THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

B-Series Bullseye: Part II

Inside Dart's New Big-Power Honda

We all know and love the Honda/Acura B-series motors and for good reason. They have been and continue to be the mainstay of the sport compact performance market. Sure, the new K-series motors are making headway with more and more performance pieces and they look to succeed the B-series once the supply of used motors becomes available in the quantities (and pricing) currently enjoyed by the B-series. But for now, Civic, CRX and Integra engine swappers, not to mention the horde of those originally so equipped, have made the B16A, B18A/B, B18C and B18C5 the performance Honda motors of choice.

The B-series motors are not just popular because of their availability, but because they offer so much performance right out of the box. How many motors can you list that meet and/or exceed the magical 100 hp-per-liter mark in stock form? Now add to that equation rapid response to aftermarket performance components, combined with tremendous availability of everything from air intake systems to serious hard parts, such as CNC-ported heads and dedicated race blocks, and it is easy to see why the VTEC motors are so popular.

The 1.6-liter B16A produced 160 hp, giving it a specific output of 100 hp-per-liter. The slightly more powerful 170hp B18C (GSR) motor was down in terms of specific output, as the additional 10 hp was accomplished via an increase in displacement. Displacing 1.8 liters, the 170hp B18C produced just 94.4 hp-per-liter. The big jump in B-series power came when Honda introduced the 195hp B18C5 (Type-R) variant. The U.S.-spec Integra Type-R motor produced over 108 hp-per-liter. The winner in terms of B-series specific output was the (non-US) Civic Type-R. The little Civic motor produced 185 hp from just 1.6 liters, giving it a specific output of over 115 hp-per-liter.

As great as the B-series VTEC motors are, there is always room for improvement. While 100, 108 or even 115 hp-per-liter is impressive, enthusiasts and drag racers are always looking for ways to make more power. Unlike most street buildups, drag racers are looking to maximize power production, even at the cost of long-term reliability. Drag race engine builders continue to push the envelope until something eventually breaks. When they find the weak spots, the weal link is removed and replaced with a stronger component. The stock Honda cranks have proven exceptionally strong, but racers have found that connecting rods need replacing if excessive power and/or engine speed is in the cards. Ditto for the factory pistons, especially if forced induction is employed on the motor. The stock pistons simply will not withstand the punishment of a turbo motor as well as a set of aftermarket forged slugs. Once you have a forged steel crank, rods and pistons, the weak point eventually becomes the factory block.

When racers really started leaning on the B-series motors, they soon realized the inherent design flaw. The increased cylinder pressure of the high-powered race motors taxed the strength of the unsupported cylinders, causing everything from blown head gaskets (or leakage) to cracked cylinders. The main design flaw of the production B-series Honda block(s) from an ultimate strength perspective is the lack of a closed deck. The production Honda B-series block features individual cylinder liners with 360-degree coolant circulation. While this is beneficial for cooling, the lack of a closed deck allows the cylinder pressure to apply leverage and eventually distort the unsupported top end of the cylinder. Savvy racers and machinists eventually got together to build simple block guards (deck inserts) and some even went so far as to machine and weld deck plates to secure the cylinders. Naturally, this machining and welding (and required sleeving) can cost a pretty penny, but in the end, you still wind up with nothing more than a modified stock Honda block.

The ideal situation would be for someone to produce a dedicated race block that cured all of the inherent design flaws of the production piece without all the hassle and expense of the machining procedures required to bring it up to race specs. Enter the Dart B-series Honda block.

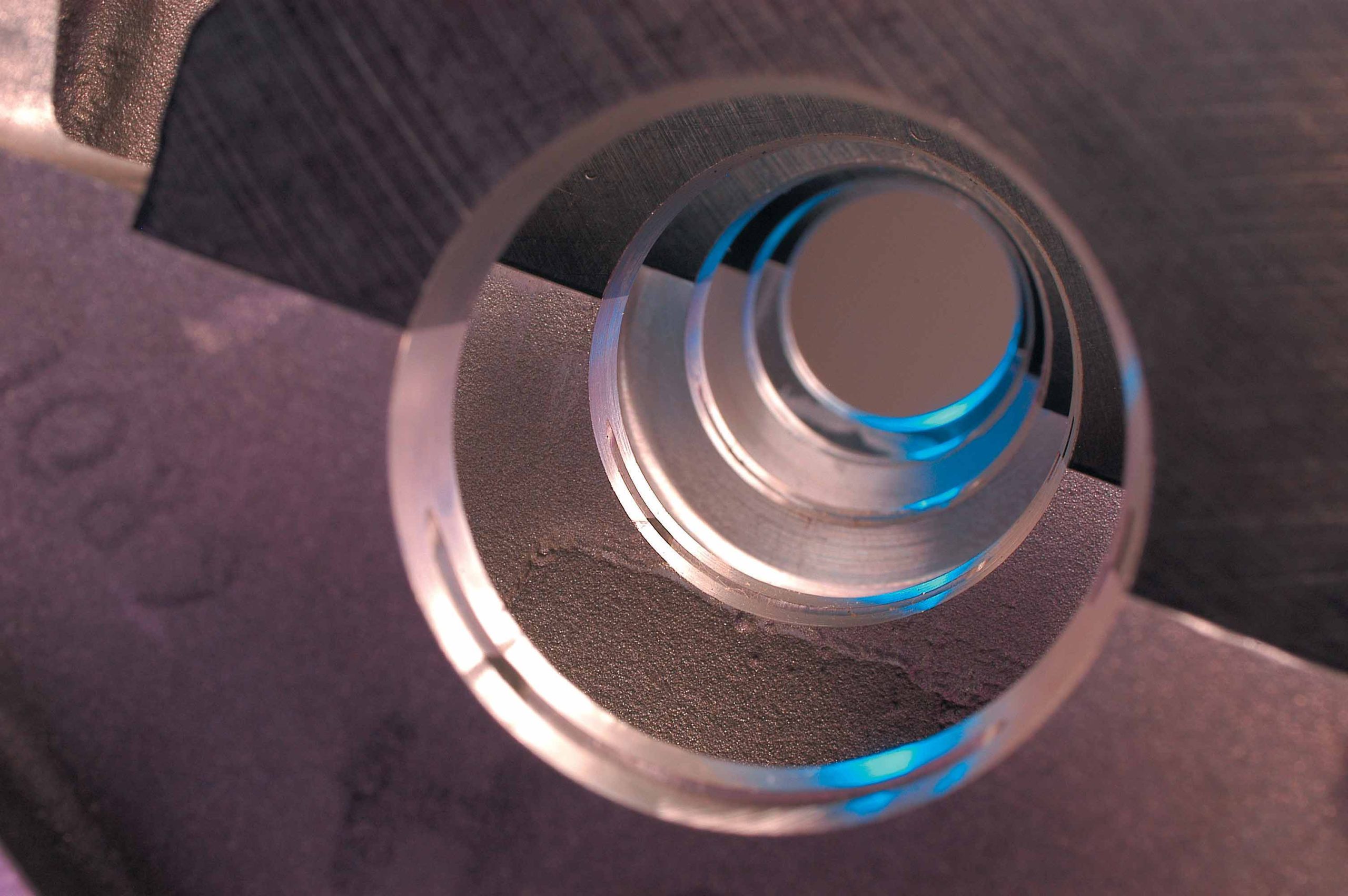

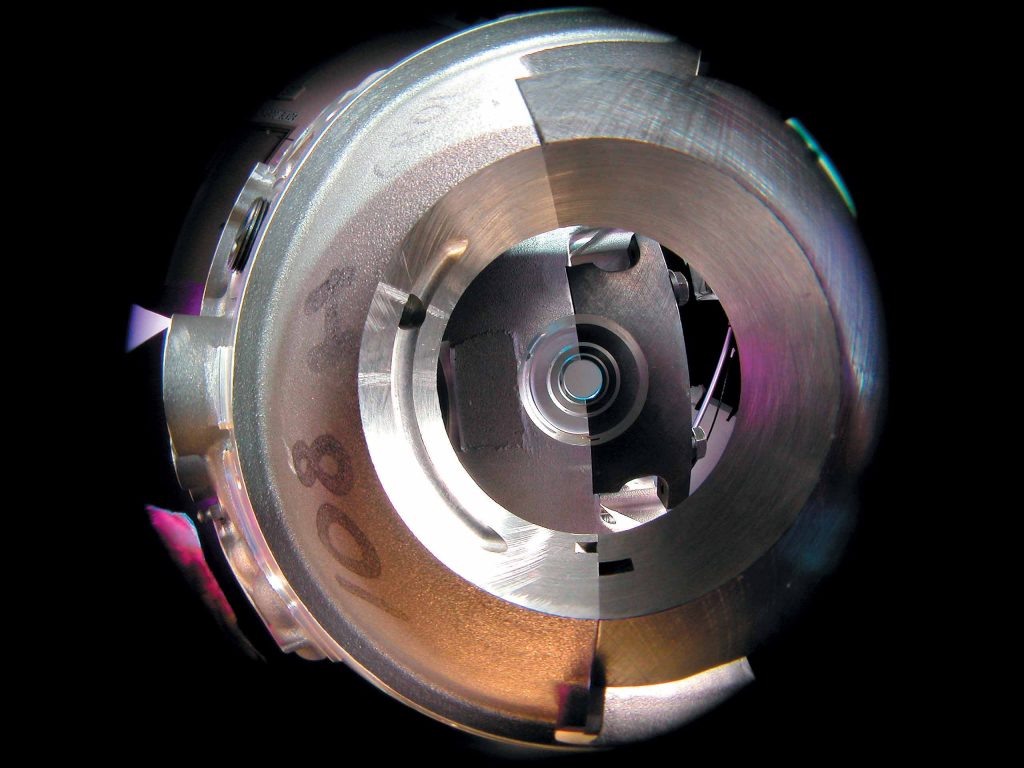

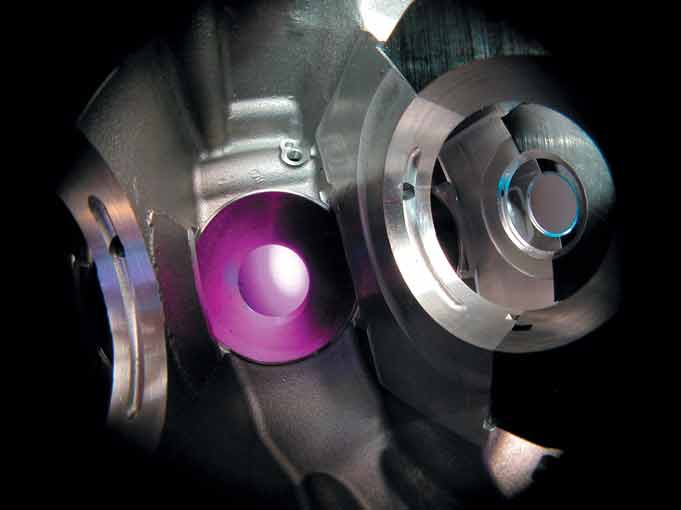

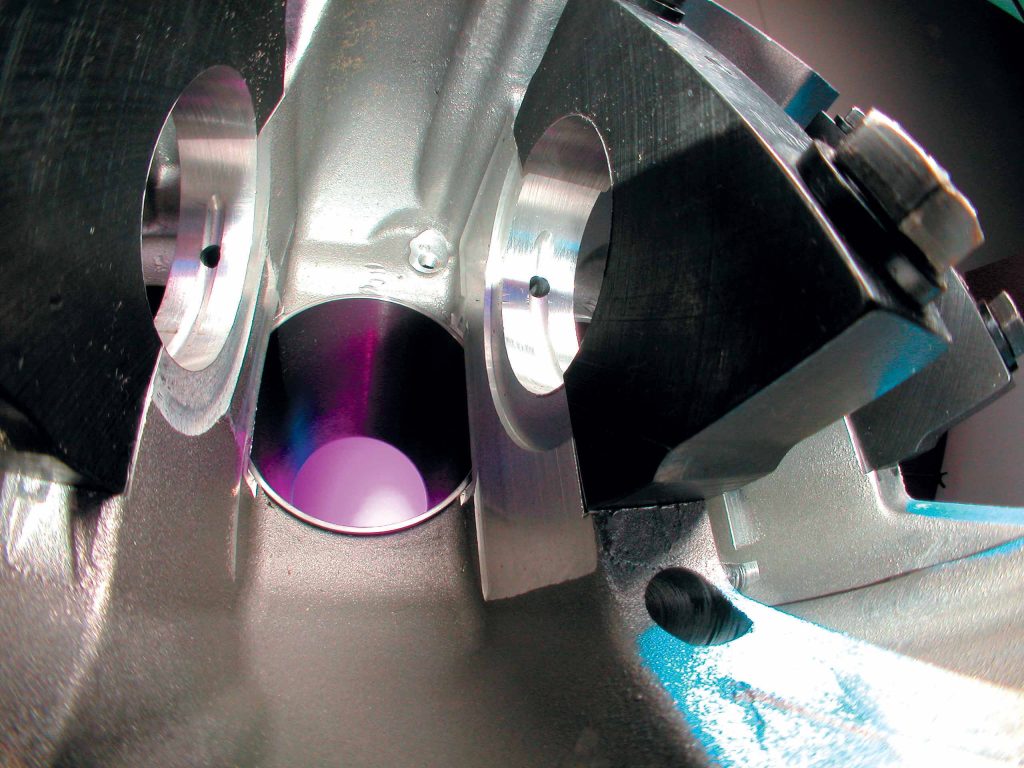

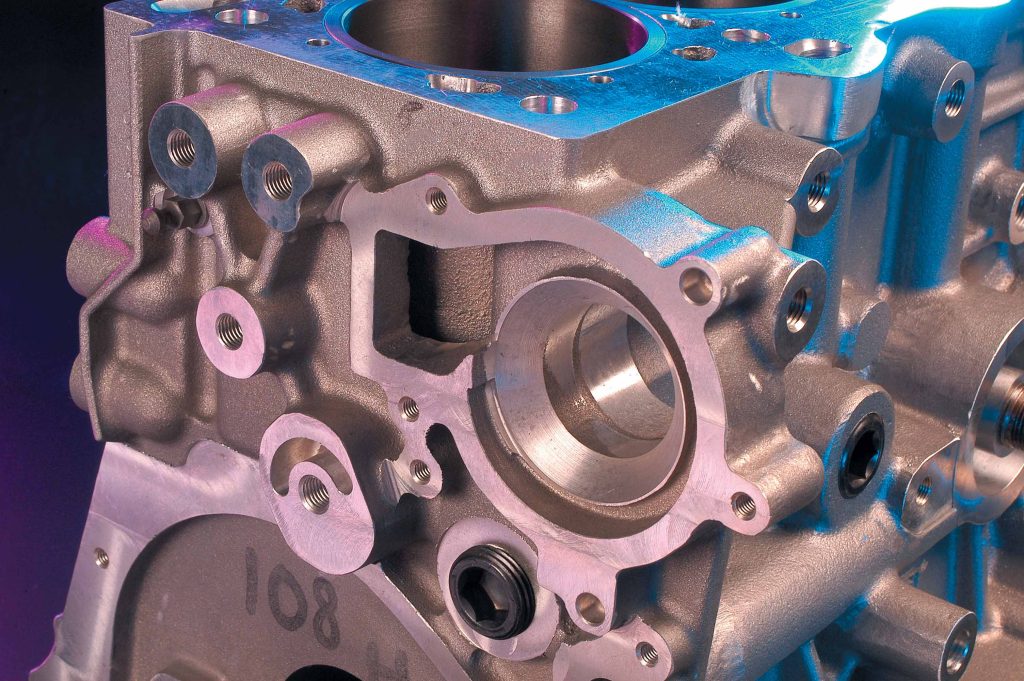

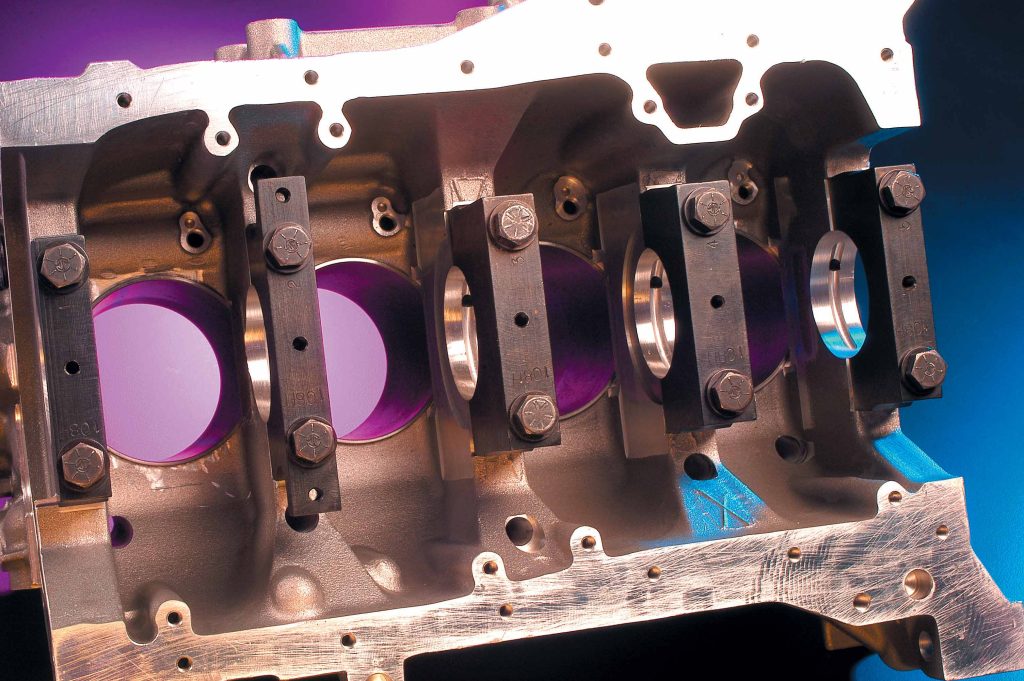

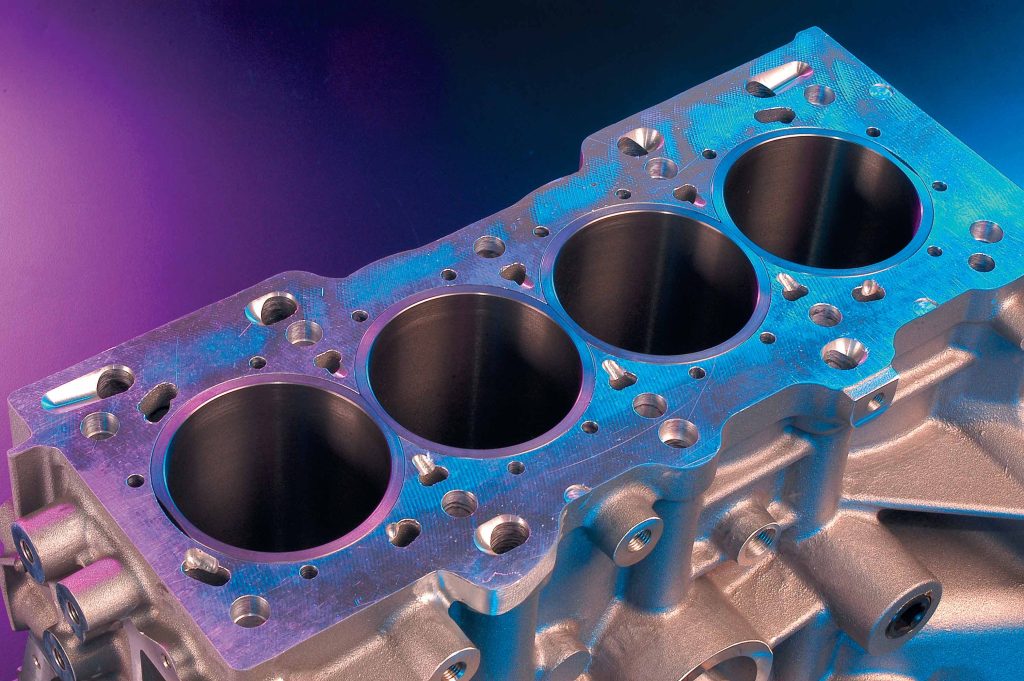

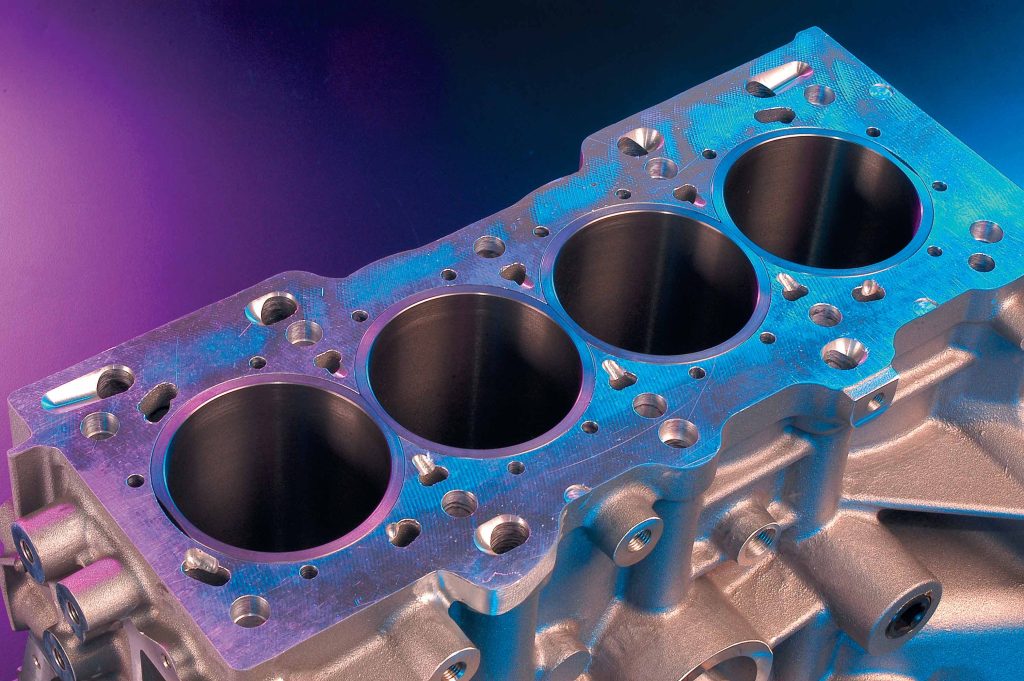

The new Dart B-series Honda block cures all of the problems associated with prepping a factory Honda block for serious horsepower. The Dart block is machined from C355-T6 virgin aluminum alloy for maximum strength and durability. The blocks feature replaceable ductile iron dry sleeves that are fully supported to reduce bore distortion and improve ring seal. In doing so, the Dart block not only improves strength and longevity, but can also help improve the power output.

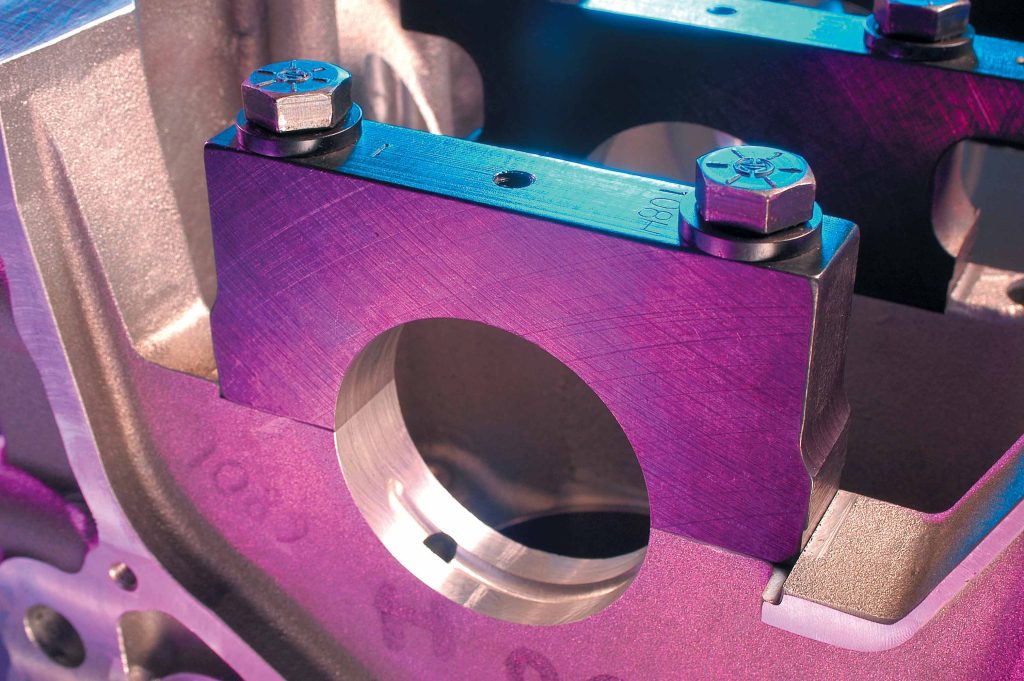

From a strength issue, the most prominent feature on the Dart block has to be the closed deck, designed to increase rigidity and improve head gasket sealing. The rigid deck maximizes head gasket sealing, all but eliminates cylinder/sleeve movement caused by cylinder pressure, and improves overall block rigidity by effectively boxing the structure. Additional features include steel main caps equipped with high-strength main bolts to improve bottom-end strength and minimize bearing bore distortion. Main bearing distortion can cause premature bearing wearing and eventual bearing failure something to be avoided at all costs in any motor.

In addition to the improved strength and rigidity, the Dart block features extra-large water jackets to increase coolant circulation around the cylinders. Localized hot spots can cause detonation. Effective coolant circulation is critical to maximize performance, whether you have a road race, drag race or even just a street motor. The Dart engineers were sharp enough to know a good thing when they saw it and retained the production piston oil squirters. This spray system incorporates small squirters located at the bottom of the cylinder bores. The squirters help reduce crown temperatures by supplying cooling oil to the bottom side of the pistons. All of the B-series VTEC motors feature this pressure-fed piston cooling system. The system was not incorporated into the B18A/B non-VTEC motors; thus LS/VTEC hybrids do not benefit from this detonation-reducing feature. To make life easy, Dart also went to great lengths to ensure that all of the factory B-series Honda components, such as oil pumps, water pumps and belt tensioners, bolted directly to its block.

In addition to the many desirable features, the Dart Honda blocks are also available in two different deck heights. The most common B-series motor used by performance enthusiasts is the short-deck B16A. The Dart blocks are available in the taller 211.5mm deck height common to the B18A/B/C motors. This taller deck height allows not only larger displacement combinations, but also provides the necessary height to run longer connecting rods and improve the rod-to-stroke ratio. It is possible to install a B18A/B/C crank in a shorter B16A block, but the attending rod ratio would be less than ideal. The Dart block allows use of cranks up to 89mm, without fear of a less-than-ideal rod ratio.

The standard B18A/B/C 211.5mm deck height is available in two different rough bore sizes. Stock B-series motors feature 81mm bores. The Dart blocks are available with either 81.5mm or 84mm bores. The combination of an 84mm bore and an 89mm crank (from a B18A/B non-VTEC motor) results in just under 2.0 liters. Additional displacements are also available by juggling the various 77mm, 87.2mm and 89mm cranks available in the B-series motors with the two standard bore sizes.

For those looking to build an even larger combination, Dart offers a block with a taller 226mm deck height. The additional deck height can be used with an 89mm crank to further improve the rod-to-stroke ratio, or you can step up to a 95mm aftermarket stroker crank. Like the standard 211.5mm-deck-height blocks, the 226mm Dart blocks are available in two different bore sizes, 81.5mm and 84mm. The combination of a 95mm crank and the 81.5mm bore results in a displacement of 1,964 cc, while combining the 95mm stroker with a larger 84mm bore results in an impressive 2,134cc B-series motor. Imagine what the torque of a 2.1-liter B-series would feel like with the right cams and intake manifold. Now think about this same combination, but with slightly less compression and a big, nasty turbo thrown into the induction mix.

Of course, the taller deck block can also be used with any of the production B-series cranks, provided the cranks are used with a custom rod length. All in all, the Dart block has plenty to offer the most serious of B-series builders. With the combination of added strength and rigidity, improved cylinder sealing and engine block cooling, and the potential for various displacements and tremendous power, it looks to us like Dart has hit the bull’s eye once again with its new block. Now couple this with the new Dart head we introduced to you last issue (ÒB-Series Bulls Eye, HCI March 04, p. 71) and you can plainly see that Dart has positioned itself as a very solid platform for some mighty impressive Dart-Honda power.

ARTICLE SOURCES

Dart Machinery

353 Oliver Dr.

Troy, MI 48084

248/362-1188