THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

QUIET DOWN

Installing Dynamat Xtreme for a Cool and Quiet Ride

Author

Josh Kaylor

Story & Photography

Why Classic Trucks Are Louder and Hotter

If you’ve ever hopped out of a classic pickup into a modern daily driver pickup, you have probably noticed the startling difference in noise and heat levels within and throughout the interior. This is because some time in the mid-’80s, pickups began receiving the same noise and heat control attention as auto manufacturers spent on cars, as they filled every nook and cranny with noise cancellation foam, sealant and padding. These insulations greatly helped cancel out noises and improved temperature control, as well as help dampen vibrations.

The Problem with Older Classic Trucks

Older classic trucks are among the worst in all these areas. They squeak, they are noisy, and do little to control heat buildup inside the cab, especially around the floorboard. Since all these trucks were originally workhorses, not much attention was paid to these areas, but this problem is easily solved. Whether you are just beginning your interior and building from scratch or retrofitting your existing truck, Dynamat offers a wide selection of noise and sound cancellation products. Dynamat engineers have designed a complete line of products, ranging from speaker kits to complete sound and noise cancellation solutions from the floor to the roof.

The Test Vehicle and Its Challenges

This International pickup is in the process of receiving a new interior, which is being done in stages, allowing it to be driven while parts of the interior are being done, as budgets permit. The truck squeaks and rattles, and the A/C fights to cool the cabin. Heat buildup can be bad, and this doesn’t begin to mention the excessive noise and oil canning throughout the interior. This problem has persisted, but now it’s time to do something about it.

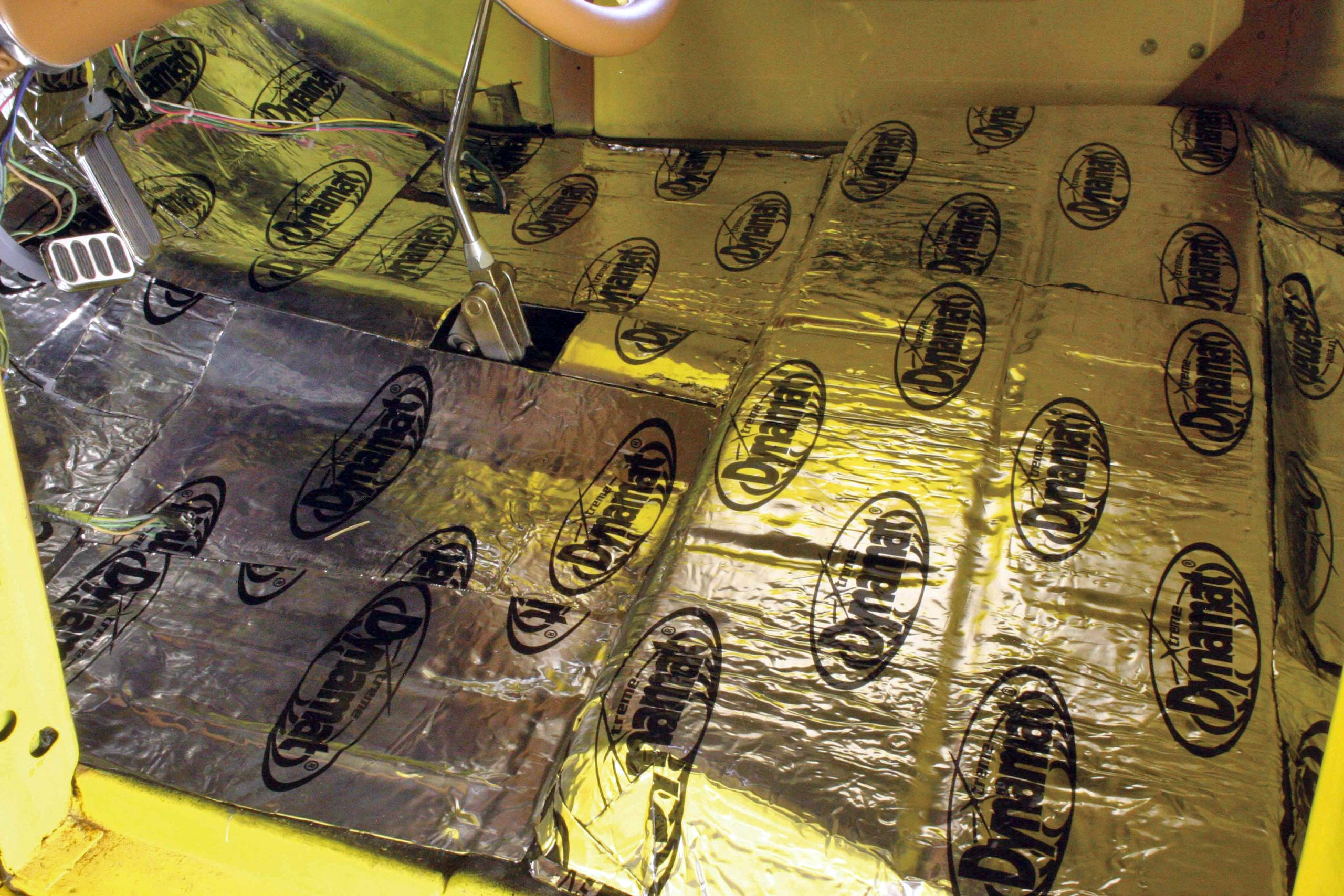

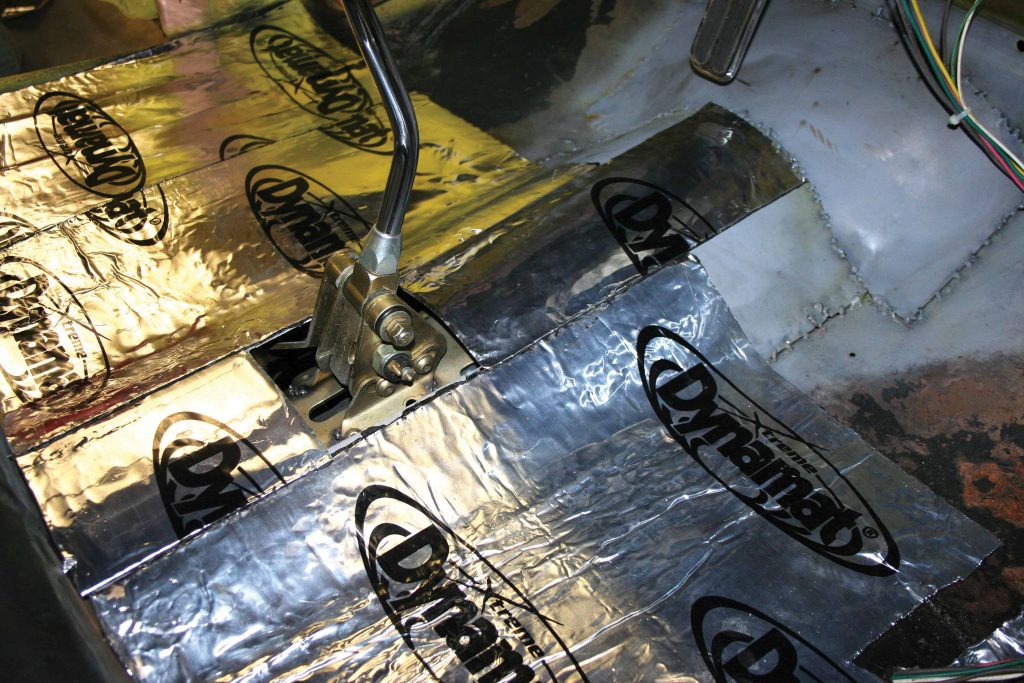

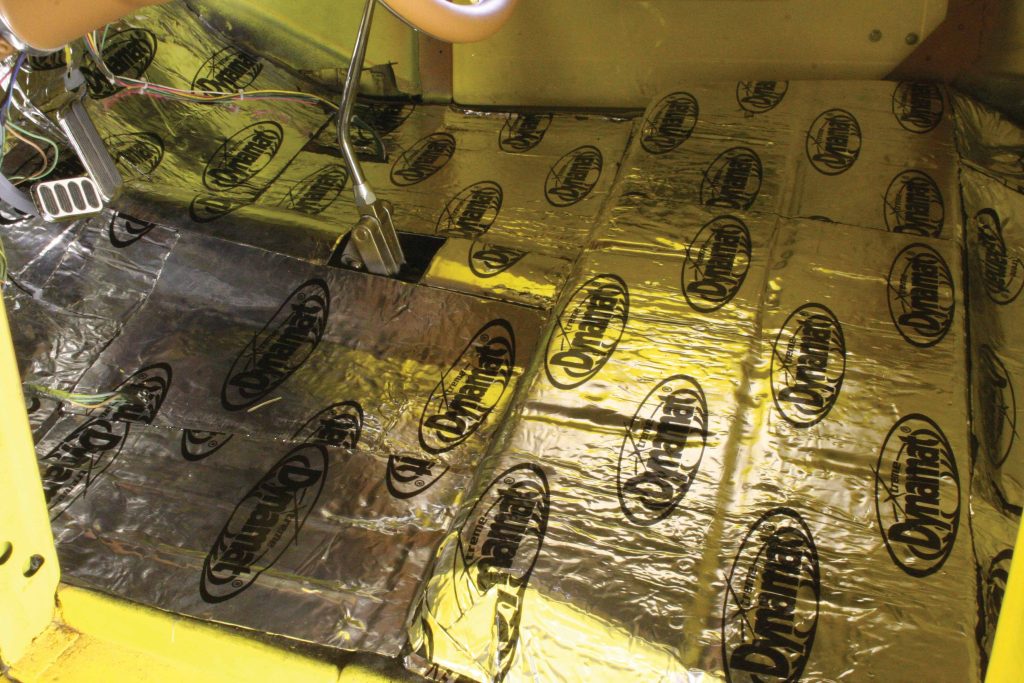

Learning the Proper Dynamat Installation Process

While visiting M&M Hot Rod Interiors, we had the opportunity to speak with Wayne and Pam McGriff about the proper procedure for installing Dynamat in the cab of a pickup or any car for that matter. M&M stresses to all of its customers the importance of installing noise, heat and sound canceling material, such as Dynamat Xtreme, into the interior of their cars. After deciding that Dynamat Extreme was right for us, we purchased the Dynamat Extreme Bulk Kit from M&M, which includes nine 18×32-inch squares. The precut squares allow you to cover 36 sq ft, which is plenty for most classic trucks.

About Dynamat Extreme

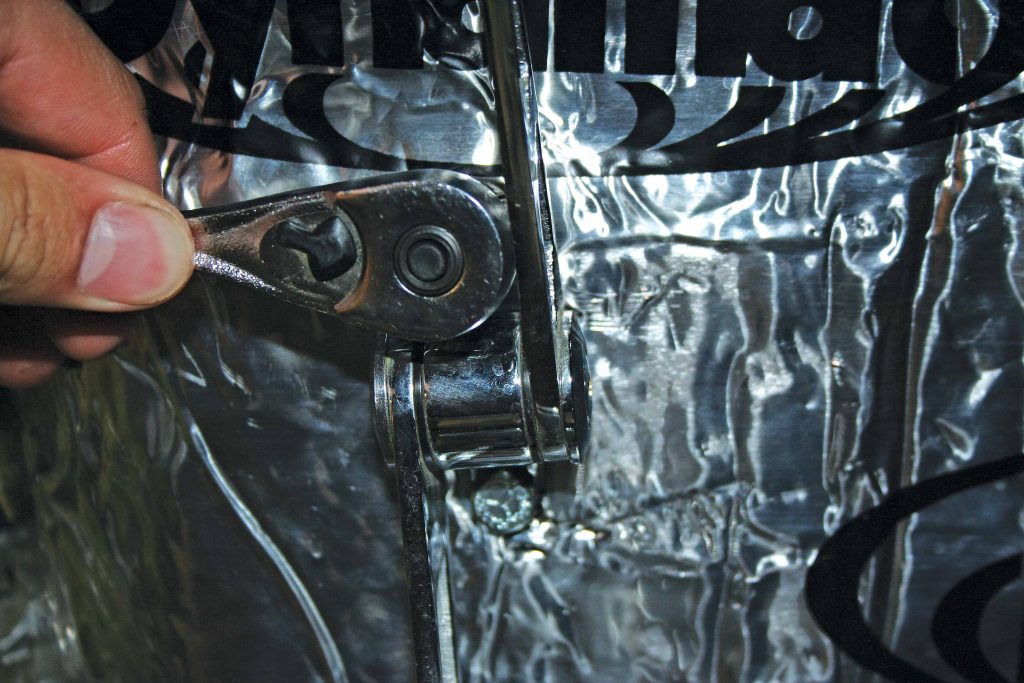

Dynamat Extreme is designed to be installed on the headliner and inside the doors, firewall, floorboard and rear of the cab. Dynamat Extreme is only about 1.7mm thick, which allows door panels and carpet to be installed over the Dynamat, without causing unsightly humps or other problems associated with thicker sound deadeners. Dynamat Extreme features a black butyl-based core with an aluminum liner designed to block against heat. The Dynamat features an adhesive back that provides a simple measure, cut, peel and stick procedure. This can be done at home with a pair of scissors, a box cutter and a small rolling pin.

Installation and Preparation

Since this truck interior had yet to be completed, the seat was removed, and interior panels thoroughly cleaned. In order to clean the steel panels, use wax and grease remover. Prepping the panels was not difficult, as Dynamat Extreme can be installed over painted surfaces that are properly cleaned of contaminants and residue. After about three hours of work, the entire interior of the truck was thoroughly lined with Dynamat Extreme.

Results and Final Impressions

During our initial road test, and without a completed interior, we instantly noticed a difference in the lack of vibration, reduced sound and lower heat inside the cabin. Follow along with us to see how it was done.

ARTICLE SOURCES

Dynamat, LLC

Dynamat is recognized around the world as quality solutions to unwanted noise & heat. Dynamat makes sound deadening and thermal insulation products for automotive, car audio, home, RV, marine and more. Dynamat is 100% proudly made in the USA.

M&M Hot Rod Interiors

13875 US Hwy. 278 E.

Holly Pond, AL 35083

(256) 796-7443

mmhotrodinteriors1982@gmail.com