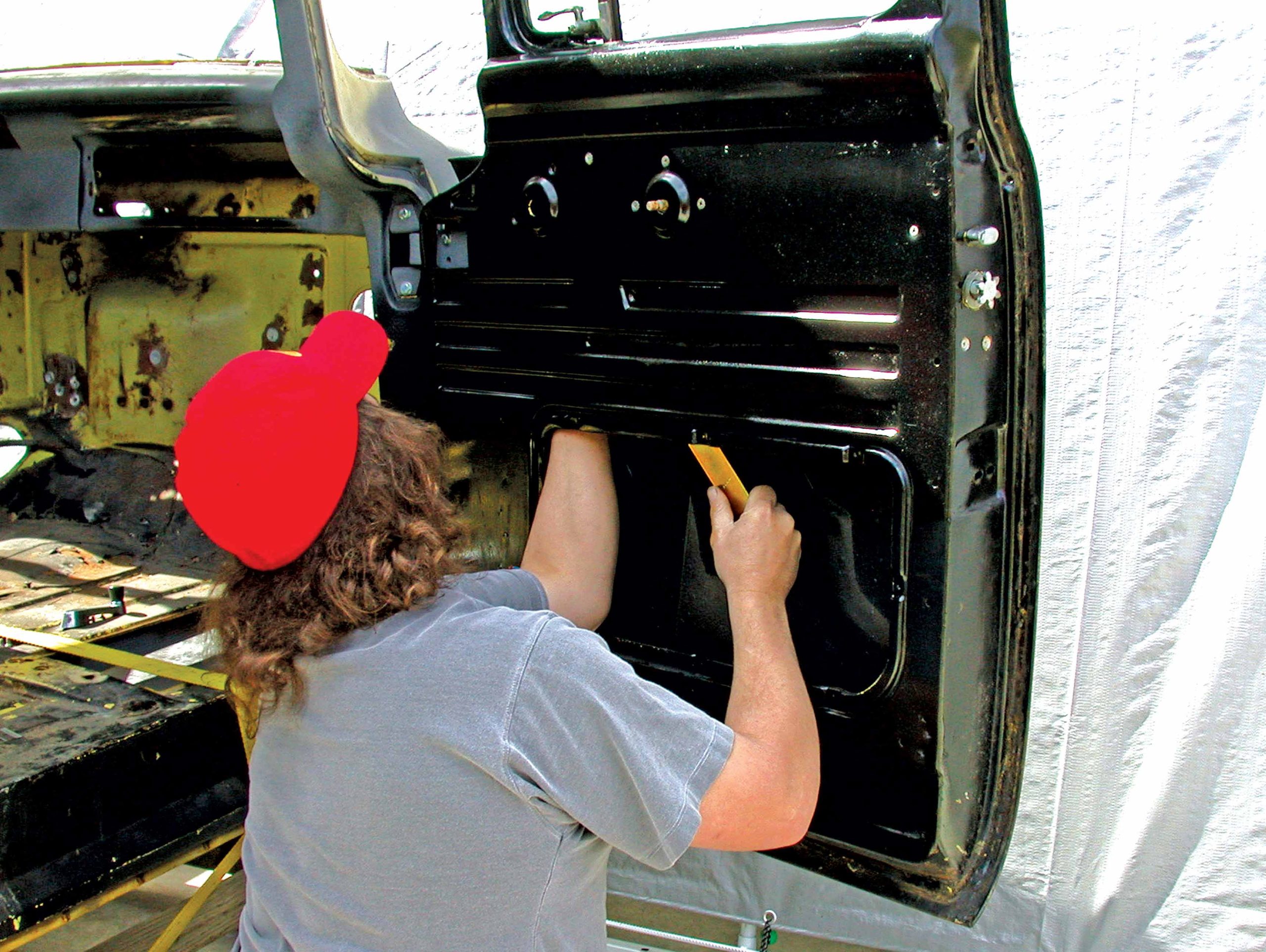

Older classic trucks are among the worst in all these areas. They squeak, they are noisy, and do little to control heat buildup inside the cab, especially around the floorboard. Since all these trucks were originally workhorses, not much attention was paid to these areas, but this problem is easily solved. Whether you are just beginning your interior and building from scratch or retrofitting your existing truck, Dynamat offers a wide selection of noise and sound cancellation products. Dynamat engineers have designed a complete line of products, ranging from speaker kits to complete sound and noise cancellation solutions from the floor to the roof.

This article delves into the process of upgrading a ’40 Chevy truck, focusing on swapping the original torque tube differential with a ’69 Camaro axle assembly and enhancing the rear suspension. It provides a comprehensive guide on reusing the leaf springs, installing new bushings, and incorporating a strong shock mount for rear frame strengthening. Essential tools like a bushing removal tool, MIG welder, and an oxy-acetylene torch are highlighted, demonstrating the intricate steps involved in modernizing early Chevy trucks.

In this detailed account, the Cimbanin brothers at Cimtex Rods in Jarrell, Texas, tackle the complex task of chopping and restoring a ’56 Chevrolet Cameo roadster. This article delves into the nuances of custom truck modification, from aligning door frames to adjusting the roof profile, highlighting the meticulous approach and expertise involved in such a project. Learn about the challenges and techniques of customizing classic trucks, as demonstrated by the award-winning craftsmanship of the Cimbanin brothers.

Over the past 20 years custom truck interiors have taken on many forms, and like so much of the world today, prices and costs for these outlandish interiors have reached new heights in every way. Molded, flowing consoles, leather and killer stereos have taken front row in the world of custom interiors, and gone are the old, plain, painted panels. Going to the local upholstery shop can mean some serious change in today’s market, as the price of materials and the cost of labor have risen dramatically. But leave it to truck guys to study the art of interiors to help contain the cost of a new look, making effective use of options throughout the build of a classic or a more modern truck. While checking out some pictures on the Internet, we happened upon this at-home molded kick panel build that cost under $50!

Adding power windows is a popular aftermarket option for classic vehicles these days. Worn-out window regulators have given people problems for years, and as replacement parts have become increasingly more expensive and harder to find, it’s simply easier and often cheaper to replace the old regulators with new electric ones. In the past we had to raid wrecking yards for parts that would adapt into our vehicles, and as expected there were generally a few problems associated with doing this. First, you don’t always know the condition of the parts being used, even though they look good; and second, you would need some background in window geometry to get the job done correctly. Finally, you need a certain level of basic fabrication skill and tools, which would be more than basic hand tools. With today’s technology and the availability of well-engineered aftermarket power window kits this has all changed, as it’s commonplace for most people to go straight to a kit designed for their vehicle.

Becky Walker, a housewife and career woman from Jarrell, Texas, has two hobbies: raising Great Pyrenees show dogs and her purple prism 53 Chevrolet show truck, appropriately named 53 PAW. About six years ago, my husband, Billy, dragged this raggedy old 53 Chevrolet farm truck home and told me he was going to fix it up for me to drive. That was the beginning of a major project that lasted over two years. We worked every night, weekend and holiday on that truck. In fact, I distinctly remember spending one New Year’s Eve, back in 2004, helping Billy change out two sets of springs.

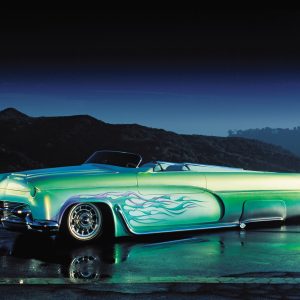

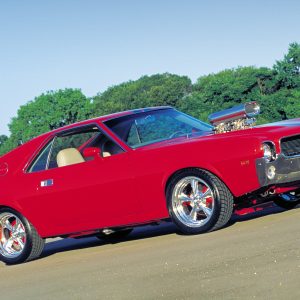

It often takes a serious challenge to test a person’s capabilities. After years of driving a string of performance cars, Terry Short wanted something different sitting in his North Tonawanda, New York, garage. So, he set out and found this ’55 Chevy big-window pickup in an apple orchard. He just knew he had met his challenge.

Terry Short’s ’55 Chevy pickup has a just-right rake, a monochromatic finish on a super-smooth body and a potent big-block Chevy. All these elements combine to make this Hot Rod Red truck a perfect cruising machine. Short’s goal was to build a truck that if you couldn’t see it, then you could certainly hear it coming. Though the roof went unchopped, the remainder of the body was extensively reworked and is devoid of chrome accessories.