Chevrolet

When starting any project that requires bodywork, rebuilding or even repainting, the first question is always, “What could possibly be lurking under the old paint that could come back and haunt us later?”

These tips are performance-oriented in nature because no matter how good-looking a matching-numbers Chevy might be, getting there and back is vital, as is prepping the car properly and inexpensively with little trouble. While six-figure projects and high-tech billet products flood the market, finding a good deal at the local salvage yard or a worthwhile part left over from a project can be just as exciting and much easier on the wallet.

First-generation Camaros are all the rage these days, and no wonder. With so many ways to bring them into a new era, they make great selections. So, while the big-block power and a five-speed trans served owner Gary Johnson well over the years, rocketing gas prices led him to a more efficient LS2 option.

Simplicity is the key here, as this ’55 Chevy perfectly embodies the sleeper theme with a no-frills look and monster power. It doesn’t even feature all the stainless Bel Air or 210 trim you normally find on most tri-5 models; but even though this is a plain-Jane 150 devoid of trim, Ernie Lankford’s all-black ’55 certainly doesn’t get overlooked.

This was a time when car manufacturers improved on their cars with much better suspension systems, larger and more efficient V-8 engines, and all the stylish creature comforts new-car customers expected. Chevrolet evolved, too, using more modern technology and a performance parts supply that enabled Chevy enthusiasts to build upon the factory offerings. Chevrolet changed what was once a basic industry, and even though those were simpler times with no computers, cell phones or electronics to speak of, the suspensions were new—but still a long way from what is available now. However, tri-5 Chevys were fast and provided a blast without all those fancy gadgets found in luxury cars at the time—just give them a two-tone Chevy equipped with a V-8 and whitewall tires, and it was all good.

Drag racing history buffs are more than familiar with the name Dick Harrell, or “Mr. Chevrolet,” one of early drag racing’s pioneer match race/funny car stars. However, there was also Dick Harrell the innovator, and he should be recognized for his incredible streetcars.

Since we don’t really have to search for vintage parts anymore, gone are the days of scouring the local “Pick-a-Part” in search for that illusive part that will interchange or convert your muscle car to bucket seats, tilt steering, A/C or some suspension upgrade. But there was a day when you and a rodding buddy could venture to your favorite junkyard and come home with a whole truckload of cool vintage goodies that would aid you in your rebuild, all in the span of a day.

Well, those days aren’t completely gone. While at the local wrecking yard looking for any useful hot rod parts, we stumbled across another enthusiast, Sean Rievley, who is in the progress of upgrading his ’71 Chevelle chassis

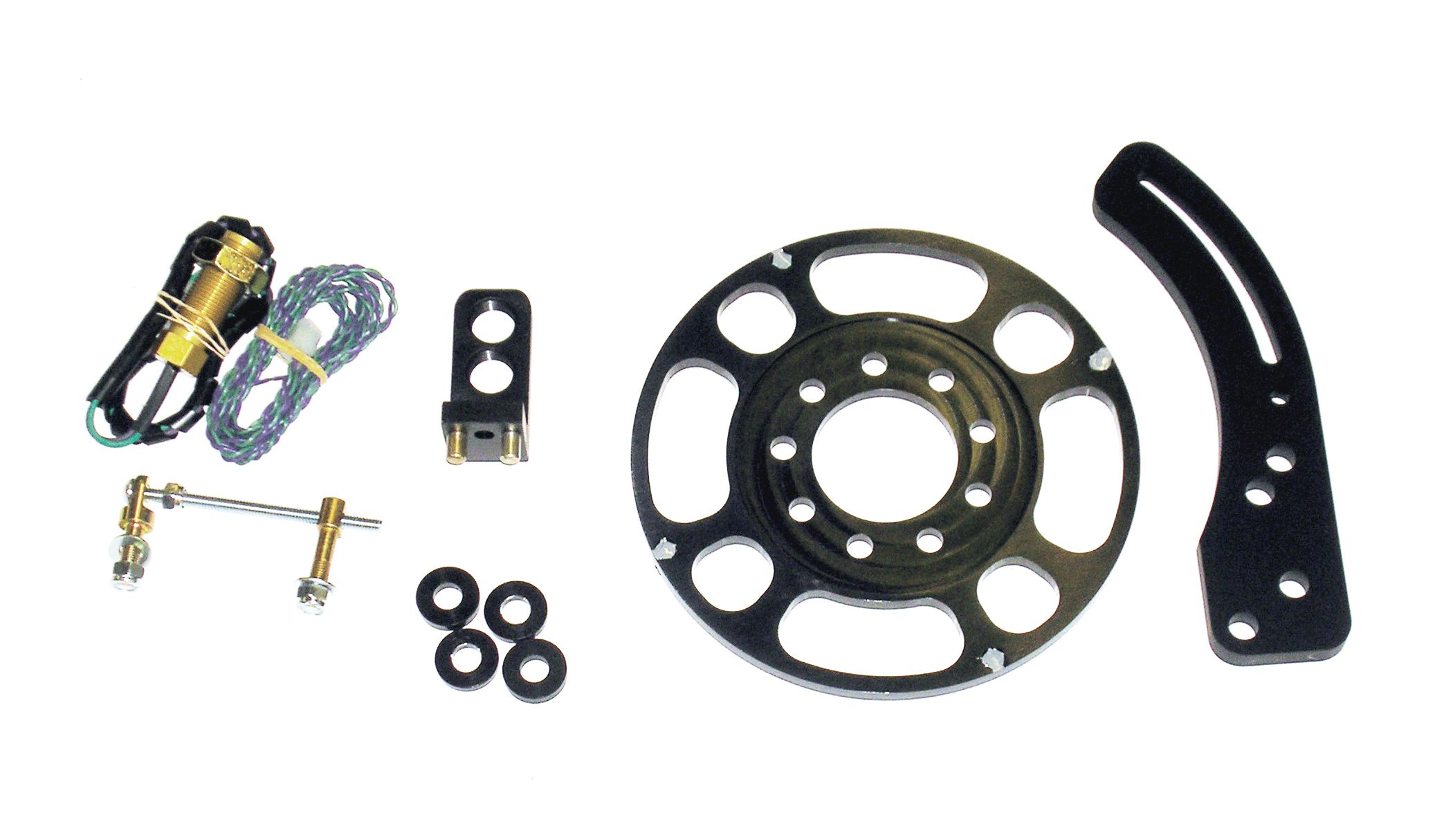

Crankshaft trigger mechanisms have been used in racing applications for a considerable length of time. In truth, they’ve actually been in service for decades. It’s a simple known fact that one of the best ways to improve engine performance is to ensure that the ignition timing is stable. That’s the whole purpose behind such a system, and that’s why racers regularly use them.

This has to be one of the nicest looking ’57 Chevrolet Bel Airs I’ve ever seen in the state of Hawaii,” I kept saying to myself as I was photographing Keith Maeda’s black cherry ’57 tri-5 Chevrolet. I mean, this thing has all the bells and whistles.

OK, we all know that it is easy to ignore automatic transmission maintenance—its messy and time consuming and no one really thinks about it until the trans starts to slip. Most transmission pans are simple stamped steel and do not have a drain plug so draining the fluid makes a big mess on your garage or shop floor. If maintaining your automatic trans was easier and less messy you would probably stay on top of the maintenance wouldn’t you?