Engine

Ford fans will always have a soft spot in their blue-oval hearts for the Windsor, the Cleveland and the big 460 FE engines—and deservedly so. If you’ve ever crawled a junkyard for one of these engines, you’ve likely passed over more than a few 351M and 400 engines to find what you are looking for. Poor factory numbers and bad word-of-mouth have made these cousins to the mighty Cleveland about as wanted as poison ivy at a nudist colony, but there is power to be found in those engines—and cheap, too.

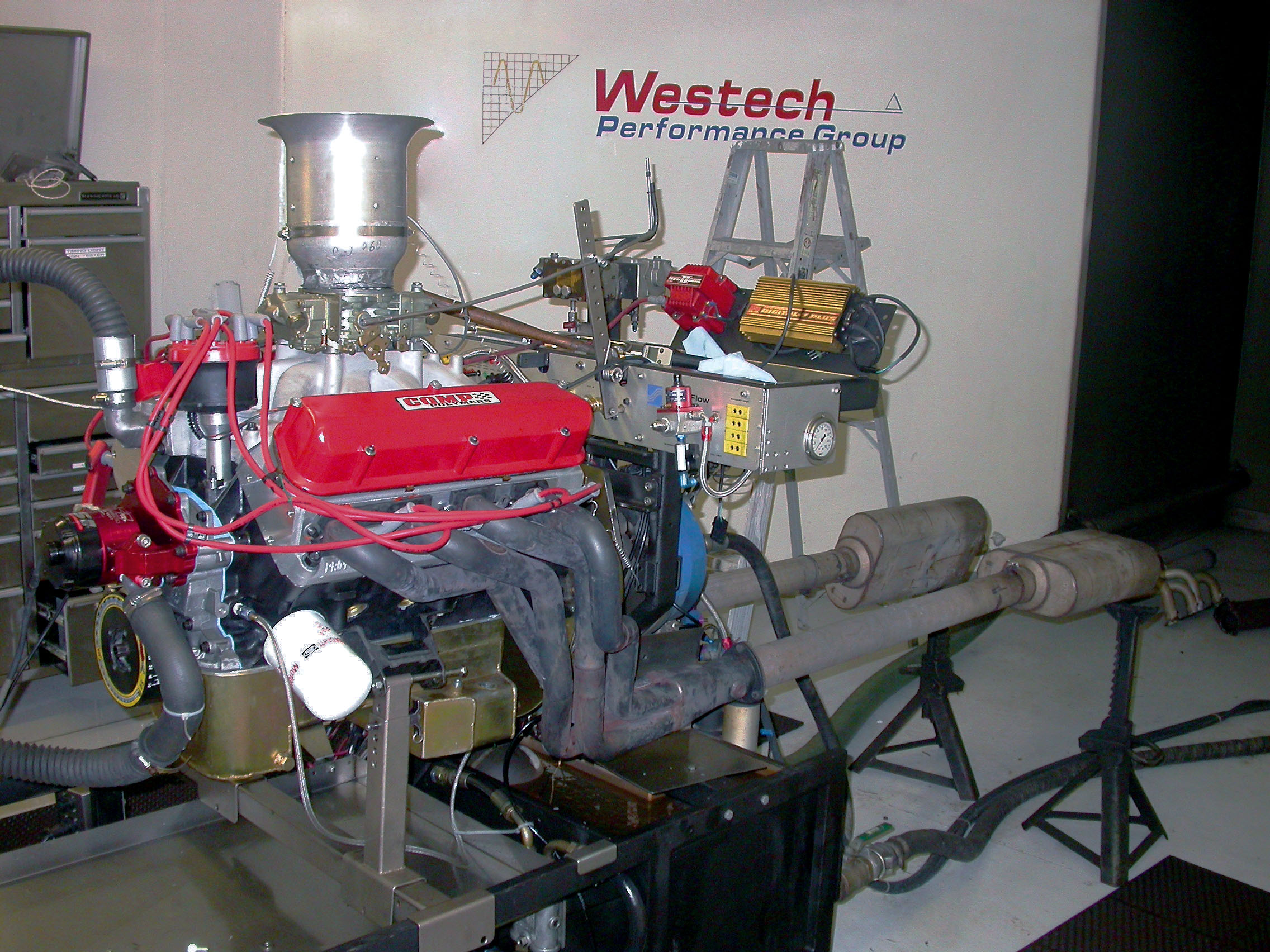

We showed you how to build a small-block engine that could make over 500 hp and 500 lb-ft of torque on 87-octane gas. It was a motor that could be driven just about every day with a hydraulic-roller cam and a good carburetor, making acquisition and maintenance almost nonexistent. Like many things we do in the engine world, the results we enjoyed—while good—just weren’t satisfying anymore. We wanted more.

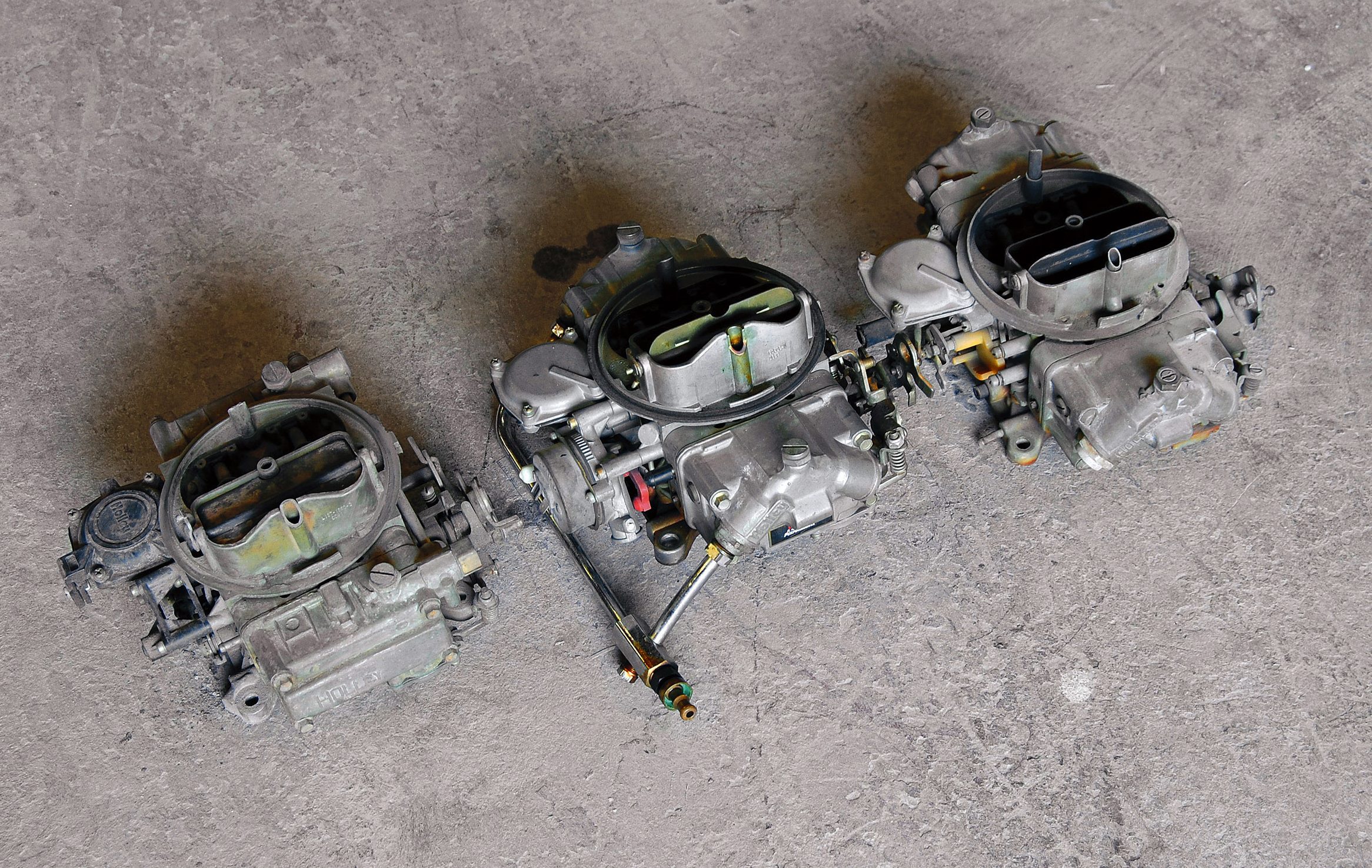

Holley carburetors have long been a staple in the go-fast world of high-performance motoring, whether it’s NASCAR, drag racing or on the street. Much like other performance-oriented products—perhaps even more so with a carburetor—a carburetor requires a fundamental setup and a degree of maintenance, and that’s considering you have chosen the correct-size carburetor for your application, at least to get it in the ballpark. Knowing how to adjust, maintain and even repair your Holley carburetor goes a long way toward helping to ensure that your carburetor will make optimum horsepower for a long time. Because of this, we decided to compile a few troubleshooting and repair tips for the popular 4150-series Holley carburetor, which is the series designation for Holley’s street/strip and racing carburetors.

Alternative-fuel sources and hybrid cars are all the rage today. Everyone from major automakers to backyard inventors is pursuing alternative fuels and energy sources. While the ultimate goal is generally to eliminate dependence on foreign oil, for hot rodders there is also the desire to invent and create a better-performing engine.

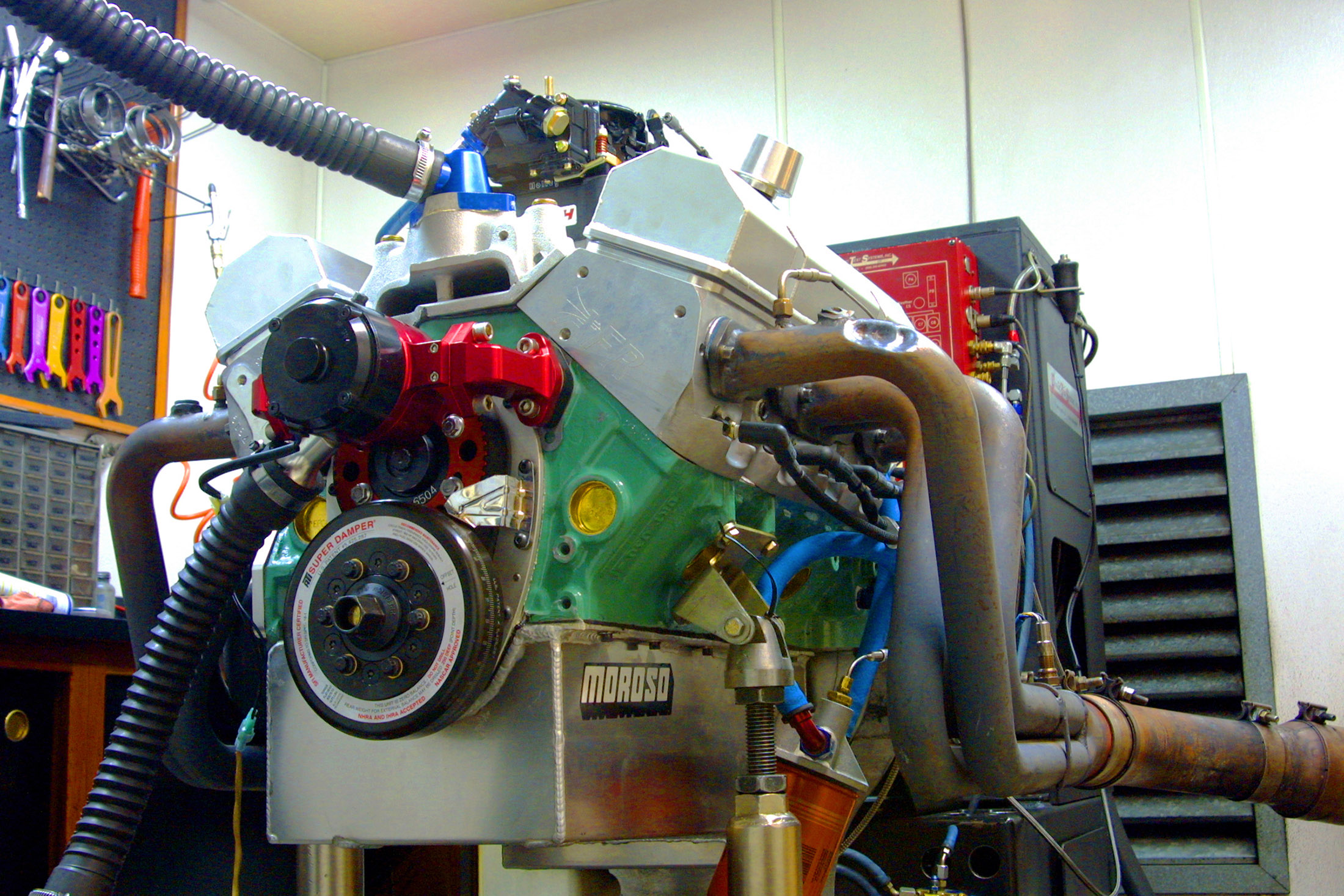

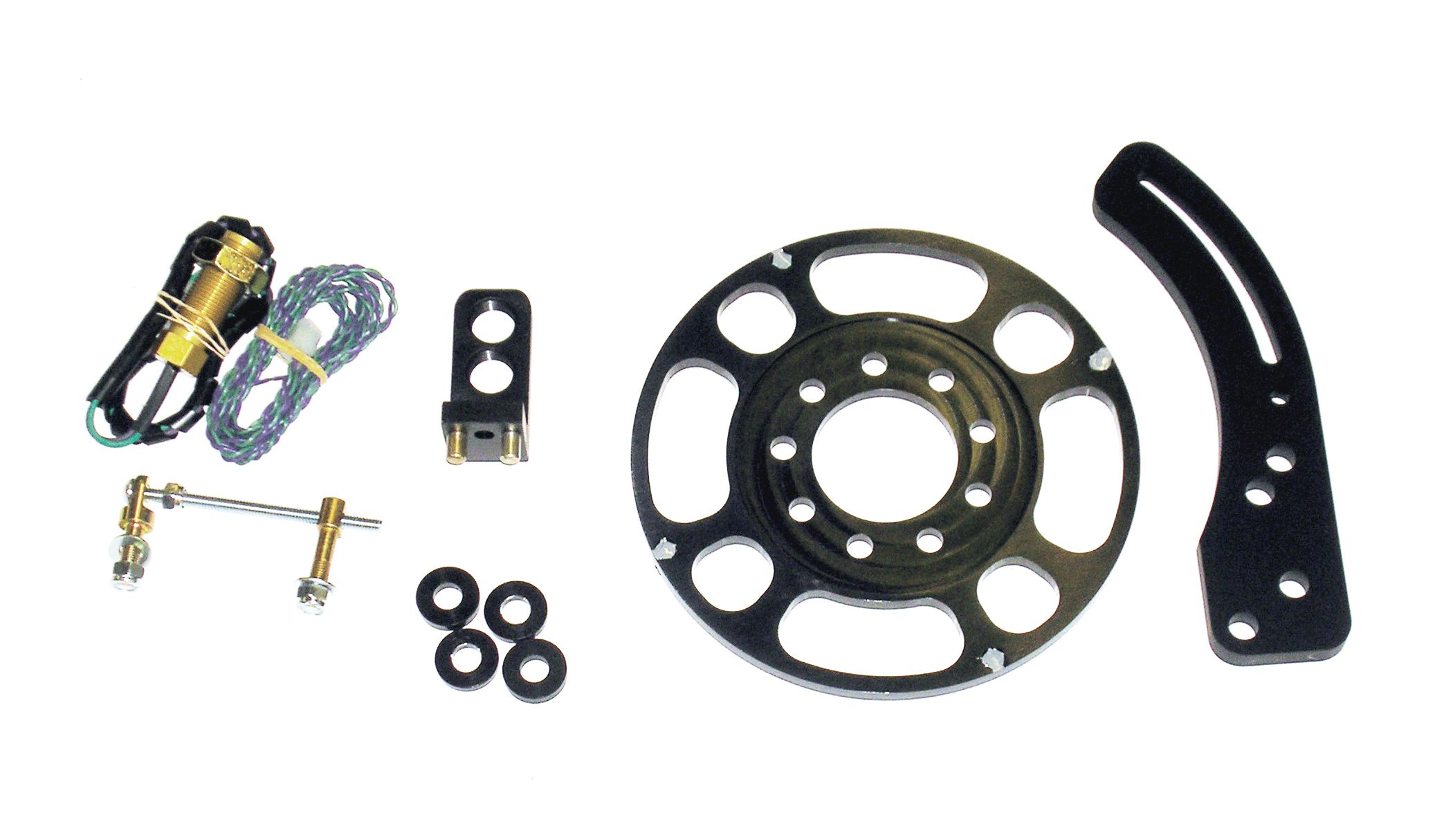

Crankshaft trigger mechanisms have been used in racing applications for a considerable length of time. In truth, they’ve actually been in service for decades. It’s a simple known fact that one of the best ways to improve engine performance is to ensure that the ignition timing is stable. That’s the whole purpose behind such a system, and that’s why racers regularly use them.

After recently purchasing a ’62 Thunderbird, it became obvious very quickly that the car needed a new engine. Our plan was to turn the car into a daily driver, and so, as long as we needed a new engine, we figured we’d add air conditioning to the car while we were at it. And if you really know your Ford history, you also know that the ’62 was the last model T-bird to come with a generator rather than an alternator—one more reason to consider an upgrade.

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

Even though we all dream of blasting through the desert at 130-MPH like Robby Gordon, most of our 4×4 adventures take place at a much more reasonable pace. Unfortunately for our engines crawling along a boulder strewn dry river bed or climbing a goat trail through a mountain pass does not always allow enough airflow to keep our engines cool with a belt driven mechanical fan. Belt driven fans are designed to keep your engine cool when traveling down a street or highway not while crushing boulders at 3-MPH and 1,500-RPM. So what can we do to keep our rigs from boiling over this summer? Follow along with us as we install a pair of 11-inch electronic cooling fans along with a programmable fan controller both from SPAL USA.

Be Cool is no newcomer to cooling heavy metal. For years it has provided cooling solutions for some of the most impressive high-performance engines to rumble down the streets and dragstrips of America. The folks at Be Cool understand that having the proper cooling components in any car or truck is vital to keep an engine safely within its operating temperature range. They also understand that to make cooling and installation easier, they had to design a full bolt-in system, a system that would fit hundreds of applications for classic cars and trucks, as well as more modern vehicles that also need cooling help.

It can be argued that one of the best mods you can make to an LS-based or Gen III motor is a camshaft change. With the number of aftermarket companies making many different types, a good cam can be found for anywhere from $300 to $1,000, depending upon what type of power you want to make and how sophisticated the cam package is. Because 99.99 percent of all vehicles on the road today are computer controlled, most aftermarket companies are able to suggest whether a new tune will be necessary or if the stock one will suffice. But with so many different options out there, it can be quite confusing as to which is the right one for you.