Street Rods

When dismantling your project car, you probably ran across the crumbling remnants of the original insulation. Old cars are notoriously “leaky” when it comes to heat and sound barriers, making them louder and hotter than the typical daily driver. Sometimes a loud exhaust system overrides the road noise, but you’ll always notice when your air conditioning system never seems to keep the cabin cool. If you’re in the midst of an interior refresh, or a full restoration, it’s a great time to consider new insulation.

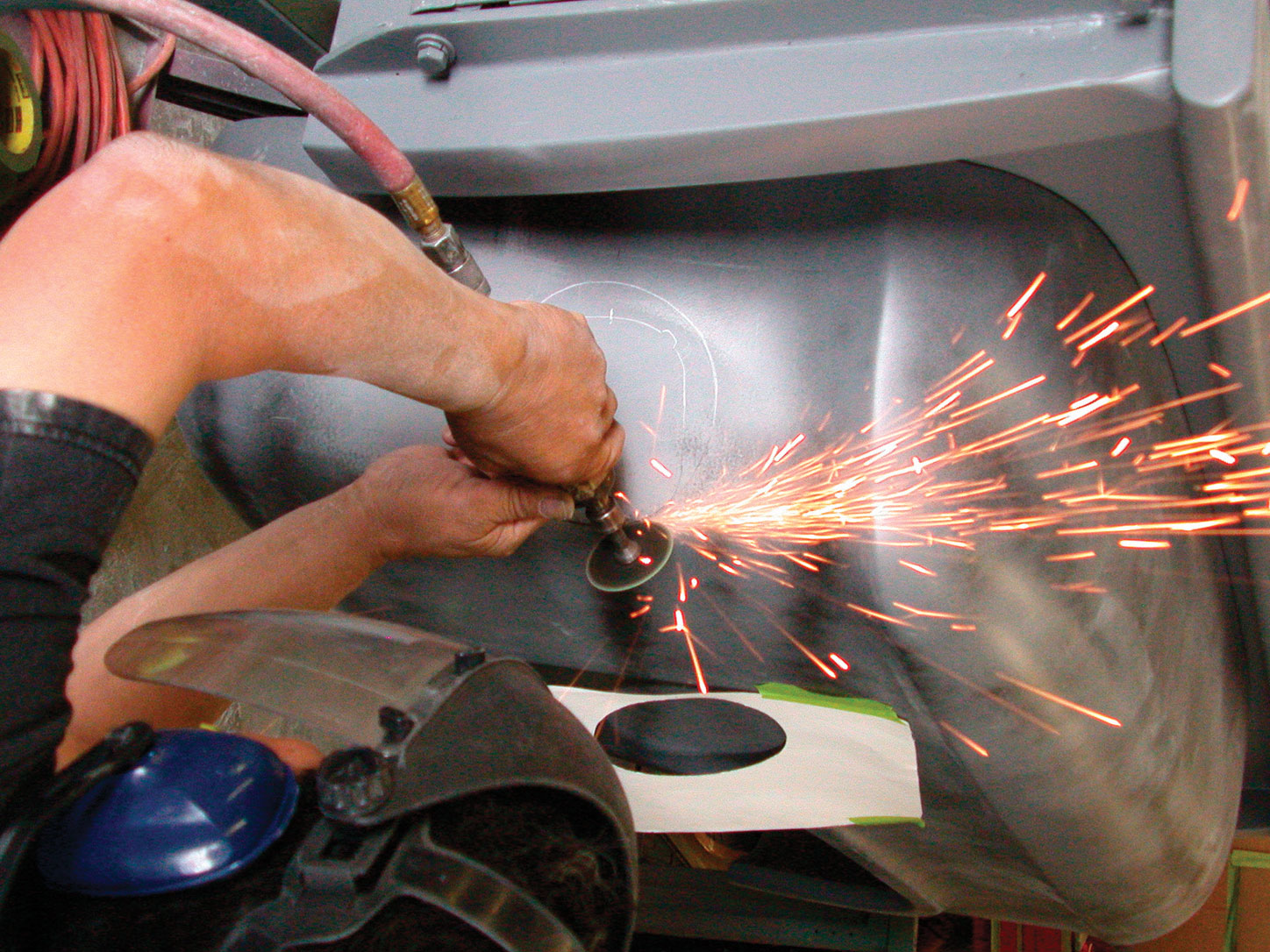

Always hard at work in the never-ending pursuit to do something just a little different, Darryl Nance and the crew at D&P Classic Chevrolet in Huntington Beach, California, recently added a pair of Chevy Cobalt taillights to one of the mid-’50s pickups that they have been working on. The Chevy is a frame-off project that was completed to exhibit all of the tricks that the D&P team can throw at it, and we were on hand when they installed the late-model lights to the old-time treasure.

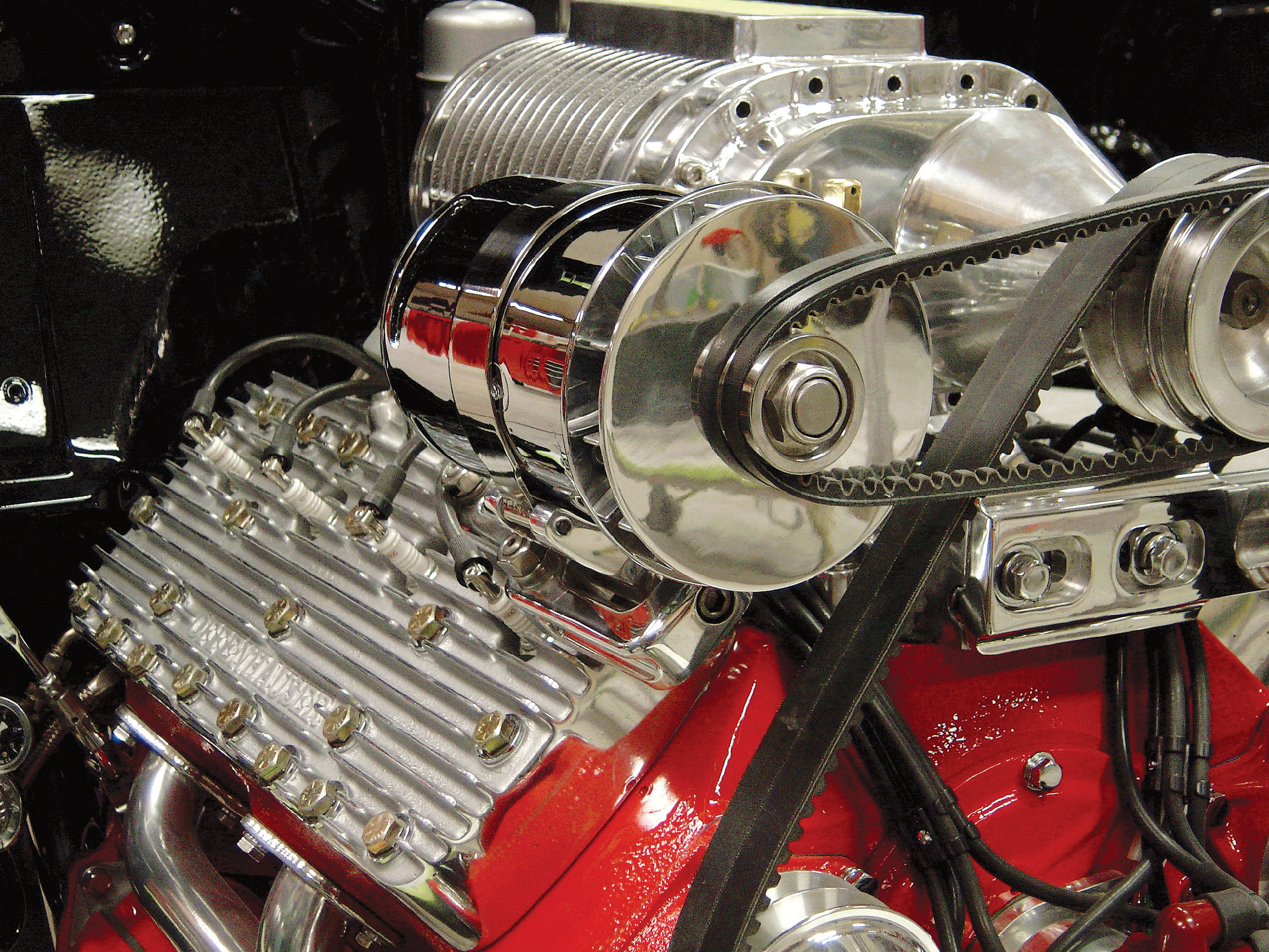

There’s a lot to like about vintage engines. Just the sheer fact that it isn’t a small-block Chevy is enough to inspire many hot rodders. Now, don’t get us wrong; the small-block Chevrolet is nothing less than awesome, but it is also the default engine of most hot rodders. Often, there is no thought involved as many rodders simply want the 350/350 treatment. That’s probably fine for most hot rodders, but there has been a real resurgence in putting vintage motors in vintage hot rods, and we love the concept. The Oldsmobile, Cadillac, Buick Nailhead and Hemi are all great candidates for powering a vintage hot rod. Parts are still available for most of these engines, some being tougher to find than others. A surprising amount of speed equipment survives for these engines, too, and companies like Offenhauser still produce a lot of vintage speed equipment.

The relentless progress of technology is a difficult topic for those of us captivated by the cars and lifestyles of a bygone era. As technology advances at an exponential rate, we now find ourselves clamoring to keep up with the latest and greatest products that simultaneously render many of our old favorites obsolete. Just about the time you figure out how to use your new digital camera and multifunction cell phone, you find out that someone decided it was necessary to combine the two. The struggle to balance the conveniences of modern technology with our nostalgia is especially difficult for many street rodders.

Until now, rodders have been severely limited by the battery-charging alternators they’ve had to select from. Rodders either utilized an OE or an OE-style alternator for their custom engine applications, or they selected one of the aftermarket units that were polished or chromed. Now, with the introduction of MSD’s Advanced Power System (APS) alternator, that’s all changed for the better.

The showroom is what every auto parts store dreams of being: diced in checkerboard black and yellow tile with a heap of pegboard. Up front, the sales counter is the hub of business, fueled by eager customers that keep the phone ringing off the hook. Bob, Sam and Robin deal one-on-one with customers, keeping all 50 states Moon-equipped.

The growing popularity of nostalgia and rat rods, along with the aging of street rodders, has meant the rebirth of vintage engines. Rocket Oldsmobiles, Buick nailheads, Y-block Fords and Chrysler Hemis are being chosen over the “bellybutton” Chevrolet small-block. Even some small-block Chevrolet engines are getting old-time flavor by using generators–some of which have been internally modified as alternators–early blocks and heads, three-deuce setups and even adapting Oldsmobile valve covers to look like something they are not.

There was a time not all that long ago, between station wagons and SUVs, when big conversion vans were the family transportation of choice. In the beginning, the Big Three considered vans to be commercial vehicles, fitted with rubber floor mats, vinyl seats and short (if any) side windows, not the decked-out, posh family transport they would become.

We know youʼve already checked out the photos or you wouldnʼt be reading this. You obviously wish to know a little more about this jack, so weʼll cut to the bottom line: If you get one of these for your very own, youʼd better not tell any of your buddies about it, or you will have to make room in the safe to store it. If they spot it in your trunk, just laugh about how you got it as a gift and hope none of them reads this article, or you will have to tape a cell phone to it to find out where it is this weekend–just when you need it!

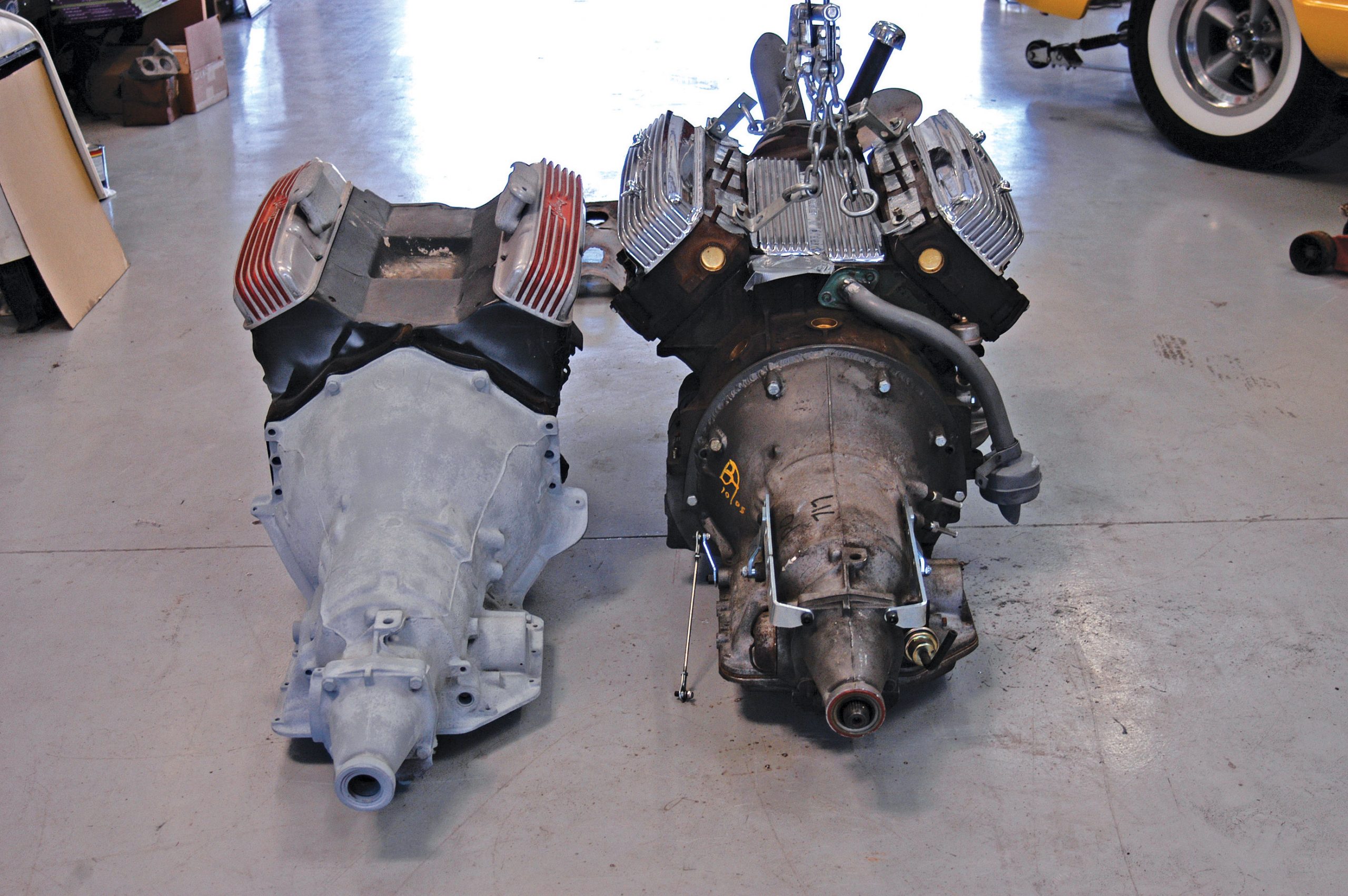

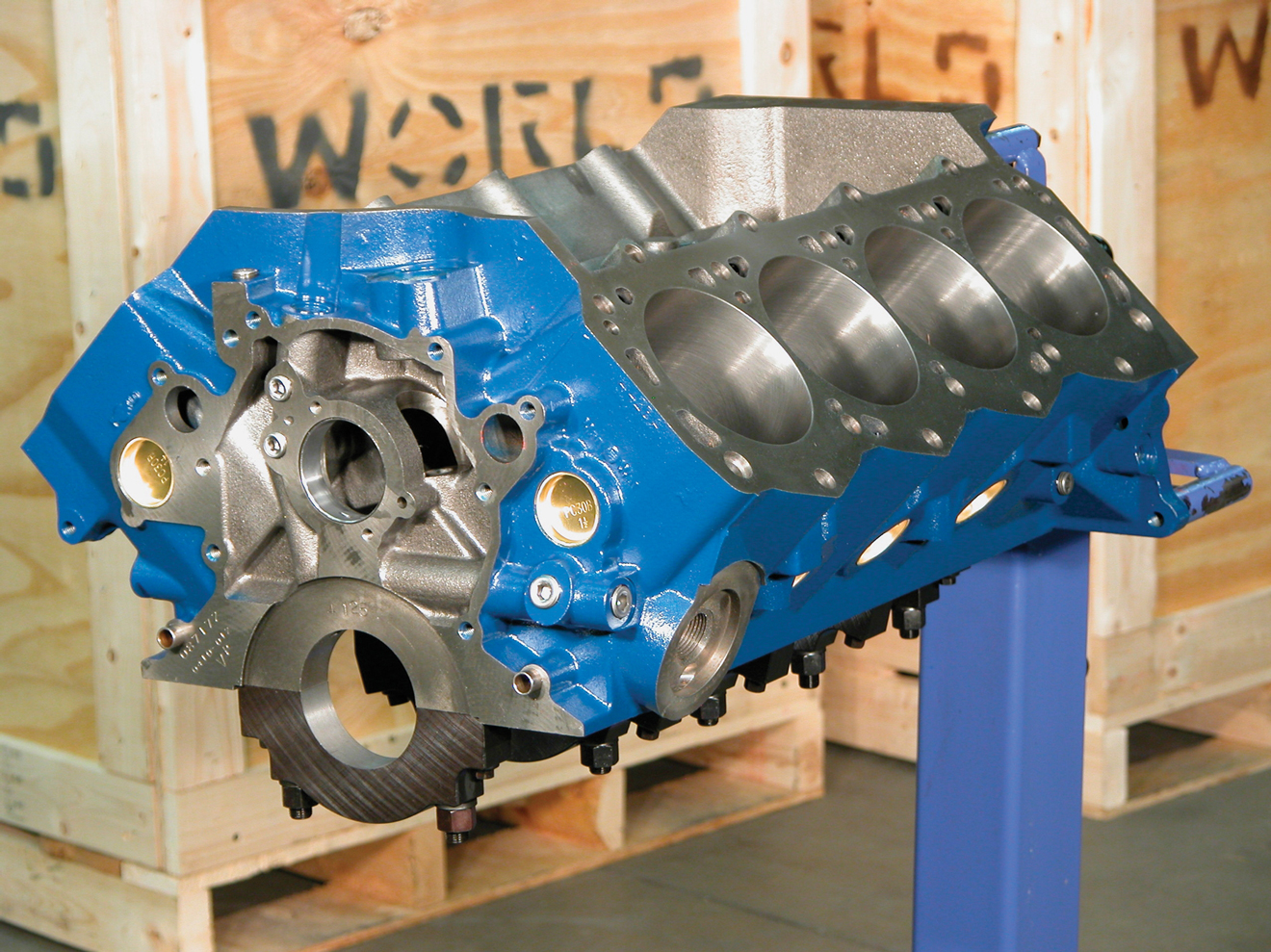

While the small-block Chevy is the popular engine choice for many enthusiasts, many are now relying on a Blue Oval heart for their performance bodies. With its link to Ford, the original body manufacturer for many of the classic cars we see today, the small-block Windsor-style Ford engine offers several advantages. When compared to Chevy, the lack of firewall clearance for a number of Chevy engine swaps is due to the rear distributor position of the engine. The front-mount distributor position is the more logical place to drive the distributor and the oil pump. Not to mention, it’s much more convenient.