THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

STOPPING BEYOND DOUBT

Wilwood Racing Technology Improves the ’03 Monte Carlo

Author

Stephen K. Anderson

Words & Photography

NASCAR Technology vs F1: Real-World Relevance

While there are those who will argue any comparison with the mega-dollar development of F1, their debate is silenced by the relative sensibility of NASCAR racing and its relation to real-world vehicles. While the exotic Ferrari Enzo street car is unquestionably a tour de force of advanced-technology performance, it has almost nothing to do with Michael Schumacher’s championship-winning F1 cars, and so it is with the rest of that illustrious field.

NASCAR’s Connection to Production Vehicles

In contrast to the other-world developments found in the F1 circus, some of the technology applied to cars circulating NASCAR facilities either is the result of developments in the Motor City or will eventually lead to products utilized by the world’s largest automakers. Stock Car racing originated from production cars, and while it is a stretch to say they share a lot with the current batch of street cars, including their bodies, they are nonetheless products of common interests.

Tracks as Testing Grounds

While racing fans see super speedways like Daytona, Talladega and Michigan, and smaller tracks such as Martinsville, Bristol and Richmond, as playgrounds and entertainment centers, development engineers fully understand their value as proving grounds. It’s at venues like these that products serve as prototypes for The Big Three, as well as smaller manufacturers in the aftermarket. And as these items are developed, more practical and cost-effective versions eventually find their way to production cars and super rods.

The Chevrolet Monte Carlo’s Role in Development

One of the favored cars that circulate these racing facilities is Chevrolet’s Monte Carlo, and while the racing versions differ greatly from those we see on the street, a paraphrase of the old saying “what’s raced on Sunday is transportation on Monday” is proving to be all too true. The Monte Carlo’s design is, in fact, a product of wind-tunnel development centering on efficiency and performance, and although it differs from NASCAR’s hybrid designs, it still shares a similar appearance. Just ask Hendrick Motorsports’ chief aerodynamicist, Gary Eakers, about this connection, because he once ran the General Motors wind tunnel before Rick Hendrick brought him in-house.

Bridging the Gap Through Braking Technology

Unlike other aspects of these cars, the one area that is directly linked between racing and production cars is braking. One of the most thoroughly challenging aspects of a racecar is controlling its braking efficiency, and Wilwood Engineering has been developing racecar brake technology since its earliest days. Born in the caldron of all forms of NASCAR racing, Wilwood has gone on to develop braking systems for other racing venues as well. And from there a rather complete line of street-based products began taking shape.

Real-World Application: Monte Carlo Brake Upgrade

As a result of these ongoing developments, numerous braking systems for street applications have been developed, including one for the Chevy Monte Carlo, which shows once again how racing does improve the breed. While these sleek Chevys certainly have an adequate braking system to start with, considerable improvements are realized when this easy-to-install and highly cost-effective package is bolted on.

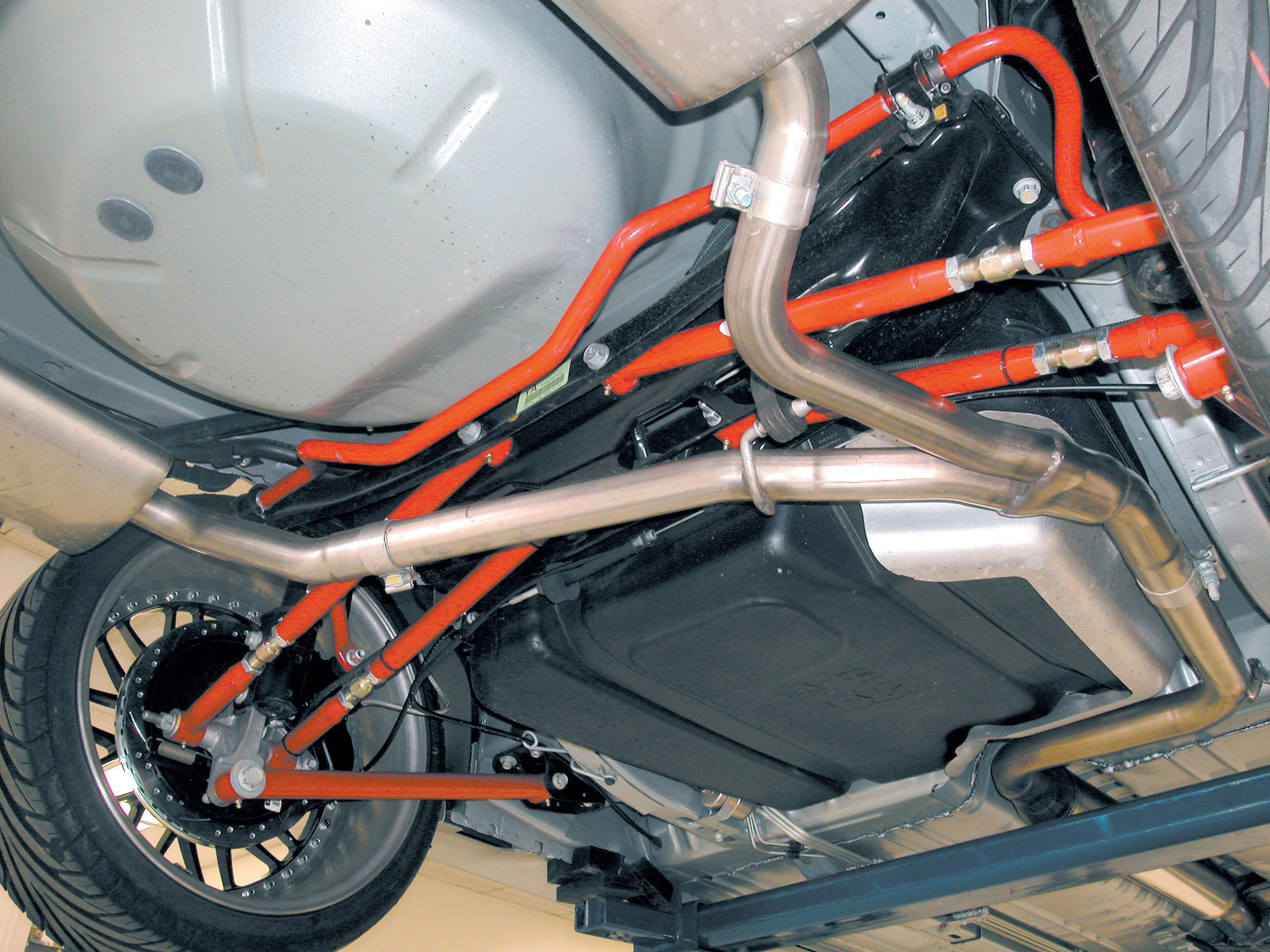

Installation with Dindo Cajulis’ Monte Carlo

We were fortunate to be on hand as Wilwood Engineering fitted its new braking package to Dindo Cajulis’ ’03 Monte Carlo. It seems this window of opportunity was, at best, a short one, because the entire installation took less than four hours, including the time needed to capture these photographic images and talk with the installer. When you consider the gains, both functional and visual, this is amazing indeed, and it shows how far our industry has come.

Who Is Dindo Cajulis?

Judging from his enthusiasm for this Monte Carlo, and performance vehicles in general (he also owns a Lotus Esprit Turbo), there is little doubt that Cajulis is a true enthusiast, yet his real commitment is not his hobby but his work. You see, Cajulis owns PhaseX, a high-tech corporation specializing in the development of braking software systems for some of the top auto manufacturers in the world. We mention this to underscore the fact that while he’s continually sharpening the leading edge of braking technology, Cajulis looked to Wilwood for his braking upgrade. That in itself should serve as testament enough, but once you’ve followed us through this installation process, you’ll see why he believes so strongly in Wilwood products.

Street Performance That Measures Up

While the streets of Southern California may not seem as torturous as NASCAR tracks such as Bristol or Martinsville, they do provide a different kind of challenge that tests vehicle stamina like few other arenas. Wilwood disc brakes are designed to handle the rigors of high-output street performance, and the company has developed a wide variety of packages so that you, too, can enjoy maximized braking in minimum time, for a variety of applications.