THE AUTO BUILDER

Featured

- All Post

- Builds

- Cars

- 01 Post Status

- _000 HIGH PRIORITY

- Trucks

- Swaps

- Performance Boats

- Builders

- 00 Sidebars

- Manufacturers

- _000 Home Sliders

- 05 Publications

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Subaru

- Plymouth

- Mercury

- Chevrolet

- Volvo

- Cadillac

- Volkswagen

- Pontiac

- GMC

- AMC

- BMW

- Buick

- Jeep

- Oldsmobile

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Acura

- Honda

- Nissan

- Toyota

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- 10 High Priority - CR Chevy Rumble

- 15 High Priority - 4x4 4x4 Builder

- 20 High Priority - SR Super Rod

- 25 High Priority - FB Ford Builder

- 30 High Priority - AR American Rodder

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- 05 High Priority - HCI Hot Compact Imports

- Back

- J.F. Launier

- Bobby Alloway

- Chip Foose

- Steve Sellers

- Boyd Coddington

- Rad Rides by Troy

- Ring Brothers

- Cal Auto Creations

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Bob Cullipher

- Jerry Nichols

- Carl Casper

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 50 Post Approved

- 10 Post Images Imported

- 27 Post Missing Content

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Choosing The Right Cam

Cam-Speak Can Be Confusing, But the Performance Is There If You Know the Facts

Author

Brad Ocock

Photography by Brad Ocock and Staff

In bench racing terms, most parts and systems of the automobile are easily understood, including engine internals. Even when one is not fully versed in the specifics of an engine build, itʼs easy to recognize large head-flow numbers when you hear them. You just need a base reference to know how much of an improvement those big numbers represent.

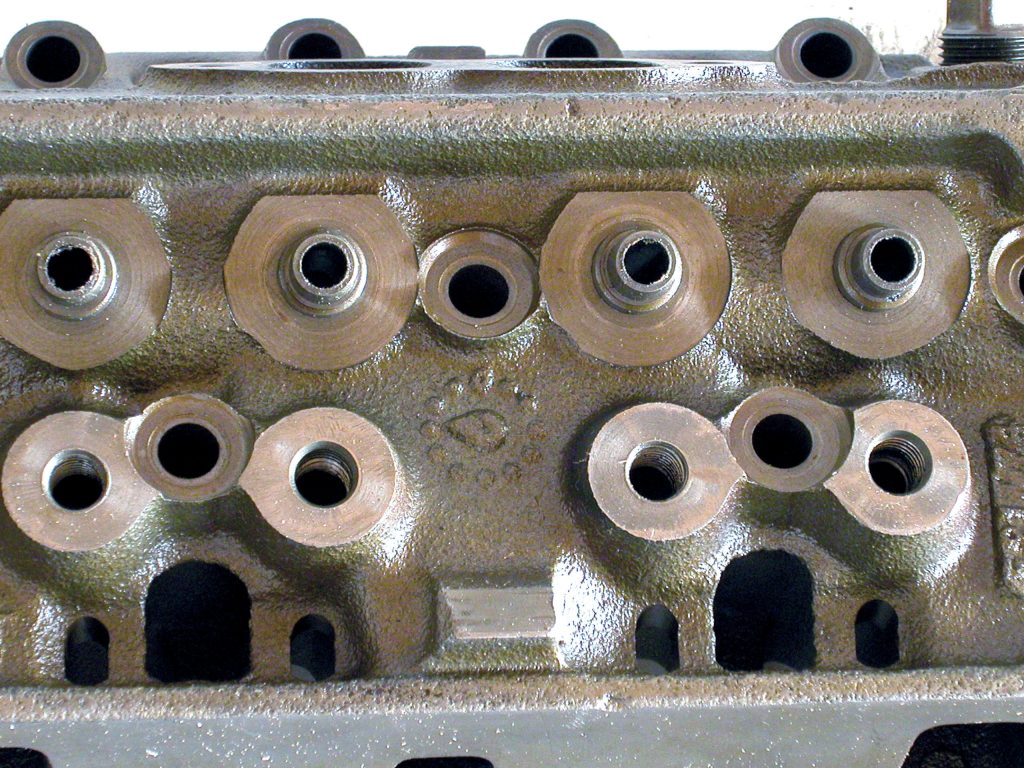

And when talking compression ratio, itʼs generally understood that this is a phase in the workings of an internal-combustion engine, in which the combination of fuel/air is compressed within the combustion chamber (cylinder), before being ignited by the spark plug. It is also generally accepted that 9.0:1 to 10.5:1 is a more acceptable compression ratio for a high-output, normally aspirated street engine, and that any ratio below 9.0:1 would be considered more suitable for a boosted application or non-performance engine. A compression ratio nearing 11.0:1 or higher is the threshold for an engine more at home on the racetrack, using higher octane than is readily available on the street.

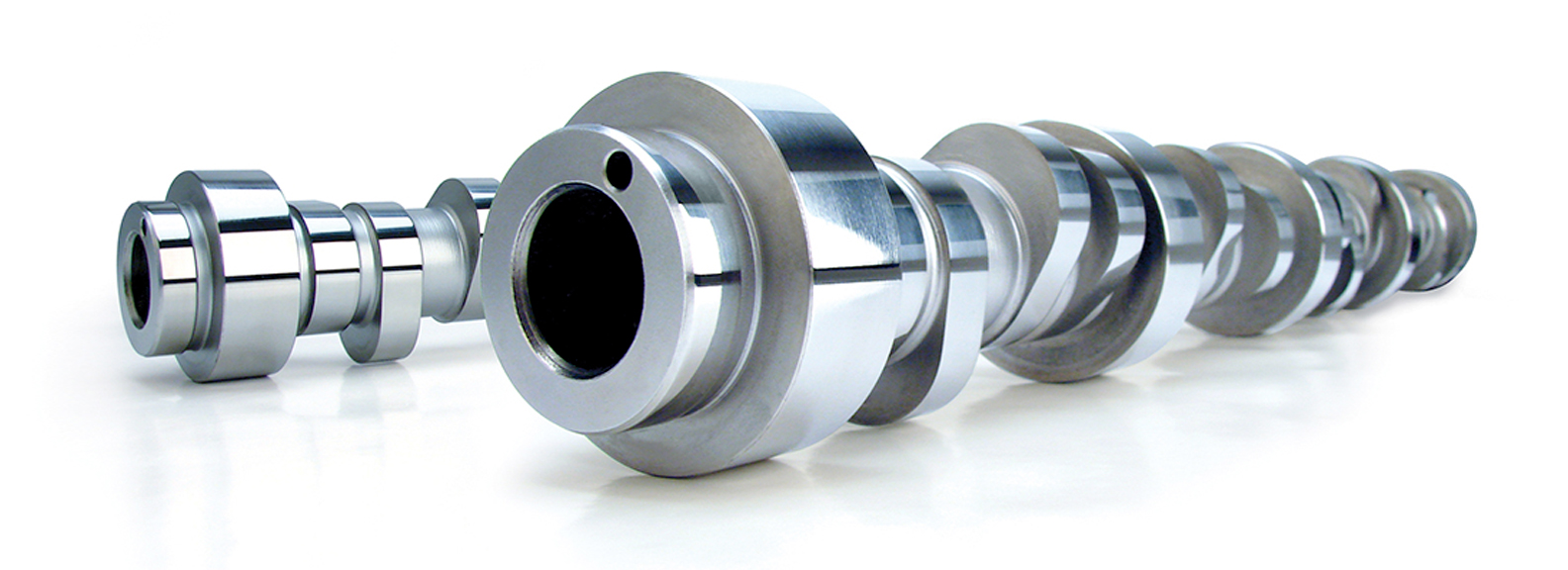

But start talking cam specs like duration, lift and overlap, or valve events as they relate to crankshaft degrees, timing and volume under the lift curve, and you begin to lose the understanding of what these mean in selecting and timing a proper camshaft. Itʼs not as important that we understand the terminology as much as how elements of cam timing can be utilized in the proper selection of a camshaft for our particular applications. There is no other component within the engine that relates to the functional operation of all your engine parts as does the camshaft, its lift and its timing.

As a result, a lot of people are running around with the wrong camshafts in their engines. They understand the importance of the cam; they just lack the knowledge and operational experience to properly select what is needed. If there is a common mistake made by most inexperienced engine tuners, it is selecting a camshaft that is too big for their applications.

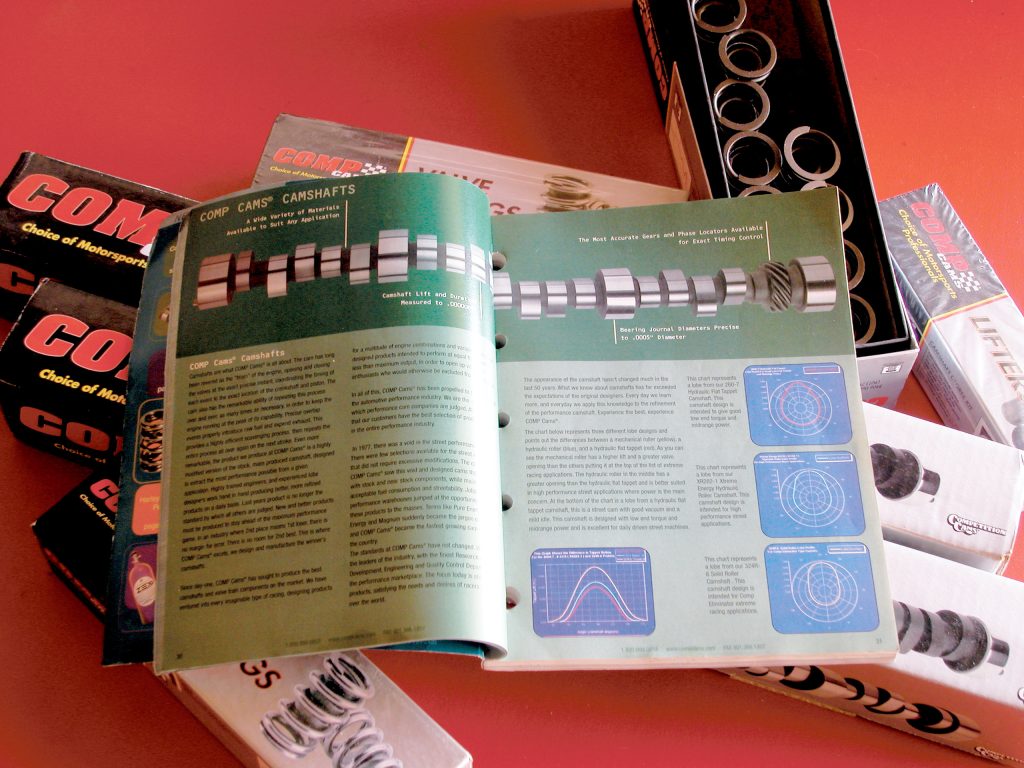

To help educate us, we took a trip to Comp Cams and spoke at length with cam designer Billy Godbold. Designing cam lobes is a mathematical science that is highly specialized. Today it relies heavily upon computers to crunch numbers for potential acceleration ramps, lifter velocities, noses, closing profiles and base circles. But thatʼs only the beginning when discussing the physical characteristics of the camshaft. When this all occurs within the engine, how the valvetrain can react to the intended cam profile is every bit as important as how much or how high cam timing events occur.

Godboldʼs professional background is in nuclear physics, and he is quick to point out that camshaft lobe and timing design is only part of the equation to building power. Controlling the valve at the other end of the valvetrain is as important as size and timing. Where Comp Cams is concerned, this task falls to Thomas Griffin. As one might imagine, Godbold and Griffin work very closely together. Griffin designs springs that will stand up to the lifts and velocities of the lobe profiles that Godbold designs. Godboldʼs job is to design lobes that will break Griffinʼs designed components (springs, keepers, retainers, pushrods, lifters and rockers). To hear Godbold tell it, he has the easier of the two jobs. To hear Griffin tell it, Billy is right.

So we asked these men about choosing cams and quickly learned that we too were nodding with glazed-over eyes. Godbold really gets excited about camshafts and their design, and will quickly outpace most anybodyʼs level of knowledge and understanding on the subject. Fortunately, he doesnʼt mind backing up and dumbing it down for those of us that are less technical.

UNDERSTANDING WHAT HAPPENS

Making the decision for what cam should be bolted in your engine boils down to simple math. Where it gets more difficult is labeling those mathematical events, and then understanding how they affect the performance of the engine in question.

To begin our explanation, letʼs start with the piston at the top of the cylinder, with both valves closed, and the spark already igniting the fuel/air mixture within the cylinder. As a direct result, the piston has started down the bore from the explosion of the gas igniting the mixture, which will last half of a crankshaft revolution and one-quarter camshaft revolution. Just before the piston reaches the bottom of the bore, the exhaust valve begins to open, allowing the force of the explosion to begin escaping out and into the exhaust port. All during this process, the exploding gas continues expanding and pushes the piston farther down into the bore. By opening the exhaust valve, the expanding gas has a place to expand and exit. The piston hits Bottom Dead Center (BDC) and starts coming back up the bore for another half crankshaft revolution, pushing the exhaust gases out the exhaust valve and into the exhaust system. As the crank continues through its revolution, the camshaft moves at half the speed to maximum lift, fully opening the valve, and then it begins to close.

Just before the piston reaches Top Dead Center (TDC), the exhaust valve is still open slightly, as the intake valve begins to open. The period of time when the exhaust valve is not fully closed and the intake valve is beginning to open is called “overlap.” Overlap is one of the most important events in the cycle of a camshaft. The exhaust stroke has expelled almost all of the spent charge, and as the intake valve opens, a scavenging effect takes place inside the combustion chamber. As the exhaust gases rush out the exhaust port, they begin to pull the fresh charge from the intake port as the intake valve opens. This flushes the exhausted gases out of the cylinder.

Once the piston passes though TDC and begins moving down the cylinder, it will suck the intake charge into the cylinder, while the valve moves into the fully open position. If the exhaust valve were open at all during this process, the piston would also suck the exhaust gases back into the cylinder, so the exhaust valve must be completely closed at exactly the right moment. If the intake valve opens too early, the piston—still on its upstroke—will push the new charge back up into the intake runner. If it occurs too late, there wonʼt be enough fuel in the cylinder, causing a lean condition. If the exhaust valve closes too early, it will trap some of the spent gas in the combustion chamber, diluting your fresh intake charge. Closing it too late will siphon too much of the incoming charge out the exhaust runner, making the engine run rich in the exhaust port.

Finally, the intake valve must be closed just after the piston reaches BDC. The quicker the intake valve closes and the closer to BDC the piston is, the more pressure will be built as the piston begins the upstroke of compression. If the piston is already on the way up before the valve is fully closed, some of the charge will be forced back out of the cylinder and into the intake port. Once the piston travels back up the cylinder, compressing the charge, the spark plug ignites it, forcing the piston back down the bore. The process then starts over again and repeats several thousand times per minute.

DURATION AND LIFT

Duration and lift are the mathematical figures generally used to rate a camshaft. Duration is easy. Itʼs the total time the lifter is rising on the cam lobe, as compared to the amount of degrees the crankshaft has rotated. If during a crankshaftʼs rotation of 360 degrees it takes 270 degrees of crank rotation for the lifter to go through its entire open/close cycle, then the cam is advertised as having 270 degrees of duration. For practical purposes, however, the description is commonly discussed in terms of how far the valve opens, not how far the lifter rises. This will add to the math because the valve moves farther than the lifter, thanks to the ratio of the rocker arm.

This is where rocker arm ratios come into play. The standard rocker arm ratio is 1.5, meaning for every inch a lifter would raise the pushrod connected to the back of the rocker arm, the arm would push the valve open 1.5 inches.

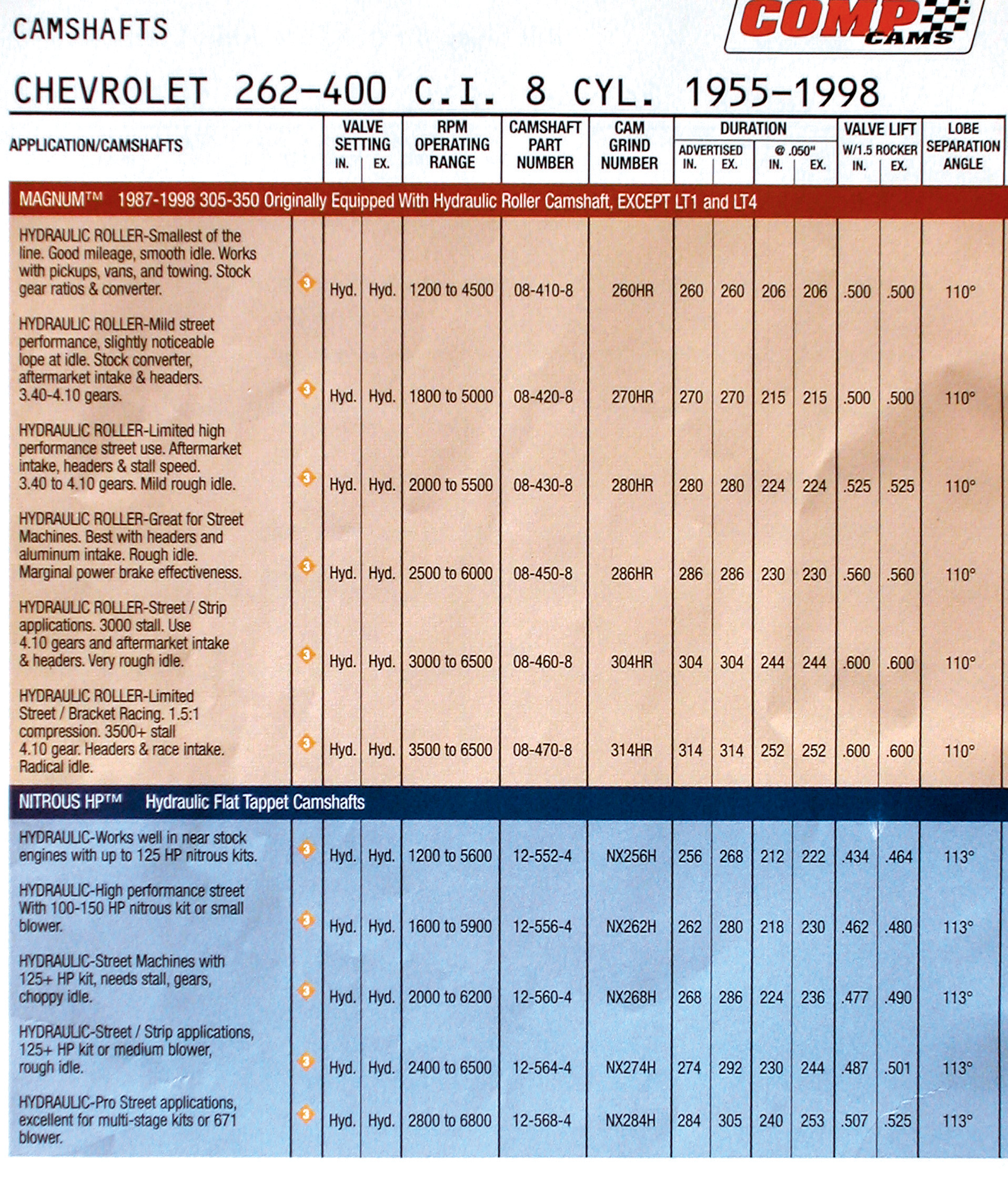

Further confusing matters is the “at 0.050-inch” description of measuring duration. “At 0.050-inch” refers to the measurement of degrees (duration) when the tappet has lifted 0.050-inch. Itʼs simply an industry standard used as a constant measurement in order to compare one cam to another. It is also very difficult to determine exactly when the lift begins its movement, as ramp rate can vary greatly among cam profile designs. By determining the length of duration is at 0.050-inch on two different camshafts, you can make a determination as to which cam has the characteristics you most want.

If, however, one cam manufacturer published its camsʼ specs as measured at 0.030-inch or 0 lift, you would have no way to compare them to other cams that were measured at different opening points. For instance, letʼs say we rotate the engine until we measure that the valve has opened 0.075-inch. Dividing by our rocker arm ratio (1.5), the lifter has moved 0.050 inch. That would be the “at 50” designation. We continue rotating the engine until the valve opens fully, starts to close again, and then is open again only 0.075 inch. The amount of degrees the crankshaft rotated is our duration.

The diagram on page 44 shows the total duration at 0.050 inch is 224 degrees. Those are the measurements: “224 degrees at 0.050-inch,” while the “advertised” duration is 270 degrees.

As you learn to discuss camshafts and further understand how they work, you will be able to judge the camshaftʼs lobe profile—and therefore, the camʼs performance characteristics—by comparing the advertised duration and the “at 50” duration, as that will indicate to you how rapidly the lifter opens. Many engine builders have learned to gauge a cam profileʼs aggressiveness by looking at duration at 0.020 inch, 0.050 inch and 0.200 inch. The 0.020-inch gives them a feel for how responsive the engine will be and how much low-end torque the engine will make. The 0.050-inch number is used to estimate where peak power will occur, while the 0.200-inch number gives an estimate of the power potential. While many engines builders can do this, it takes running a great number of camshafts through an engine before you can begin to identify patterns of operation among measured profiles.

LOBE SEPARATION ANGLE AND INTAKE CENTERLINE

The lobe separation angle of a cam is the number of degrees between the peak lift points of the intake and exhaust lobes on a camshaft. Once a cam is ground, you cannot change the relationship between the lobes.

The intake centerline is the relationship between the peak lift on the intake lobe to the pistonʼs TDC moment. Maximum lift occurs at the lobe separation angle, which isnʼt adjustable on the camshaft itself, but may be adjusted in relationship to the crankshaft rotation. This is understood as advancing or retarding a camshaft. You are simply moving the time the valves begin to open in relationship to when the piston gets to the top of the cylinder. Remember, however, that the overlap of the intake and exhaust valves is built into the camshaft itself. Overlap does not change on the camshaft, which means you are moving the overlap in relation to the piston reaching TDC as well.

The lobe separation angle will affect how long the valves stay open in relation to the crank speeds in physical time, not degrees of rotation, which affects the engineʼs performance. With a wider separation, you will have a wider, flatter torque curve that holds up better in the higher-rpm bands because the valve physically stays open over a longer period of time while the crankshaft spins fast, giving the induction system more time to fill the cylinder. At lower rpm, the valve will stay open a very long time (not in crankshaft degrees, but in physical time), which will result in the engine bogging down.

With a closer separation angle, the intake valve opens and closes sooner. Thus, as an engine runs at lower crankshaft speeds (lower rpm) the valve opens sooner in the crankshaft cycle, and at lower speeds everything is slowed down, including how long it takes the valve to close again. This will allow more fuel into the cylinder, making more power at lower rpm. However, as you increase speeds, the valve is open for a shorter period of time, not allowing as much charge into the engine, so the engine will not make as much power at higher rpm. A closer separation angle is good for lower rpm, where most of our street driving is done. A wider separation angle is better for mid-range and higher rpm, where a higher-rpm race engine runs.

TUNING WITH OVERLAP

We stated earlier that overlap is very important in tuning how your engine performs. The amount of overlap (when both the intake and the exhaust valve on the same cylinder are open simultaneously) will determine how much the end of the exhaust cycle pulls the intake charge into the cylinder. Obviously, the more air/fuel you have in the cylinder, the stronger your engine is going to run. The right amount of overlap will help fill the cylinder. However, too much overlap will hurt performance because there comes a time when the air/fuel mixture will start escaping out the exhaust port if the exhaust valve hangs open for too long. The engine components used are factors in selecting the amount of overlap the engine needs.

For instance, if you have huge combustion chamber and a high-rpm engine, you will need all the scavenging effect you can get from overlap to help fill the cylinder. Big-inch engines will also need this help. However, if you have a small-displacement engine with small combustion chambers, you will lose intake charge (and therefore power) if you have too much overlap, as the exhaust valve stays open and allows the incoming charge to escape the cylinder out the exhaust port. The velocity of your intake ports and manifold runners will also affect how much overlap you need. If you have very high-velocity ports, they wonʼt need as much help filling the cylinders; but again, this will also be affected by the displacement of the engine.

In the end, it all has to work as a complete package. If youʼre running stock heads on a small block and plan to drive it primarily on the street, youʼd want to select a cam with overlap and duration that will work with smaller combustion chambers, smaller displacement and lower rpm. A huge lobe separation angle and a lot of overlap is going to overfill the combustion chamber, making the engine bog down off idle, while the over-scavenged charge that escaped into the exhaust port is going to ignite there, leading to cherry red headers. (But itʼll sound cool!)

By the same token, if youʼre running a big-inch engine with heads that flow like 12-inch water mains, youʼre going to need all the scavenging you can get, since the piston going down the bore isnʼt going to create enough vacuum to pull in an adequate intake charge.

Thereʼs no doubt that there is a lot of information to digest here, but taking it in small bites will make it easier to process. Getting a hold of a Comp Cams catalog will also help explain things. But if all else fails and you still donʼt really understand how crankshaft rotation, camshaft time and the resultant characteristics affect an engineʼs performance, the second-best thing you can do is call a manufacturerʼs tech line or a trusted machinist/engine builder. Ask what he recommends. The smartest thing you can do is follow a professionalʼs advice to the letter, since more than likely he has passed an awful lot of camshafts through an engine to arrive at his conclusions.

ARTICLE SOURCES

Comp Cams

A Division of Edelbrock

8649 Hacks Cross Rd.

Olive Branch, MS. 38654

1-800-999-0853