July 2023

Delve into the world of aftermarket Mustang II-style independent front suspensions, a popular choice for upgrading classic trucks like the ’53 Chevy. Discover how these suspension kits provide improved ride quality, enhanced safety, and better performance, making them essential for modernizing vintage vehicles.

This article dives into the unique modification of a 1967 Chevy Suburban by Mike Dempsey, who reimagined it into a shorter, Tahoe-styled version. It also features Ken Farrell’s Retro Tek company, which has revolutionized the EFI system to combine the aesthetics of classic cars with the efficiency of modern technology. The article covers various aspects of vehicle modification, including chassis adjustment, engine upgrades, and the integration of advanced fuel systems.

Since the start of the modern automotive era, shortly following WWII, the SUV has been used for mass transportation, taking people to and from their desired destinations. This began with the early depot hacks, and that has turned into a massive SUV marketplace, complete with blinged-out Tahoes, Suburbans, Explorers and all manner of crossover vehicles made to look more truck-like, and offering two and three-row seating. These larger-than-life automobiles and trucks have made as much of an impact on the truck-buying public as the pickup.

Discover the critical role of a properly matched transmission in your truck’s performance and longevity. This article delves into the signs of transmission failure, emphasizing the impact of driving habits on transmission health. Explore an alternative to the common flatbed trip to the dealership by learning about TCI Automotive’s StreetFighter transmission. With its robust build, enhanced performance features, and no-core-charge policy, TCI offers a convenient and reliable solution for truck owners. Follow a detailed account of a 4L60E StreetFighter transmission installation, providing valuable insights for DIY enthusiasts and a glimpse into the meticulous craftsmanship at TCI Automotive’s Mississippi facility.

We heard of the Glenn Patch Collection a couple of years ago from a friend who had visited Patch’s warehouse in Scottsdale, Arizona. We were told of the quality of the restorations, as well as the variety of different cars, but the thing that intrigued us most was the fact that the entire collection consisted of cars and trucks manufactured in 1957.

How many times have you heard the following: I sold my first truck for $1,000 and wish I had never gotten rid of it. If you have, then you understand the mental grief generally associated with selling your first truck. What can make matters worse is to find out the new owner wrecked it, sold it or that it was eventually parted out or scraped. Perhaps you have succumbed to one of these unfortunate circumstances, leaving you to long for that first ride. Longtime classic truck enthusiast Eddie Rudd of Knoxville, Tennessee, knows that empty feeling, as Rudd drove a not-so-flashy 66 Chevy 1/2-ton to and from work during his teens, and even into his 20s, it served as his daily driver. Times changed, Rudd became a father and soon learned the uncomfortable truth that the truck no longer allowed the entire family to ride comfortably. Rudd knew the truck had to go, so in March of 1982, he sold it to a friend.

Builders Joe Keenum and Dan Ehle are best friends and business partners. Initially drawn together by their love for classic cars and trucks, the two have created a number of super rods and classic trucks over the years out of their shop in Leighton, Alabama. Keenum and Company has built trucks that compete with the best of the top-name builders in the country. Producing upwards of a dozen custom vehicles a year, the duo decided it was time to go it a bit further and build a radical shop truck that would showcase the expert craftsmanship the shop is capable of producing.

After running across this 1972 Chevrolet 1/2-ton pickup in early 2006, they felt this was the classic truck that would make the ideal candidate for the project they had in mind. 0nce Keenum and Ehle acquired the truck, they began the extensive build. The truck was a nice driver, and the previous owner performed a rather simple hot rod restoration, leaving the truck on the frame and updating a few of the components here and there. However, Keenum and Company had other plans for this classic.

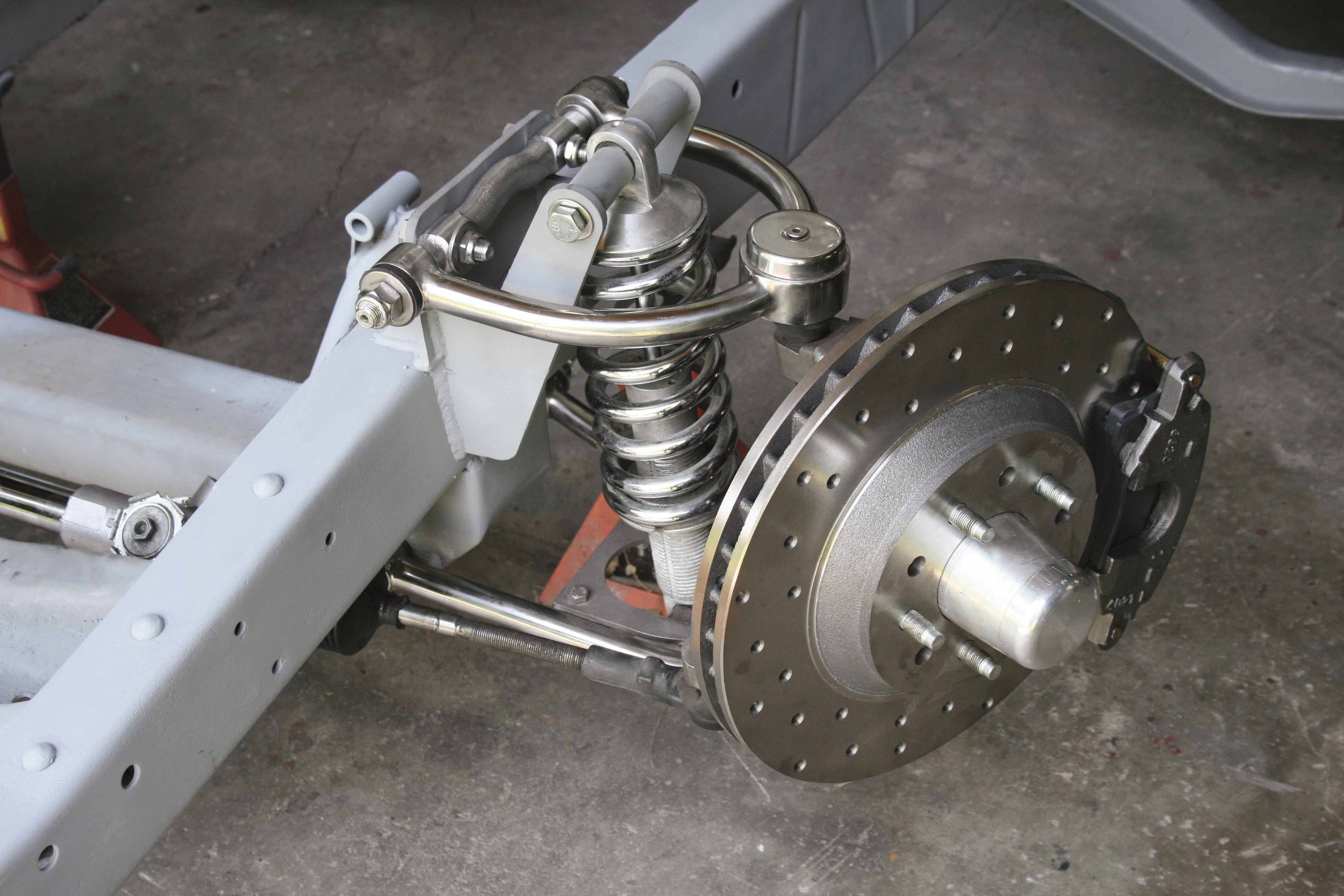

Lowering a truck usually involved cutting coils and shaving bump stops. Out back, the rear end was treated to lowering blocks, a few pulled leaf springs or heated coil springs. Over the years, manufacturers began to address these demands, as lowering coils, spring leaf blocks, dropped spindles and flip kits were offered. Times changed with the introduction of airbags, as owners were able to slam their pickups with full ride height adjustability. Air Ride Technologies (ART) is one of those companies offering quality suspension solutions for truck owners, with kits that fit specific applications.

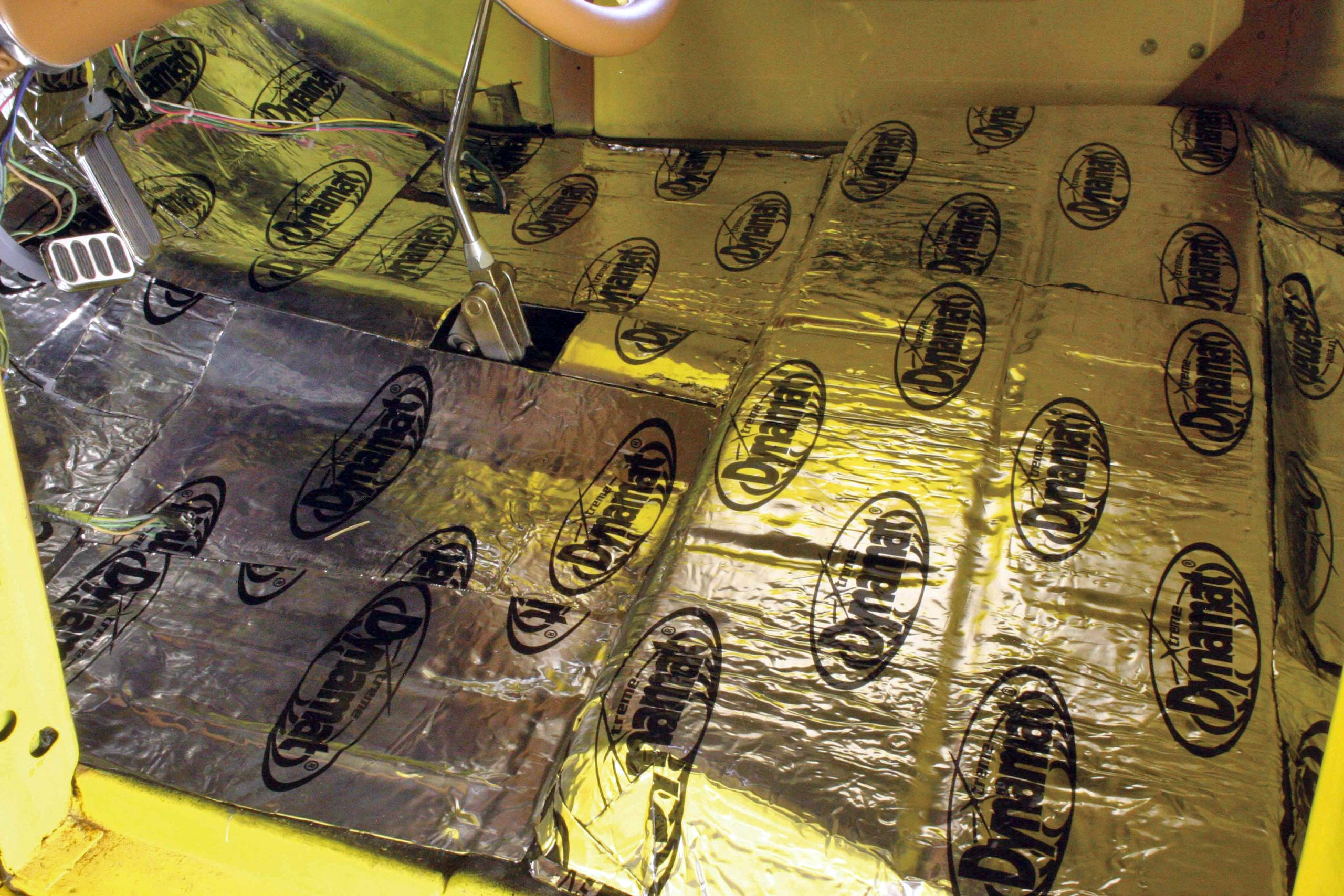

If you’ve ever hopped out of a classic pickup into a modern daily driver pickup, you have probably noticed the startling difference in noise and heat levels within and throughout the interior. This is because some time in the mid-’80s, pickups began receiving the same noise and heat control attention as auto manufacturers spent on cars, as they filled every nook and cranny with noise cancellation foam, sealant and padding. These insulations greatly helped cancel out noises and improved temperature control, as well as help dampen vibrations.

Older classic trucks are among the worst in all these areas. They squeak, they are noisy, and do little to control heat buildup inside the cab, especially around the floorboard. Since all these trucks were originally workhorses, not much attention was paid to these areas, but this problem is easily solved. Whether you are just beginning your interior and building from scratch or retrofitting your existing truck, Dynamat offers a wide selection of noise and sound cancellation products. Dynamat engineers have designed a complete line of products, ranging from speaker kits to complete sound and noise cancellation solutions from the floor to the roof.