THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

HOW A G-MACHINE WORKS

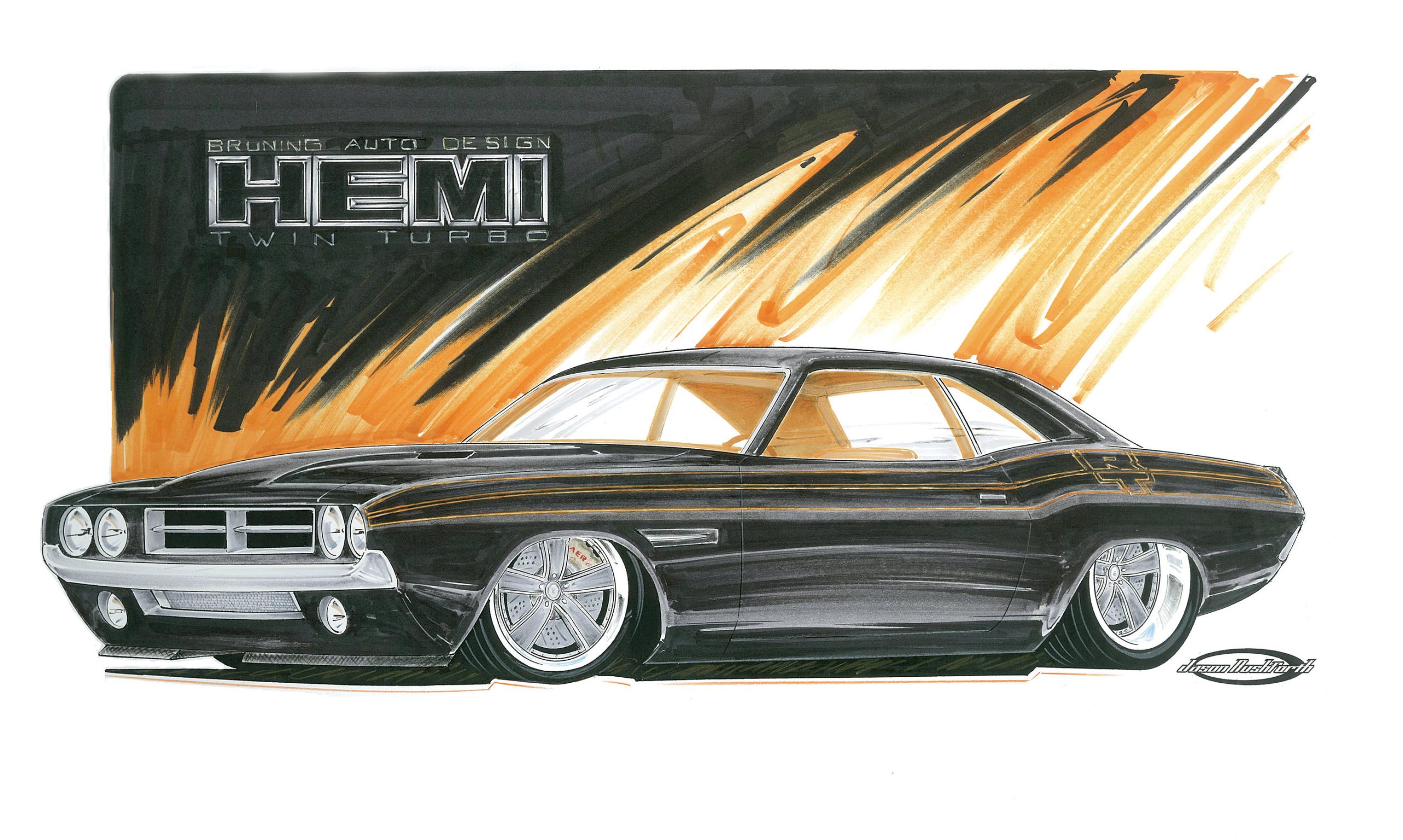

A ’70 Challenger That’s Being Reborn Into the 21st Century as a Modern-Day Super Sports Car

Bruning Auto Design’s Spectacular ’70 Challenger Build

It’s all taking place at Bruning Auto Design in Vancouver, Washington, where this ’70 vintage Challenger is undergoing much more than a revamp. At a time when enthusiasts are looking for Chrysler E-bodies to restore and upgrade as show-quality daily drivers, Bruning becomes engrossed in what we would term a truly spectacular but real-world ’70 Challenger.

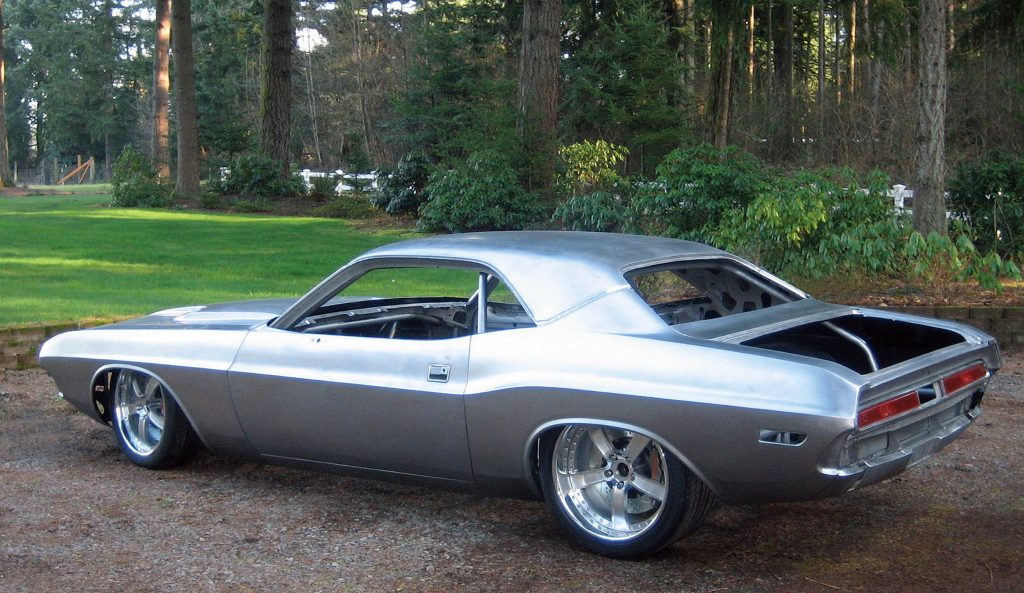

A Unique Foundation and Chassis Design

The foundation for this car is unique to say the least, as the build incorporates an elaborate chassis designed to create a sinister muscular stance and ultra-low ride height, but it’s more than just having the right attitude, as the chassis under this Mopar will ensure that it drives and performs as well as any modern-day supercar. Well, it is a supercar.

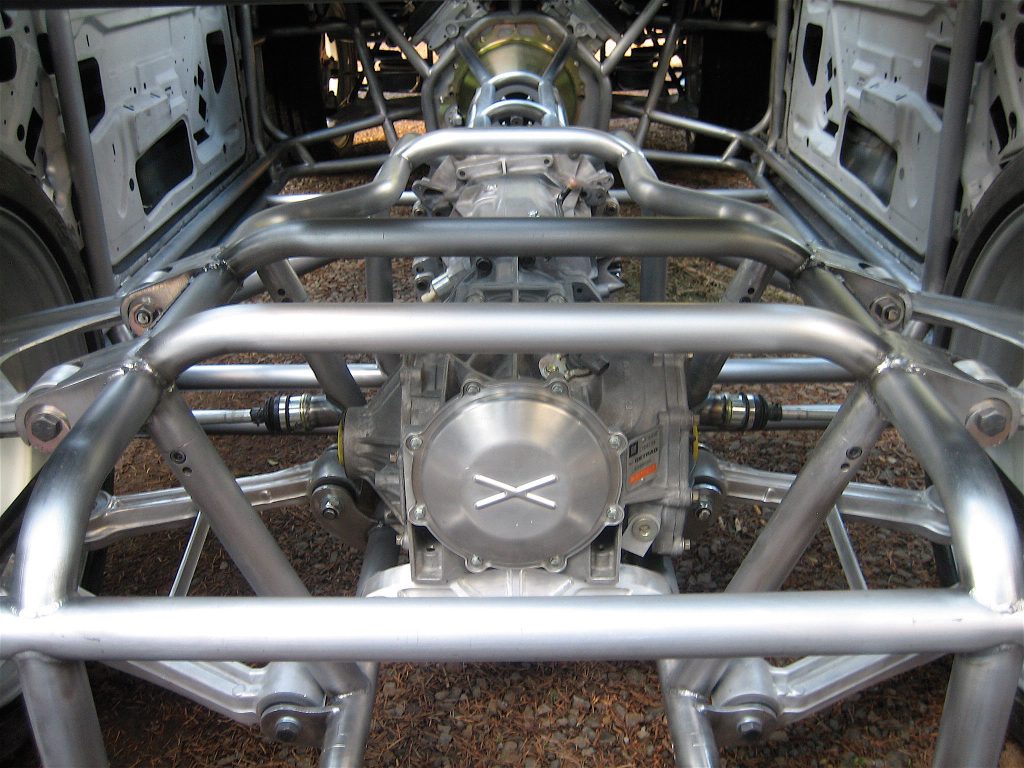

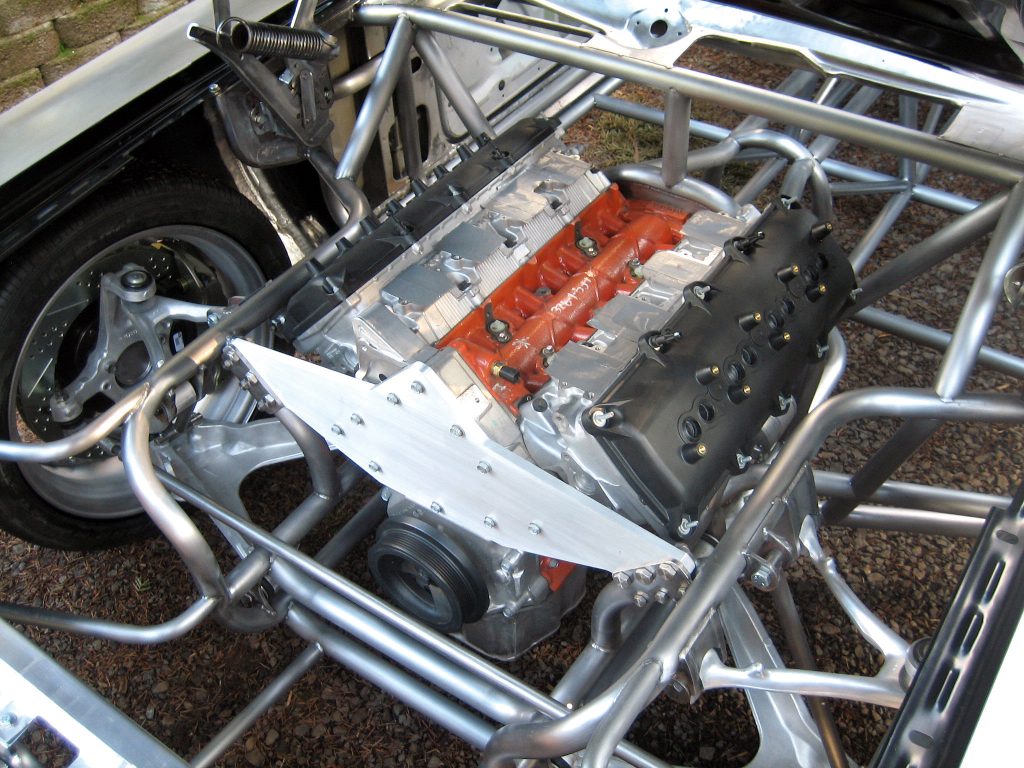

Handcrafted Tubular Chassis for Optimum Performance

To drive that point even further, take a look at the handcrafted tubular chassis. It is an intricate combination of designed-in strength that takes form to triangulate the body for optimum chassis rigidity. Along the way, the Bruning team ensured that its fabrication exudes the craftsmanship and detail found in hand-built racing technology. And you find this at every bend of the tubing, at every fish-mouthed tubing juncture, as the beautifully TIG-welded chassis has been constructed with the utmost care. It’s also been built around C5 Corvette front and rear suspension components, as well as the complete Corvette six-speed transmission and torque tunnel. This was to improve weight distribution and to provide the same superior handling characteristics you might find on a C5R Corvette, if there were one running around.

Custom Wheels and Impressive Braking System

The custom-built three-piece 19- and 20-inch Rushforth rims, naturally, are wrapped in large—and by large we mean huge for this car—245- and 335mm tires, and this is all backed by equally impressive 15-inch Baer rotors with six-piston clamps. This is in keeping with the notion that this Hemi-powered Challenger will be a stout runner, and an even more impressive handler, and because of that, it must have equal power to slow it for corner entrances and bring the mass of acceleration to an abrupt halt. Which is your perfect equation—go fast, with brutal acceleration, or come to a stop with equal and opposite reaction?

Twin-Turbocharged 6.1-Liter Hemi Power

The Hemi power is the new 6.1-liter Hemi, which rests under an R/T hood. But get this: As if 425 hp wasn’t enough, this Hemi will be force-fed all the air it can handle, via not one but two turbochargers. The twin turbos feed through handcrafted stainless steel intake plumbing and equally impressive stainless steel exhaust headers. Considerable thought was given to the routing of all this large tubing, which is no small feat to fit within the confines of this pony-car body.

Subtle Yet Effective Body Modifications

As the illustration suggests, and the all-metal mock-up clearly shows, the car will be sinister looking, in spite of the fact that body mods have been kept to a minimum and will be subtle. Oh, there are plenty of modifications, but they’ve been done so expertly that it will take a careful eye to figure out exactly why this Challenger looks to have an appearance all its own. Obviously, much care has been extended to the wheel arches, as you don’t fit this size rubber under a car by accident. In addition, the front wheel wells have been moved closer to the front some 2 inches, and they’ve been moved up 1 inch. This was done to accommodate the stretched wheelbase of the chassis and to fit the tires for that extremely low stance.

An Optimum G-Machine

You could safely call this Challenger an optimum G-machine, for that is what it is being built to do. No doubt, it will pull Gs to equal the likes of the world’s best and most expensive sports cars, but there’s more to this project. Aside from the G-machine concept, reliability and durability rank right up there with the designed-in performance this car will undoubtedly display once it is stitched in leather and fit with dark windows, adding to its sinister appeal. To ensure that all goes as planned, the part of this build that is most impressive to us is the creativity that has gone into its basic architecture, as well as the attention to detail throughout, and this can only be achieved through the incredible craftsmanship that has gone into this one-of-a-kind Challenger.

The Anticipation Builds

Can you say fun to drive? The whooshing sounds this forced-air Hemi will make will have some scratching their heads, but not nearly as much as the side-loaded tire squealing will. We can’t wait. Stay tuned!

ARTICLE SOURCES

Bruning Auto Design – CLOSED

11616 NE 212th Ave.

Brush Prairie, WA 98606

360/254-0066