THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Cooler Runnin’

Hardin Marine’s Extreme Series Components Keep Our Baja’s Blown Engine Running Strong and Cool

Author

KURT FLACHBART

WORDS & PHOTOGRAPHY

All summer you’ve dreamed of passing all those boats that have blown by you since June. Now that time has come. You plunk down a large stack of greenbacks for a nasty supercharger and wrench all weekend bolting it in. Now comes the moment of truth. As you tear down the lake, all eyes are on the gauges, and the oil pressure is heading south too quickly. What could be wrong? You let off the throttle for a bit and all the vital signs return to normal.

We’ve ran into this exact scenario before. We installed an R-Tech Supercooler on the ProCharged Dorr’s Marine Engine 502cid motor in our Baja 250ES. The install was a huge success with a whopping 9mph increase in top speed. The boat worked well, but what we weren’t expecting was the huge increase in oil temperature from the gain in horsepower. If we had stayed on the throttle for a good 5,000-plus-rpm run, the oil temperature would have shot for the moon and oil pressure would have dropped to an uncomfortable level, forcing us to back out—what fun is that?

To find a solution, we turned to Hardin Marine. After some discussion with Hardin Marine technical personnel about our application, we decided that the entire cooling system needed an upgrade; it needed to be capable of handling all the horsepower that the R-Tech Supercooler/ProCharger combination was building. We decided on a new seawater pump, a large capacity oil cooler and an oil thermostat (to keep oil temperatures warm enough to cook off any condensation), as well as a complete system designed to control all of the temperatures within the proper ranges.

The results were astounding. With the new Hardin Marine cooling system, the engine flowed more water through the intercooler and temperatures came down to a much more acceptable 172 degrees after the cooler at 4,000 rpm and only 184 at 5,000-plus. Let’s take a closer look at how the installation went.

Because we were running a very large intercooler, a two-stage raw water pump was chosen for a starting point in this project. Hardin Marine’s dual-stage Extreme Series pump fit the bill perfectly, with one impeller chamber feeding the intercooler and a separate one to supply the motor. It also features billet construction and polished stainless steel; it was a shame to have to bury this beautiful piece down in the bilge.

The new water pump bolted right onto the mighty big block without a hassle, and we were ready to start plumbing the new water system. The next step was to pick an oil cooler that could support 800-plus horsepower and 8 psi of boost. Scott Price at Hardin Marine suggested we run a 3-inch diameter, 25-inch-long oil cooler. This might sound like overkill, but when you plan to use an oil cooler and thermostat combination, you can run as large of a cooler as you wish. Too much is always better than too little, as the thermostat will regulate the oil flow to the cooler proportional to demand. A bonus with the single-engine boat is that there was no shortage of room for the massive cooler. We mounted it to the floor of the engine compartment with the polished aluminum brackets supplied by Hardin.

Our next step was selecting an oil thermostat. If you boat in a colder climate, condensation in the oil can be a problem when running a large oil cooler. The moisture from condensation can wreak havoc on the valvetrain due to the pitting of valve springs, cam lobes and related lifter problems, which can and will cost you a motor if the oil is too cold. The use of an oil thermostat ensures that your oil comes up to temperature by bypassing the cooler until it reaches the desired temperature (212 degrees Fahrenheit in our case). It is then kept from overheating by diverting flow to the oil cooler, providing the necessary temperature control to keep the oil within its proper operating range.

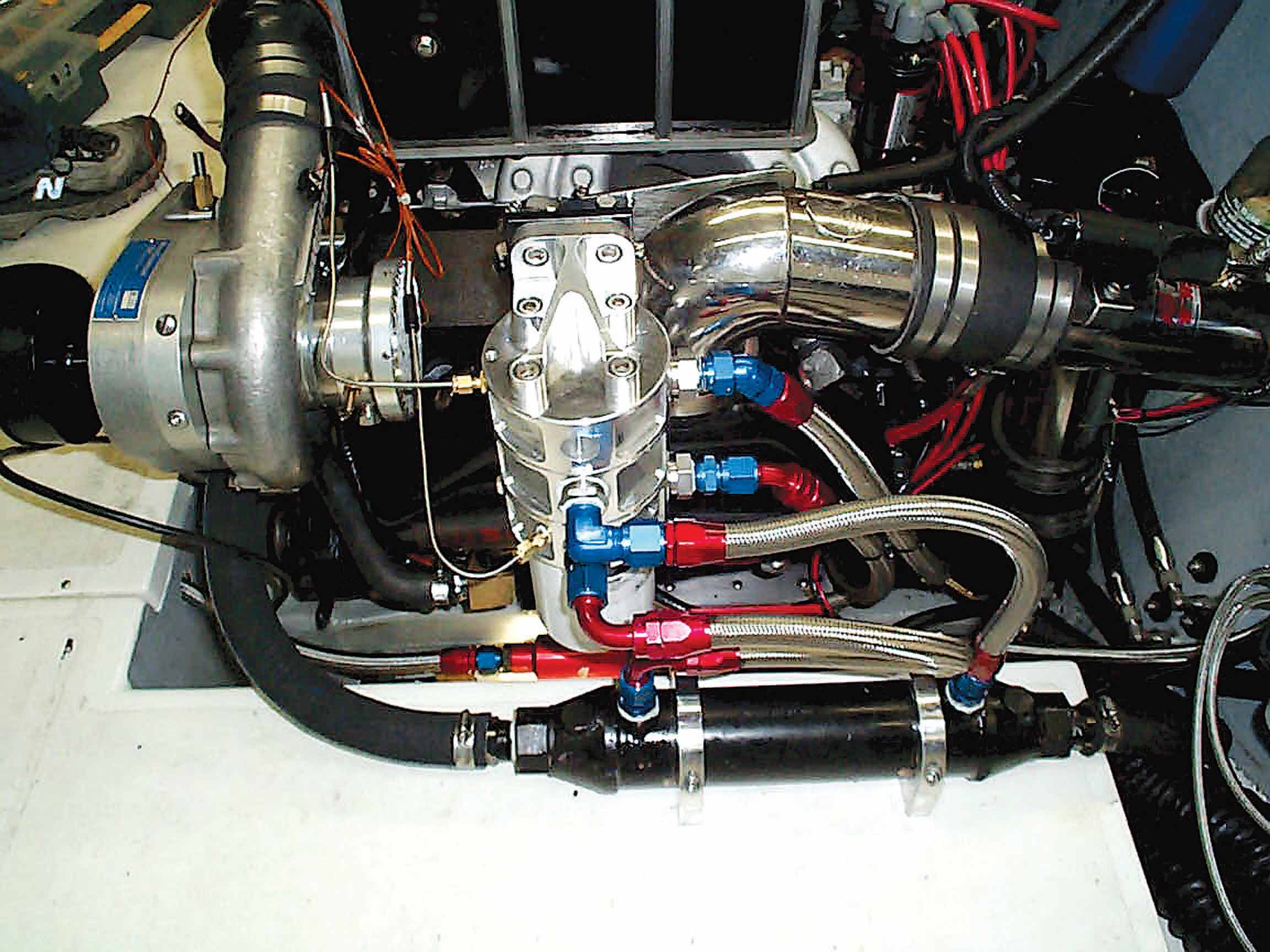

Our thermostat was the Hardin Marine Extreme Series thermostatically-controlled remote oil filter mount. This is a beautifully constructed piece. CNC-machined and made of highly polished billet aluminum, this part will dress up any engine compartment. After a few minutes of deciding where to mount the thermo-filter, we decided to custom-fabricate a simple bracket from angle iron and mount it to the exhaust riser out of harm’s way.

Since the parts from Hardin Marine dressed up the engine compartment so nicely, we decided to go all out and plumb the new oil cooling system with Aeroquip braided stainless hose and anodized fittings.

The entire cooling system re-vamp went off without any major issues. The complete installation took us just about eight hours to complete. We were extremely impressed with the level of engineering support and the quality of product that Hardin Marine delivered for this project. Now it was time to compare numbers and see how efficient our new oil cooling system would be.

Before the install, we ran some baseline tests. For our tests, we installed calibrated thermocouples before and after the oil cooler to be sure we got the full story. The R-Tech Supercooled M1 ProCharged 502 could easily cook the oil when we were making boost. The stock MerCruiser oil cooler provided adequate cooling when the engine was at 4,000 rpm with max. oil temperatures of 221 degrees before the cooler and 196 degrees after the cooler. When we tested at 5,000 rpm and 5.5 lbs of boost, the oil temp skyrocketed to ridiculous levels. Oil pressure dropped from overheating the oil. Water temperature was a chilly 54 degrees, and oil temperature before the cooler reached 270 degrees and was still climbing. Temperature after the cooler was 235 degrees, even with the chilly late-season lake water running through the stock oil cooler. These unacceptable oil temperatures, particularly if continued to run, would have surely destroyed the motor, especially because lake water temps during the majority of our season are in the 68- to 70-degree range.

We were now ready to test the boat with the new combination of parts installed. The first thing we noticed was how much more water was flowing out of the intercooler dump; it was shipping water in a big way. You can never have too much cool water flowing through the intercooler, so the more, the better. As we headed out into the lake, we took oil temperature readings before and after the cooler every 30 seconds at 4,000 rpm. Temperatures were fairly level until the oil started to warm up. The Hardin Marine oil thermostat opens at 212 degrees. When the oil finally reached 224 degrees before the cooler, temperature after the cooler were 212. Thirty seconds later, temperature before the cooler had risen to 230 degrees, and wham, the thermostat opened, bringing the temperature down to a cool 172 degrees.

Testing at 5,000 rpm produced equally positive results. With the oil sufficiently heated, we were holding the throttle at 5,000-plus rpm for several minutes at a time. After a five-minute run at five grand, temperatures stabilized at 243 degrees before the cooler and a very comfortable 184 degrees after the cooler. The cooler oil temperatures also kept the oil pressure well over 60 psi throughout all our tests, which (for those of us that like to run hard) is an upgrade that makes all the difference. Now that’s what we call cooler running!