THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

GOING PRO

A Look Inside the New Dart Pro 1 CNC Aluminum Ford Head

Author

Richard Holdener

Story & Photography

Producing Horsepower Requires Air and Fuel

Producing horsepower requires two major ingredients, namely, air and fuel. Of course, the two must be supplied in the correct proportions and at the proper time; but improving power is a simple matter of adding airflow. Naturally, additional fuel will be required once the airflow is improved, but the first item on the horsepower priority list should always be more airflow.

The Connection Between Airflow and Horsepower

The connection between airflow and horsepower should come as no surprise to any true enthusiast. The difficulty comes not from knowing that more airflow is needed but rather how to actually go about improving it. When it comes to airflow, three components are primarily responsible for the breathing characteristics of an engine, namely, the intake manifold, cylinder heads and camshaft. Sure, the displacement, carb and header sizing all play a part in the eventual power, but it is the cam and cylinder heads that will make or break a good performance engine. For this article, we will concentrate our efforts on the cylinder heads, or, more specifically, the new Pro 1 CNC aluminum cylinder heads from Dart.

Features of Dart Pro 1 CNC Heads

Recently released from Dart, the new Pro 1 CNC heads for the 5.0-liter Mustang (actually the entire Ford Windsor family) feature a number of important design criteria that help improve the flow characteristics compared to stock 302 heads. The first thing you will notice is that the new Dart heads are cast of lightweight aluminum (355T6), and not steel. Aluminum helps improve performance by reducing the overall vehicle weight. Dropping a good 45 to 50 lbs off the nose of any car will make a noticeable difference in not only acceleration but also handling and braking. In addition to improving the all-important power-to-weight ratio, the aluminum construction also helps raise the detonation threshold (making the engine less likely to detonate). Credit the heat-dissipation qualities of the aluminum for the aluminum-headed engine’s reduced sensitivity to detonation. The final feature offered by the aluminum, though one you hope you’ll never have to use, is the ease of repair. Damaged aluminum heads are more easily repaired than their cast-iron counterparts. No one plans on holing a piston or tossing a rod, but should the aluminum head become damaged, know that it can usually be brought to as-new specs by a competent repair shop.

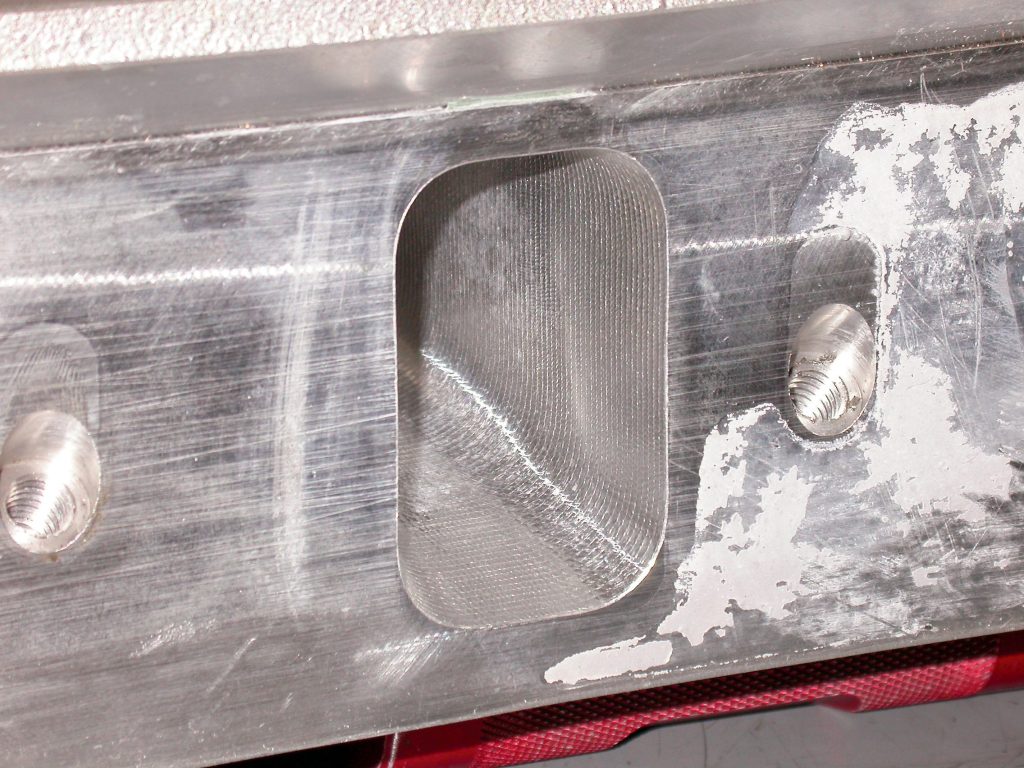

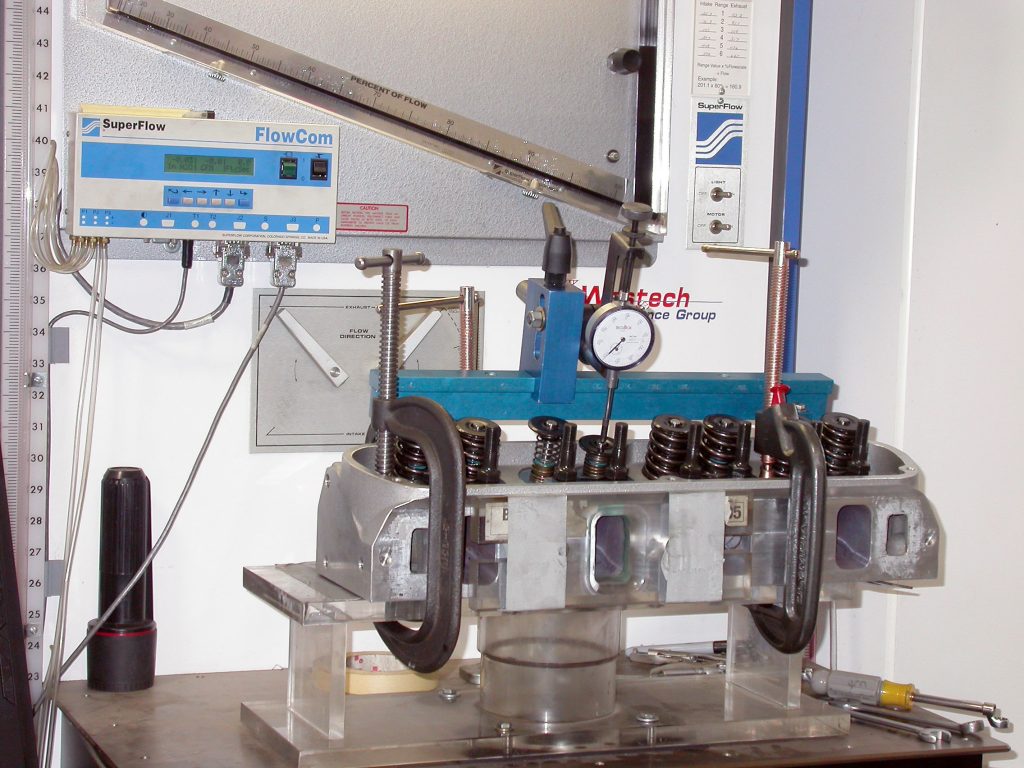

Benefits of CNC Porting

While the aluminum construction of the Dart Pro 1 heads is appealing, it is the airflow potential offered by the CNC porting program that really makes this head shine. The acronym CNC means “computer numeric controlled,” a fancy name for computerized porting. Having the head ported by computer-controlled cutters allows for precise, consistent airflow between ports. Hand porting takes years of experience to master, and short of the tedious procedure of porting and flow-testing each runner numerous times during the process, it is difficult if not impossible to replicate identical flow characteristics for each port. Naturally, a similar procedure is also necessary to set up the CNC program initially, but once configured, the CNC program can replicate flow numbers with computerized precision. The only thing limiting the effectiveness of the CNC porting is core shift of the head itself, as the program must orient itself on a known position on the head. Core shift can change the position of the port walls ever so slightly, but what ultimately happens is that the precision porting offered by the CNC program is applied to a not-so-precise wall location. This situation is unusual and can be handled with the proper setup procedure, something Dart seems to have a handle on if our heads are any indication of the quality consumers are to expect.

SPECIFICATIONS

Material: 355T6 Aluminum

Chamber Size: 62 cc

Intake Valve Material: Stainless steel

Exhaust Valve Material: Stainless steel

Intake Valve Size: 2.05

Exhaust Valve Size: 1.60

Intake Port Volume: 210 cc

Exhaust Port Volume: 76 cc

Intake Port Location: Stock

Exhaust Port Location: Raised 0.135 std & spread bolt patterns

Intake Port Dimensions: 2.150 x 1.300

Exhaust Port Dimensions: 1.420 x 1.420

Recommended Intake Gasket: Fel-Pro 1262

Recommended Exhaust Gasket: Fel-Pro 1487

Recommended Head Bolts: Dart & 351 1/2 od ARP 154-3603, 302 7/16= ARP 154-4003

Recommended Head Studs: Dart & 351 1/2 od ARP 154-4003, 302 7/16= ARP 154-4005

Intakes: Most with standard port location

Milling: Min 50cc (0.0065=1cc) flat mill

Pistons: Most 20-degree

Pushrod Length: 8.250 (roller cam); always check

Guideplates: Comp Cams PN 4816

Retainers: 10 degree

Spark Plugs: 0.750 Reach gasketed—Champion C59C/C59YC (Denso IQ24)

Spring Pockets: 1.437D=130 lbs. at 1.80 installed height (hydraulic roller or flat tappet); 1.550D=195 lbs. at 1.90 installed height (solid roller)

Valve length: Std 4.890 or 5.015 (+0.100) roller

Valve Stem Diameter: 0.3415-11/32

Recommended Valvetrain: Accepts roller rockers 3/8 or 7/16 stud mount

Valve Guides: 0.5 OD Mag Bronze (0.002 press)

Valve Guide Length: 2.100

Valve Guide Clearance: 0.0014-.002 (with 0.3415 diameter valve stem)

Valve Guide Spacing: 1.876 (moved 0.050 from stock)

Valve Seats: Hardened Ductile Iron 0.006 press

Valve Seat Diameter: Int: 2.160 x 1.810 x 0.350; Ext.: 1.650 x 1.350 x 0.350

Valve Seat Angles: Int.: 32 – 45 – 60 – 70; Ext.: 37 – 45 radius

Stud Girdle: Standard

Torque: Head bolts 7/16—70 lb-ft;1/2—100 lb-ft

Block Use: Dart Iron/Alum or any Production Ford W

Weight: 23 lbs

Specifications of Dart Pro 1 CNC Heads

According to Dart, the new Pro 1 CNC heads come with healthy 210cc intake ports and 76cc exhaust ports. Naturally, the size of the ports ultimately affects the flow potential, but size is not the sole determining factor (bigger is not always better). To put the 210cc intake port into perspective, the stock 5.0-liter Ford casting (model E7TE) measures just 127 cc. The disparity carries over to the exhaust port as well, with the Dart Pro 1 measuring some 32 cc larger than the stock 44cc exhaust port. The valve sizes are equally large on the Pro 1. With a (Chevy-sized) 2.05-inch intake and a 1.60-inch exhaust, the Pro 1s are significantly larger than those in a stock Windsor casting (1.78-inch intake/1.46-inch exhaust). The combination of the sizable runner volume, precise CNC porting and impressive valve sizing adds up to just one thing—big airflow. The intake ports on the Dart Pro 1 CNC heads flow 140 cfm more than the stock 5.0-liter heads, a considerable feat considering that the stock heads flow 160 cfm. To put these numbers into perspective, the Dart heads flow a whopping 88 percent more than the stock heads. The exhaust flow is even more impressive, with the Pro 1 heads coming in at 221 cfm compared to just 112 cfm for the stock heads, a gain of nearly 100 percent.

Calculating Horsepower with Dart Pro 1 CNC Heads

While the Dart Pro 1 CNC head certainly has a ton of impressive features and appears to offer exceptional airflow, how does that translate into horsepower? Actually, there is a formula to convert maximum intake airflow into potential horsepower. We will explain in a moment just what we mean by “potential” horsepower, but for now let’s take a look at the airflow/power formula. The formula states that horsepower is equal to the maximum airflow times 0.257 times the number of cylinders, or:

HP = Max Airflow x 0.257 x Number of Cylinders

Testing the Dart Pro 1 CNC Heads on a Custom 418 Windsor Stroker

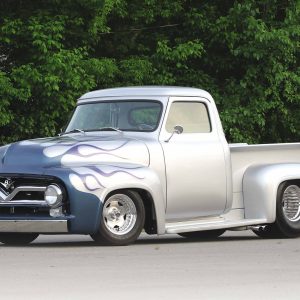

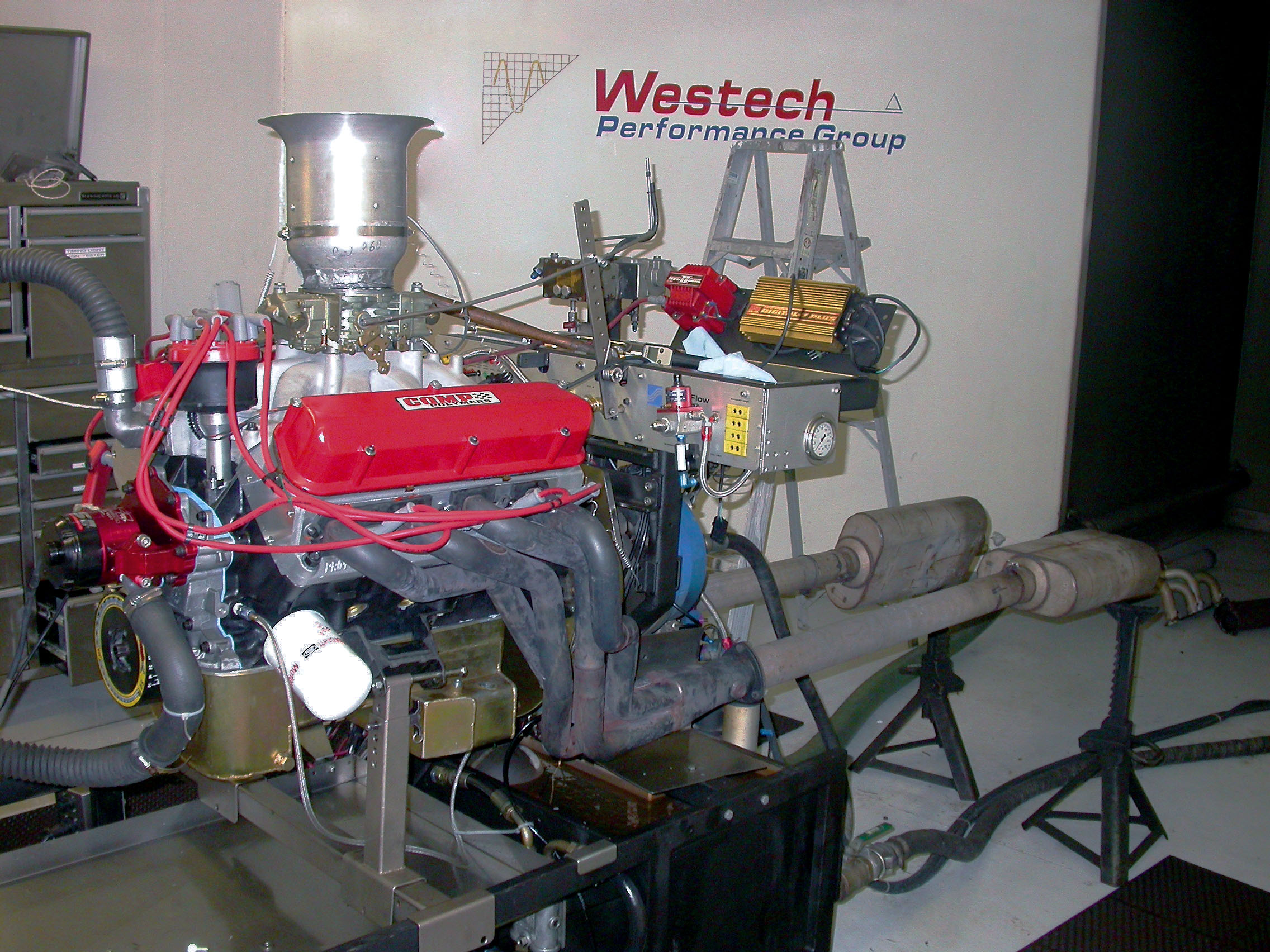

Rather than simply provide our readers with airflow numbers and call it a day, we decided to see just how close we could get to the numbers suggested by the power formula. Knowing we were looking for over 600 hp, we built an engine capable of utilizing every bit of airflow offered by the new Dart Pro 1 heads. The short block came from Coast High Performance and featured a 351 Windsor block stuffed to the gills with a custom stroker kit that upped the displacement from the standard 351 ci to a full 418 cubes. The displacement change came primarily from the increase in stroke from 3.50 inches to 4.10 inches. The block was bored 0.030-inch over, but that was responsible for only 5 extra inches. The big-inch Windsor featured 12.0:1 compression thanks to a set of forged pistons from Probe Racing. The 418 stroker also included custom-length forged connecting rods. Knowing we needed a healthy cam to produce over 600 hp, we selected a solid-roller profile (from its oval-track offerings) that offered a 0.688-inch intake lift, 0.672-inch exhaust lift and a 264/268 duration split at 0.050 inch. The aggressive roller cam also featured a tight 106-degree lobe separation angle. The Dart heads were topped off with an Edelbrock Super Victor intake and a 950hp Holley carburetor. Also present was a set Hooker Super Comp headers, an MSD ignition and a CSI electric water pump.

Results and Real-World Application

After installing the heads using Fel-Pro 1011-2 head gaskets and 1/2-inch ARP head studs, we installed the intake and carb and warmed up the 418-inch beast on the Westech engine dyno. After bringing the engine up to temperature, we allowed 30 minutes of break-in time for the new combination. A few steady-state loads at 4,000 rpm told us we were on the right track, as the stroker thumped out some impressive torque numbers of over 525 lb-ft. Naturally, we were anxious to see how long the curve held above 525 lb-ft, as our calculations told us that a torque reading of 525 lb-ft at 6,100 rpm would put us very near our power formula target of 615 hp. The initial torque readings of 525 lb-ft were actually just the beginning, as the Dart-headed 418 thumped out a peak reading of 564 lb-ft at 5,100 rpm on its way to exceed the targeted 615 hp suggested by the power formula. After some minor jetting and a few degrees of timing, the engine finally produced 625 hp at 6,600 rpm, exceeding the formula number of 615 hp by a solid 10 hp. Obviously, the 418 combination responded well to the new Dart Pro 1 CNC heads.

Dart Pro 1 CNC Head Flow—CFM at 28 inches

Lift | Stock Intake | Pro 1 Intake | Stock Exhaust | Pro 1 Exhaust |

0.050 | 29 | 33 | 19 | 23 |

0.100 | 55 | 59 | 40 | 49 |

0.200 | 110 | 122 | 75 | 106 |

0.300 | 142 | 181 | 101 | 154 |

0.400 | 160 | 233 | 110 | 191 |

0.500 | 157 | 272 | 112 | 211 |

0.600 | 158 | 293 | 112 | 218 |

0.700 | 155 | 297 | 112 | 222 |

ARTICLE SOURCES

Dart Machinery

353 Oliver Dr.

Troy, MI 48084

(248) 362-1188