THE AUTO BUILDER

Featured

Two-Day Trunk

History of the The Grand National Roadster Show Hall of Fame

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

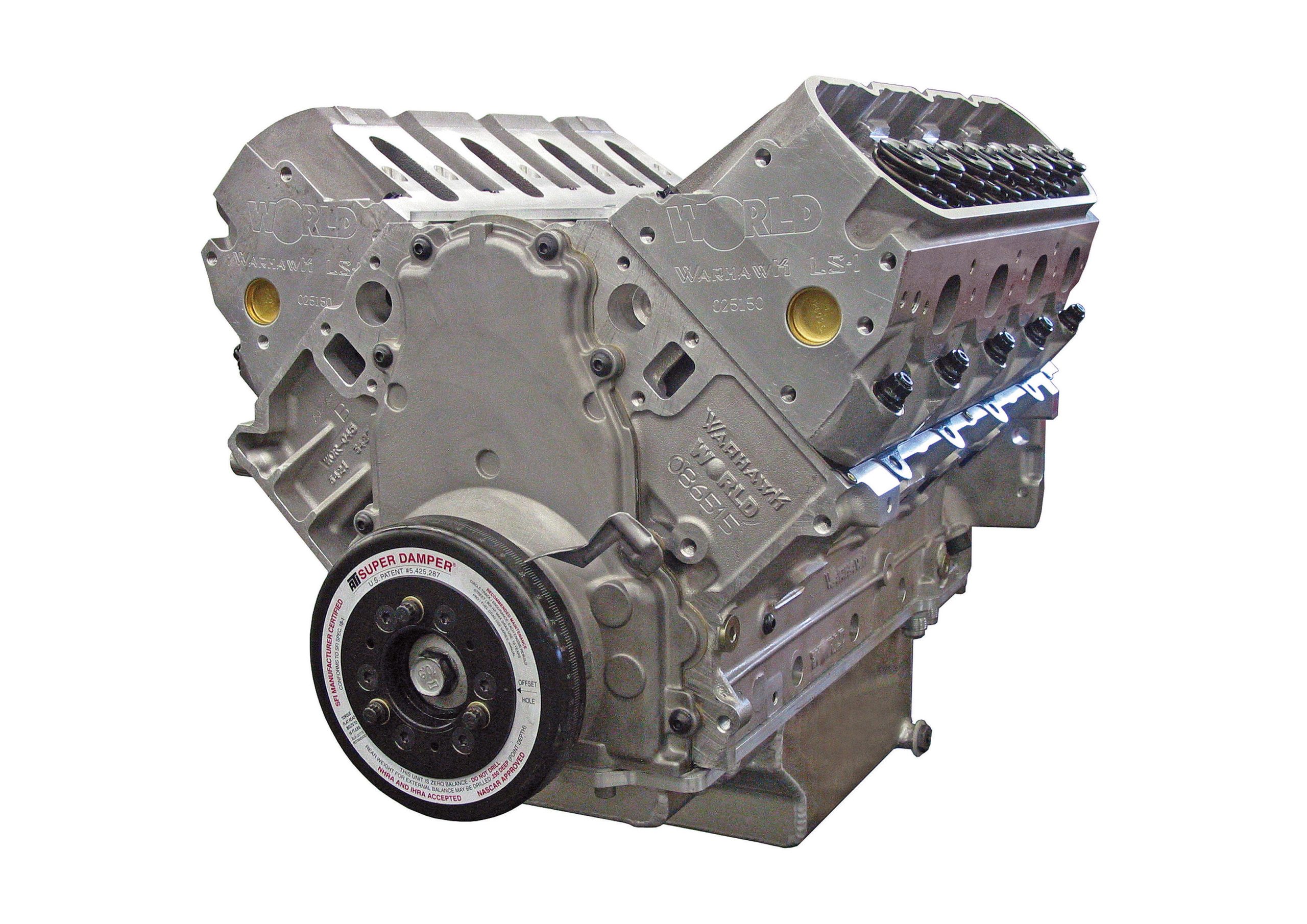

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

628HP LS7X BUILD

Taking the Already-Efficient High-Line LS-Series Small Block to a New Level of Performance—They Call It the LS7X

Author

Stephen K. Anderson

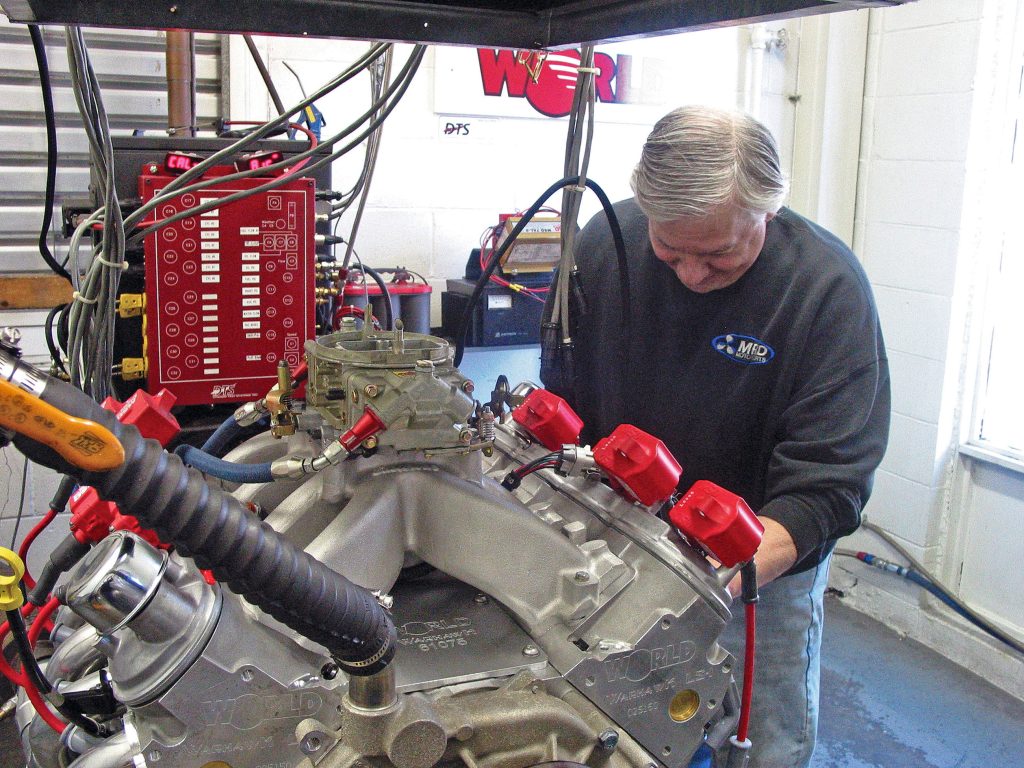

Photography Courtesy Bill Mitchell Perfromance (World Castings)

The Thrill of Horsepower and Torque

Some of the greatest feelings in life come with a rise in rpm, a dropped clutch and tests of traction stretching the boundaries of our physiology. These are the emotions many of us cherish, and while many factors can evoke such emotions, the single most influential force behind these kinetic kicks is torque (which is then equated into horsepower).

Components Behind the Numbers

Beyond these numbers are the components united to produce the measurable results we long for, which in the end are the efficiency and dependability of all the individual components we unite that determine our return on investment and, more important, the level of excitement created between the gas pedal and the pavement below.

Room for Improvement Beyond Factory Performance

While automakers have gone to considerable lengths to expand the output and efficiency of today’s engines, continually refining existing designs, as well as searching for that next new level of internal-combustion components, there is often room for improvement in what the factories provide, as the final result must comply with warranty and emissions constraints—an extremely complex equation. They are also governed by cost constraints levied by bean counters and myopic managers with little or no understanding of performance, or the real cost of innovation. Engineering improvements are often not enough, as they too are governed by the cost of development. What really matters—beyond the end use that the engine and its parts were originally designed for—reflects on the capability within the field, and how enthusiasts and high-performance purists put them into application.

Extracting the Power Left on the Table

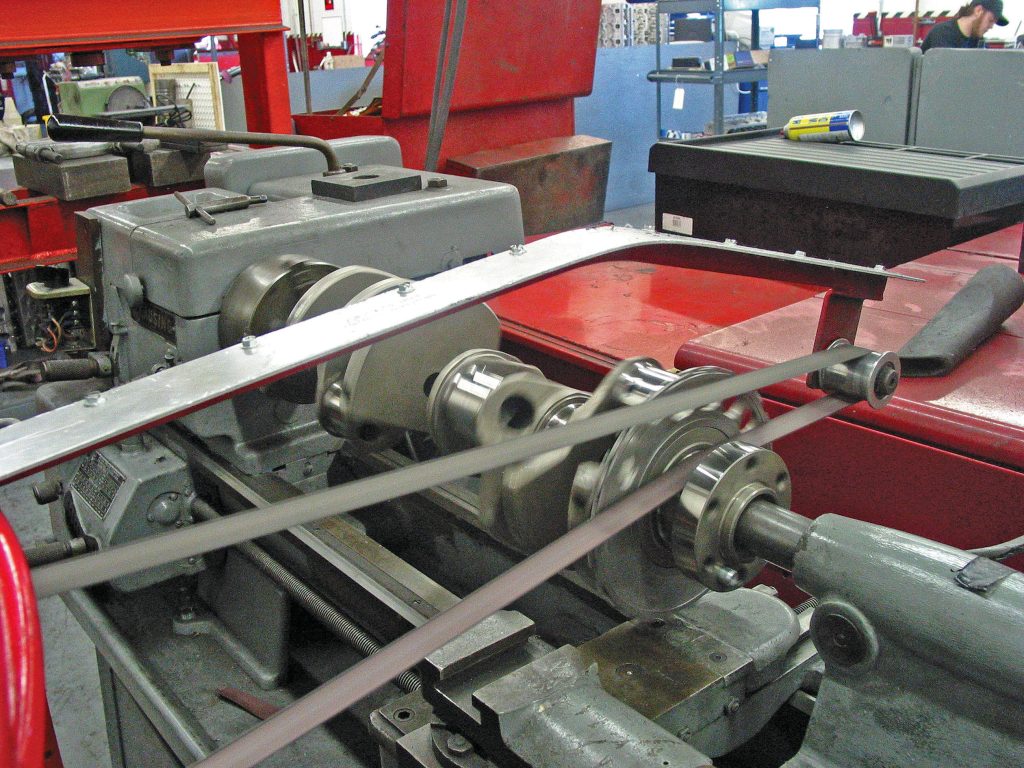

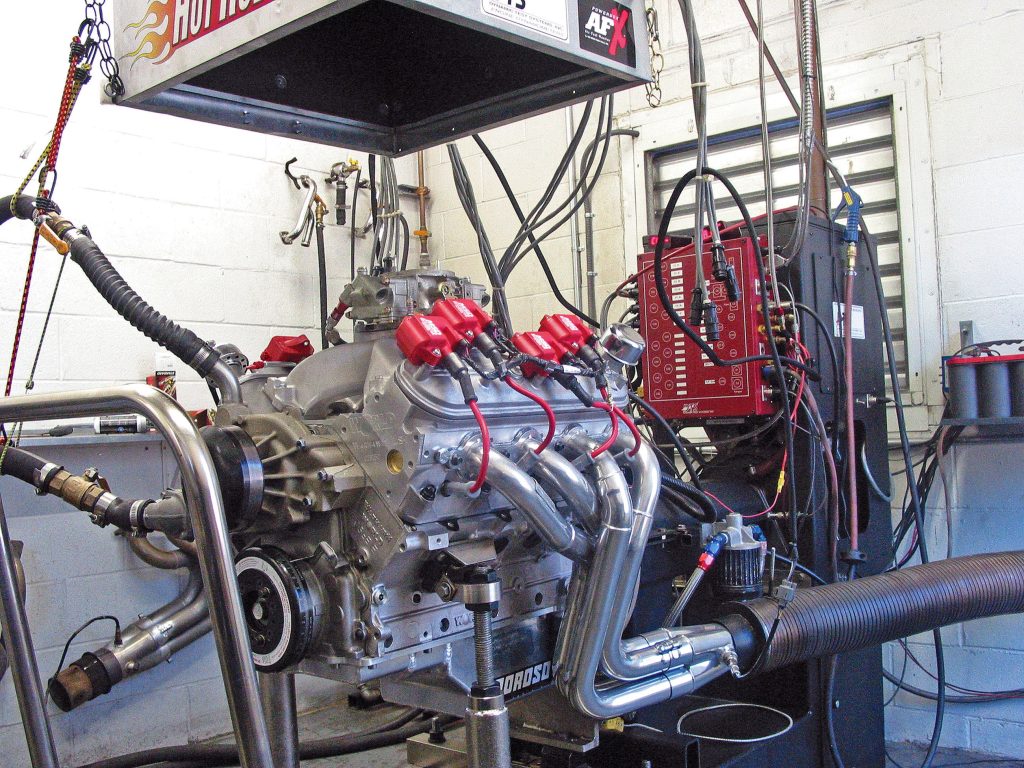

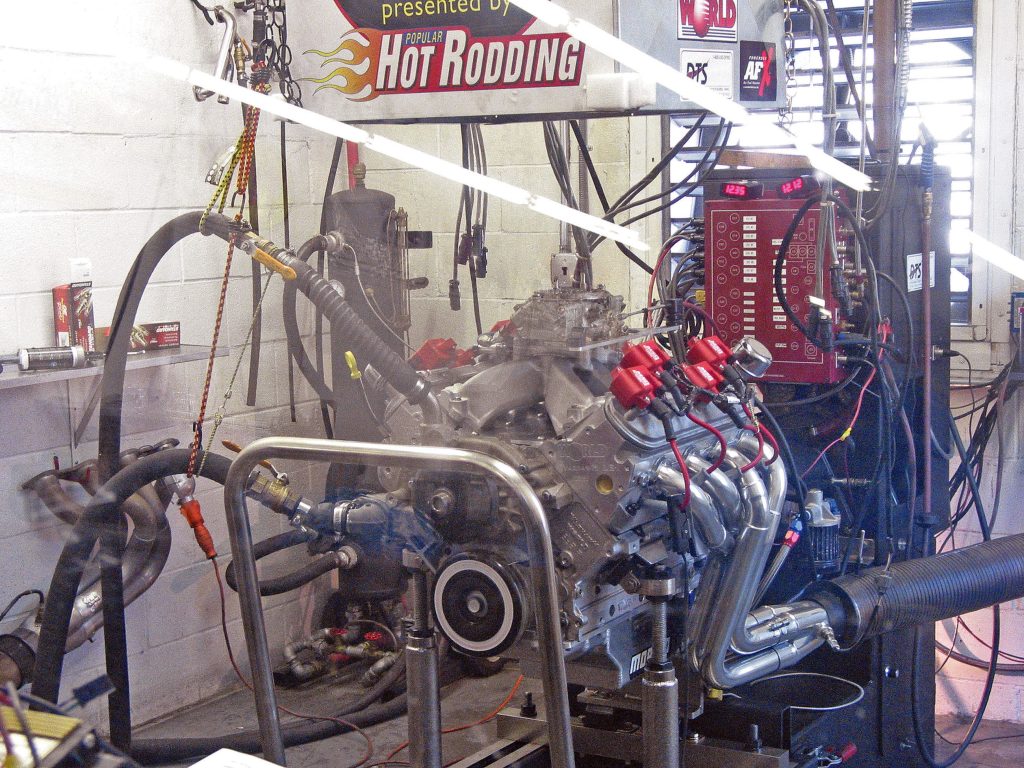

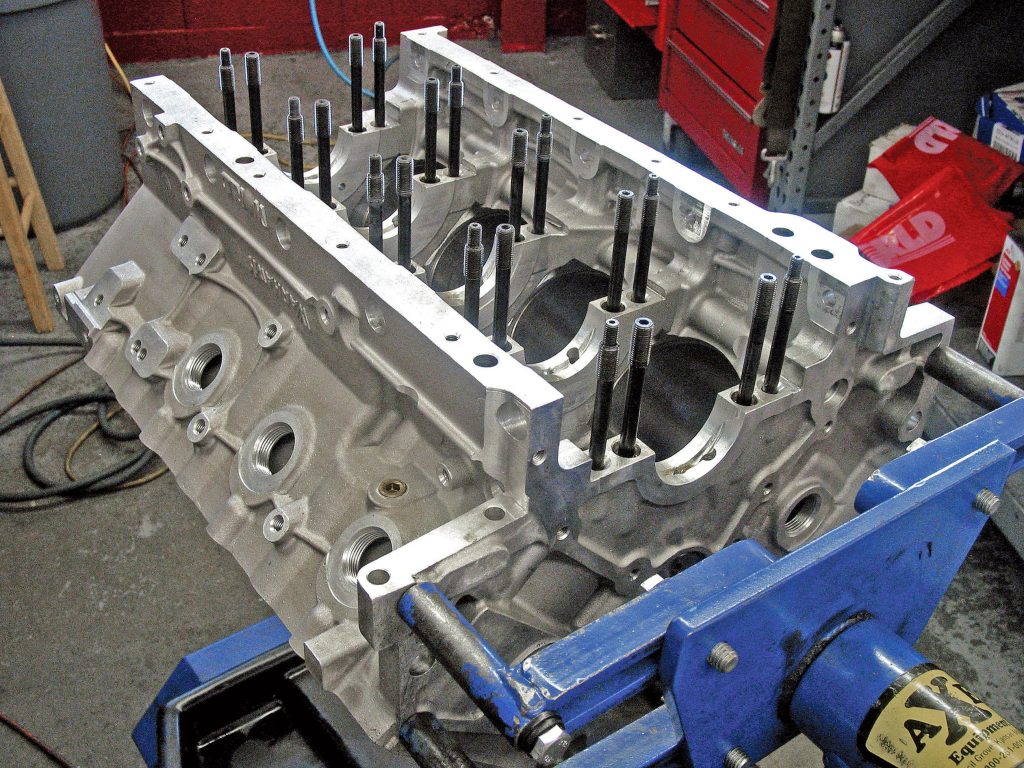

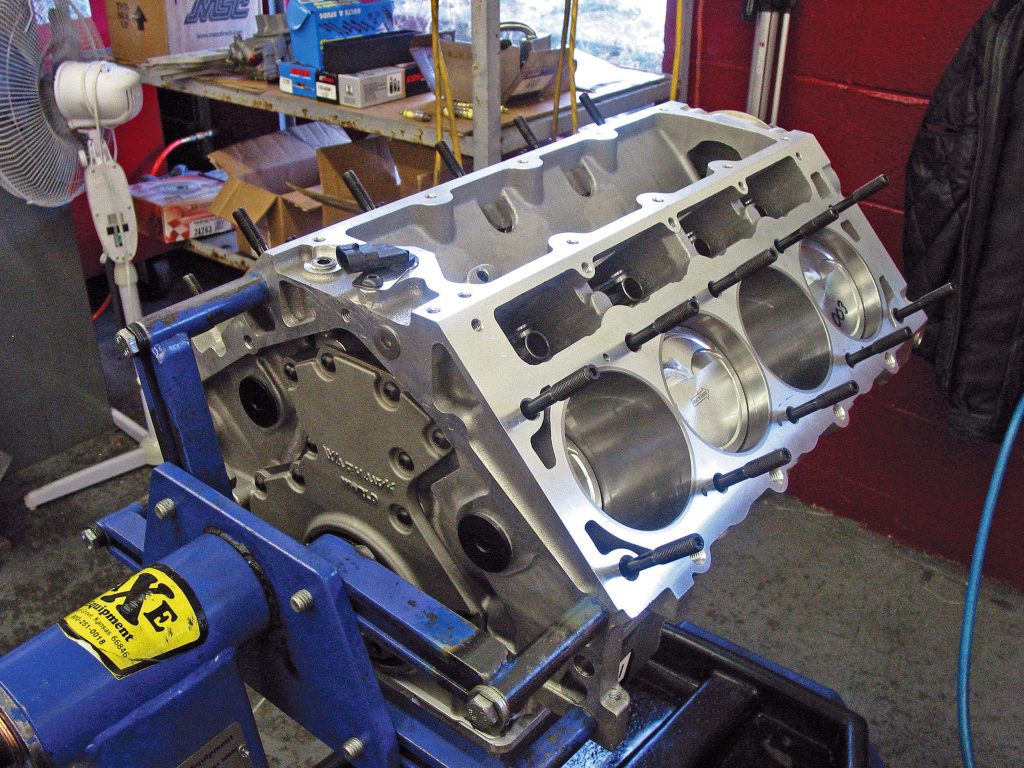

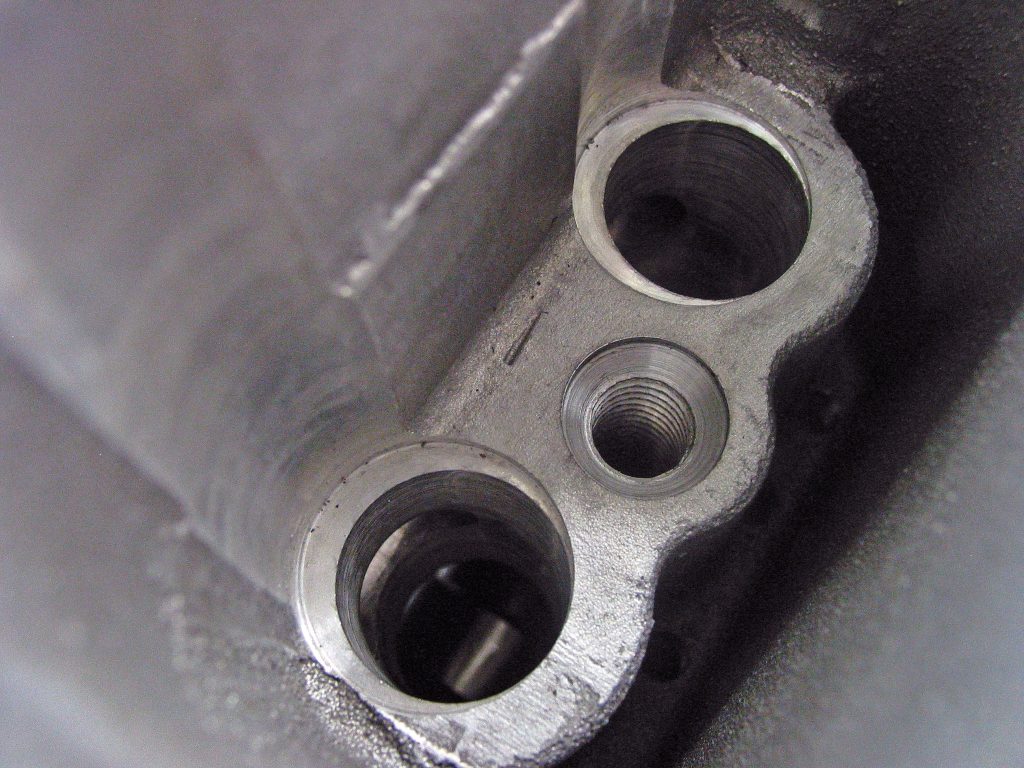

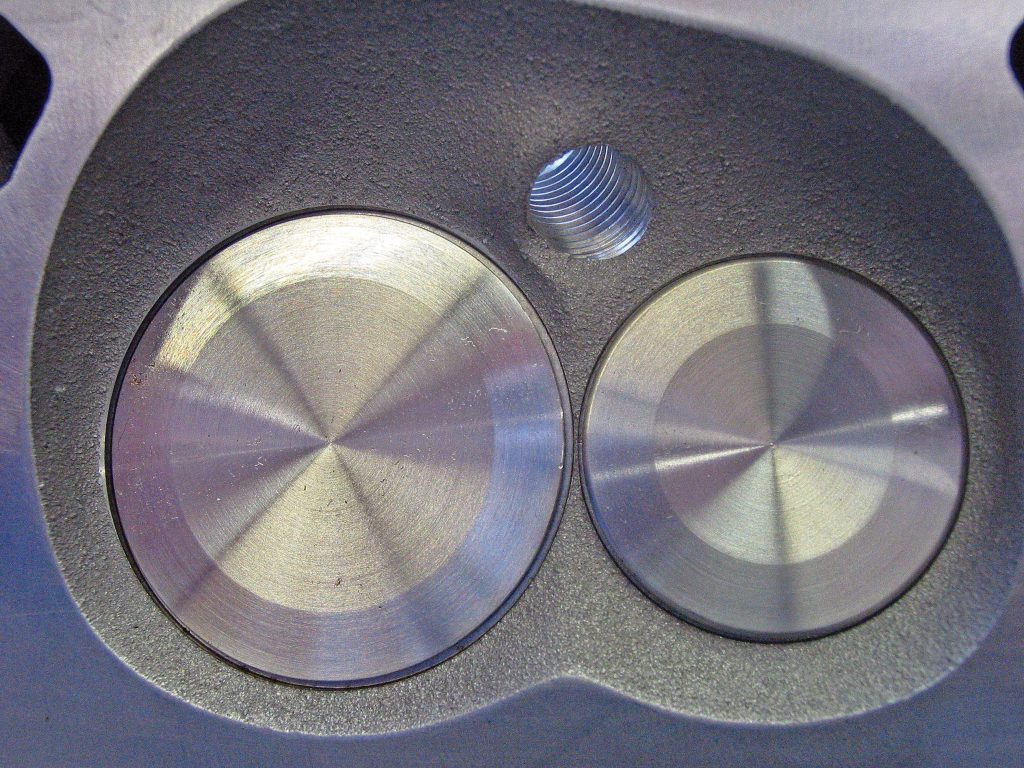

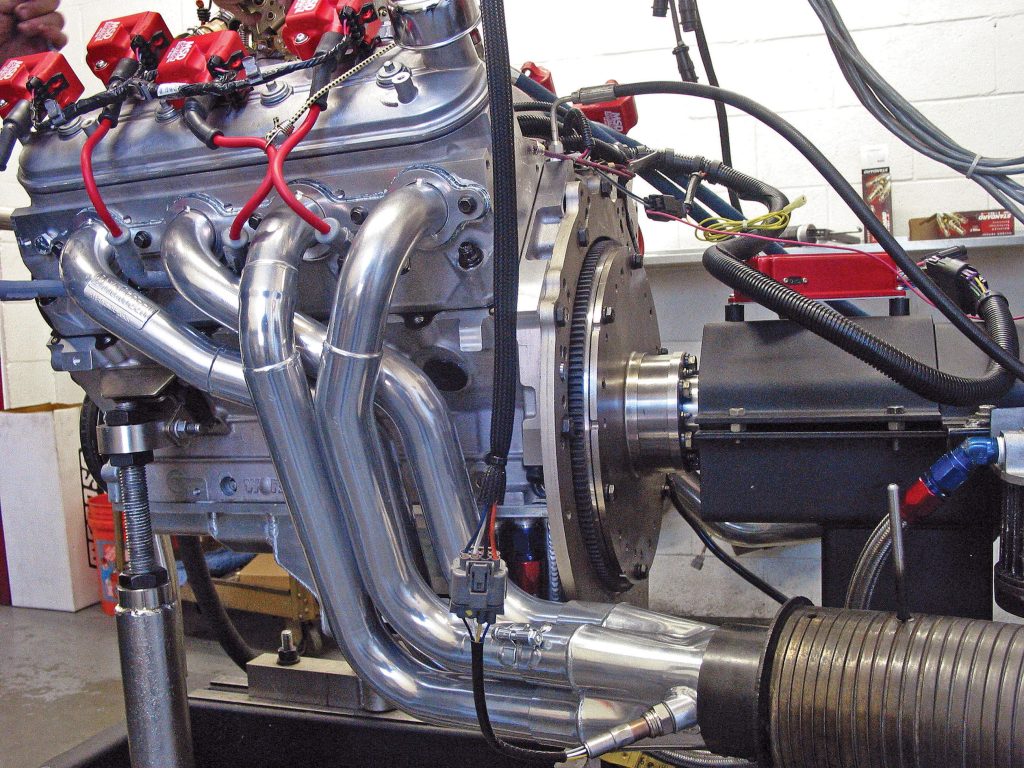

With power left on the table, it is the goal of the enthusiast to extract that power. Enter all manner of high-performance add-ons and power enhancers that will test the mettle of anything Detroit has to offer. And this is where some assemblies get into trouble, and why the small-block Chevy has been the darling of rodders everywhere. Also aware of that power left on the table, World Products understands just where that power was left. As it has repeatedly built upon existing corporate foundations, making them better with enhanced casting cores, this has resulted in its own line of engines, basically. Starting with newly designed components intended to wring out unrealized potential, yet fit within the stock confines (sometimes), these World Products engines are refined to all-new standards. Every one of them purpose-built, the parts and engines go through extensive research and development long before new castings are machined into geometric perfection. Then everything must be tested on the dyno for power and durability. Anything less would be only warmed-over parts. While they may offer improvement, such parts would be prone to breakage, just like the originals, which is why World has gone to such lengths to improve on how the internal parts work in more demanding displacements and power levels within castings that can handle all the abuse.

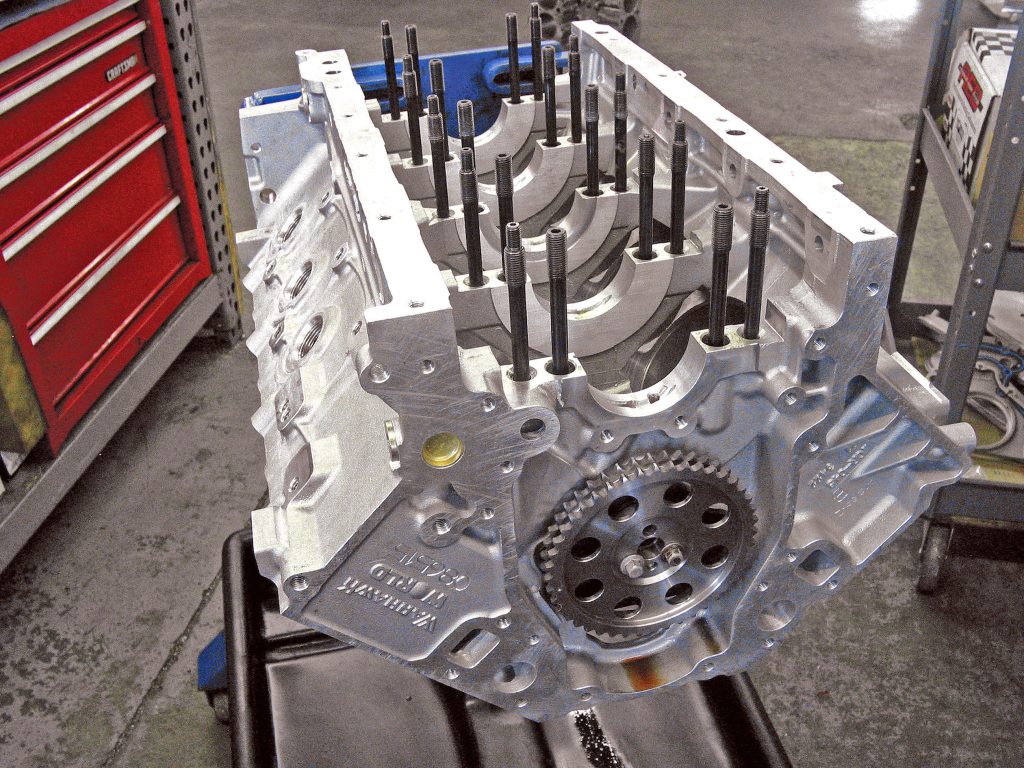

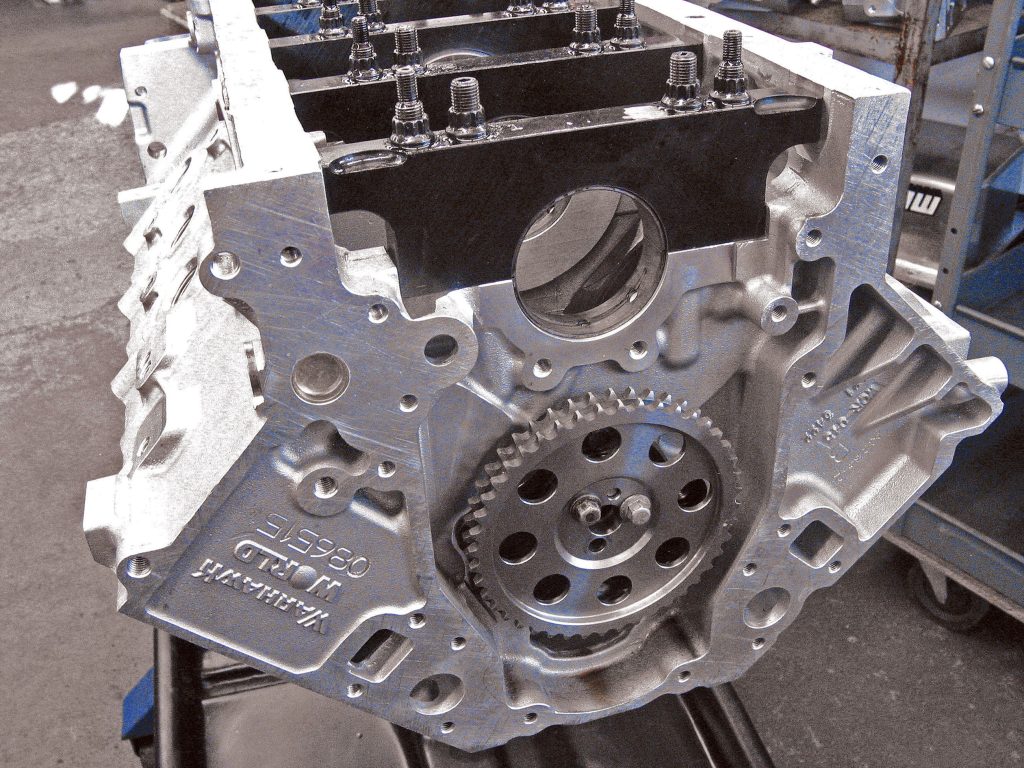

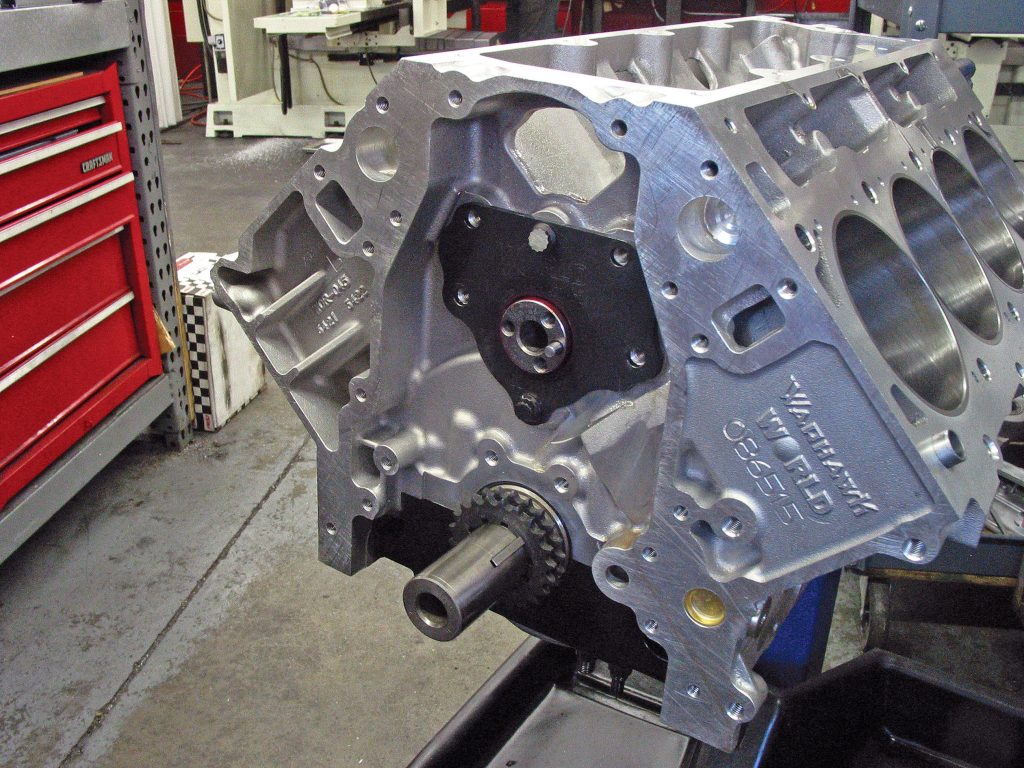

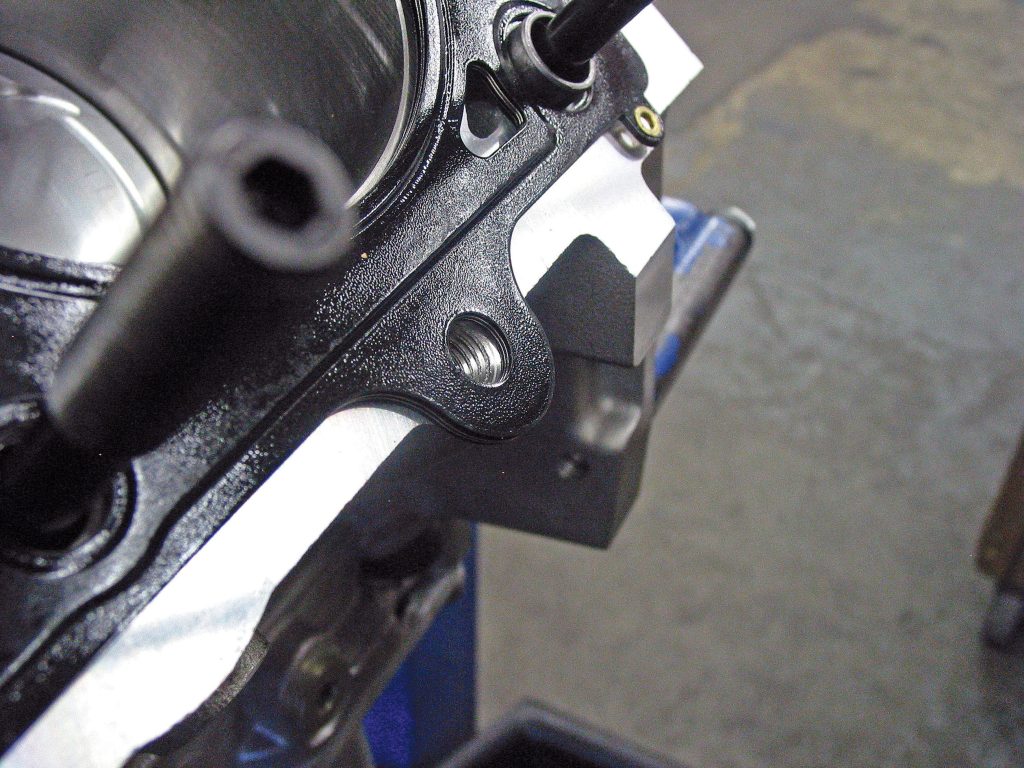

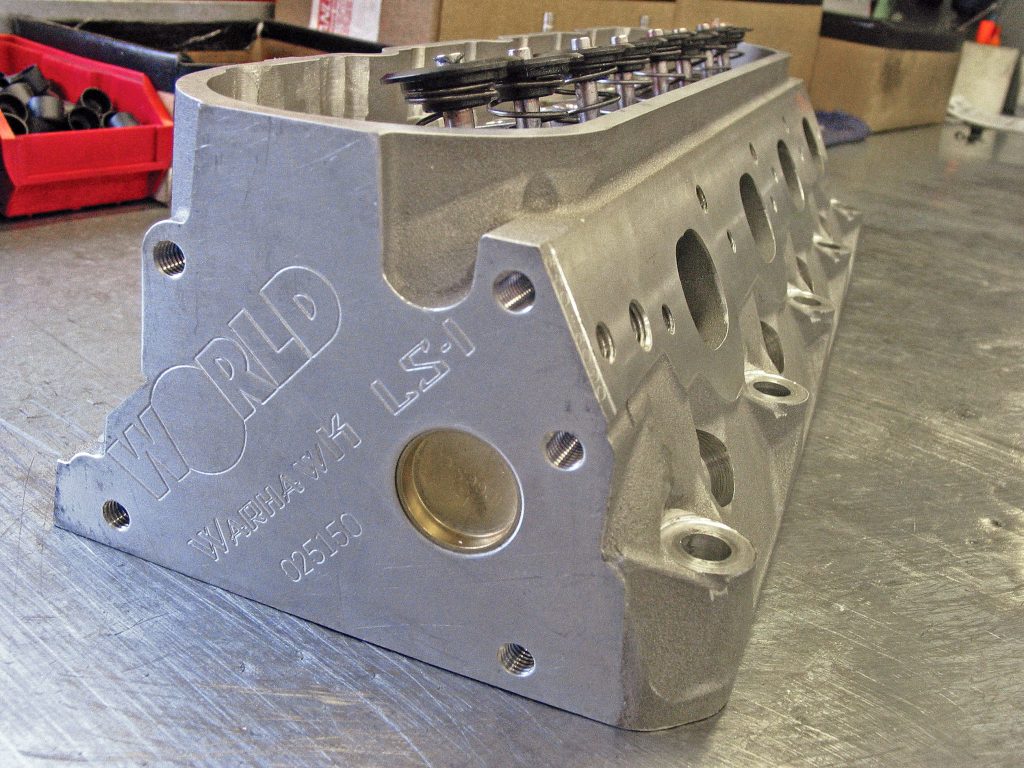

Building Upon Proven GM Foundations

GM built the original LS1 over a decade ago, and World Products built upon the beauty of this simple and highly capable engine design, just as it did with the small block and the infamous Merlin big blocks and heads. Now it has its own line of products that not only replace existing componentry but also improve upon the power capability. From bare blocks to reconfigured cylinder heads, and matching every component in between, it’s easy to see the high-performance benefits of these highly effective components.

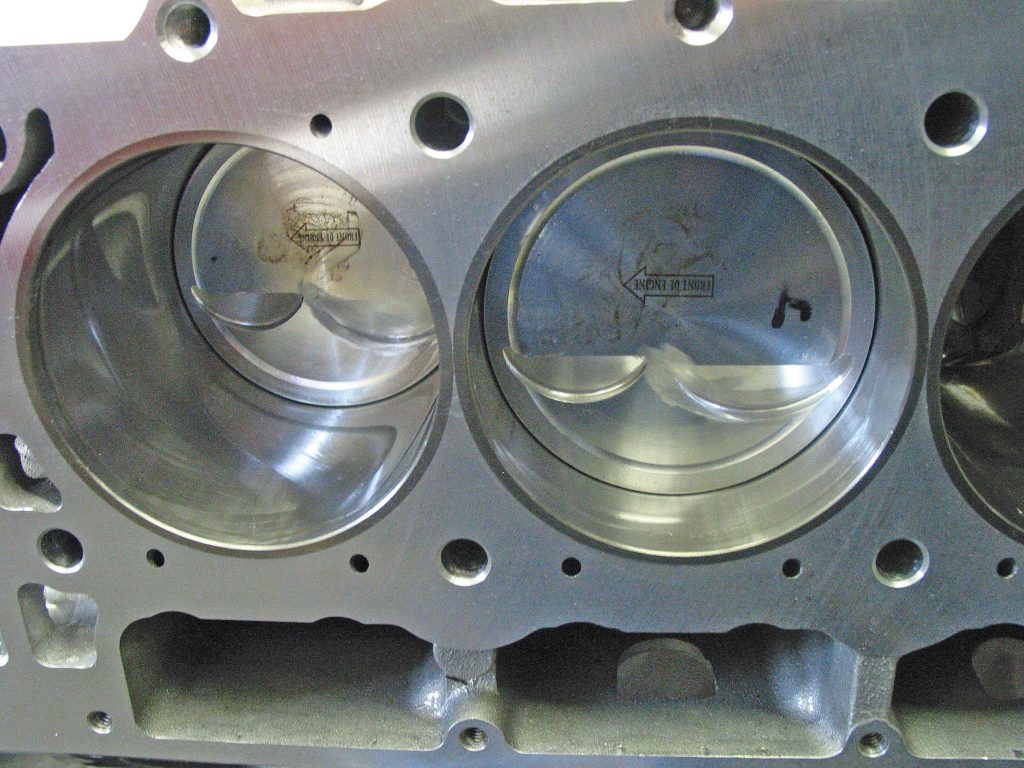

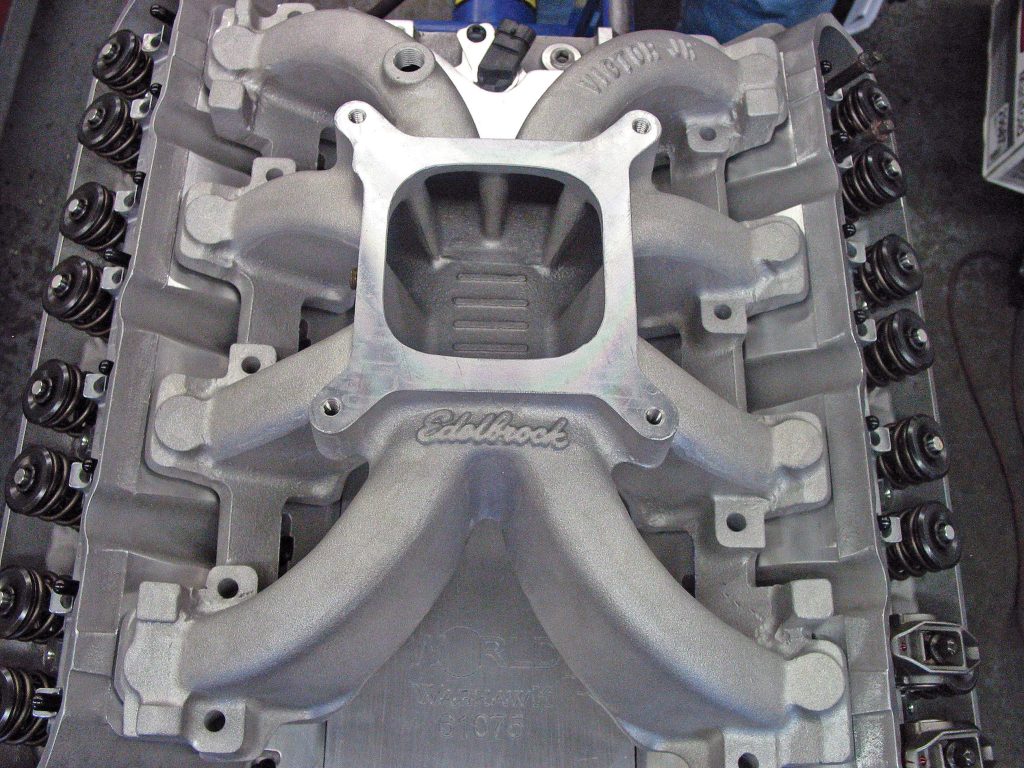

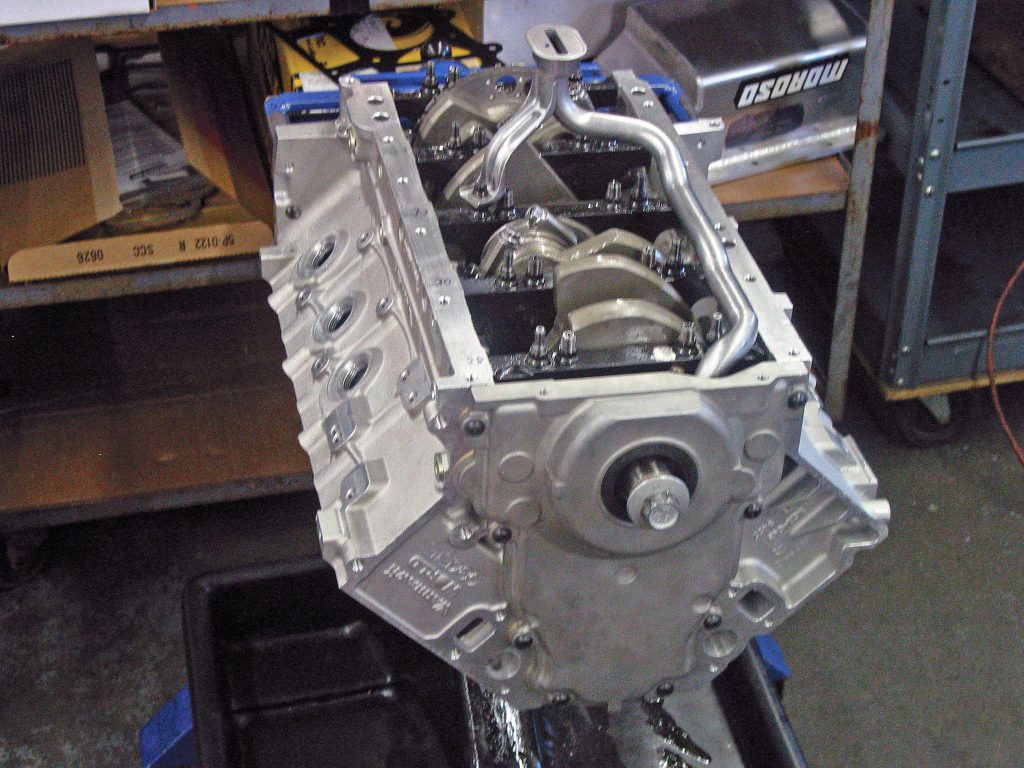

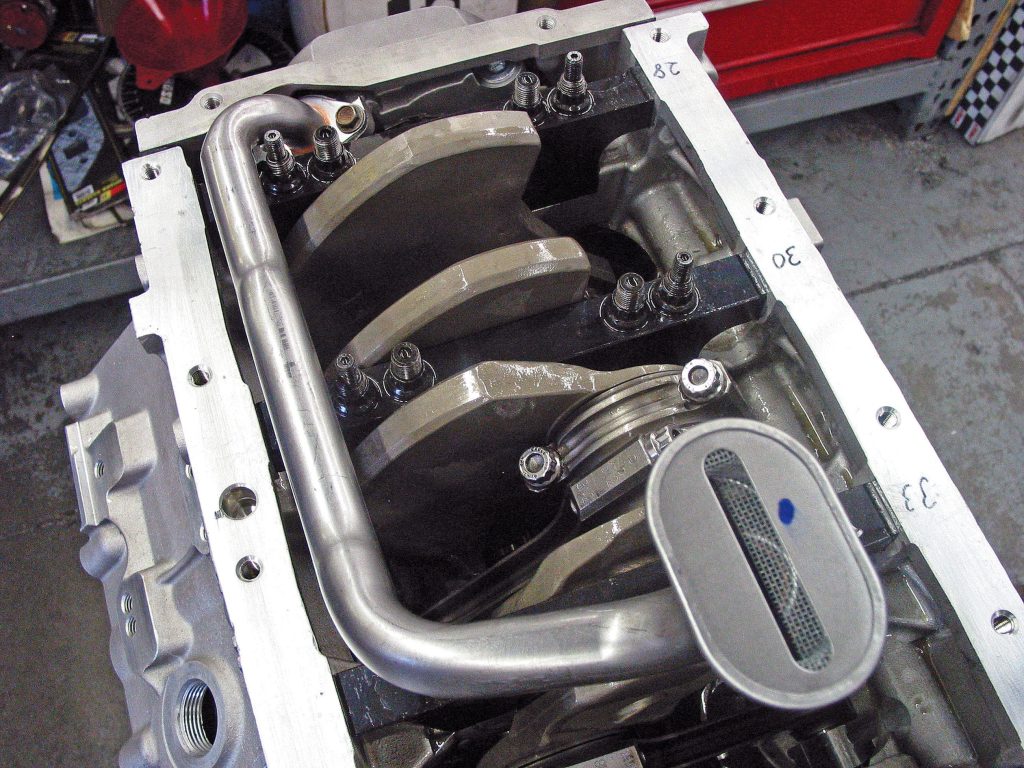

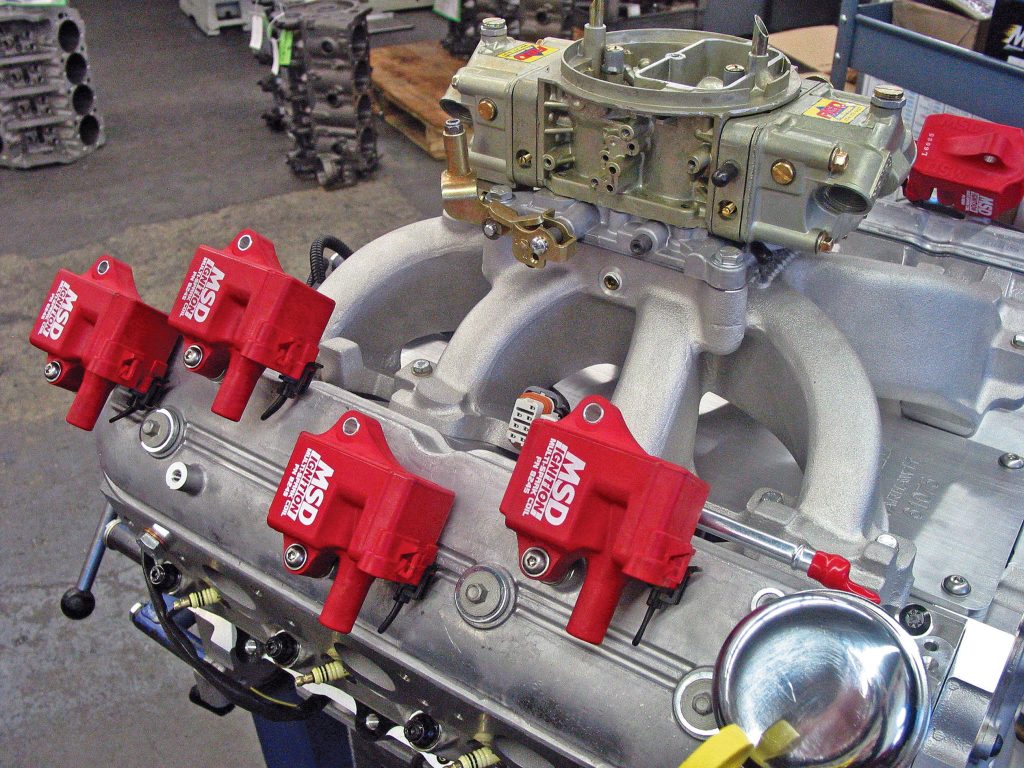

The Evolution of the LS7X Design

That now has been translated to high-level LS designs, improving on the 427-inch naturally aspirated LS7. At World, that translates into a brand-new LS7X design, which we’ve chronicled in Chevy Rumble before. You can have it your way—a complete engine straight off its dyno test and ready for installation, or you can opt for a partial engine assembly so you can incorporate a specific induction system, or whatever else you wish to personalize. Or you can buy all of the parts and build your own. As with all World engines, and the parts that fill them, when you consider a World Products high-output crate engine as special as the LS7X, know that they are built to provide a reliable and powerful return on the dollars spent, which was the whole idea of this design improvement in the first place.

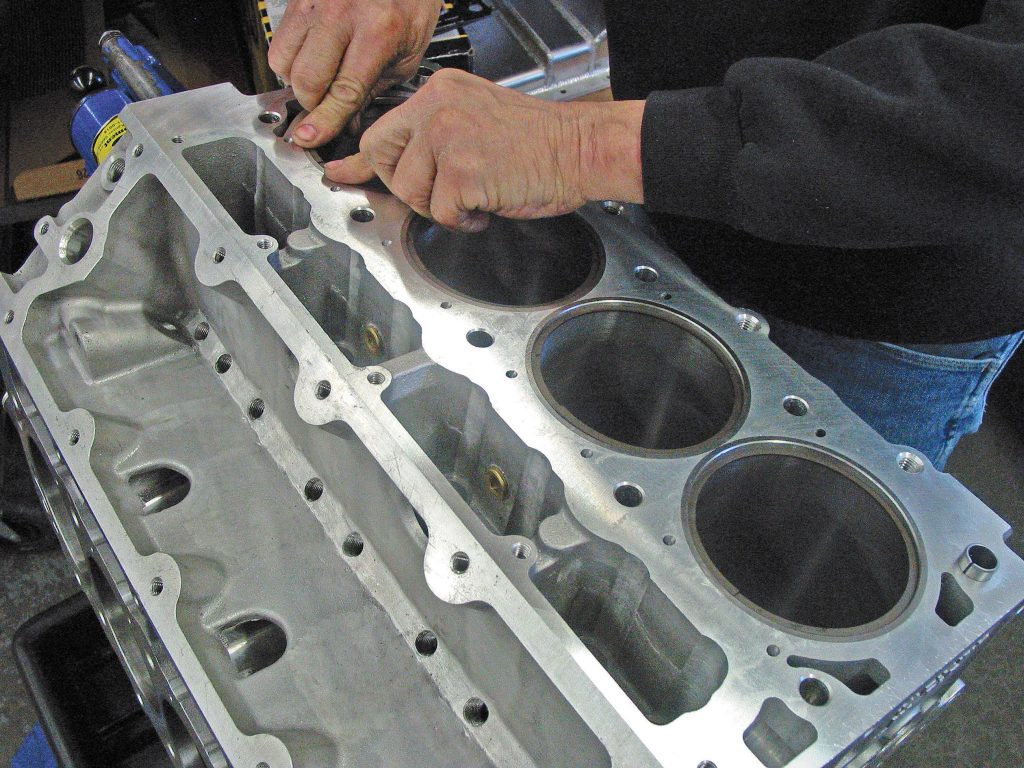

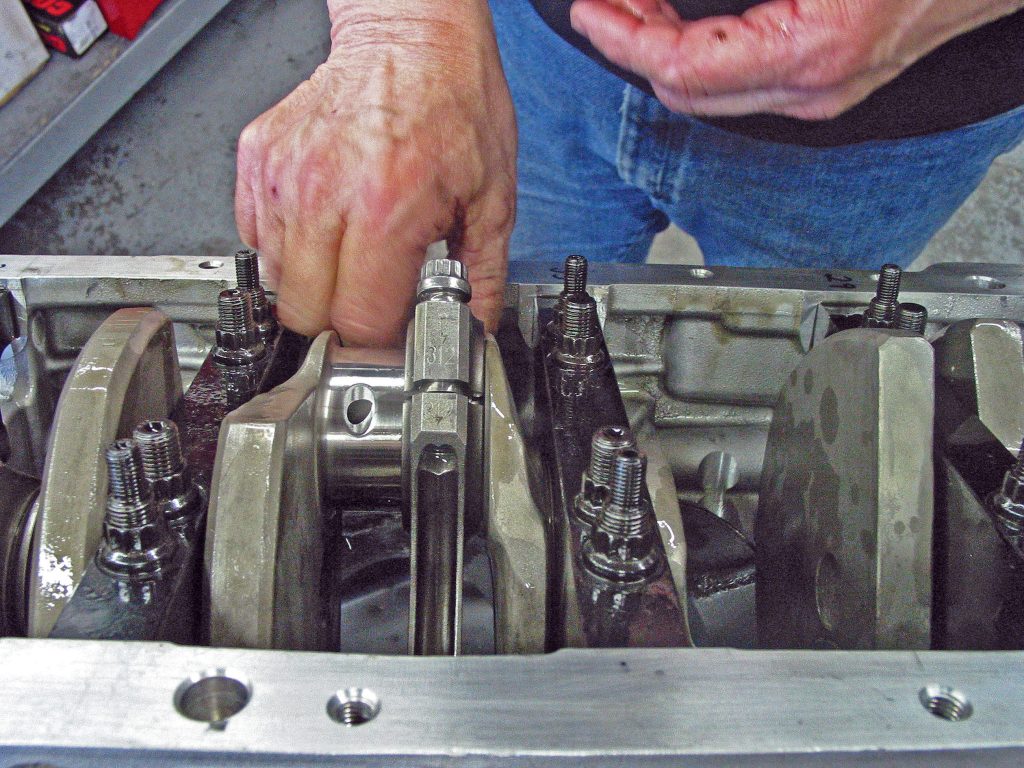

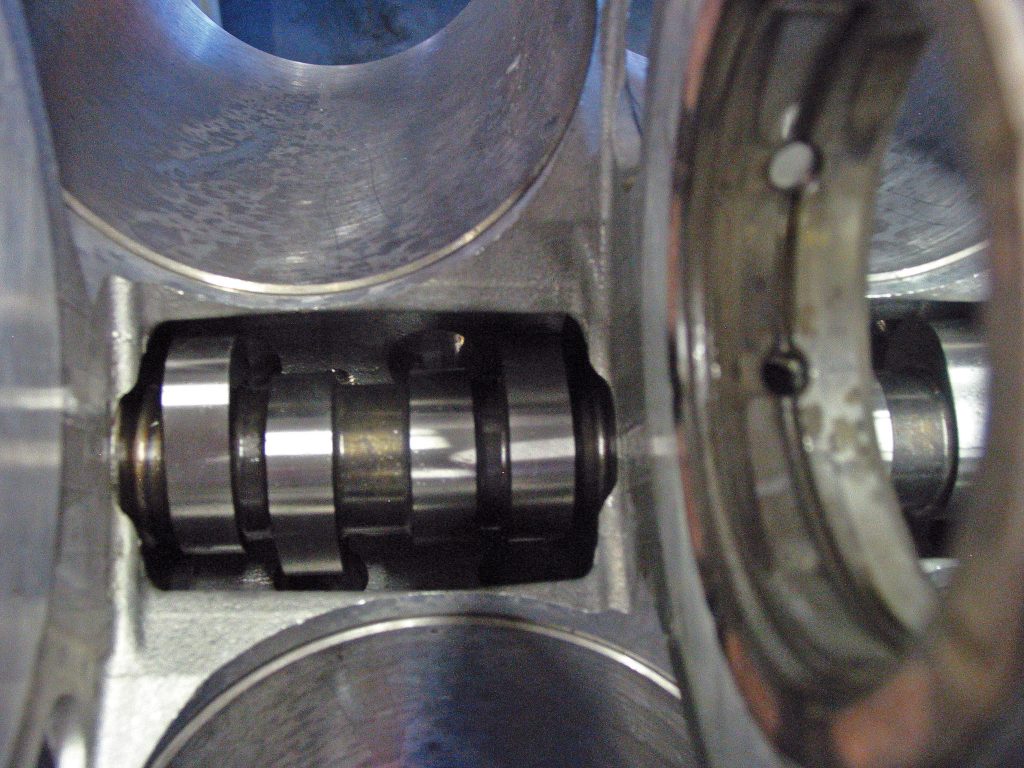

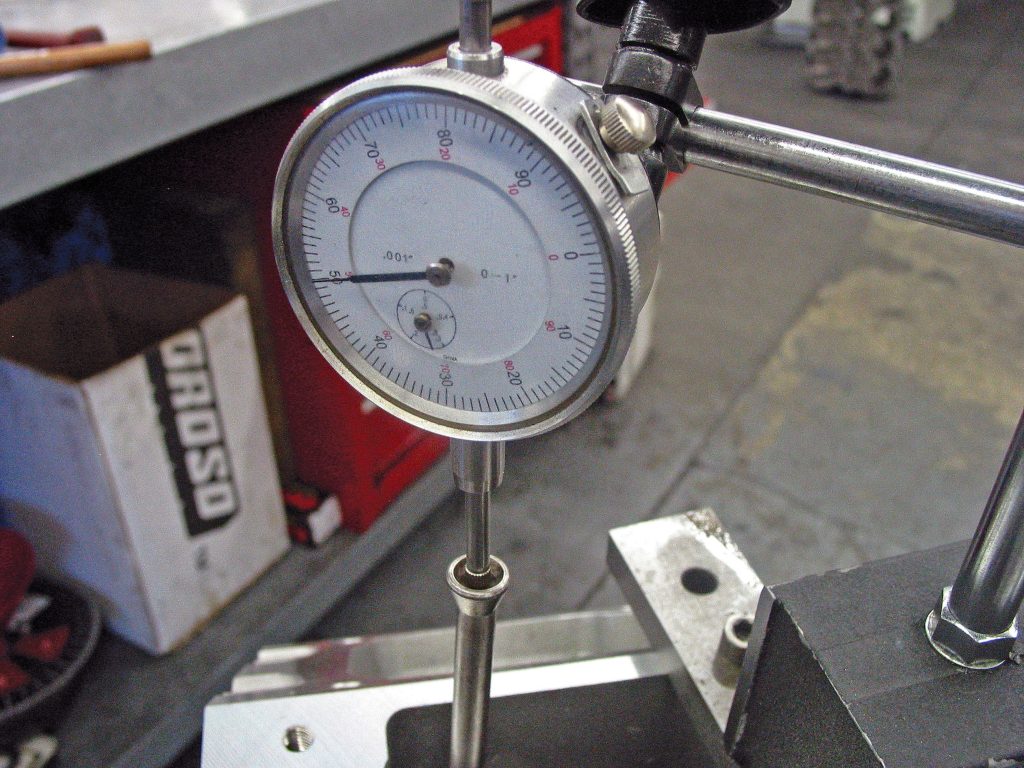

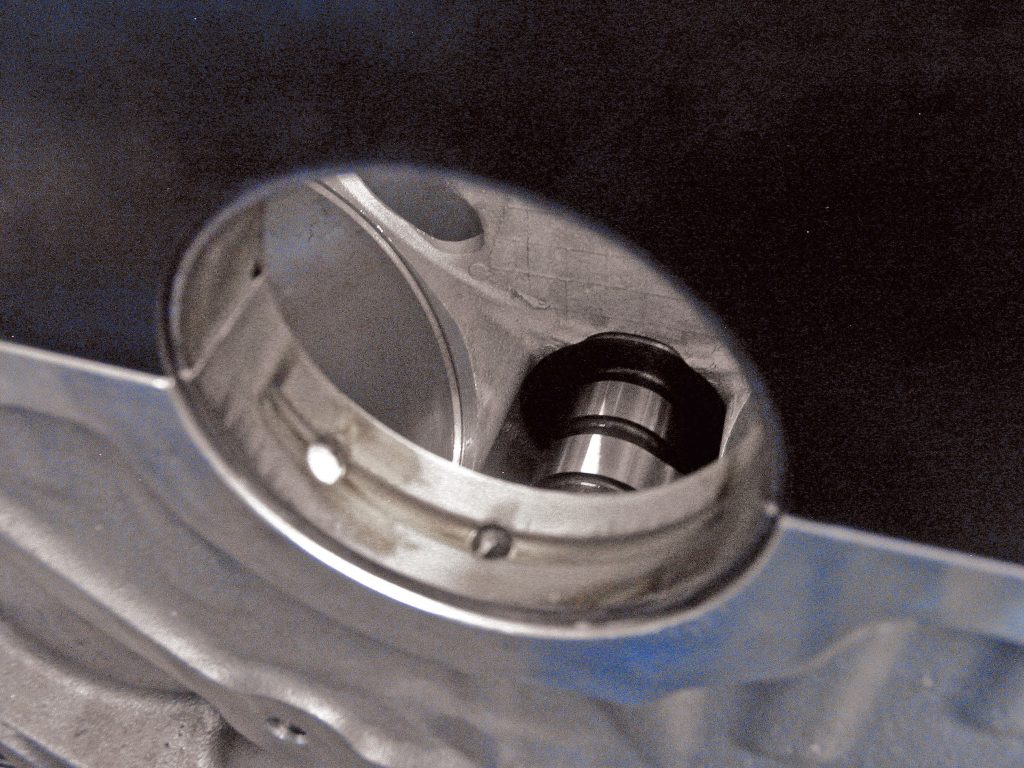

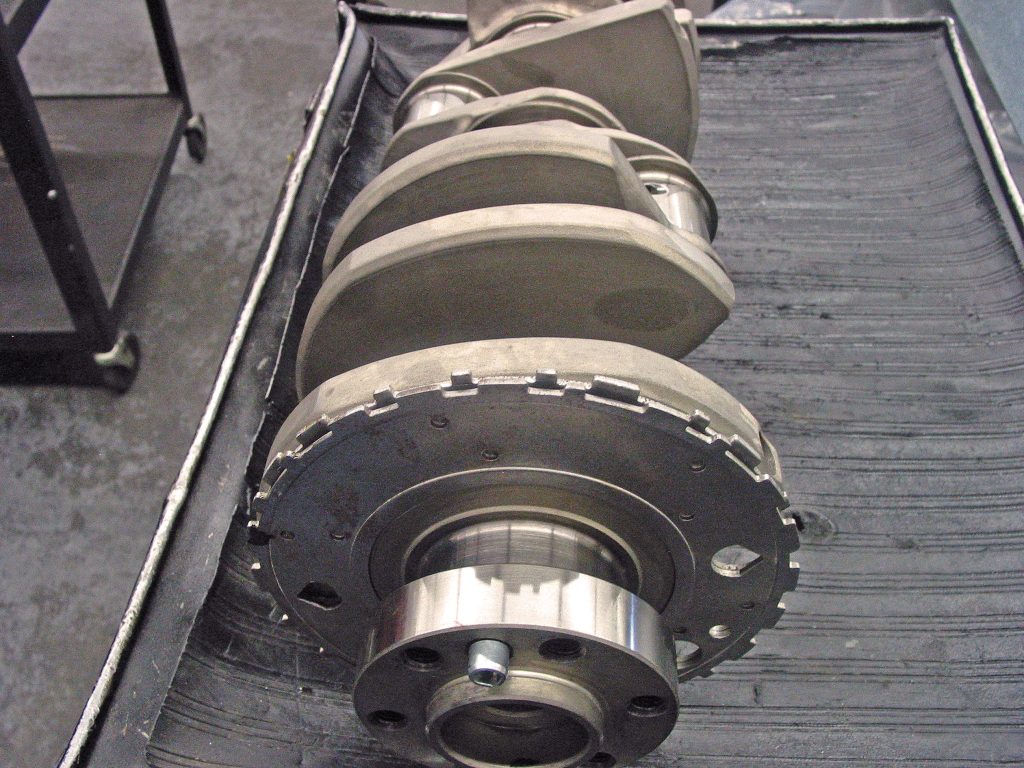

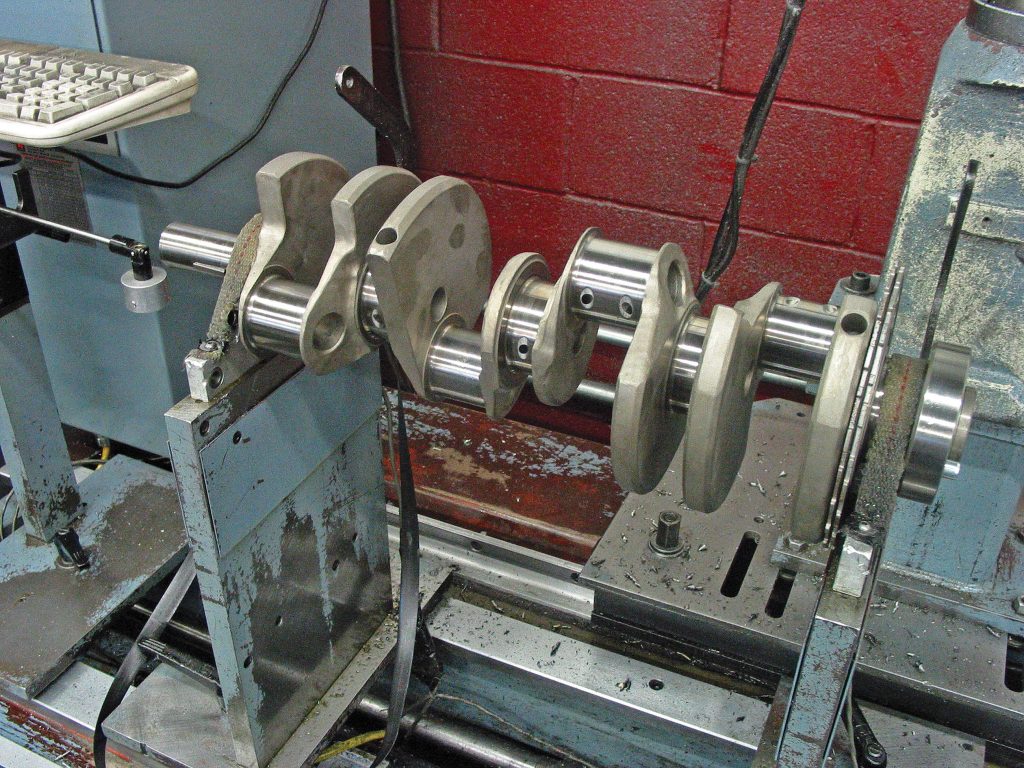

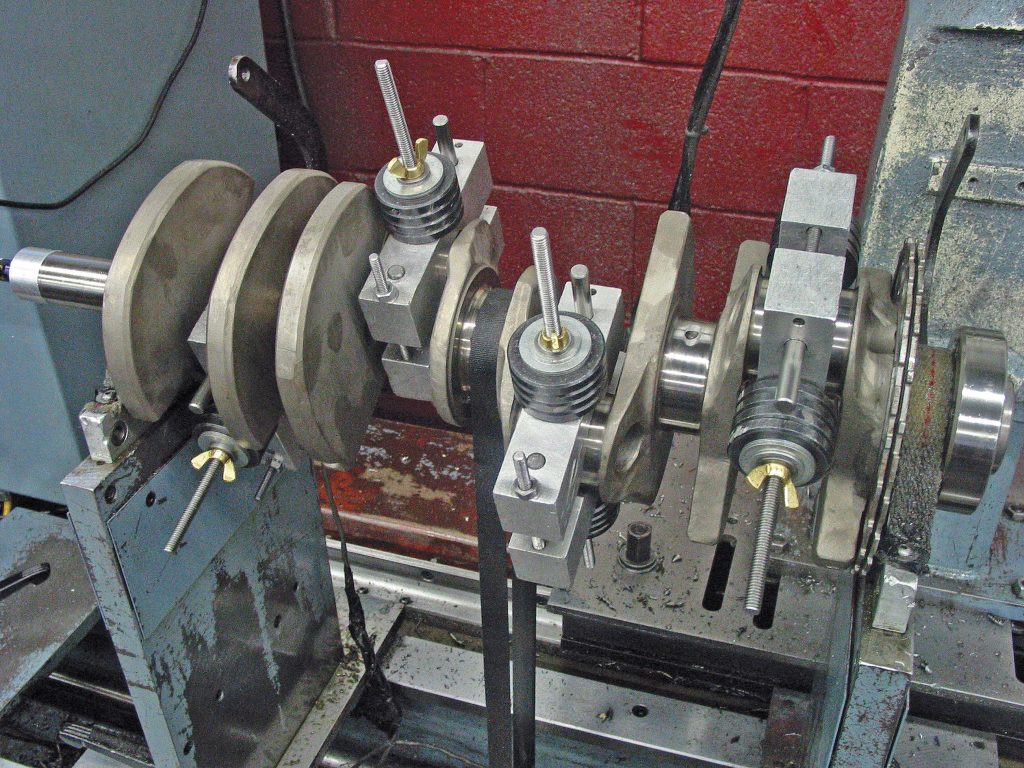

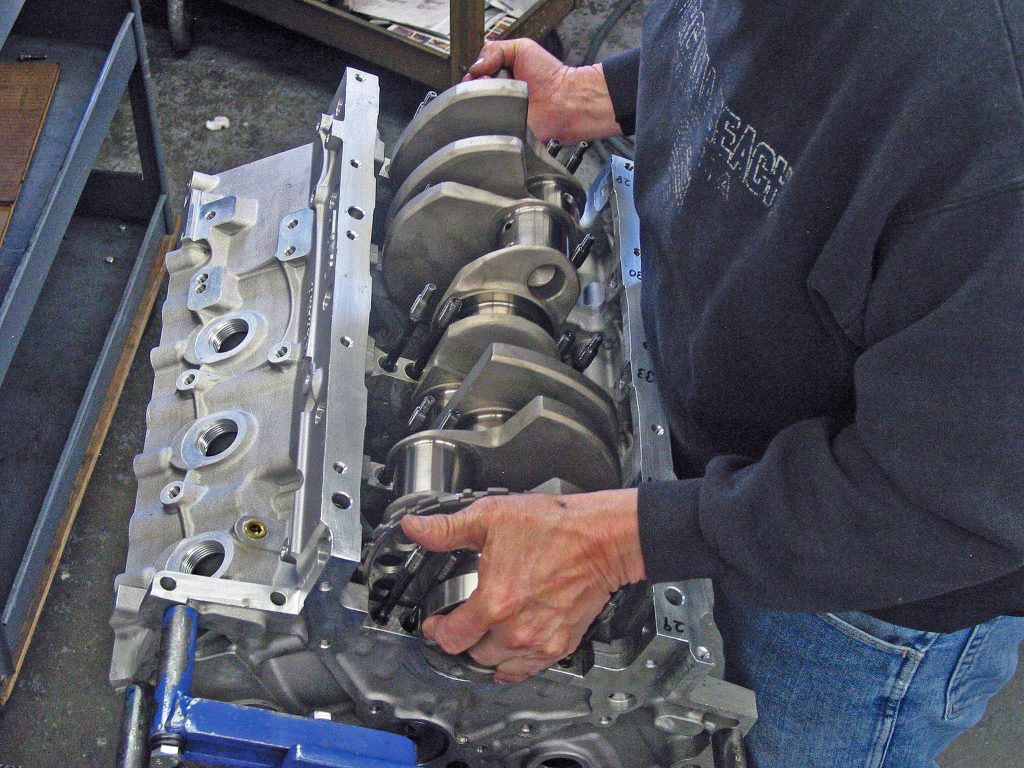

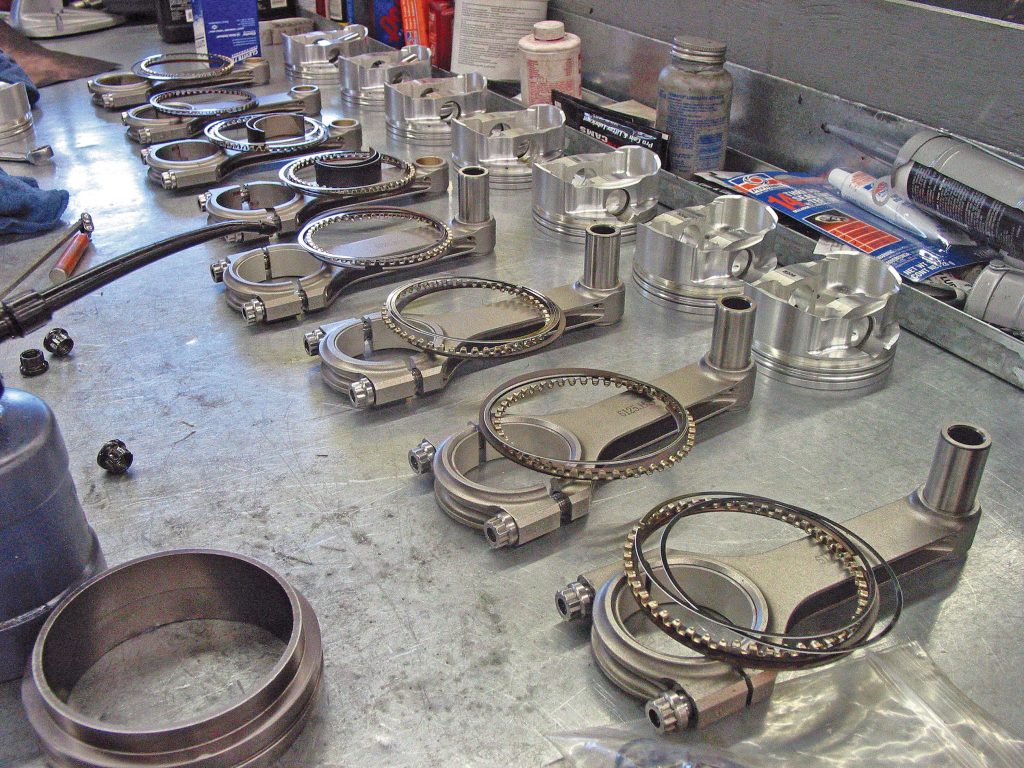

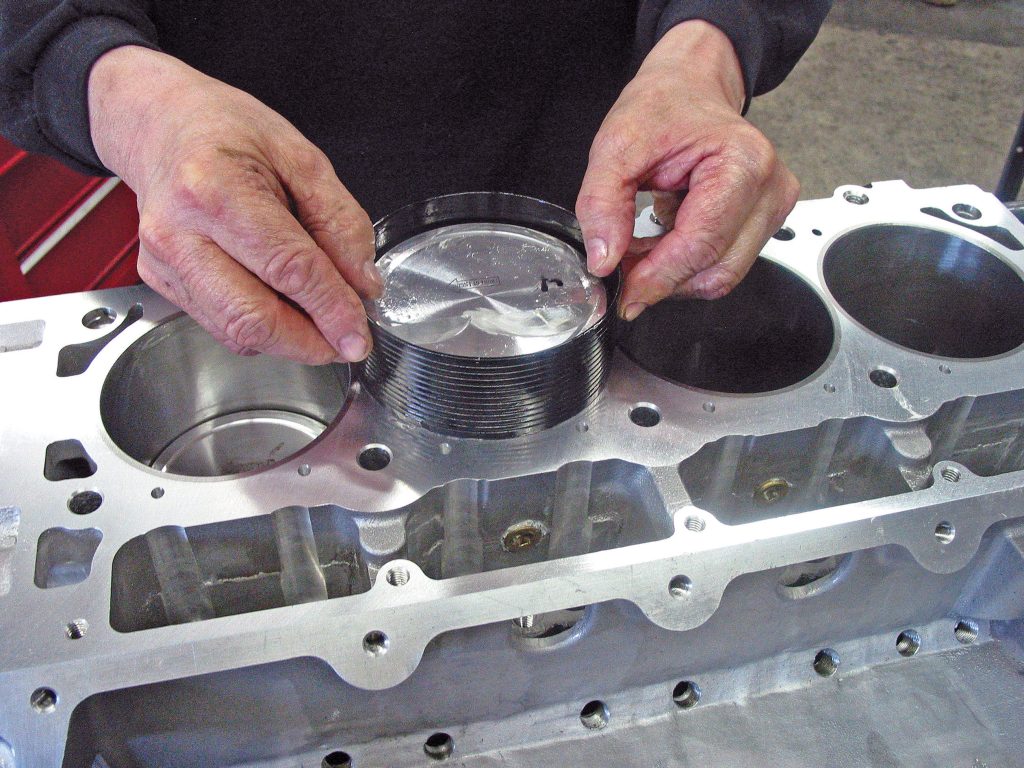

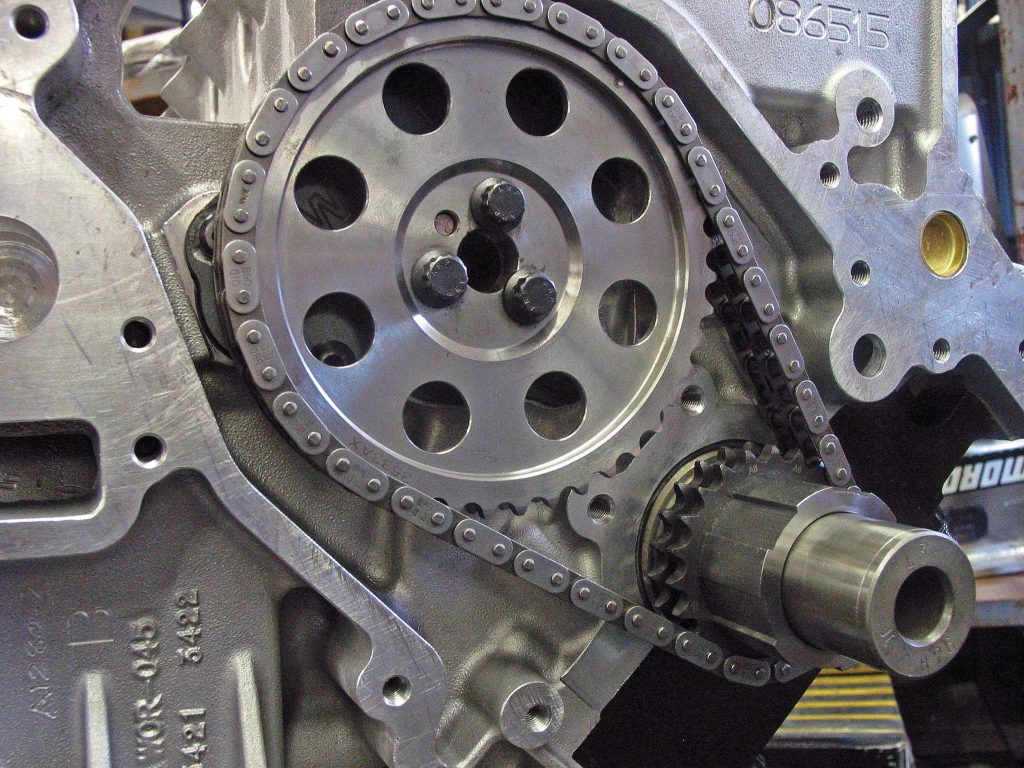

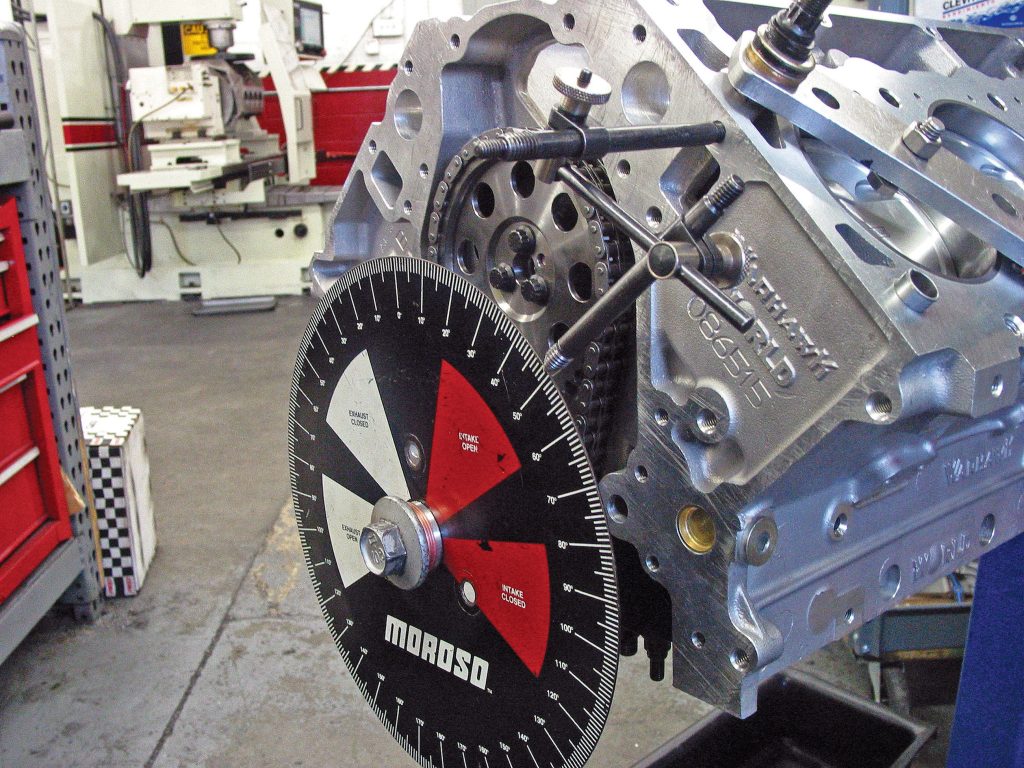

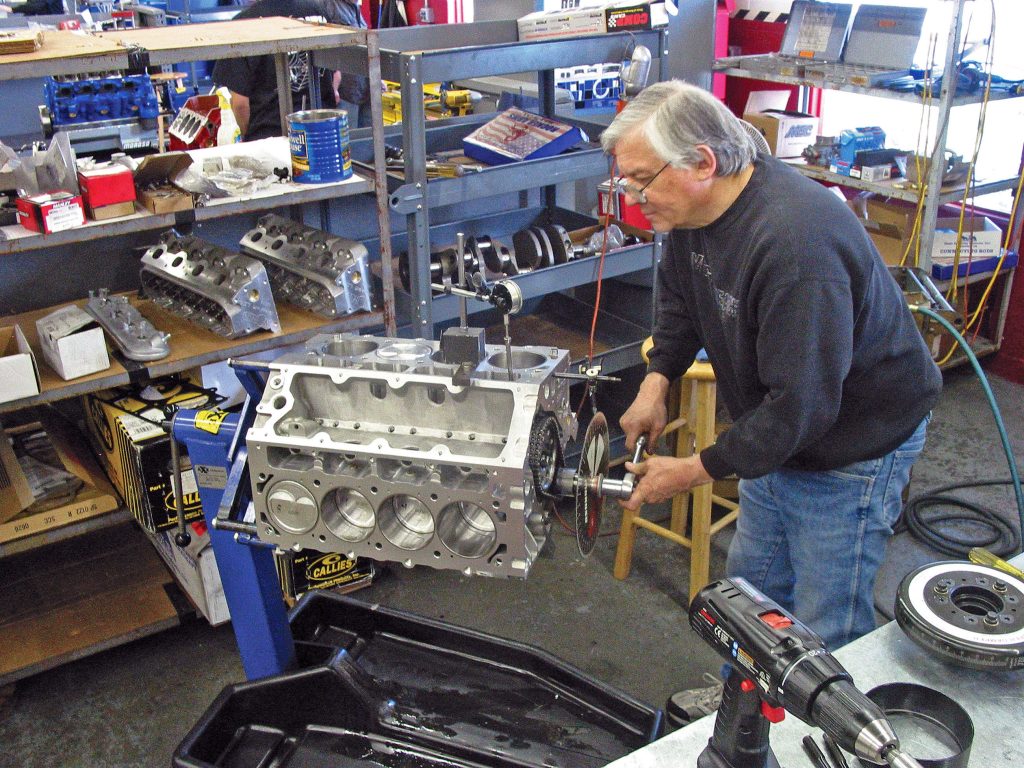

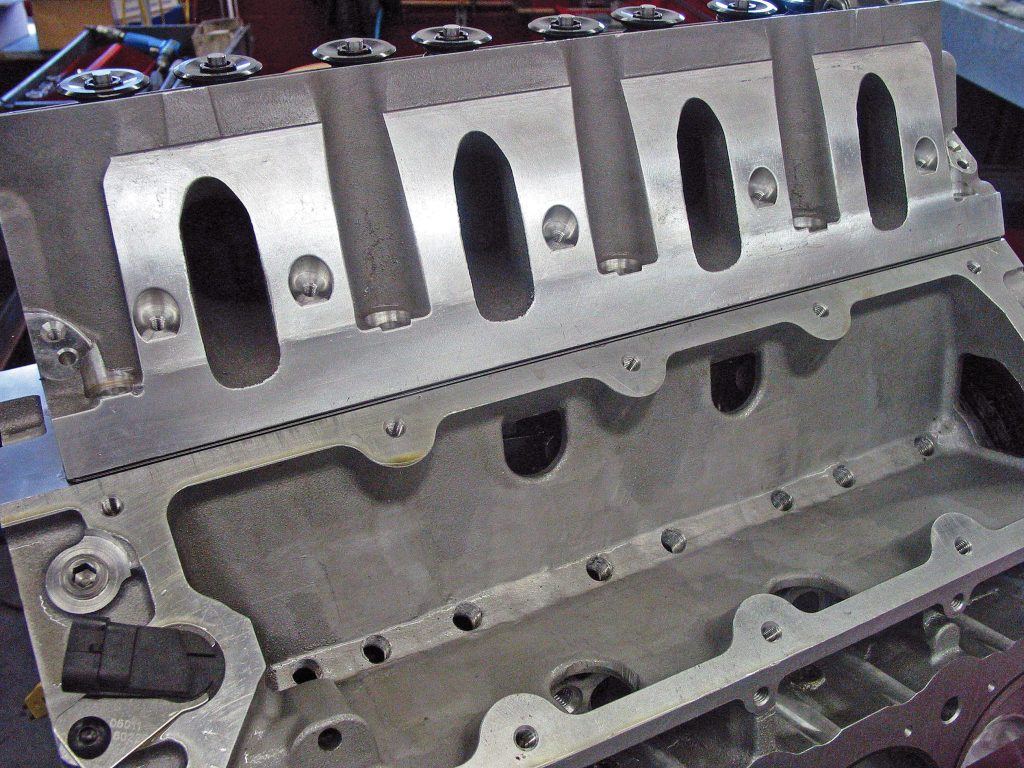

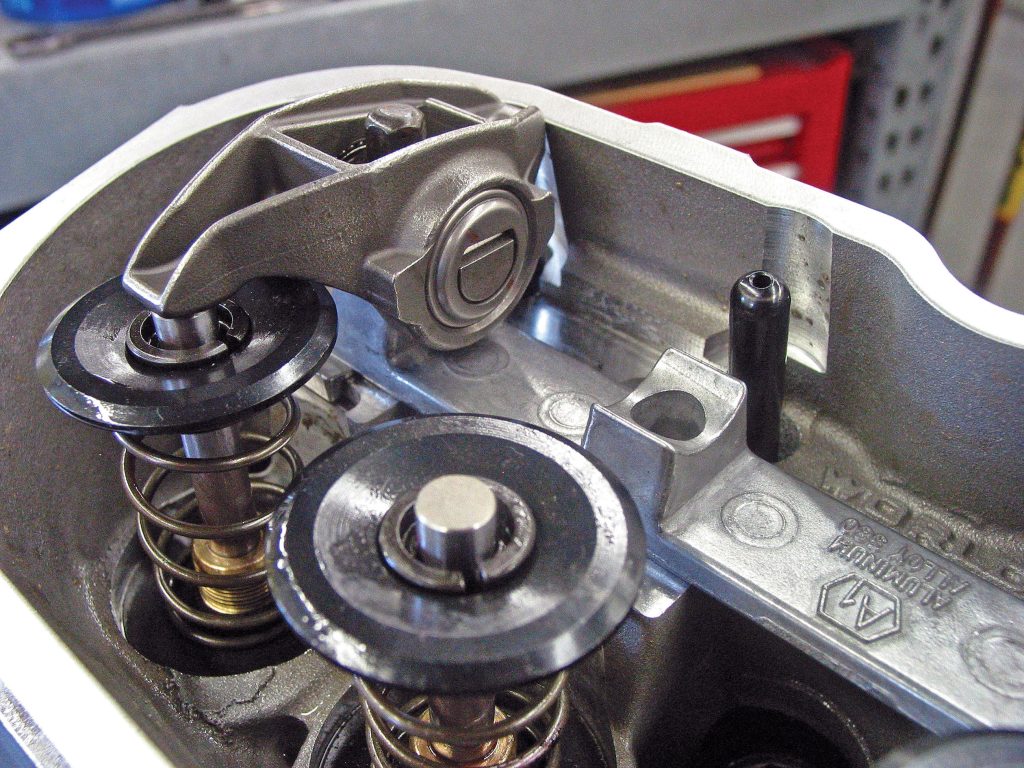

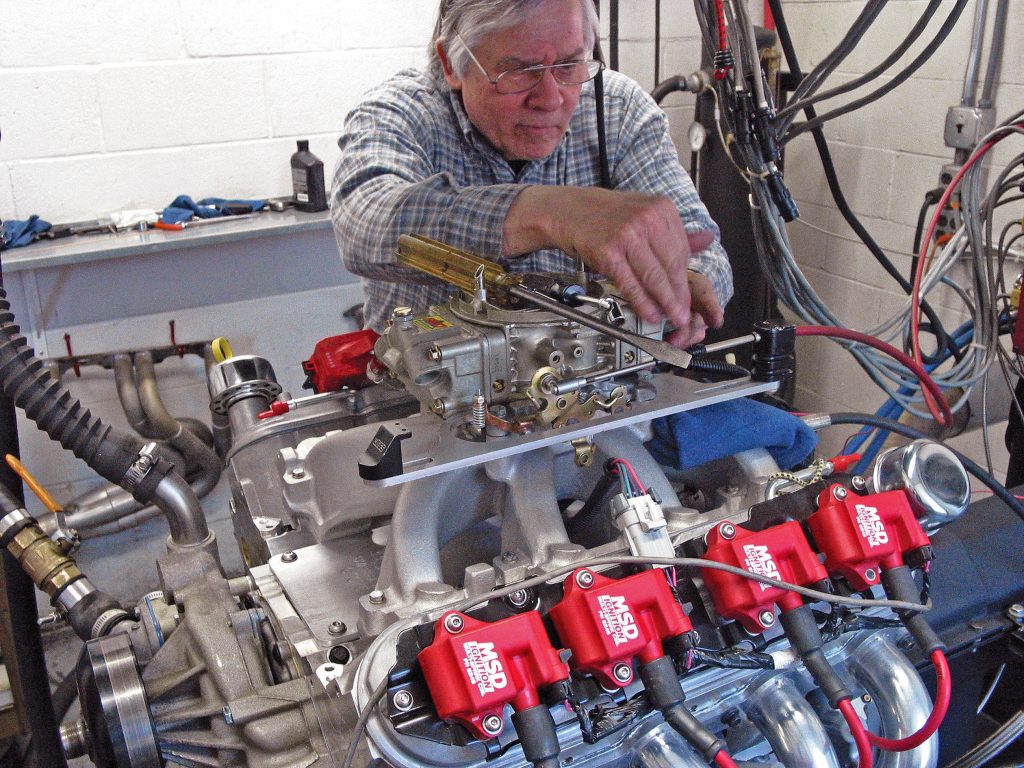

Following the LS7X Assembly

Although discussing, reviewing and writing about these engines provides insight into the benefits these components offer, we couldn’t wait to follow the assembly of one. That’s the best way to illustrate the quality of components and how they all fit together, so you are aware of every component, as well as the types of crate engines in the World Products inventory.

From Prototype to Performance

This particular engine assembly process is a special one, as we followed the early prototyping stages of World’s LS7X engine from the bare bones up. And while we will review only some of the details incorporated here, you will no doubt understand why World Products engines have gained the strong following they have today. It’s all about quality and the parts, and the fact that such power is only an e-mail or phone call away. It’s truly astonishing!

Impressive Numbers, Proven Performance

If it’s numbers you’re looking for, how’s this? Here’s an extremely streetable LS7X engine that pumped out 628 hp at 6,200 rpm and 578 lb-ft of torque at only 5,200 rpm. How’s that for impressive? Here’s how it was built.