THE AUTO BUILDER

Menu

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

DASHING F100

Installing a ’59 Impala Dash Into a ’56 Ford F-100.

Author

Warren Boughn

Story & Photography

We have shown you how to shave door handles, install custom outside door handles, round door corners, build suicide doors, add bear claw latches and so on. Now we’re going to offer you a personal favorite custom touch—installing a dash from a ’59-’60 Chevrolet Impala into a ’56 Ford F-100.

This how-to is intended to spark your interest, provide you with an idea and separate your truck from most of the others. It’s not a difficult swap, and you will find that car dashes that are from the same era as the truck lend themselves to this swap very well.

Follow along as we explore the custom install of a great-looking car dash in a truck.

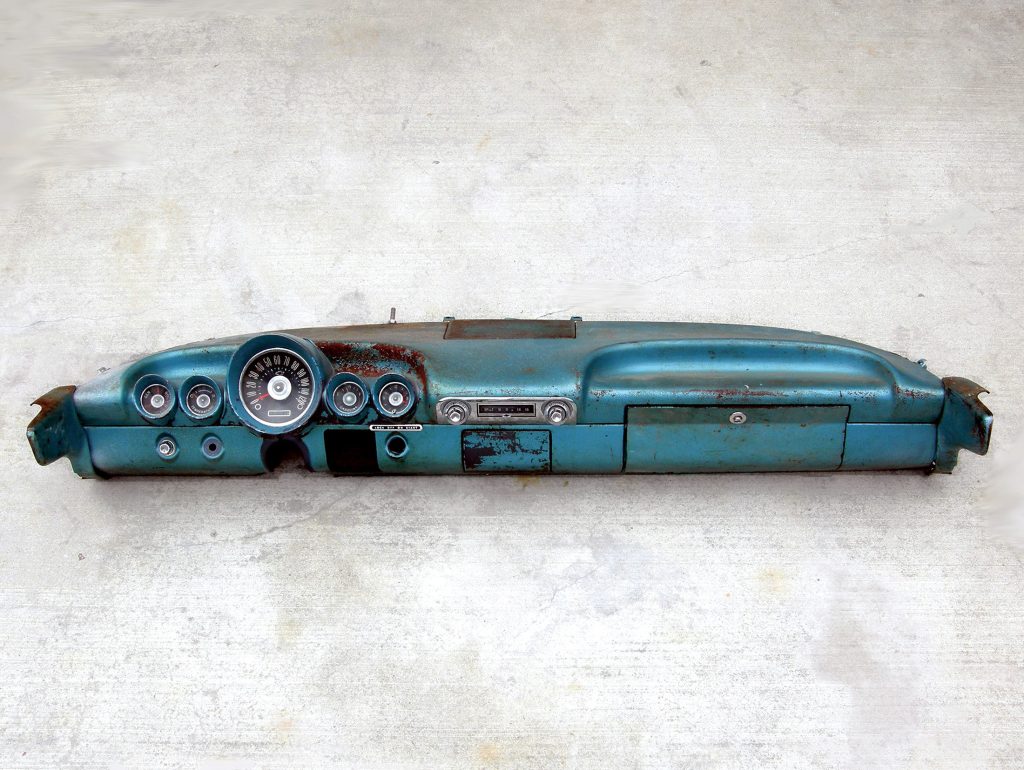

2. This is what our almost stock ’56 F-100 dash looked like before it was removed. The switch holes had been filled in previously.

3-4. The first thing we did was find the center of the gauges and mark the dash.

3-4. The first thing we did was find the center of the gauges and mark the dash.

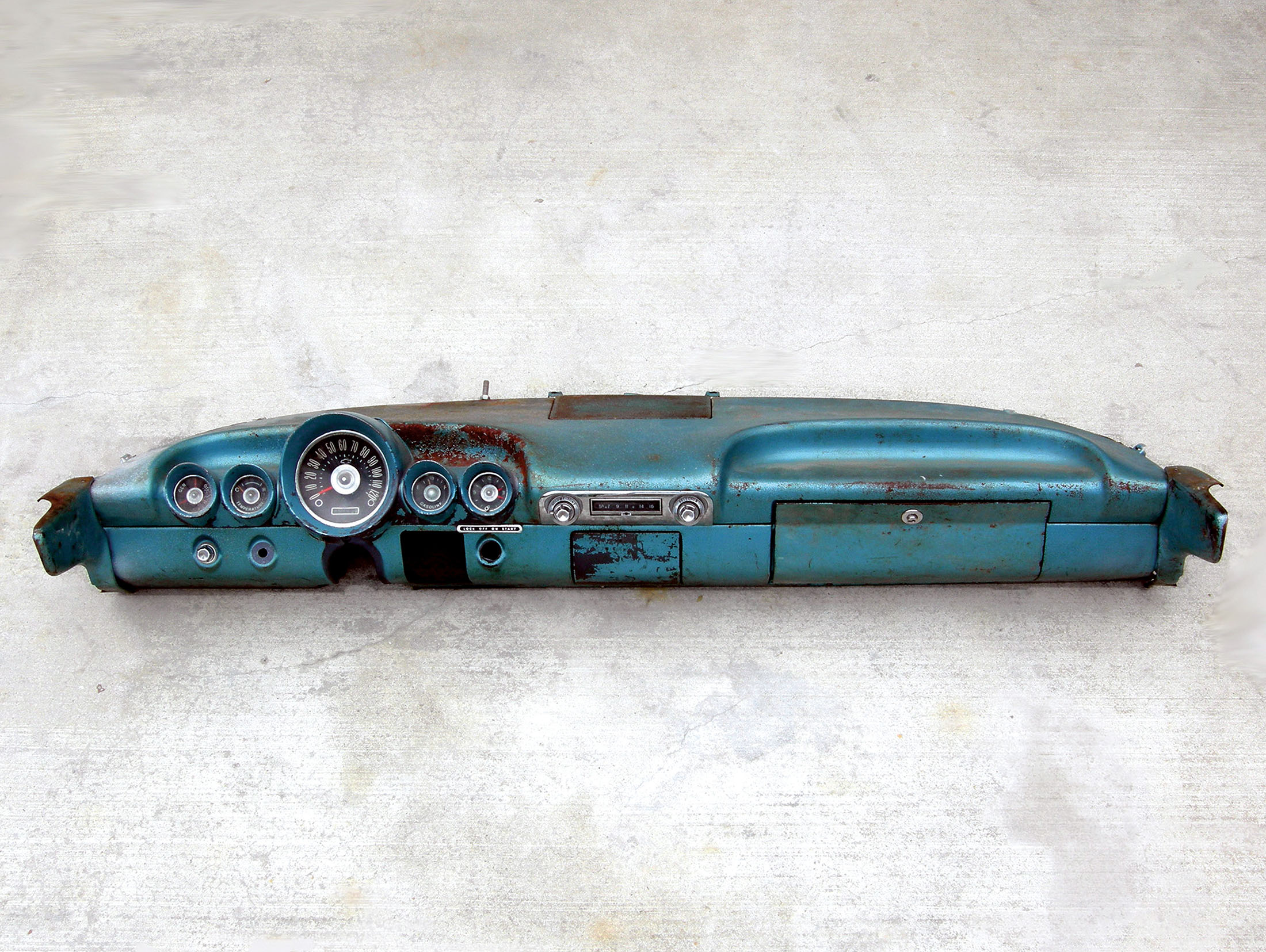

5-6. Next, we measured from our mark to the driver’s-door pillar. This measurement will be used to locate the new dash on the left side. As you can see, the dash is definitely wide enough for our project and will need to be trimmed.

5-6. Next, we measured from our mark to the driver’s-door pillar. This measurement will be used to locate the new dash on the left side. As you can see, the dash is definitely wide enough for our project and will need to be trimmed.

7. We used a plasma cutter to remove the F-100 dash face. We left a small lip surrounding the windshield area to attach the Impala dash to later. This way we can retain the upper F-100 dash trim and the defrost vents.

8. This is how the cab looks with the dash removed. Notice that the sides are double-walled.

9-10. We measured the Impala dash in both width and depth to get an idea of where we will be trimming it. This was compared to the new opening we now have.

9-10. We measured the Impala dash in both width and depth to get an idea of where we will be trimming it. This was compared to the new opening we now have.

11-12. We started fitting the Impala dash into the F-100 cavity by trimming the depth, followed by the dash braces.

11-12. We started fitting the Impala dash into the F-100 cavity by trimming the depth, followed by the dash braces.

13. All of this was followed by cutting the dash in two pieces (1-1/2 inches off-center), thus separating the dash.

14. We predetermined that the dash was 3 inches too wide. By removing 1-1/2 inches off-center each way, we will have removed 3 inches in two cuts instead of 3 inches by cutting it exactly down the middle and then 1-1/2 inches off each end.

15-16. The driver’s side is the first to be marked with the shape of the Impala dash and trimmed to size, as the gauge cluster location is critical.

15-16. The driver’s side is the first to be marked with the shape of the Impala dash and trimmed to size, as the gauge cluster location is critical.

17-18. Now that the Impala dash shape has been cut into the old dash sides, we can temporarily clamp it into place and check the fit. Notice that the lines of the truck dash and Impala line up perfectly, making it look as though it was meant to be.

17-18. Now that the Impala dash shape has been cut into the old dash sides, we can temporarily clamp it into place and check the fit. Notice that the lines of the truck dash and Impala line up perfectly, making it look as though it was meant to be.

19 Now that we’re happy with the fit and location of the Impala dash, we made a paper template of our cutout and transferred it to the other side. We will trim the excess metal as we did previously on the driver’s side.

20. We noticed that our dash was a little too deep and needed slight trimming. We used aviation snips for this.

21. With both dash halves clamped into place, we can mark our second cut to narrow the dash. Our 3-inch prediction was right on the money. If we were off slightly, we could have adjusted for it at this point by either leaving or removing more material.

22. Here’s a look at the pieces we removed from the center of the dash. The next step was to sandblast and primer the dash halves.

23-24. Our new dash mounts underneath the lip we left around the windshield. We found that it was blocking the defroster vent holes. We marked and removed those areas from the dash.

23-24. Our new dash mounts underneath the lip we left around the windshield. We found that it was blocking the defroster vent holes. We marked and removed those areas from the dash.

25. If you look closely, you’ll see that the dash sides are not flush with the pillar, which allows the stock kick panel to make up the difference. Since our dash is a little taller, we want to flush-fit this section.

26-28. This is how we went about the transformation. We started by removing the excess material in the dash edge, welding it back together and grinding it smooth.

26-28. This is how we went about the transformation. We started by removing the excess material in the dash edge, welding it back together and grinding it smooth.

26-28. This is how we went about the transformation. We started by removing the excess material in the dash edge, welding it back together and grinding it smooth.

29. Remember there were a few missing pieces when we received our dash? We made and welded in plates to fill in the holes and give the dash a smoother look.

30-31. The welds were ground smooth next. We added an extra switch indent for a more symmetrical look, and we needed it for our heater switch. Again, the dash was ground smooth and then primed.

30-31. The welds were ground smooth next. We added an extra switch indent for a more symmetrical look, and we needed it for our heater switch. Again, the dash was ground smooth and then primed.

32-33. We started installing the passenger’s dash half first. It helps to have someone help you do this step. The dash and lip from the other dash need to be pushed together tightly and tack-welded.

32-33. We started installing the passenger’s dash half first. It helps to have someone help you do this step. The dash and lip from the other dash need to be pushed together tightly and tack-welded.

34-35. The driver’s half was positioned next. We started joining the two halves together by tack-welding the seam in the middle of the dash. Before positioning the dash, we added filler pieces to smooth out the dash where the speaker grille and ashtray were to the driver’s side.

34-35. The driver’s half was positioned next. We started joining the two halves together by tack-welding the seam in the middle of the dash. Before positioning the dash, we added filler pieces to smooth out the dash where the speaker grille and ashtray were to the driver’s side.

36-37. Just as we did on the passenger’s side, we tack-welded the dash to the lip from the original F-100 dash.

36-37. Just as we did on the passenger’s side, we tack-welded the dash to the lip from the original F-100 dash.

38-40. This is how our dash looked after it was tack-welded together. Our tack-welds are a couple of inches apart for now.

38-40. This is how our dash looked after it was tack-welded together. Our tack-welds are a couple of inches apart for now.

38-40. This is how our dash looked after it was tack-welded together. Our tack-welds are a couple of inches apart for now.

41. We will continue tack-welding. Between the tack-welds, be sure to tighten the spacing until it becomes a continuous weld, skip around the dash and don’t apply too much heat to any one area. This is very time consuming, to say the least, but it’s necessary to keep the dash from warping too much. The dash is made of thin 20-gauge sheetmetal.

42-43. Here is a peek at the freshly ground welds. If you didn’t know any better, you would think it came this way from the get-go.

42-43. Here is a peek at the freshly ground welds. If you didn’t know any better, you would think it came this way from the get-go.

44. The radio portion of the dash is the last thing to complete. We will remove the radio-knob support brackets, leaving a rectangular hole in the middle of the dash.

45. This is the piece that will fill in the old radio hole. We made it from leftover sheetmetal we weren’t using.

46. Next, the radio filler piece is positioned, welded and ground smooth.

ARTICLE SOURCES

Precision Street Rods & Machines – CLOSED

19158 Roscoe Blvd

Northridge, CA 91324

818/886-5018