fabrication

Let’s face it, most of us are working within the confines of a set of unwritten, yet clearly defined, rules of hot rodding. Stance, engine choice and wheels are for the most part selected from a menu of items that come “pre-approved” by our peers. Sure these rules work most of the time, and they provide a degree of certain acceptance when you’re building a traditional pre-’49 hot rod. But all in all, it also makes us a group of conforming nonconformists. However, for some hot rodders (and they are in the minority) building hot rods is about pure ingenuity, a total lack of peer pressure and joy of mixing parts from various sources and making it all work.

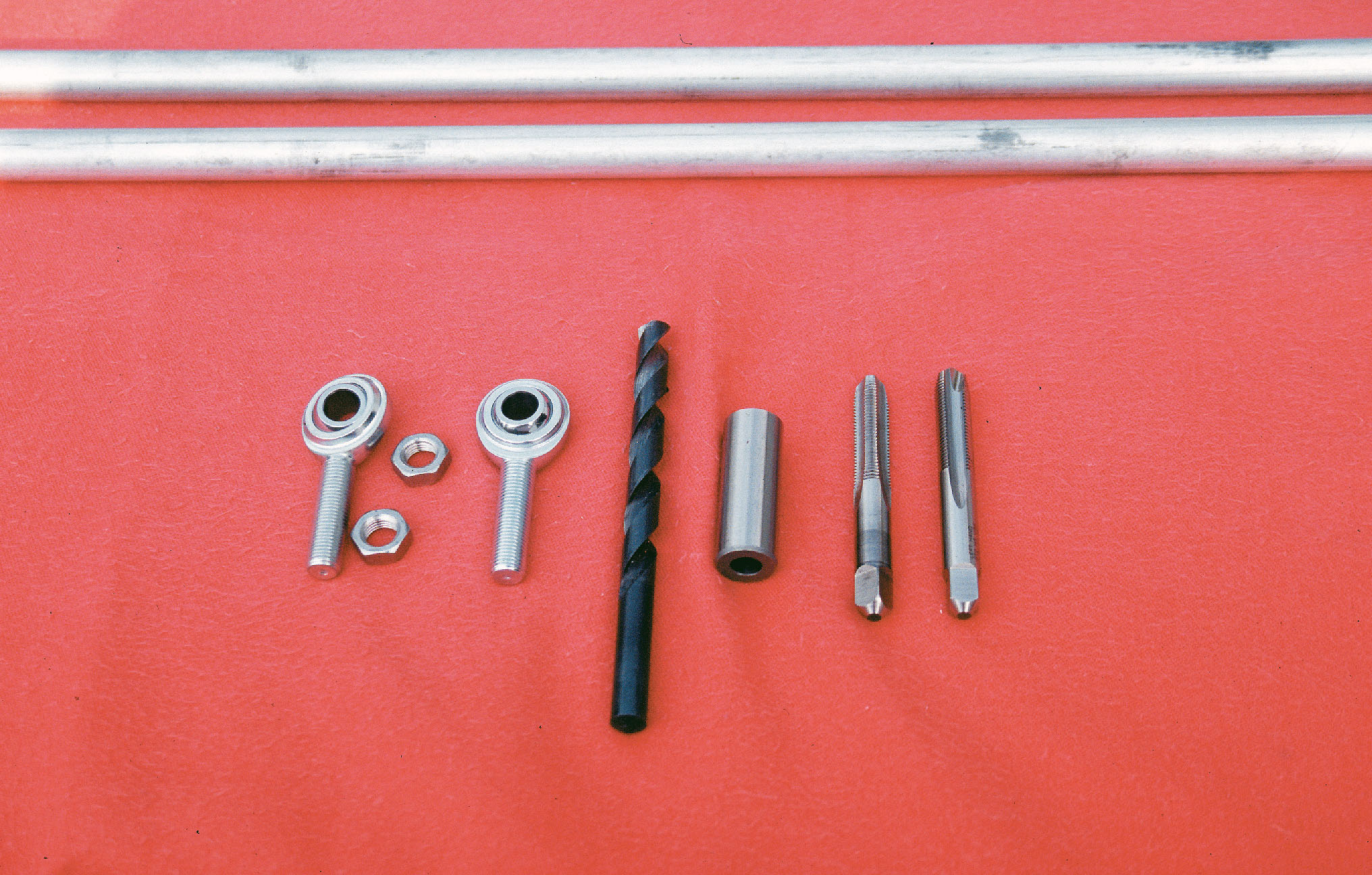

This is a story about two tensioners, one fabricated with machine tools and the second fabricated in a garage with a minimum of tools. In fact, the only power tool you will need is a drill motor, yet the finished products will be almost identical.

Your first response to fabricating something may be, “I don’t have the necessary tools; I don’t have any way to get the materials I will need.” If you have a door number so the UPS man can find you, you have everything you need. The materials list at the end of this story contains everything you will need. The rod-end bearings and lock nuts were purchased from AFCO Hot Rod Parts. The aluminum round stock and cutting tools were purchased from MSC.

Tom Lawson was attending the Goodguys West Coast Nationals with his family and friends when a friend of his father-in-law, Bill, also a street rodder, walked up and started talking to everyone in the group.

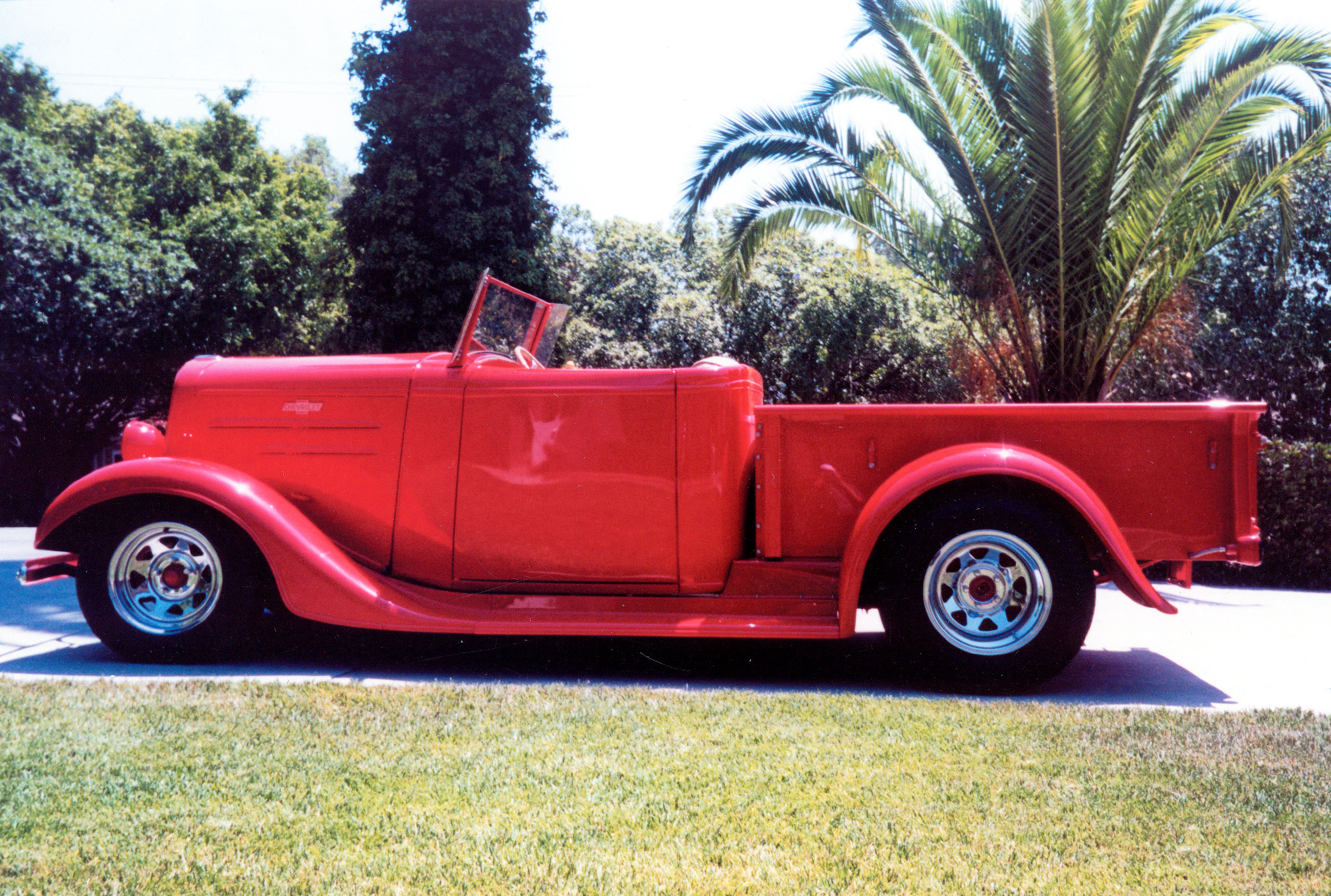

If you own a Ford or Chevy, most of the parts you will need to build a street rod are readily available, and from a variety of suppliers. We have written numerous stories about kits for these cars in our family of rodding magazines, and some of them were a direct replacement for the original. By and large, they worked perfectly and bolted right in, as designed. These types of kits are convenient for many street rod builders, as well as street rod shops, and they are part of what has helped grow our hobby into such a broad special-interest group. But in addition to the “normal” and most popular rods, there were many other great cars made in the pre-war era, and some of them can be a real challenge to street rodders because there are no pre-manufactured parts, and no kits that make them easy to build. Sounds like the old days, right? Well, that’s the modern world for you–even our hobbies have become targets of convenience.

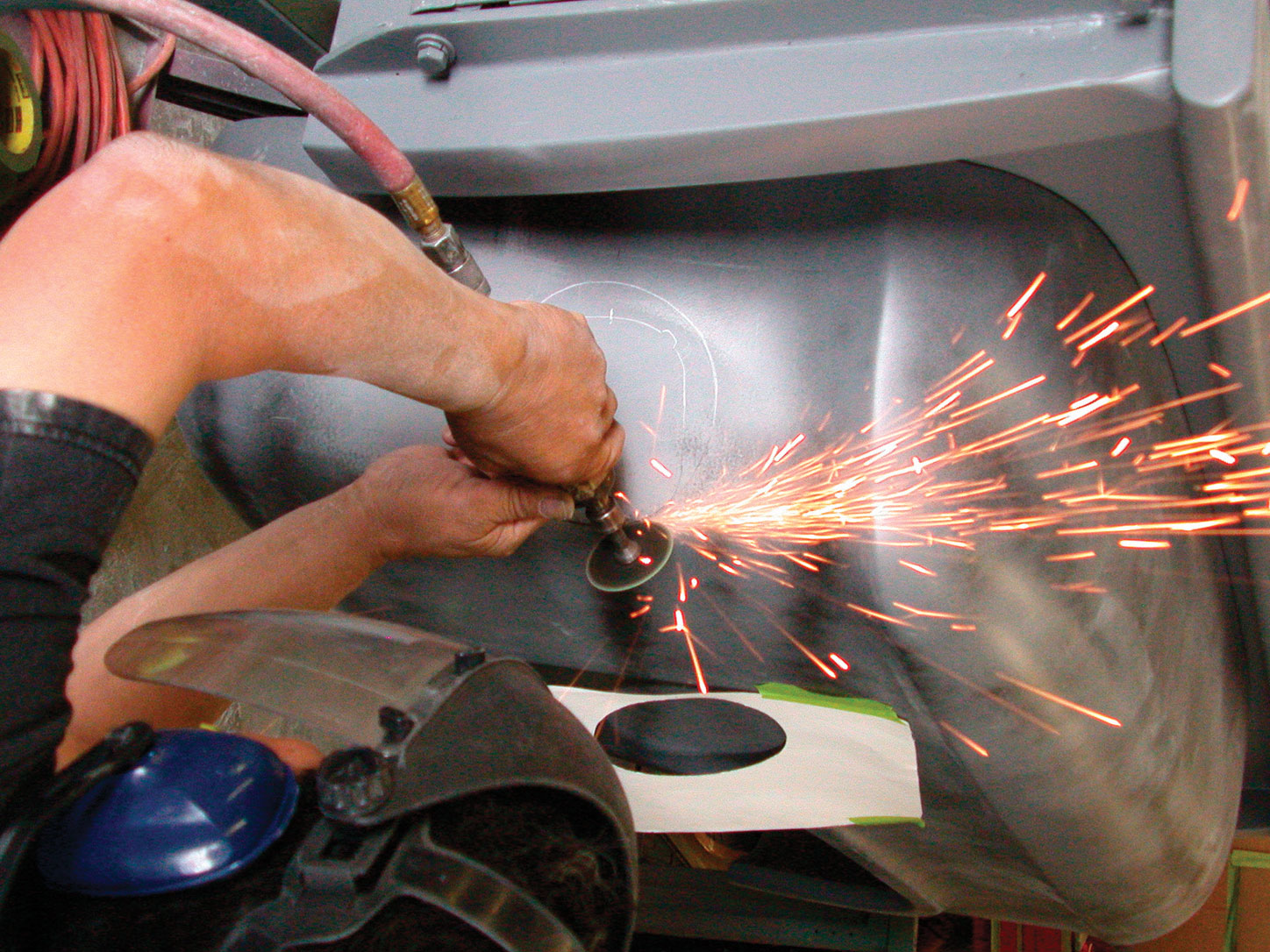

Always hard at work in the never-ending pursuit to do something just a little different, Darryl Nance and the crew at D&P Classic Chevrolet in Huntington Beach, California, recently added a pair of Chevy Cobalt taillights to one of the mid-’50s pickups that they have been working on. The Chevy is a frame-off project that was completed to exhibit all of the tricks that the D&P team can throw at it, and we were on hand when they installed the late-model lights to the old-time treasure.

For every hot rod shop that has a show on TV, there are countless smaller shops that will never get mainstream TV exposure or clothing lines sold at Wal-Mart. But all across the country, it’s these smaller shops that turn out the majority of the street and super rods that you and I enjoy, and that we see at shows. And even though these little guys may not have big reputations yet, they churn out consistent and excellent work—and, that is precisely how some of these smaller shops will eventually become bigger shops with even more prestige.

“Real hot rods have axles,” or so they say. That was our story, and we stuck to it fondly for more than 10 years. The ’47 Ford sedan delivery we drive came to us with a new Super Bell dropped axle and four-bar linkage professionally installed by Dick Jones’ shop in Campbell, California. It wasn’t really a hot rod; more like a primered beater with no interior, very little glass and enough rattles that a radio was a waste of time. It was a project car for another magazine for several years, and as such was the subject of many tech articles, updating it with all manner of great stuff. But it was still a primered beater, so the axle suited it just fine, and we got many miles of enjoyment out of this setup. Oh, it could have had a nice, new IRS more than once, but it just wasn’t that kind of car.

If you attend car events in California, such as NHRA’s California Hot Rod Reunion in Bakersfield, the West Coast Kustoms show in Paso Robles or the L.A. Roadster Show in Pomona, you will notice that rat rods are a growing segment of the hot rod hobby. Years ago, when they started becoming a common sight at many of the shows, the mechanical aspects of most of the cars were scary at best. You could see cars with no springs, some without floorboards, and many constructed with less-than-desirable stick welding. It is this type of construction that created the name “rat rod.” Fortunately, over the past few years there has been an attempt to upgrade the construction of rat rods, even though the enthusiasts want to use as many original parts as possible.