400HP Shootout: All-Motor vs. Nitrous

Performance enthusiasts are a funny bunch. They all seem to agree that “as much as possible” is the correct answer when asked, “How much power do you want?” But they certainly disagree about the best way to get there.

Fans of the all-motor route seek to optimize the flow, efficiency and compatibility of their chosen components. Obviously the forced-induction crowd relies on boost to produce those huge power numbers, while the nitrous contingent adds just a little squeeze. There are arguments for and against all three methods, as it takes one heck of an all-motor buildup to equal the power of a blower or turbo motor.

Since power output and cost are interrelated, at some point building more NA power becomes expensive. Blowers and turbos offer impressive power potential, but problematic blower belts and turbo lag are both issues that require attention. Of course, nitrous owners are labeled bottle babies, but it is hard to argue with the amount of power that is available at the push of a button.

While the debate will rage on as long as people have different opinions, the reality is that there is not one ideal avenue for performance. If one method suited every possible application and budget, then all others would cease to exist. Even if we limit the desired power output to 400 hp, it doesn’t take a genius to see that that same 400 hp would be used differently for a diesel truck application than a hot street/strip Mustang. The diesel truck application would certainly want the 400 hp to occur much lower in the rev range to help bolster torque production. By contrast, the hot street/strip Mustang is going to want peak power much higher in the rev range to maximize acceleration.

In addition to being application specific, the power output can be component specific as well, as there are many different combinations that can be assembled to reach the desired goal of 400 hp. In the case of our theoretical 400hp modular Ford motor, it is possible to take a stock or mild combination and add a blower, turbo or nitrous oxide. It is also possible to achieve the power goal by upgrading the stock engine with the right combination of performance components. Now all you have to do is decide which one best fulfills your power/performance/budget requirements.

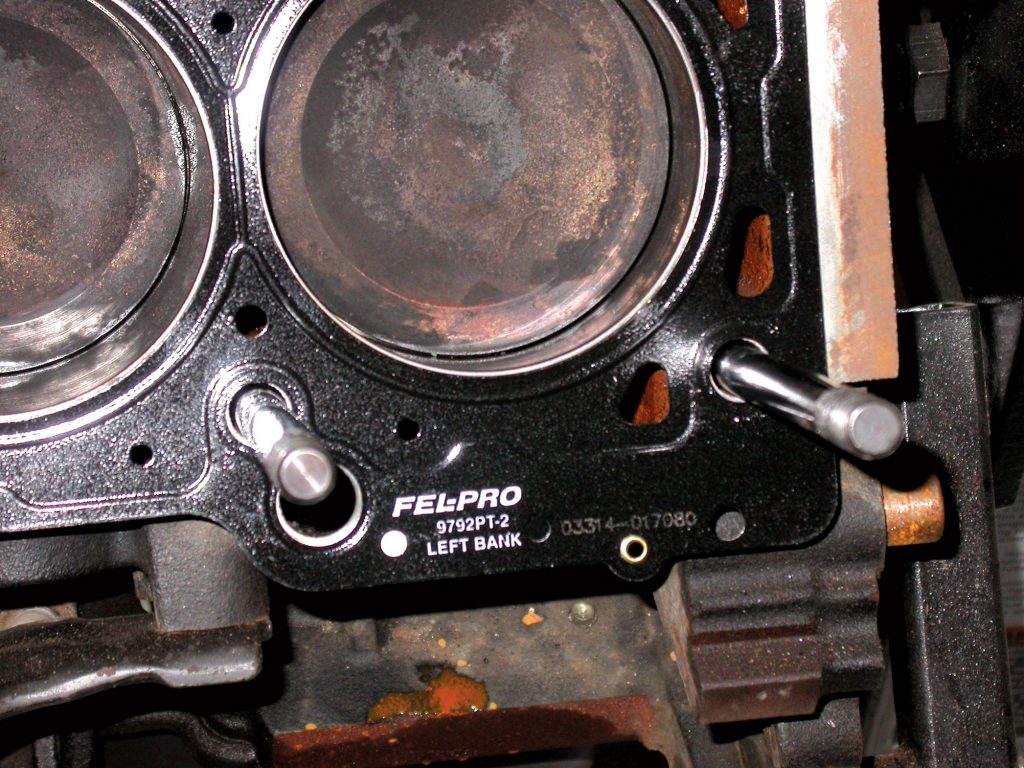

What better way to illustrate the different methods of achieving the same power goal than to take a stock engine and subject it to a pair of buildups? The goal for this pair of buildups was to take a stock modular motor (in this case from a 1998 4.6-liter, two-valve Mustang GT) and perform the necessary steps to produce 400 honest (dyno-proven) horsepower. Buildup No. 1 was a simple one. Basically we just installed a Zex nitrous kit on the stock engine. Actually, the 4.6-liter, two-valve engine came from the engine bay of a Mustang GT (supplied by Mustang Specialty Parts). The test mule was a high-mileage unit, but a compression test revealed that it still had plenty of performance miles left.

After upgrading to Lucas synthetic oil, the engine was installed on the engine dyno and equipped with a Meziere electric water pump, a set of Hooker long-tube headers and a FAST engine management system. Damage to the stock throttle body during shipping required the swap to an Accufab throttle body, but testing has shown that the larger throttle body offered no additional power on this otherwise stock engine. Using the FAST management system, the 1998 GT engine was tuned to provide 270 hp at 5,100 rpm and 347 lb-ft at 3,500 rpm. These non-Power Improved engines were not known as rev happy, but they did manage to produce acceptable low-speed torque. Torque production from the 4.6-liter, two-valve engine exceeded 300 lb-ft from 2,500 rpm to 4,700 rpm.

You may be wondering why an otherwise stock 1998 GT engine rated at just 225 hp produced 270 hp on the engine dyno. The answer is easy, as the Ford rating of 225 hp comes with a complete induction system and a full exhaust, including cats and full accessories. The rating also includes running at operating temperature and using the factory tune (for air/fuel and timing). For our “stock” test engine, we changed just about every parameter, including running a revised inlet system (open filter and section of 3-inch tube), a free-flowing exhaust consisting of Hooker headers feeding 3-inch collector extensions, and absolutely no accessories (only an electric water pump). We also optimized the air/fuel and timing curves using the FAST management system (the factory tune is much more conservative).

To this optimized stock combination we added a Zex wet EFI nitrous kit equipped to provide 125 extra horsepower. The jetting on the Zex kit was adjustable, but we felt pretty safe with the 125hp shot, since we dialed back the timing in anticipation of the nitrous (per the Zex instructions). The Zex kit supplied both fuel and nitrous to a single-fogger nozzle located in the inlet tube in front of the throttle body. We made sure to optimize the nitrous pressure (to 900 psi) by heating the bottle. The trick Zex system was able to learn the TPS curve to ensure activation only under full throttle.

Adding the 125hp shot to the 270hp engine improved the power output of the 4.6-liter, two-valve engine by 131 hp, from 270 hp to 401 hp. If you check out the accompanying curve, you will see that the power was down slightly in the lower rev range. This was due to the reduction in ignition timing (by 4 degrees), although most of this could be brought back with more tuning. Activating the nitrous increased the torque production from 347 lb-ft to 499 lb-ft. Harnessing 500 lb-ft on street tires is going to be a difficult proposition, especially since the extra 150 lb-ft is unleashed at the touch of a button. The torque production exceeded 400 lb-ft from 3,900 rpm to 5,100 rpm. The Zex nitrous allowed the near-stock 4.6-liter, two-valve engine to produce over 380 hp from 4,000 rpm to 5,700 rpm, making for a significantly improved power curve.

We suspect that additional tuning could have elevated the power curve past 4,500 rpm (bringing it closer to 400 hp), as the combination was a tad on the rich side. Even still, the mild two-valve engine became a 400hp screamer at the push of a button. We always love working with nitrous oxide, since the power gains are tremendous, while the expenditures in both time and money are significantly reduced (compared to an all-motor or even forced-induction setup). One 400hp buildup down, one more to go.

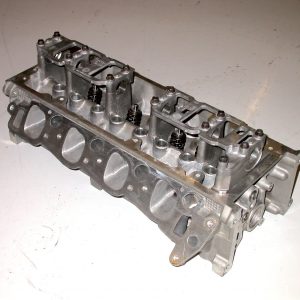

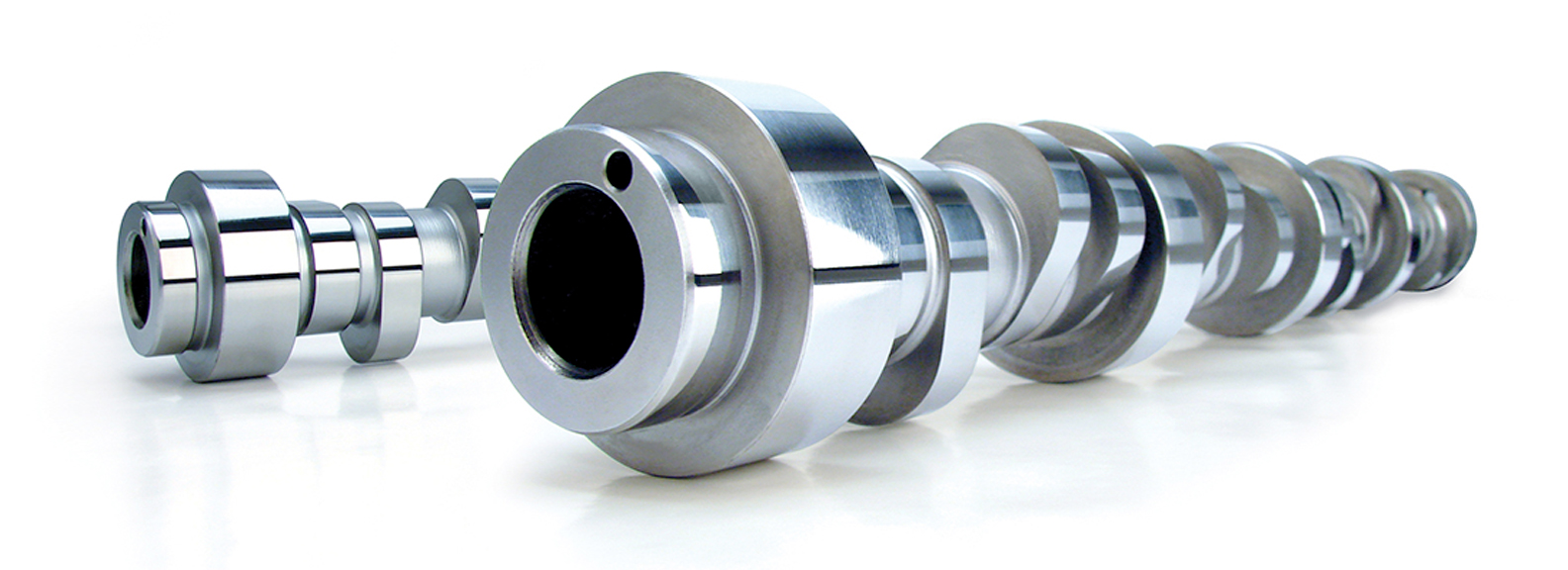

The 400hp Zex nitrous combination was almost too easy. We knew from experience that the all-motor build would be somewhat more time consuming, but the results were certainly worth the effort. This is especially true for those who want their power available all the time without concern about filling the bottle. Taking the basic bolt-on route, we replaced the factory power-producing components with more efficient aftermarket versions. Off came the stock 1998 heads, cams and intake manifold and on went CNC-ported heads from Total Engine Airflow, XE274H cams from Comp Cams and the late-model Power-Improved (PI) intake manifold. The late-model PI heads (ported by TEA) not only offered additional head flow (roughly 45 cfm per runner), but they also increased the static compression thanks to smaller combustion chambers.

Additional upgrades to the 1998 engine included a set of Hooker 1-5/8-inch long-tube headers feeding a 3-inch exhaust (the same system used on the stock and nitrous combinations), an Accufab 75mm throttle body and an inlet elbow and free-flowing air intake system. The all-motor combination was once again run with a FAST engine management system that allowed us to dial in the timing and fuel curves. This was a critical part of the buildup, as the new components required significant fuel and timing changes.

The combination of the additional compression, head and intake flow and cam timing had a positive effect on the power output of our test engine. In fact, the all-motor route actually outperformed the nitrous combination by a scant 5 hp. Using the stock short block with the TEA heads, Comp Cams and PI intake, the 4.6-liter two-valve produced 406 hp at 6,000 rpm and 393 lb-ft of torque at 4,800 rpm.

Given the torquey nature of the stock non-PI engine, we expected the modified engine to sacrifice torque production down low. After all, we did add much wilder cam timing. Luckily for us, the tradeoff in low-speed power was minimal. Credit the additional static compression for minimizing the low-speed losses. Torque production from the all-motor combination exceeded 350 lb-ft from 3,700 rpm to 6,100 rpm, making for one sweet power band. Rather than choose between the two, perhaps we should just add the nitrous kit to this all-motor combination and see what happens. We should easily be able to exceed 500 hp and 550 lb-ft of torque, but that is another test for another day. For now, know that 400hp buildups come in all shapes and sizes. Which one is best? Who cares? Just pick one and get out on the road!