THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Engine

- Fuel System

- Electrical

- Outdrives

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Back

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- Chevrolet

- Cadillac

- Pontiac

- AMC

- Buick

- Jeep

- Lincoln

- Ford

- Honda

- GMC

- BMW

- Mitsubishi

- Dodge

- Nissan

- Chrysler

- Subaru

- Toyota

- Plymouth

- Mercury

- Volvo

- Volkswagen

- Oldsmobile

- Acura

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Chip Foose

- Ring Brothers

- Jack Fuller

- Bob Cullipher

- Jerry Nichols

- Bobby Alloway

- Jesse James

- Carl Casper

- J.F. Launier

- Steve Sellers

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- George Barris

- West Coast Customs

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- 27 Post Missing Content

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Power Adders

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

MORE IS BETTER

Author

Joe Daniels

Story & Photography

Installing an Airaid Intake System

When it comes to engines, there is no question that better breathing means more horsepower and torque. It’s a power principle that performance automotive magazines have been preaching for years. More air in, more air out equals improved horsepower and torque. Oftentimes this improved efficiency means better mpg, too.

To fully understand this power principle, you have to understand the inner workings of your typical four-stroke gasoline engine. An engine is essentially a giant air pump. The up and down motion of the pistons moves specific volumes of air through the engine. The quantity of air depends on a lot of factors, including the displacement of the engine, the size of the intake system, camshaft configuration and how efficient the exhaust side of the equation is.

So where is the additional power found in this equation? By improving the efficiency of an engine in any one of the critical areas—or better yet, all of them—you can make more power. For this article we will focus on the intake side of the engine.

Most manufacturers face quite a challenge when it comes to designing intake systems for today’s trucks. First off, the intake system has to fit the platform (model). More important, the intake system also has to thoroughly filter the incoming air to the engine. In terms of noise, the intake system has to be somewhat quiet. The end result is what’s found on today’s trucks. Does it work? Yes. Is there room for improvement? Yes.

On the stock intake system, the main airflow restrictions are usually the design of the intake box itself; the actual air inlet where the box meets either the inner fender or the radiator bulkhead; and the factory, paper-style filter inside the box. The easiest upgrade to any intake system is to simply change the filter from the original paper element to a high-flow-style filter. But to extract the optimal performance from an engine, the next step to better breathing is to change out the complete air box for an aftermarket intake system.

Airaid has developed a simple, bolt-on air intake system for late-model GM trucks that not only improves breathing but also can generate an additional 18 rear wheel horsepower. The system utilizes a computer-designed cool air dam (CAD) that replaces the restrictive factory air box for maximum airflow. The heart of the CAD system is Airaid’s premium SynthaFlow air filter, which not only outflows the stock element but consistently filters dirt down to 2-3 microns.

The install was performed on an ’04 Chevy Avalanche fitted with the 5.3-liter V-8. The Airaid intake system fits all GM V-8s, including the 4.8-, 5.3- and 6.0-liter engines. The end result of this install was better breathing for the engine, which dramatically improved throttle response and power. The late-model GM system is also offered with an Airaid modular intake tube for enthusiasts wanting a smooth tube to replace the factory “accordion” tube that leads to the throttle body.

Best yet, the installation of Airaid’s smog-legal, bolt-on system can be accomplished by the at-home mechanic in less than an hour. TB

1. Airaid’s complete intake system for GM trucks (part No. 200-145) includes the modular intake tube. The kit comes complete with all necessary mounting hardware, couplers and detailed instructions for an easy do-it-yourself installation.

2. For easier access to the throttle body, the engine cover should be removed. Only one 10mm bolt holds it in place.

3. The next step is to loosen the clamp that holds the mass air meter to the factory air box.

4. With the engine cover out of the way, it’s easier to access the coupler that holds the intake tube to the throttle body to loosen the clamp.

5 The factory intake tube has a support pin assembly that’s attached to a bracket on the upper radiator hose. A screwdriver will separate the pin from the bracket.

6 With the clamps loose, the factory intake tube, complete with the mass air meter, can be removed.

7. Since the mass air meter needs be reattached to the new Airaid intake, it is separated from the factory accordion hose and the air box. The factory coupler on the air meter will also be reused.

8. With the ducting and the mass air meter disconnected, the factory air box can be removed.

9. The mounting plate that holds the factory air box is held in place by five 10mm bolts.

10 With the bolts removed, the box simply lifts out.

11. The next step is to assemble the Airaid cold air dam using the enclosed hardware from the kit, as per the instructions.

12. Once the cool air dam is assembled, the 6-inch filter adapter is added.

13 The completed CAD assembly fits where the factory air box was located.

14 The box is bolted down using the supplied bolts and washers.

15 To ensure a proper seal at the throttle body, Airaid included a factory GM seal with the kit. The seal attaches to the kit’s modular intake tube.

16 The mass air meter is attached to the back of the intake using the original factory coupler.

17 The Airaid modular intake tube attaches to the mass air meter with the supplied silicone coupler.

18 Once the modular intake tube is in place, all of the connections are tightened.

19 One of the final steps of the install is to add the Airaid premium high-flow air filter.

20 The finishing touch is the addition of the weatherstripping. This forms a seal between the cool air dam and the hood of the truck. You can also add the weatherstripping before you install the box in the vehicle.

21 Here’s what the finished install looks like. The Airaid system flows much more air than the stock system and is good for a claimed 18 additional rear wheel horsepower.

PART-TIME POWER

Any truck enthusiast who has ever bolted on larger-than-stock tires or pulled a trailer knows that there can never be enough torque, especially in the low- to mid-rpm ranges. The never-ending hunt for grunt just got easier, thanks to the folks at Airaid. Its helix-bore PowerAid throttle-body spacers are famous for enhancing an engine’s low-end torque and midrange powerband, while also helping in the fuel economy department.

Any truck enthusiast who has ever bolted on larger-than-stock tires or pulled a trailer knows that there can never be enough torque, especially in the low- to mid-rpm ranges. The never-ending hunt for grunt just got easier, thanks to the folks at Airaid. Its helix-bore PowerAid throttle-body spacers are famous for enhancing an engine’s low-end torque and midrange powerband, while also helping in the fuel economy department.

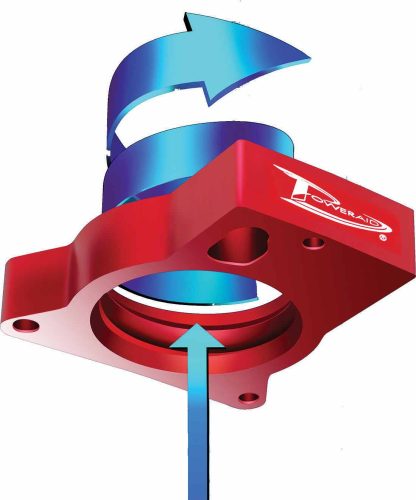

Okay, but how do they actually work? The patented helix-bore design puts a spin on the incoming air charge. This boosts velocity and improves atomization of the air/fuel mixture into the intake and combustion chamber. The result is a boost in torque from approximately 800 to 3,000 rpm. Also, with improved efficiency in filling the combustion chamber, it’s not uncommon to see a boost in fuel economy as well.

The PowerAid throttle-body spacers simply install between the throttle body and the intake manifold. Each PowerAid comes complete with all the necessary mounting hardware and detailed installation instructions. PowerAids are available for a variety of both gas and diesel applications.

PowerAid’s patented helix-bore design spins the incoming air for increased velocity and a denser air charge at the combustion chamber, resulting in improved throttle response and more low-end torque.

After removing the engine cover for easy access to the throttle body, the first step of the install is to loosen and remove the intake tube that attaches to the throttle body. The throttle body is held in place by three nut-and-stud combos. Remove the nuts first. A Torx socket is used to remove the studs from the intake manifold. These will be replaced with the new bolts that come with the PowerAid. On some ’04 and ’05 GM trucks, it is necessary to rotate the upper radiator hose clamp for added clearance. Using the supplied gaskets and bolts, the PowerAid simply installs between the intake manifold and the throttle body. With the bolts finger tight, a ratchet is used to tighten each one.

The finished install should look like this. Note the clearance between the hose clamp and the drive-by-wire solenoid on the throttle body. That’s why the clamp must be rotated. The final step is to reinstall the intake tube.

ARTICLE SOURCES

Airaid Filter Company

2688 E. Rose Garden Lane

Phoenix, AZ 85050

800/498-6951

www.airaid.com