THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

ADVANCED SUSPENSION

Author

Josh Kaylor

Story & Photography

Installing A More Modern Mustang II-Style IFS In An Advanced Design Chevrolet Pickup

Since the introduction of aftermarket Mustang II-style independent front suspensions in the early ’80s, they have found their way on a great number of projects, trucks included. Its popularity today has established this basic design as the most common suspension upgrade for both early Ford and Chevrolet pickups originally equipped with straight axles.

The aftermarket has largely provided these gains, as a great number of Mustang-style IFS kits are available, some more elaborate and expensive than others. The Mustang-type IFS allows owners to quite easily improve the ride and drive quality of their older trucks, not to mention creating a great new static attitude as well as providing safety of operation. And once you have a basic kit and crossmember that provides the basics for the install, also available are adjustable shocks, stainless and chromed A-arms, rack-and-pinion steering selections, including power steering, lowered spindles and all manner of impressive disc brake setups to choose from.

The early trucks that have become so popular today were originally designed to haul things and were utilitarian in their design. For their time they provided a suitable, strong suspension that could withstand these loads, but that came with a stiff penalty—rough riding. Today, even more has changed, with our better roads and more capable vehicles, old classic pickups are out of place, and in fact, in their stock form they are somewhat of a safety concern. They don’t stop and cannot comfortably cruise at the traffic speeds we find on the roads today, and that’s mainly because they are made of outdated componentry and systems. Going in, if we are to upgrade an early pickup as a daily driver, especially a high-performance one, with an IFS installation kit of one kind or another, is almost essential if the truck is going to be driven on a regular basis.

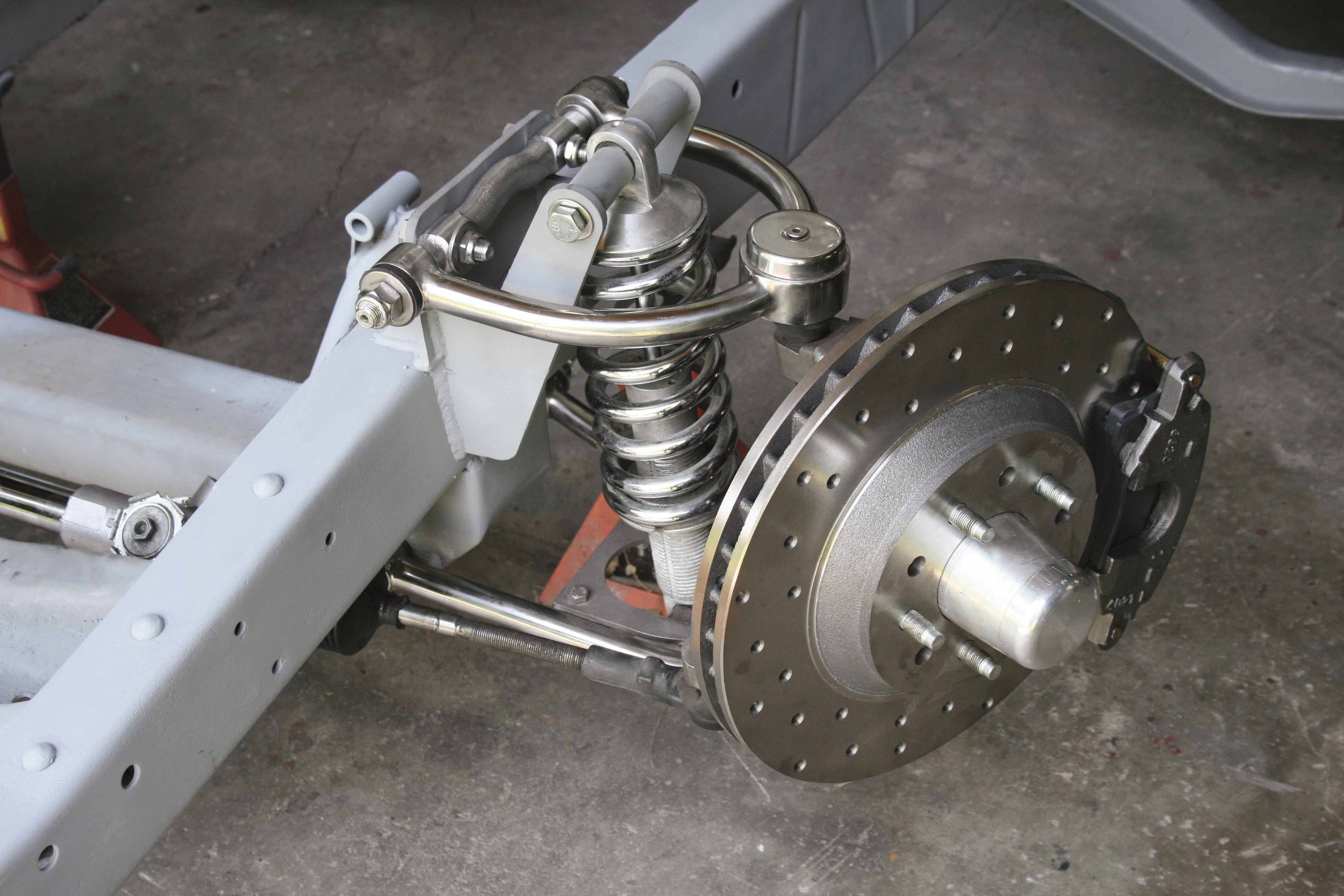

When Jim Walker decided to begin the upgrades to his ’53 Chevy to make it safer at highway speeds, he knew the stock drum brake and straight axle setup would have to go. So to replace the straight axle front suspension, he purchased a Fat Man Fabrications IFS kit and ECI 13-inch disc brakes. The Fat Man IFS features a weld-in crossmember, polished tubular upper and lower control arms, dropped spindles, coilover shocks, and a new manual rack-and-pinion steering. Fat Man recommends a ’79-’93 Mustang rack-and-pinion for their improved road feel, not to mention availability.

To complement the IFS kit, Walker chose to upgrade the standard 9-inch Mustang disc brakes with ECI’s new 13-inch two-piece brakes, complete with a 5-on-4.5-inch bolt pattern. The ECI brakes feature billet hubs along with drilled 13-inch rotors and GM single piston iron calipers. This brake upgrade should provide the Chevy with plenty of stopping power. The smaller, more readily available bolt pattern will also allow Walker a wider selection of aftermarket wheels.

Since the kit requires intensive welding and chassis measurements to ensure the crossmember is centered perfectly in the wheel well and square in the frame, Walker delivered the Fat Man IFS kit, along with the truck, to G&S Custom Fabrication & Suspension (256/232-9512) in Athens, Alabama. Installing the front suspension can take such a shop as little as six hours, but consider that not everything will be perfect going in, depending on the condition of the frame and the amount of prep time needed before welding can begin, as most installs will take eight hours or more from start to finish. Simply times this by the hourly shop rate, and if you are not planning to perform this install at home, that’s how much you can expect to spend for installation alone. And if you have more work done while the truck is in the shop, the price will go up from there.

Of course, compared to the cost of purchasing all the tools needed, which include a MIG welder, cut-off tool, plasma cutter, frame bobs, levels and the customary hand tools (wrenches, sockets and so on), the price of an at-home installation can begin to look costly, but then once you have the basic tools, it’s all quite easy and readily affordable. Follow along as G&S shows us how. G&S Fabricators Greg Blaydes and Jared Osborne handled the IFS install in an early Chevy pickup, enabling you to decide if this is a job for you, and if you would be wise to tackle the installation at home. TB

ARTICLE SOURCES

Engineered Components Inc.

Dept. TB

P.O. Box 841

Vernon, CT 06066

860/872-7046

Fat Man Fabrications

Dept. TB

8621-C Fairview Rd., Hwy. 218

Charlotte, NC 28227

704/545-0369