THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

IMPRESSION

The Standard-Bearer for Future Generations

Come of Age

Only slightly reminiscent of the car it is based upon, the lines expressed through the flowing body and adjoining components, and all of the well-placed details, give one the impression of speed, style and a hint of great classics of the past. And while it may take on a hint of flavor of classics past, the overall concept is entirely its own—a coach-built car done for these modern times.

Six Years of Creative Effort

To comprehend the full effort expended in this impressive creative expression, first understand that six years have gone into its creation, through the combined skills of an impressive team of craftsmen, who by now are familiar to many. Many of these same artisans teamed once again with one of the world’s most proven commodities in automotive foresight and stylized guidance, and together they have shaped several memorable vehicles, including two past Ridler award winners, a feat that has eluded many.

Chip Foose’s Enthusiasm

Chip Foose needs no introduction these days, as he’s welcomed into millions of homes on The Learning Channel each week to share his love of cars with those who are chosen to have their cars transformed on “Overhaulin’.” There’s no mistaking Foose’s enthusiasm for the automobile, no matter what the genre, as he quickly grasps a mental concept, lays it out on paper and puts it into motion through his crew of craftsmen. Foose himself also has considerable car building and painting talent, having spent many years as a journeyman in father Sam’s custom shop. Then it was off to Art Center College of Design, where he honed his fine eye and funneled the knowledge he needed to be a thought-provoking auto designer and custom fabricator.

Working with Ken Reister

Meanwhile, as the show continues for another season and the “reality TV” cars are cranked out weekly, projects such as this one go on for some time, especially when Foose is able to team up with such customers as all-around car guy and past Ridler winner Ken Reister. This can be important for a project as involved as this one was, as it is a tremendous benefit for a designer/builder to be working with someone who understands what is required to reach the pinnacle of automotive creativity.

Initial Concept and Development

Having shared their ideas over dinner at Fishbones in Detroit in 1999, Reister and Foose came up with a plan, and from that initial concept a number of one-quarter-scale drawings were made. From there, a one-quarter-scale model was worked up so the smaller details could be worked out and decided upon. Some time after, a full-sized wooden buck was created as a foundation for the body panels, to ensure uniformity from side to side. After all, there wasn’t an original to go by. This is just as the coach builders did so many years ago—start with a cowl and build from there.

Marcel’s Custom Metal

At this stage, Marcel’s Custom Metal was called upon to form the various contours from 18-gauge steel to the rather involved requirements. As with so many projects in the past, Marcel’s came through with precisely what was needed for the foundation of this project. It’s interesting to note that none of the panels are joined at the peak, as one might expect, as this would soon weaken and eventually break the seam as structural loads and vibrations tore at them. Instead, the peak is created in one side of a panel and then joined somewhere below it to the remaining panel, in turn creating a much more rigid piece. As always, Marcel, Mark and Luc de Ley got it right, and while the panels left their hands bare and unfinished, there was no mistaking what was to come in the flowing shapes they had created from flat stock.

Assembly at Huntington Beach Shop

Once back at Foose’s Huntington Beach shop, an extremely focused effort began in uniting those panels with several aspects of the build. The front fenders and running boards, for example, were initially made as one piece, to maintain a flowing line between and across their length. They then were cut into two pieces below the A-pillar to make installation a possibility. An exceptional amount of time was also spent pocketing every body panel so that no exposed edges were visible, and while it might go unseen, the satisfaction comes in knowing that all of it, right down to the last detail, has been done right. And then there are all of the contoured brass moldings used as accents, each of which represents an amazing amount of time to create. Such is the level of detail found throughout this car.

Consistent Design Theme

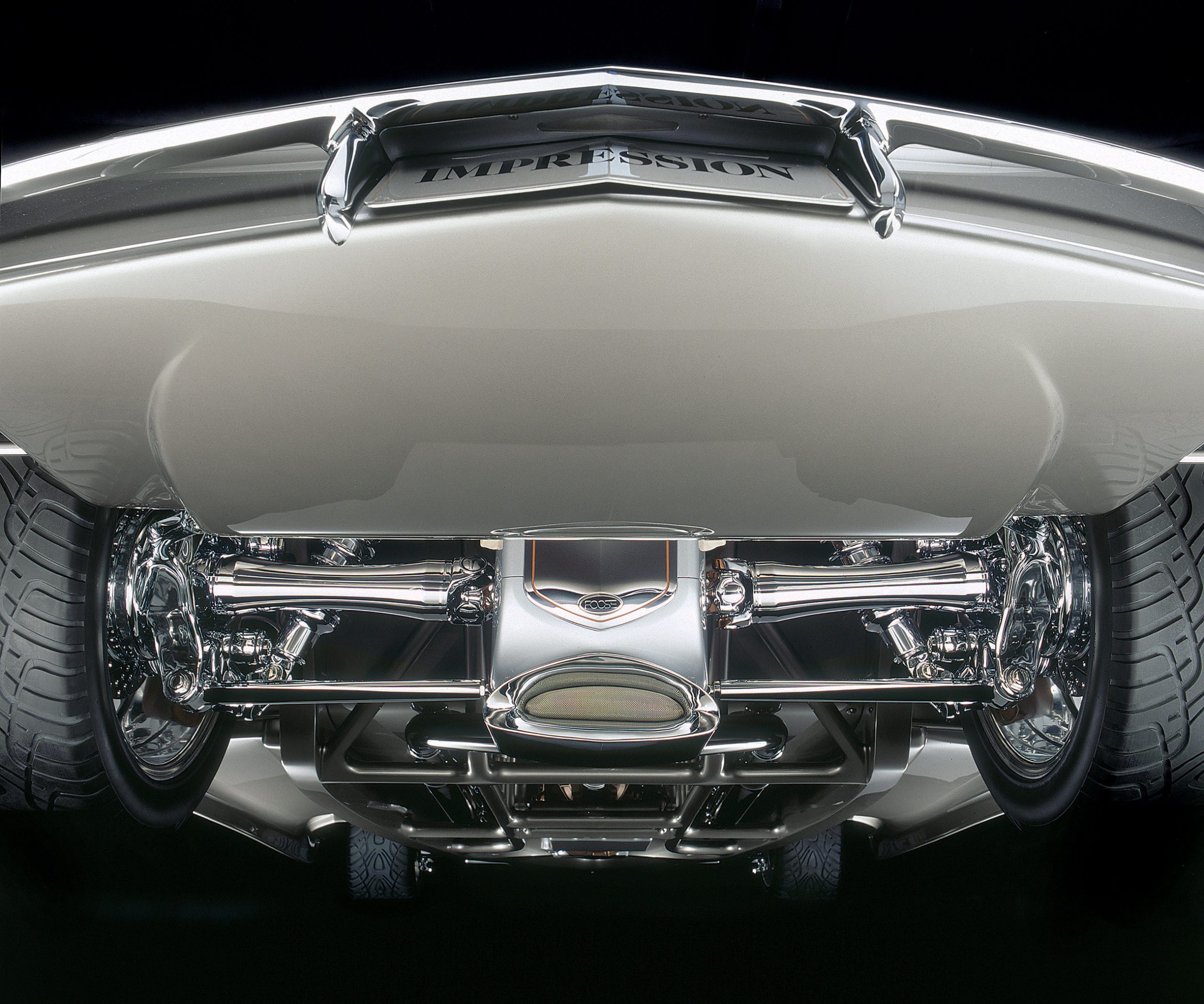

One of the unique approaches to this “’36” is the consistent theme that runs through the various details, the underside of the hood, as well as the hood and trunk hinges, the windshield frame, the steering column support, the frame, the wheels and, oh, even the tires. Look closely and you’ll see a soft triangle repeated in these areas, as even the tire tread follows the theme mirrored in the spokes of the wheels. It’s obvious that BFGoodrich backs special efforts such as this, as these tires were specially cut to Foose’s specifications. Of course, these particular tires are used for display only, while another set of BFGoodrichs is fitted to a second set of identical custom rims for road use; and if you’re thinking, “Yeah, right, it’ll never be off a trailer!” know that Reister can and will drive the car “up the road.” But that will come a little later, once their pre-selected show schedule is fulfilled.

Foose Wheels and Engineering

The newly designed Foose wheels (20×10-inch rears and 18×8-inch fronts) combine a soft lip design with offsetting spokes uniting in the integral center cap. Fully machined on both sides, the finish is so lustrous that it’s easy to miss the Foose emblem floating in the burnt-orange striped rim. Looking through the spokes, it’s also easy to confuse suspension bits that are peeking through as part of the wheel. So nice is the machine work on these one-of-a-kind components—the uprights, the A-arms and other related hardware are all built around this chassis—that it’s difficult to imagine how much time went into their development. Then again, when you see how the A-arms and the chassis have been seamlessly concealed beneath surrounding bodywork, you realize how much advanced planning went into uniting the various elements into a continuous flow of art and, most important, engineering.

Functionality and Aesthetics

It’s one thing to build something beautiful, but it’s quite another to make so many special alterations function as intended. That’s why Foose created full-sized patterns for SAC to use when creating the frame. From there, it went to John West Fabrications to develop the chassis. As you can see, the suspension pieces seem to flow into and with the chassis, and in the case of the independent rear suspension, they incorporate special detailing that alters the way people look at it. The differential, for instance, is concealed beneath a beautiful finished four-piece cover, complete with leather boots to allow movement of the rear-steer links.

Suspension Details

The dampers combine Bilstein height-adjustable shocks with Carrera coilover springs with a number of special details. These include a machined aluminum sleeve that conceals the treads for the adjusters, along with other caps and body pieces that help integrate the coilovers into the design. Even the Baer brake calipers and rotors were detailed to blend with the visual aspects of this amazing machine art. Chrome was used throughout, even on the aluminum components, to maintain a consistent appearance that works well with the beautiful exterior color.

Eye-Opening Details

Looking from below, this car is truly an eye-opening pleasure, as details such as the rear suspension seem right in place with neighboring panels, including the rearward gas tank cover, mirroring its beauty. And so it is with the fully molded framerails integrating several different aspects of the chassis without so much as a bolt, washer or nut showing. In fact, if you’re looking for any evidence of mechanical, electrical or water interface, spend your time instead looking for what you will find—such as the two drains for the requisite fluids and a third for powering up. Almost conspicuous in the void of any other fasteners, the first (top) bolt is actually hollowed out to receive an electrical jack to power the lighting and other systems during a show. The other fasteners incorporate a special half-turn operation that releases Freon through one while the other drains coolant. Beyond trick! This is also a clean and simple way to change fluids.

Frame and Engine Detailing

Farther forward, the frame again displays a familiar triangle shape, which centers on the LS1 Chevy located overhead. Here, too, the level of detailing is enough to cause veteran car builders to stand back and wonder, as they know only too well what is required to get these components to look as they do in this nontypical installation. While the internals of the 345hp LS1 Chevy remain unchanged, every external surface of the engine and transmission has been smoothed as if it were a finished body panel and then coated in corresponding colors that offset and enhance the primary color used through the body and interior. From there, every fastener, plug or mount was carefully crafted to either conceal or detail, as needed.

Exhaust System

The headers are a good example of this commitment and, dare we say, exhaustive approach. While the outside diameter of these coated pipes is 2-1/2 inches, a collar concealed in the individual flanges adjoining the heads actually sizes down internally to match the port size of the LS1 cylinder heads. They even have integrated oxygen sensors that are concealed just along the bottom edge of the pipe, and they’re just as beautiful all the way back to the chromed and flared tip. Combined with the vintage-style valve covers sprouting cloth wire covers, most observers have trouble identifying the true power source, as it was Foose’s intention to pull off an original Flathead look, but in modern style and with a totally modern powerplant. And then there are two additional runners (one on either end) to conceal the wiring around the intake manifold. Combined with a 1L80E transmission, there’s more than enough power to propel this roadster, but as we said, that’s for another day in the not-too-distant future.

Interior Detailing

Slide into the interior, and the same emotion evoked by the body and chassis comes ’round again, with Jim Griffin’s exquisite detailing and flawless application of materials joining past and future. The layout of special Stewart Warner gauges integrated with custom molding flowing from the dash is straight from the ’30s, as are the door custom panels and seating incorporating Haartz cloth inserts with cream leather. The center console is right in place, with its custom shifter and custom molding continuing the theme, which follows through in the custom steering wheel. When the top is in place, chromed internal top bows tell of an earlier age while giving shape to the area. The same molded detail follows the window openings, which is right in keeping with the molding along the beltline and Foose’s custom windshield, fitted with Five Axis glass. Entertainment comes through loud and clear from a hidden Clarion head unit. As far as you look, there’s more detail to be found, right down to the finely woven and machined pedals.

Continuing Design Theme

It’s here that the continuing theme returns through numerous V-8 emblems, shown again in the wheel centers, the tip of the hood, the center of the top and a number of other areas, as well. The most obvious may actually go unnoticed. It’s just too cool: from the front, the V-8 emblem is incorporated in the ’37-style headlights, which are specially made from a combination of pieces, including hand-formed brass rings. They fall nicely around the most involved grille Dan Fink ever made. This ’36 grille was Fink’s finest effort, and it’s easy to see why he’s proud of it, and we of him. Beautiful in its flowing contours, it is yet another special aspect of this highly refined roadster. Similar finery flows out from the rear panel, where the custom taillights float off a winged mount centered on the license surround. The taillights consist of a ’37 Ford housing fitted with an internal reflector, along with 12 LEDs circling a center bullet with its own LED. From behind, the look is mesmerizing, especially when it becomes apparent the lights are floating above the fender.

Team Effort and Details

We could go on for pages about all the details that have been incorporated into this car, as well as all of the individuals who expended thousands of hours refining it. But this effort is about a team, and the results clearly show a fine team effort. Beyond this car’s attachment with those who built it, there are certain to be millions of others who are impacted by its rare, beautiful coachwork. Its sleek and powerful lines involve the handiwork of artisans, with all of the careful detail we’ve come to expect in boutique jewelry and finely crafted art pieces; but this effort is far more than that, as it is a living, breathing, growling road machine fully capable of sucking up the blacktop with the best of them. But before it takes to the road, it’s hard to imagine people’s amazed stares and growing appreciation once they begin taking in everything there is to see. This is one car that lives up to its reputation, as Foose and crew set a new level of coachwork, as admirers can see how far detail can really go and how difficult it is to find the never-to-be-seen details that help form the character of the vehicle. It is truly amazing, and the true worth comes in knowing that every aspect of this car is, for lack of a better word, perfect, even those elements that cannot be seen. In this case, the results made the perfect impression—strong, distinct and lasting.

Impact and Recognition

There’s no question that Reister’s “Impression” has impressed enthusiasts around the country. They were lined up 10 deep at times as it was vying for the Ridler at the Detroit Autorama, and the tension was certainly in the air. As they waited for the announcement, Reister, Foose and the large development team were feeling it. Then came the adulation of knowing their hopes had been fulfilled and their efforts rewarded. And as automotive creativity goes, understand that what you see here will be more impacting than one might imagine, as this car, more than any other to date, will provide the standard by which others will be judged.

“AS YOU CAN SEE, THE SUSPENSION PIECES SEEM TO FLOW INTO AND WITH THE CHASSIS, AND IN THE CASE OF THE INDEPENDENT REAR SUSPENSION, THEY INCORPORATE SPECIAL DETAILING THAT ALTERS THE WAY PEOPLE LOOK AT IT. THE DIFFERENTIAL, FOR INSTANCE, IS CONCEALED BENEATH A BEAUTIFUL FINISHED FOUR-PIECE COVER, COMPLETE WITH LEATHER BOOTS TO ALLOW MOVEMENT OF THE REAR-STEER LINKS.”

“THIS IS ONE CAR THAT LIVES UP TO ITS REPUTATION, AS FOOSE AND CREW SET A NEW LEVEL OF COACHWORK, AS ADMIRERS CAN SEE HOW FAR DETAIL CAN REALLY GO AND HOW DIFFICULT IT IS TO FIND THE NEVER-TO-BE-SEEN DETAILS THAT HELP FORM THE CHARACTER OF THE VEHICLE.”

BEYOND THE CALL

It All Comes Down to Time Spent

It’s impossible to chronicle, or even comprehend, what is involved in a six-year project like “Impression.” After all, the combined hours applied to its many aspects would amaze even the most experienced rodders, as everyone involved knew what this car was going to be. In the end, all of the time and expense of building this car was worth it. Apart from the honor of the Ridler award, or the Ridler Builder’s award that was awarded to Foose, the reward of building this car came in the result—a highlight in automotive history.

ARTICLE SOURCES