THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Hot Four Cylinder

HIGH-TECH, STATE-OF-THE-ART, FOUR-CYLINDER POWER FOR THE RIGHT ROD

Author

Carroll Hamilton

Photography By Carroll Hamilton, Ford Motor Company, and Minister Racing Engines Limited

In Search of a Modern Four-Cylinder Powerplant

In search of an engine to power a ’40s-style hot rod sitting tall on skinny tires and ’35 Ford wires, we began looking for a four-cylinder engine that had power, efficiency and all of the modern hookups to power this project. Something along the lines of a state-of-the-art, 200hp plus, dual overhead-cammed, fuel injected, four-cylinder engine would do, especially if it was one that Henry’s heirs built.

Our search didn’t take us far, and we soon found that there are lots of four-cylinder engines available. The Internet hooked us up with builders and manufacturers of four-cylinder engines whom we never knew existed. And after weighing all the options, the choice came down to either the Ford Zetec or the later model Ford Duratec, also known as their I-4 global engine. A catalog website called my ford focus, www.myfordfocus.com, lists many Zetec and Duratec products by manufacturer, dealer and others.

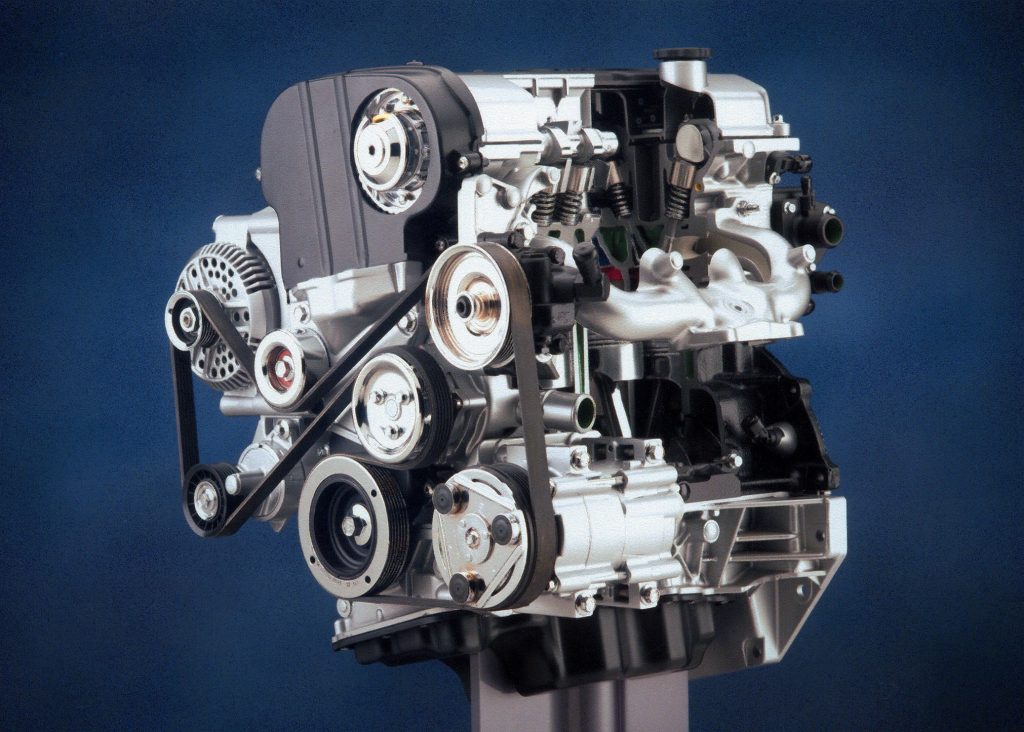

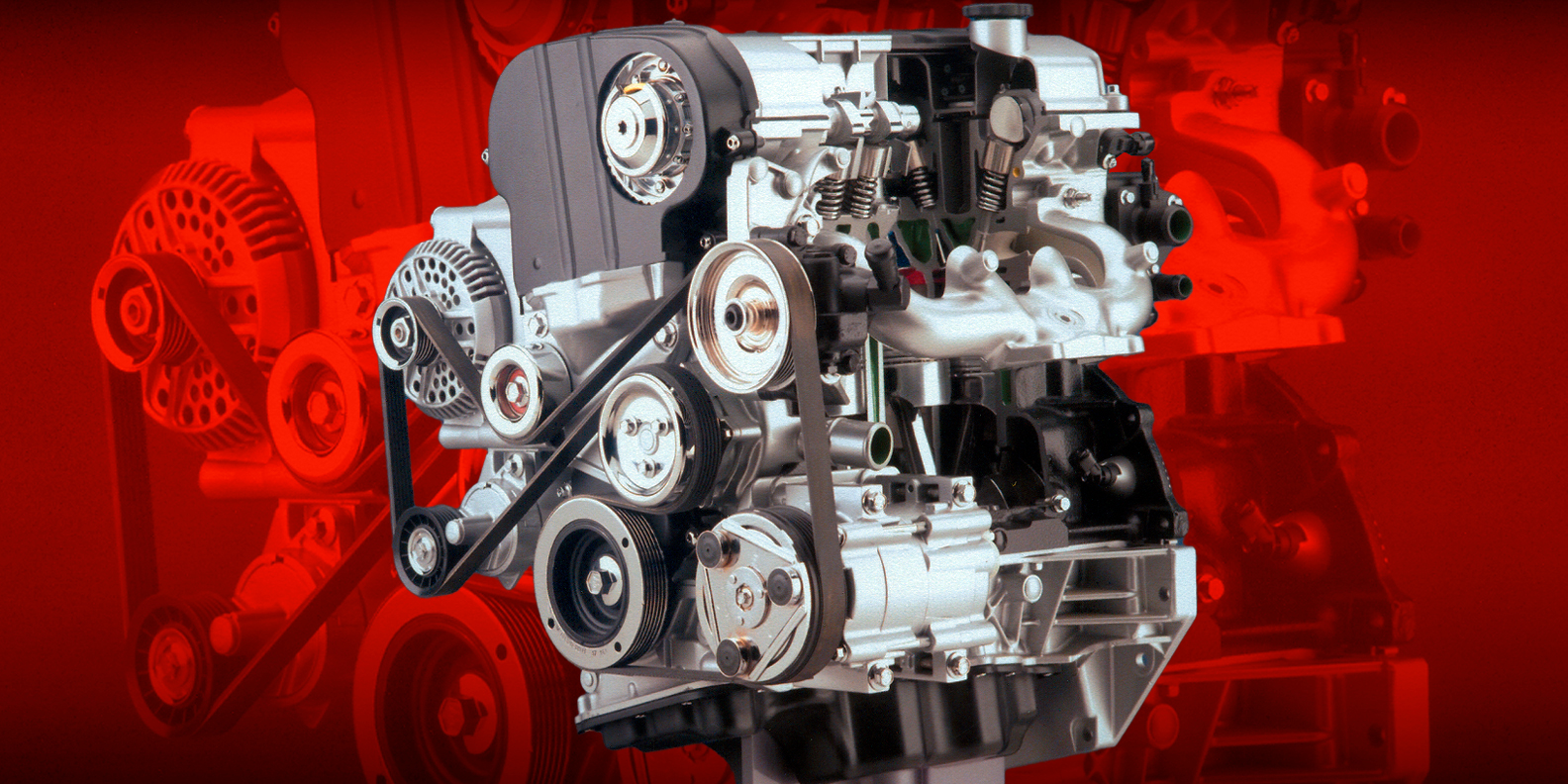

Ford Zetec Engine Overview

The Zetec E was developed in the early ’90s for the Mondeo/Contour program, in 1.6-, 1.8- and 2.0-liter configurations, with dual overhead cams, 16 valves and spark plugs located in the center of a pentroof combustion chamber. The block is cast iron, and the head is aluminum. Early production engines have magnesium cam covers, while later model covers are made of plastic. The engines are produced in Mexico, the UK and Spain with an advertised horsepower of 130 at 5,750 rpm for the standard 2.0-liter, and with torque at 127 lb-ft at 4,250 rpm.

The ’03 SVT version of the Zetec advertises 170 hp at 7,000 rpm and 145 lb-ft of torque at 5,500 rpm. This engine, we are told, has some trick stuff straight out of the Cosworth brain trust. Those numbers are quite good for a stock four-cylinder, but more is available from the aftermarket, and rebuildable Zetec engines are also plentiful from salvage yards.

Ford Duratec I-4 Global Engine

The Duratec HE four-cylinder design came from Cosworth and was intended for Formula 1 use in a turbocharged, high-tech configuration. Formula 1 dropped the turbos and added more cylinders, and this killed the Duratec’s intended application. So when Ford acquired a controlling interest in Cosworth, they began building the engine in Europe for the Ford Mondeo. Ford decided that the merits of the inherent design strength intended for Formula 1 racing—along with the free-flowing cylinder head, easy to regulate emissions, lightweight, adequate power and so on—were strong enough reasons why the engine should become a global engine platform. In order to distinguish the Duratec four-cylinder from the Duratec six-cylinder, the global engine four-cylinder was named the I-4.

Mazda, also owned in part by Ford, was given the task to engineer the manufacturing processes for the I-4, making it adaptable to a wide range of applications. A highlight of Mazda’s design process was the ability to cast the alloy engine block in 54 seconds. The I-4 program yields approximately 1.5 million units per year and is built in the USA, Mexico, Spain and Japan. Designed to replace eight of the Ford family engines, including the Zetec, the Duratec is available in 1.8-, 2.0- and 2.3-liter versions.

Duratec Construction and Performance

Like the Zetec, the I-4 engine features dual overhead cams, 16 valves and spark plugs located in the center of a pentroof combustion chamber. The I-4 is all aluminum, including a cast aluminum oil pan, and it weighs 40 pounds less than a Zetec. The block construction features a deep skirt design (the lower sides of the block extend below the crankshaft centerline). Cylinder-head construction is aluminum-silicon alloy, thermally treated for strength and durability, with an asymmetric four-valve-per-cylinder design. The double overhead cams are driven by a silent chain drive.

Advertised horsepower for the 2.3-liter engine is 135 hp at 5,000 rpm. The torque number is 153 lb-ft at 4,000 rpm, and aftermarket go-fast parts are quickly coming online. For all these reasons, this engine would make an excellent choice in a lightweight street rod, even with a stock I-4 crate engine.

Kansas Racing Products and Alternative Four-Cylinder Options

As we searched for information for our engine project, Kansas Racing Products in Chapman, Kansas, was instrumental in providing us the necessary information to help in our engine selection. Gerry Dedonis, the Director of Special Projects for KRP, informed us that KRP has their own cast-iron, four-cylinder engine block, one that is not based on the Zetec or Duratec engines, but an improved version of the overhead-valve GM-Pontiac Superduty iron four-cylinder racing engine.

What they did, rather than being limited by the poor selection of four-cylinder heads, was allow the KRP block to accept most any small-block V-8 head—GM, Ford or Mopar—and even most aftermarket heads, including high-flow CNC-ported units. When a Ford small-block head is used, the block carries the Ford part number M-6010-B180. When a GM head is used, the block is cast with the GM Performance part number 10093306. There is no recognized Mopar part number as of yet. If you want something exotic and powerful to power your next rod, the KRP engine may be just the ticket.

Selecting and Inspecting a Zetec Engine

In addition to its own engine, KRP can also provide Zetec and Duratec crate engines or quality rebuildables suitable for aftermarket performance conversions. We chose a rebuildable Zetec engine, and KRP shipped it out in about a week. If you buy a used engine from a salvage yard or a rebuildable one here, here are some things to look for:

- Check for damage to the timing covers, upper oil pan (aluminum part), valve cover and intake manifold if you are using it (signal throttle body applications). These parts can easily be damaged in a frontal accident.

- Check for water under the spark plug boots. This is common and normally won’t cause a problem. If you find water in the plug area, dry it right away. After all the water is removed, pull the spark plugs, making sure the threads are not damaged, and replace the plugs. Check spark plug wires and replace if necessary.

- Make sure the alternator bracket is not broken (the one above the oil filter).

- Check the oil, making sure it is not contaminated and that it doesn’t smell burnt.

- Check the engine serial number and make sure it corresponds with your receipt. Most local inspection centers will need to verify this information before you can register your car. The engine serial number is located on the left rear lower corner of the block, just above the upper (aluminum) oil pan.

Power Potential of Modern Four-Cylinders

We found no problems with our engine, and we set about making decisions for bolt-on horsepower upgrades and transmission options. The Ford four-cylinder Zetec E 2.0-liter engine and the I-4 2.3-liter engine produce just over 1 hp per ci in their stock form. The ’03 SVT version of the Zetec advertises 170 hp, or 1.4 hp per ci.

This is plenty stout when you consider that 1 hp per ci was attainable only by skilled engine builders only a few short years ago. As these mighty little four-bangers show, engine design and efficiency have come a long way. With extensive internal and external changes, these horsepower numbers can be greatly increased, easily doubled and if you’re good, nearly tripled. However, with just a few bolt-ons, these numbers can be dramatically increased to the point that these four-cylinder engines can supply enough power to light up the tires of most street rods.

Oil Pan Solutions and ECU Upgrades

The Zetec engine is installed at a slight angle in a normal front-wheel drive application, and upright when you install it in a rear-wheel drive application. Because the oil pan is slanted, that wouldn’t leave much of a sump and could be a problem in difficult cornering situations. A search for an answer uncovered Snakebite Performance, the parts arm of Dynamic MotorSports.

They distribute Superformance Cobra kit cars as well as the Superformance S-1 sports car, and because the Superformance S-1 is set up to be powered by a Zetec engine, Snakebite developed necessary parts and upgrades. Two such parts are a lower oil pan and an oil pump pickup designed to fit the Zetec when installed in an upright position. The pan is manufactured from steel plate and is nicely baffled.

Webcon Fuel Injection Systems

While the stock throttle-body fuel injection is efficient, it’s far from racy-looking, and the Ford electronic management system is not very user-friendly when used outside of a Ford automobile. Snakebite has an electronic control unit (ECU) produced by Webcon, a division of Standard Motor Products of Europe.

The Webcon Alpha systems come in three basic packages: Alpha Bronze, Alpha Gold and Alpha Platinum. These systems are simple bolt-ons with pre-programmed mapping—no need for hours of dyno time. The multi-throttle-bodied injection system with cams can add 60 hp.

Performance Parts, Nitrous, and Exhaust

Ford Racing offers an assortment of high-performance parts that can produce upwards of 300 hp from a Zetec engine, including camshafts, intake manifolds and even a supercharger. We chose an Edelbrock Sport Compact EFI Nitrous System, adding an instant 50 hp.

For the exhaust, Sanderson Headers custom-built a ceramic-coated header to clear the Zetec dipstick in a rear-wheel drive configuration, secured using Stage 8 Locking Fasteners.

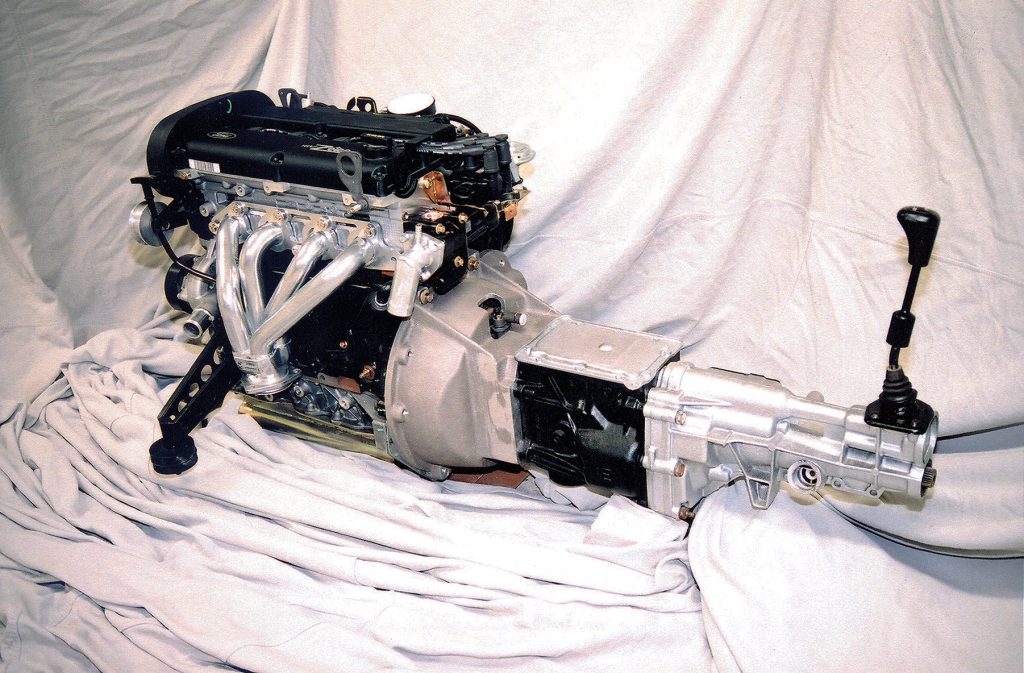

Transmission Options and Final Thoughts

The key link in a rear-wheel drive conversion is the bellhousing adapter. We used a Snakebite Performance bellhousing adapter mated to a Ford Type-9 transmission, a compact five-speed with tight ratios ideal for lightweight rods.

With the engine and transmission match-up complete, all that’s needed now is to get busy on the chassis. Soon we will be motoring around in a computer-managed, highly efficient, 200hp, four-banger-powered Model A rod—and we can’t wait to see what it will do on the bottle.

ARTICLE SOURCES

Edelbrock

2700 California Street

Torrance, CA 90503

800/416-8628 (Tech Line)

Ford Racing Performance Parts

44050 Groesbeck Hwy.

Clinton Township, MI 48036

586/468-1356 (Tech Line)

Kansas Racing Products - CLOSED

1205 Manor Dr.

Chapman, KS 67431

785/922-6644

Minister Racing Engines Limited -CLOSED

Unit G, 17 Revenge Road

Altbarn Industrial Estate

Lordswood, Chatham, Kent ME5 8UD

United Kingdom

Sanderson Street Rod Headers

517 Railroad Ave.

South San Francisco, CA 94080

650/583-6617

Snakebite Performance

2647 Morgan Lane

State Route 128

Ross, OH 45013

800/297-6253

Other Zetec and Duratec Engine Sources

Raceline Performance Engineered

2 Henley Park Farm Cottages

Pirbright Road

Normandy, Nr Guildford

Surrey, GU3 2AE,

United Kingdom

Circle Performance Racing Engines

971 Main Street

Brockton, MA 02301

508/580-5844