Street Rods

“I shouldn’t have sold that car.” How many times have you heard an enthusiast make that statement? It seems that a great many of us regret selling our favorite rides over the years, whatever the reasons.

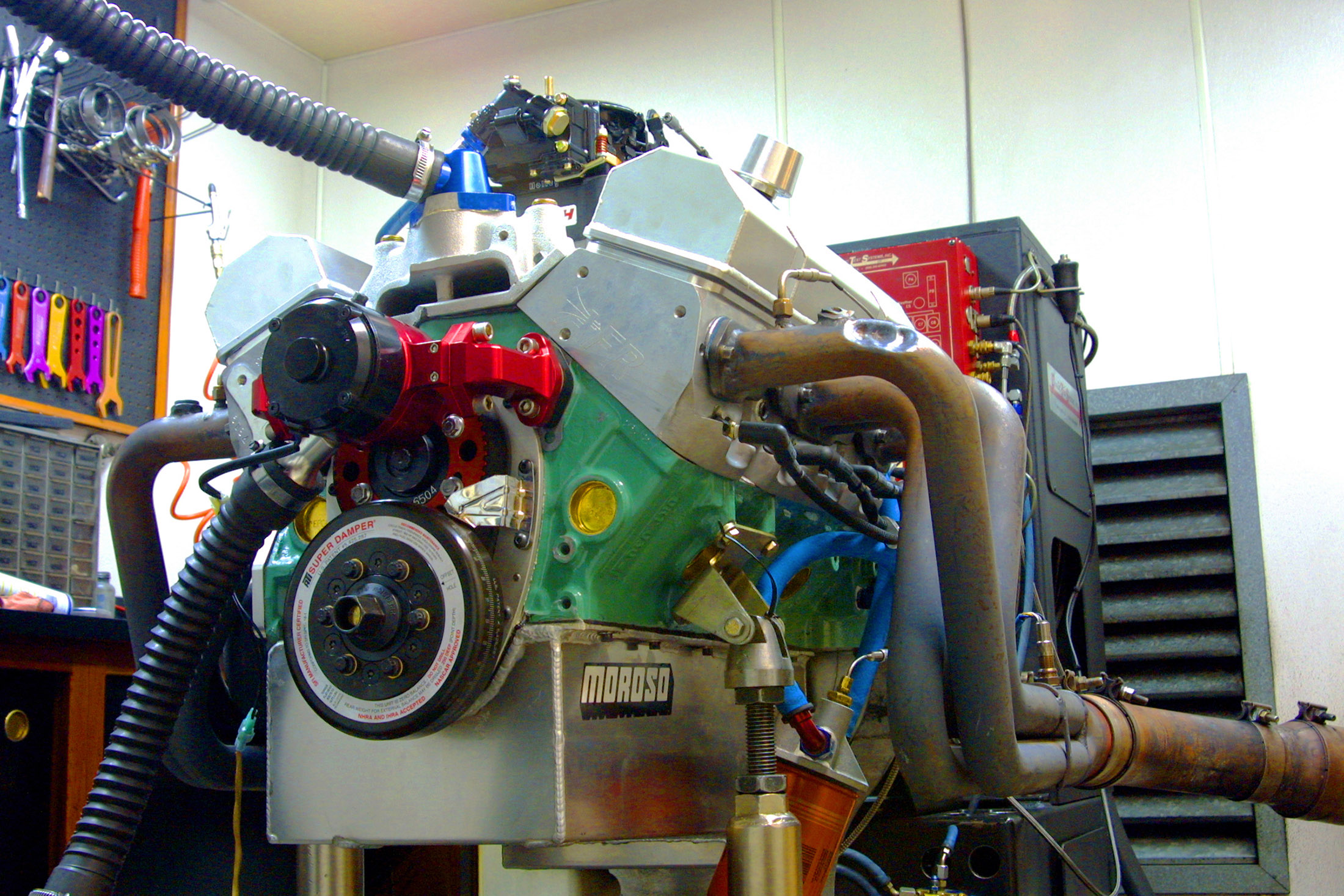

We showed you how to build a small-block engine that could make over 500 hp and 500 lb-ft of torque on 87-octane gas. It was a motor that could be driven just about every day with a hydraulic-roller cam and a good carburetor, making acquisition and maintenance almost nonexistent. Like many things we do in the engine world, the results we enjoyed—while good—just weren’t satisfying anymore. We wanted more.

When starting any project that requires bodywork, rebuilding or even repainting, the first question is always, “What could possibly be lurking under the old paint that could come back and haunt us later?”

These tips are performance-oriented in nature because no matter how good-looking a matching-numbers Chevy might be, getting there and back is vital, as is prepping the car properly and inexpensively with little trouble. While six-figure projects and high-tech billet products flood the market, finding a good deal at the local salvage yard or a worthwhile part left over from a project can be just as exciting and much easier on the wallet.

Simplicity is the key here, as this ’55 Chevy perfectly embodies the sleeper theme with a no-frills look and monster power. It doesn’t even feature all the stainless Bel Air or 210 trim you normally find on most tri-5 models; but even though this is a plain-Jane 150 devoid of trim, Ernie Lankford’s all-black ’55 certainly doesn’t get overlooked.

This was a time when car manufacturers improved on their cars with much better suspension systems, larger and more efficient V-8 engines, and all the stylish creature comforts new-car customers expected. Chevrolet evolved, too, using more modern technology and a performance parts supply that enabled Chevy enthusiasts to build upon the factory offerings. Chevrolet changed what was once a basic industry, and even though those were simpler times with no computers, cell phones or electronics to speak of, the suspensions were new—but still a long way from what is available now. However, tri-5 Chevys were fast and provided a blast without all those fancy gadgets found in luxury cars at the time—just give them a two-tone Chevy equipped with a V-8 and whitewall tires, and it was all good.

Over its history, the HCCA has been pivotal in orchestrating events, rallies, and exhibitions spotlighting antique automobiles, offering a platform for enthusiasts to exhibit their cherished vehicles, exchange expertise, and cultivate enduring connections. This year, the 2024 HCCA National Convention and Tour made its way through Chattanooga, Tennessee, and surrounding areas.

Mustangs are usually not candidates for sleepers, because everyone knows Mustangs have plenty of power from the factory for their lightweight bodies. This example, owned by Mike Skiles, looks like an original ’69 Mustang, but as soon as the engine is fired, that logic is thrown out the window.

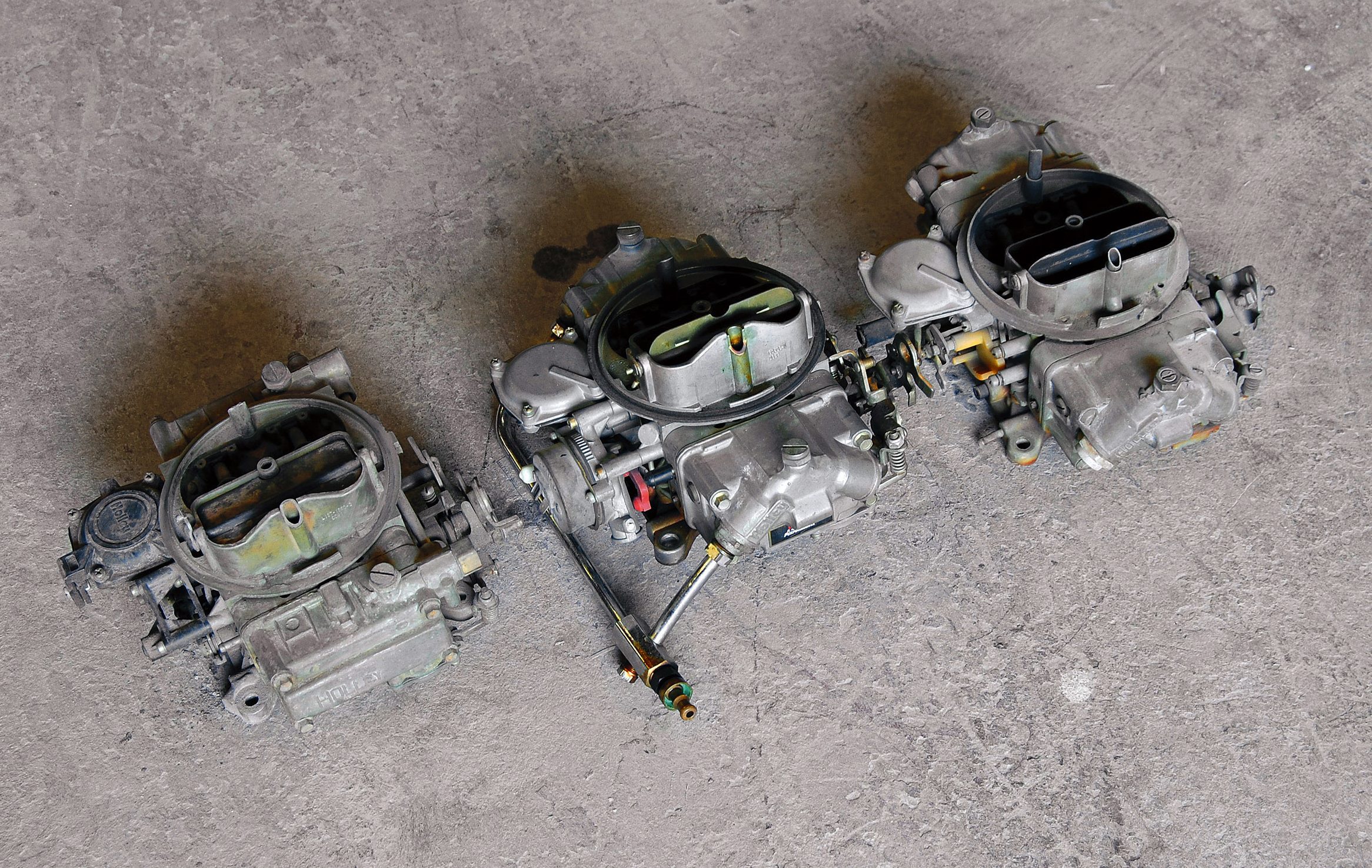

Holley carburetors have long been a staple in the go-fast world of high-performance motoring, whether it’s NASCAR, drag racing or on the street. Much like other performance-oriented products—perhaps even more so with a carburetor—a carburetor requires a fundamental setup and a degree of maintenance, and that’s considering you have chosen the correct-size carburetor for your application, at least to get it in the ballpark. Knowing how to adjust, maintain and even repair your Holley carburetor goes a long way toward helping to ensure that your carburetor will make optimum horsepower for a long time. Because of this, we decided to compile a few troubleshooting and repair tips for the popular 4150-series Holley carburetor, which is the series designation for Holley’s street/strip and racing carburetors.

Alternative-fuel sources and hybrid cars are all the rage today. Everyone from major automakers to backyard inventors is pursuing alternative fuels and energy sources. While the ultimate goal is generally to eliminate dependence on foreign oil, for hot rodders there is also the desire to invent and create a better-performing engine.