THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

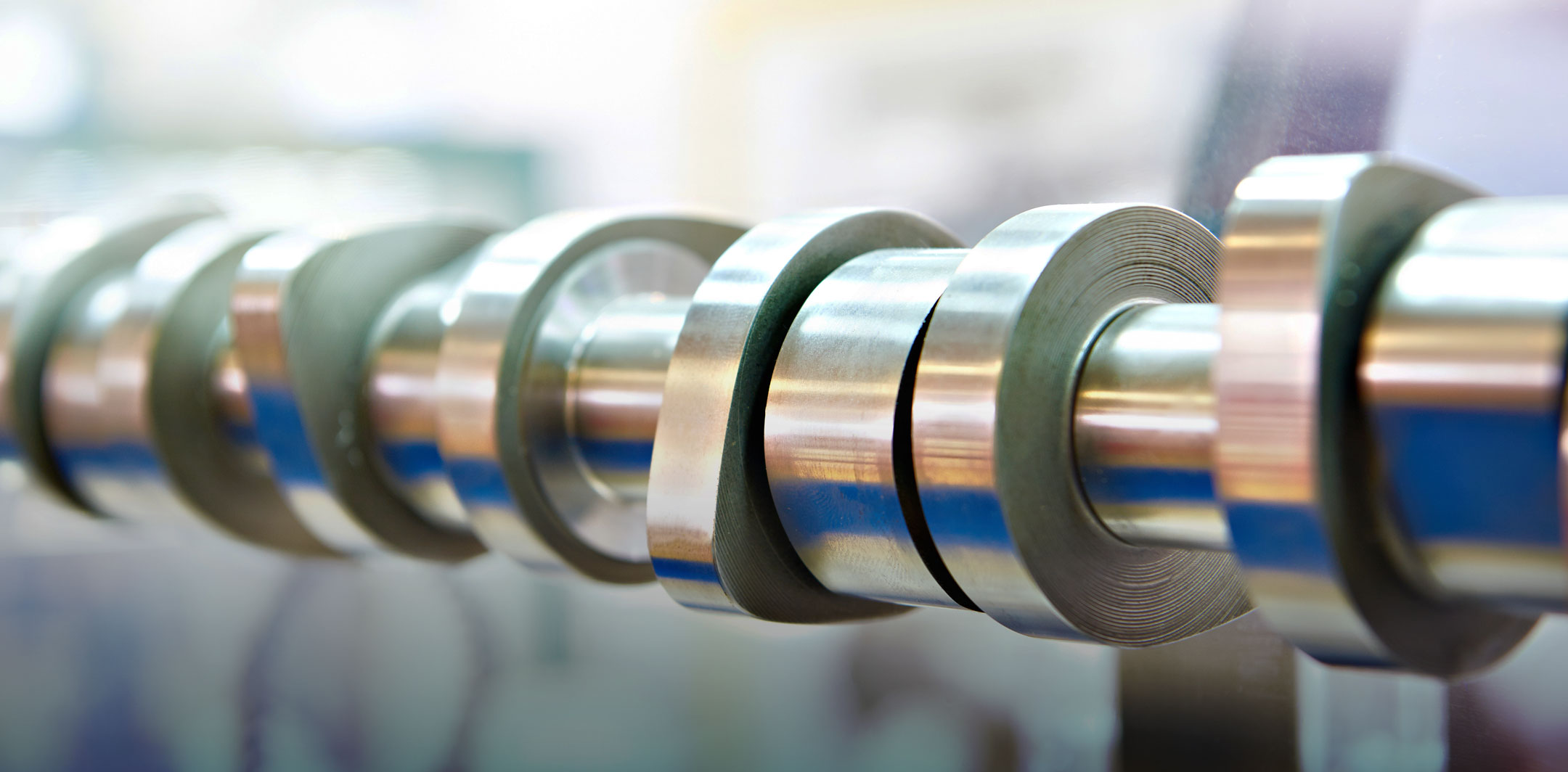

How to Choose a Camshaft

Author

Richard Holdener

Story & Photography

Camshaft Power Gains

Would you believe that one of these cams could provide an extra 200 hp to your combination? It’s true. Actually, the truth is that the installation of a stock cam will cost you as much as 200 hp.

Aftermarket Performance Cams

But any of the aftermarket performance cams will offer a significant power gain over the stock stick. On the right combination, replacing the stock cam with an aggressive hydraulic-roller cam improved the power output of a small-block combination by just over 200 hp.

Factors Affecting Power Output

The power output of a motor is a function of the displacement, engine speed, and the individual components chosen for the given displacement and engine speed. While three variables may not seem like much, the third variable can be broken down into millions of combinations.

Relationship Between Displacement, Engine Speed, and Components

Not surprisingly, the displacement, engine speed, and individual components are all closely related. In basic terms, the smaller the displacement, the higher the engine speed required to produce a given power output. The higher engine speed will naturally dictate specific engine components designed to promote high-rpm power production.

Importance of the Camshaft

One of the key ingredients in determining the eventual power output and effective operating range of the motor is the camshaft. Short of some wild induction system, it is the camshaft that also determines the overall character or personality of the motor. Build the wildest high-compression combination you can imagine with ported heads and a super single-plane manifold, and see what happens when you install a stock cam.

Effects of Camshaft Profiles

The thing will idle and behave basically like a tame stock motor. The same combination with a wild roller profile will offer a lumpy idle, surge at low engine speeds, and charge like a freight train once you reach the effective operating range of the cam.

Understanding Camshaft Elements

Since the cam has such a dramatic effect on the overall character of the motor, it is important to understand the basic elements (lift, duration, and lobe separation angle) before we offer recommendations for specific applications. Therefore, we should first have a basic understanding of how the average four-stroke engine works. This will help us put the cam events into proper perspective when the discussion turns to the important subject of overlap.

Four Strokes of an Internal Combustion Engine

As indicated by the description, the internal combustion engine can be broken down into four relatively distinct events (or strokes): power, exhaust, intake, and compression. Since the events are ongoing, we can begin anywhere; but we will start with the piston all the way at the top of the cylinder, with both the intake and exhaust valves closed.

Power Stroke

Depending on the ignition timing, the plug fired some 10 to 30 degrees before TDC, and the expanding gases (air and fuel) have forced the piston downward, causing the crank to spin. The event of this force is called the power stroke, where power from the expanding gases is pushing down on the piston. It is important to note that each stroke lasts only 0.5 crank revolutions (that’s a quarter turn of the cam since it is spun half the speed of the crank).

Exhaust Stroke

After the power stroke comes the exhaust stroke. The power stroke has forced the piston downward and sometime just before reaching BDC, the camshaft will begin to open the exhaust valve on that cylinder. By this time, all of the expansion of the air/fuel mixture has taken place. The residual cylinder pressure begins to push the burnt mixture through the open exhaust valve. The remainder of the exhaust gases are evacuated after the piston passes BDC and begins traveling upward on the exhaust stroke. As the piston is moving upward, the exhaust valve opens completely to maximum lift (dictated by the cam profile) and begins to close.

Overlap: A Critical Element of Cam Timing

It is at this point that one of the most critical elements of cam timing comes into play. Just before the piston reaches TDC and the exhaust valve has not completely closed, the intake valve begins to open. The event where both the intake and exhaust valves are open is referred to as overlap. During this period, the outward-moving exhaust gases create a scavenge effect that can siphon or help draw the intake charge into the cylinder.

With the intake valve opening slowly, the outward rushing exhaust gases not only siphon some of the intake charge into the cylinder, but some of that intake charge actually escapes out the exhaust port. Once the piston passes TDC and begins moving downward, the intake charge is pulled in very quickly. The closing point of the exhaust valve now becomes critical to keep any unburned exhaust charge from being drawn back into the open exhaust valve. This overlap period is critical for maximum performance.

Intake Stroke

The intake stroke occurs right after the overlap period. The intake valve follows the piston down and reaches maximum lift around 106 degrees after TDC (which is defined as the intake centerline). After reaching BDC, the piston starts back up to compress the newly drawn intake charge. The compression only occurs when both the intake and exhaust valves are closed. Some time before reaching TDC on the compression stroke, the spark plug fires and we start all over again.

Understanding Camshaft Elements

Now that we have a basic understanding of the events in a typical four-stroke motor, we can take a look at the elements that make up a camshaft—namely lift, duration, and lobe separation angle. Cam lift is the easiest element to understand, as it refers to the amount of lifter (or lobe) rise (in inches) offered by a given profile. The difference between lobe lift and valve lift is that valve lift refers to the lobe lift of the cam profile multiplied by the rocker ratio. Most small-block Chevys came equipped with 1.5-ratio rockers; thus, the lobe lift of a cam would be multiplied by 1.5 to achieve the actual valve lift. Naturally, it is possible to install higher-ratio rockers to increase the valve lift with the same lobe lift. For instance, 1.6-ratio rockers are common upgrades for small-block Chevys.

Valve Opening and Closing Rates

Opening and closing the valves is not achieved instantaneously. The valves are opened and closed at a rate specified by the cam design. Basically speaking, high-lift, short-duration cams feature aggressive ramp rates that open and close the valves quickly. Reducing the lift or increasing the duration lessens the ramp angle. In most cases, steep ramp angles improve performance, but a balance must be struck since aggressive ramp angles also make life tough on the remainder of the valvetrain (springs, pushrods, and rockers).

Camshaft Duration

The next camshaft element is duration, which refers to how long (in crankshaft degrees) the cam keeps the valve(s) open. Cam duration is somewhat less universal than lift values, as the duration figures must be defined at some starting lift point. It is difficult to determine exactly when (in crank degrees) the cam starts lifting the valve. Adding to the difficulty was the fact that different cam manufacturers provided duration figures based on different starting lift values. Many manufacturers rated their cams at 0.006-inch lift, others at more or less lift. Obviously, the different starting and ending points affected the advertised duration, despite similar cam profiles.

Standardizing Cam Duration

Eventually, the cam manufacturers came together on a standardized duration figure to rate cam profiles. The agreed-upon starting and ending lift value for cam duration was 0.050-inch, which means the cam duration started after the lobe lift reached 0.050-inch lift and stopped after closing to 0.050-inch lift. This value differs substantially from the advertised duration figures often quoted, but as we said, advertised duration numbers vary based on the starting and ending lift points used for the measurement.

Lobe Separation Angle

The final element provided on the cam card (or catalog) is lobe separation angle. The lobe separation angle is the number of degrees separating the peak lift points of the intake and exhaust lobes. If you were to draw a line intersecting the intake and exhaust lobes, the lobe separation angle would be the number of degrees separating the two lines. The number of degrees between the center lift point of the intake and exhaust lobes is fixed once the cam has been ground.

Lobe Separation Angle vs. Intake Centerline

Lobe separation angle is often confused with lobe center, or more accurately, intake centerline, which refers to the position of the center lift point of the intake lobe in relation to the TDC of the piston. Unlike the lobe separation angle, the intake centerline can be changed relative to the crankshaft by advancing or retarding the cam (using an adjustable timing gear). Although the actual effect will be determined by your particular combination, advancing the cam will usually improve bottom-end power, while retarding the cam will increase top-end power. Advancing and retarding the cam will also affect ignition timing, so make sure to readjust the distributor a like amount of the cam advance or retard.

Stock Cam Profiles

Now that we have covered the basic elements of the camshaft, we can start to look at specific recommendations. With the exception of a few small-block cams from the muscle-car era, stock SBC cam profiles offer a combination of low lift and short duration.

Design Goals of Stock Cam Profiles

Stock cam profiles were obviously not designed with maximum power in mind. Maximum power production is almost never the design goal of a cam profile, even on the most radical drag race roller cam. Unless used as a stationary generator drive, your average Chevy V-8 will have to run effectively at a variety of different engine speeds, and even in a race application, power production will be critical over a given rpm range.

Peak Horsepower Considerations

It is important to remember that peak horsepower is usually the last variable that should be considered when selecting a cam, especially for a street application. Stock small-block cams usually offered duration figures (rated at the standard 0.050-inch) under 200 degrees. The short duration was combined with lift values near 0.400-inch lift. These are rough guidelines, but meeting emissions standards, fuel economy, and valvetrain longevity goals called for the use of wimpy cam profiles. The stock cam profiles got a bit more aggressive once Chevy introduced the hydraulic roller grinds, but even those were mild compared to those offered by the aftermarket. The 0.400-inch lift and 200 degrees of duration offered by the stock cams will help put the aftermarket performance grinds into perspective.

Choosing a Cam for a Street Small Block

Choosing a cam for a street small block is not difficult. There are many different grinds available from the variety of cam manufacturers. The manufacturers’ catalogs offer a wealth of information, including the cam specs and effective operating ranges. Of course, the effective operating range will vary with the remainder of the components and the actual displacement of the motor. The smaller the displacement, the higher the effective operating range for a given cam profile. By this we mean that the same cam run in a 283 will make peak power higher than if we installed it in a 383ci or 400ci small block.

Using Catalog Operating Range Numbers

The operating range numbers supplied in the catalogs should be used as guidelines; don’t be afraid to call the cam tech line for advice on your particular application. Your chances are good that the manufacturer has run a given cam in a combination similar to yours, and can provide helpful data or information on the results. This is especially true of an off-the-shelf catalog grind for a small-block Chevy.

Knowing Your Combination

When choosing a cam, it is also important to make sure you know the remainder of your combination. If the cam is the only change in an otherwise stock motor, your choice will be different than if you were building a dedicated strip motor. Make sure to have as much information as possible before calling the cam tech lines, as the more information you have, the more likely you are to choose the right cam for your application.

Being Honest About Usage

Speaking of applications, make sure to be honest about what the motor will be used for. You don’t know how many times we’ve heard the answer “As much as possible” to the question of how much power one wishes to make. Actually, the power question should never be asked, and instead replaced by the usage question. Will the motor be used in a daily driver, a dedicated racecar, or something in between? Being honest about the usage will make life much easier.

Matching the Cam to the Application

For instance, if the motor will be installed in a street rod that will be used in rod runs and never see a dragstrip, why install a radical cam grind that only offers improved power at high rpm? The cam will make the motor temperamental, thirsty, and overall difficult to drive. Who wants to spend their time behind the wheel of a rumpity beast that is never offered the opportunity to clean the carbon off the spark plugs? You’d be better off with a milder grind that provides plenty of low-speed torque, impressive throttle response, and decent fuel economy. If you spend most of your time running below 3,500 rpm, it only makes sense to install a cam that will maximize power production in that rpm range.

Matching Components for Optimal Performance

The camshaft isn’t the only component that will determine the effective operating range of the motor. Your typical RV/towing cam has no place on a motor equipped with a set of fully ported AFR 227cc heads, a single-plane Super Victor intake, and a 1050 Dominator carb. The same holds true of a full race roller cam on an otherwise stock 350. Your intake and heads must be matched with the cam profile to produce the optimum combination.

Cylinder Heads and Cam Choice

The cylinder heads also play an important role in the cam choice, as the head flow characteristics can help with cam selection. When choosing a cam profile, the lift figures should be based on the flow rate of the cylinder heads. It doesn’t make much sense to install a 0.700-lift cam on stock heads that stop flowing at 0.500 lift.

Physical Limitations

Flow figures aside, physical limitations, such as valve-spring coil bind and retainer-to-seal clearance, can also limit cam lift values. For most production small-block Chevy cylinder heads, lift values will be kept under 0.500 lift and usually closer to 0.450 lift. The intake-to-exhaust flow relationship of the cylinder head will also determine whether you should employ a single-pattern or dual-pattern cam. On most stock Chevy heads, a dual-pattern cam (where the intake and exhaust lift and/or duration figures differ) will be preferred. For most stock cylinder heads, opt for a cam with more exhaust lift and duration than intake, which will help make up for the poor flow rate of the stock exhaust ports.

Increasing Cam Duration

In general terms, increasing the cam duration will increase the effective operating range of the motor by shifting the torque curve higher in the rev range, thereby improving horsepower production. Mathematically speaking, producing the same torque values at a higher engine speed will increase horsepower production. Shifting the torque curve will also have the unfortunate side effect of reducing low-speed power. There is almost always a trade-off, and the increase in top-end horsepower comes with a penalty of lost low-speed torque.

Benefits of Mild Stock Cam Upgrades

The benefit of improving the power output of a motor equipped with a mild stock cam is that it is possible to increase power production across the board without any penalty in torque production. Take a stock four-barrel 350 Chevy and add a small, hydraulic, flat-tappet cam with duration figures between 203 and 212 degrees. Chances are that power will improve everywhere, from idle right to redline.

Example of a Mild Cam Upgrade

The Pure Energy 246PE from Comp Cams is a perfect example of this type of mild upgrade, as this dual-pattern cam offered 0.429-inch intake lift, 0.438-inch exhaust lift, and a 203/212 duration split (at 0.050-inch). It also had the extra benefit of being emissions-legal for all 1987-and-earlier carbureted small blocks. Other cam manufacturers offer similar grinds. The mild cam grind will work great with the stock heads, cast-iron Q-jet intake, and stock exhaust.

Lift Values and Valve Springs

Given the limitations of the stock cylinder heads, lift values for most street applications should be kept below 0.500-inch lift unless porting has been performed to improve the head flow. It will also be necessary to upgrade the valve springs to accommodate the increased valve lift and maintain adequate valvetrain control at the elevated engine speeds offered by a cam upgrade. Most stock cams sign off below 5,000 rpm, while even a mild upgrade will allow an additional 300 to 400 rpm. It is possible to install more aggressive cam profiles in an otherwise stock small block, but cams with more than 212 degrees of duration will be best applied to a modified motor equipped with a set of headers and free-flowing exhaust.

Performance Improvements with Cam Upgrades

We produced 280 hp with a stock-cammed 350 equipped with stock heads, Q-Jet intake, and headers. Adding a set of mildly ported stock heads and the Comp 246PE cam increased the power output to 340 hp, while the torque was up to 400 lb-ft. Adding a set of aftermarket aluminum heads and a slightly wilder cam (roughly 224 degrees of duration) increased the power output to 425 hp and torque to 445 lb-ft. Cams with 268 degrees of advertised duration (224 degrees at 0.050) would best be used with aftermarket or ported stock heads. (The GMPP Vortech heads could also be used successfully with this level camshaft, but modifications would be necessary to facilitate the high lift).

Smooth Idle and Improved Power

Cams with duration figures less than 210 degrees should offer a smooth idle with plenty of vacuum. Every step up in cam duration will likely decrease the idle vacuum yet improve overall power production. On our test small block, we improved the power output from 2,600 rpm all the way to 6,000 rpm with cam profiles up to 224 degrees at 0.050-inch. There was a slight loss in power compared to the stock cam below 2,500 rpm.

Trade-Offs with Larger Cam Profiles

Stepping up to cam profiles with duration figures beyond 224 degrees will require a trade-off. The additional power will cost extra idle vacuum and fuel mileage. Large-displacement small blocks (383 or 406 strokers) can take advantage of larger cam profiles without sacrificing low-speed torque production or even idle quality. Of course, this is a moot point if you are simply looking for a cam upgrade for your existing 350. It is, however, something to consider if you are planning on rebuilding your small block and opt for a very affordable stroker crank rather than a simple rebuild. Cams in the 230- to 240-degree duration range are best left to stroker or street/strip applications.

High-Performance Results and Streetability

Our 355 small block produced 540 hp with a 242/248-degree duration hydraulic roller cam, but it was hardly what you would call streetable. Sure, it could be driven on the street, but in our minds there is a big difference between the phrase “It could be driven on the street” and actually being streetable.

ARTICLE SOURCES

Comp Cams

www.compcams.com

800/999-0853

3406 Democrat Rd. Memphis, TN 38118

Crower Cams & Equipment

www.crower.com

619/661-6477

6180 Business Center Ct. San Diego, CA 92514

Holley

www.holley.com

270/782-2900

1801 Russellville Rd. Bowling Green, KY 42102

MSD

www.msdignition.com

915/855-7123

12120 Esther Lama, Ste. 114 El Paso, Texas 79936