Drag Race

Okay, we weren’t quite that naive about what we read regarding upgrading to 1.6 rockers on our small-block Chevy for the first time, but it was close.

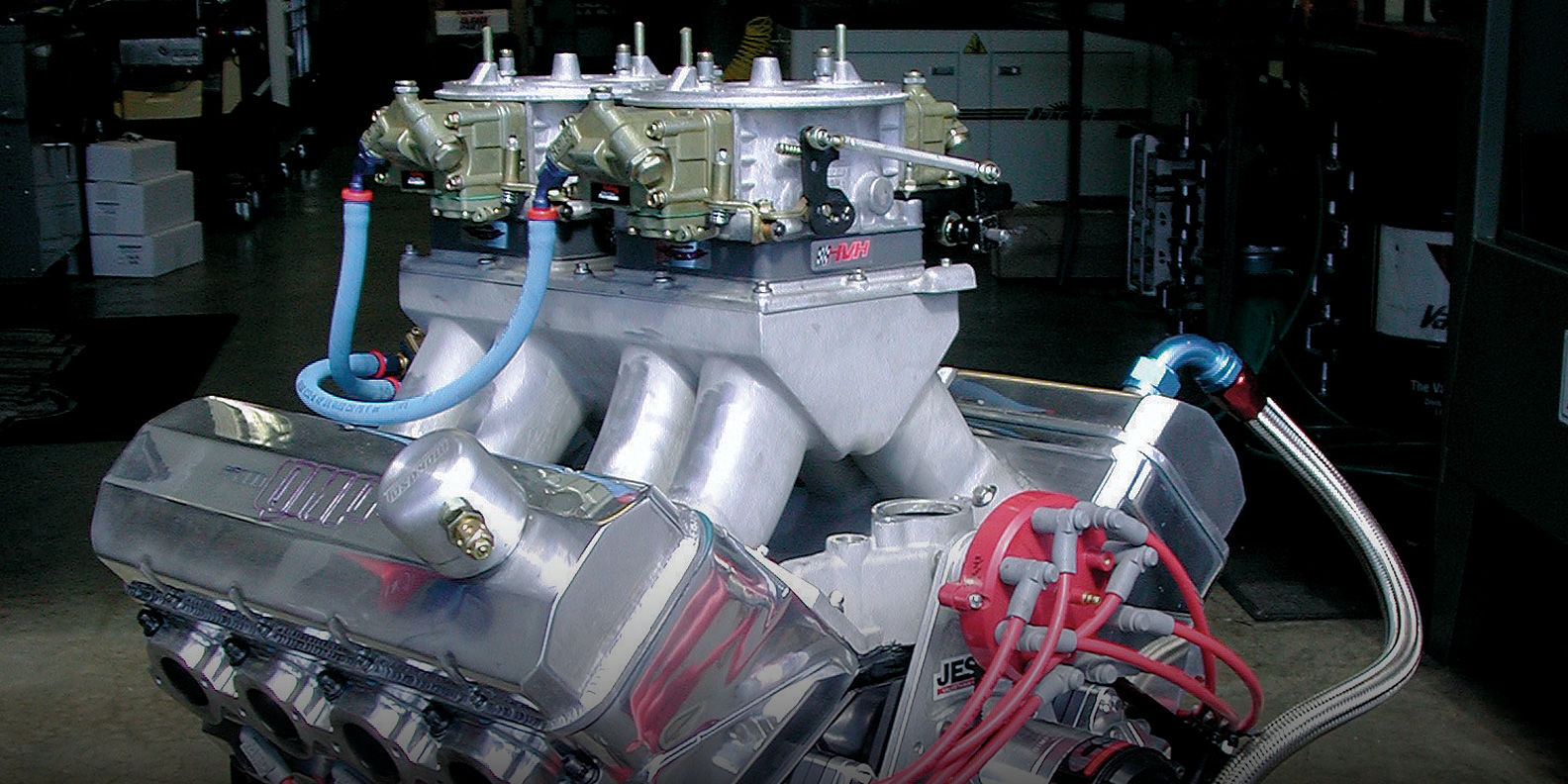

The engine in question was a decent runner with 30,000 miles on the mild-performance rebuild. The rebuilt engine was purchased used, and among its selling points were 0.030-over 9.5:1 pistons, moly rings, 1.5 roller rockers, a Performer RPM intake and a brand-new Holley 750cfm carburetor. The cam wasn’t a perfect match to the torque converter used in the previous installation nor was the final-drive gear ratio. As a result, the owner planned on stepping down on the cam chart to a Comp 286H-10 cam, which came with the engine in its original box. Also included were a brand-new factory Z28 oil pan and a factory timing chain cover to replace the cheap chrome pieces. For $300, the engine package was a deal, and one we couldn’t pass up. We sold the aforementioned chrome pieces and matching valve covers for $50, getting us the engine at the bargain price of $250, and we still had the new cam and lifters on our shelf.

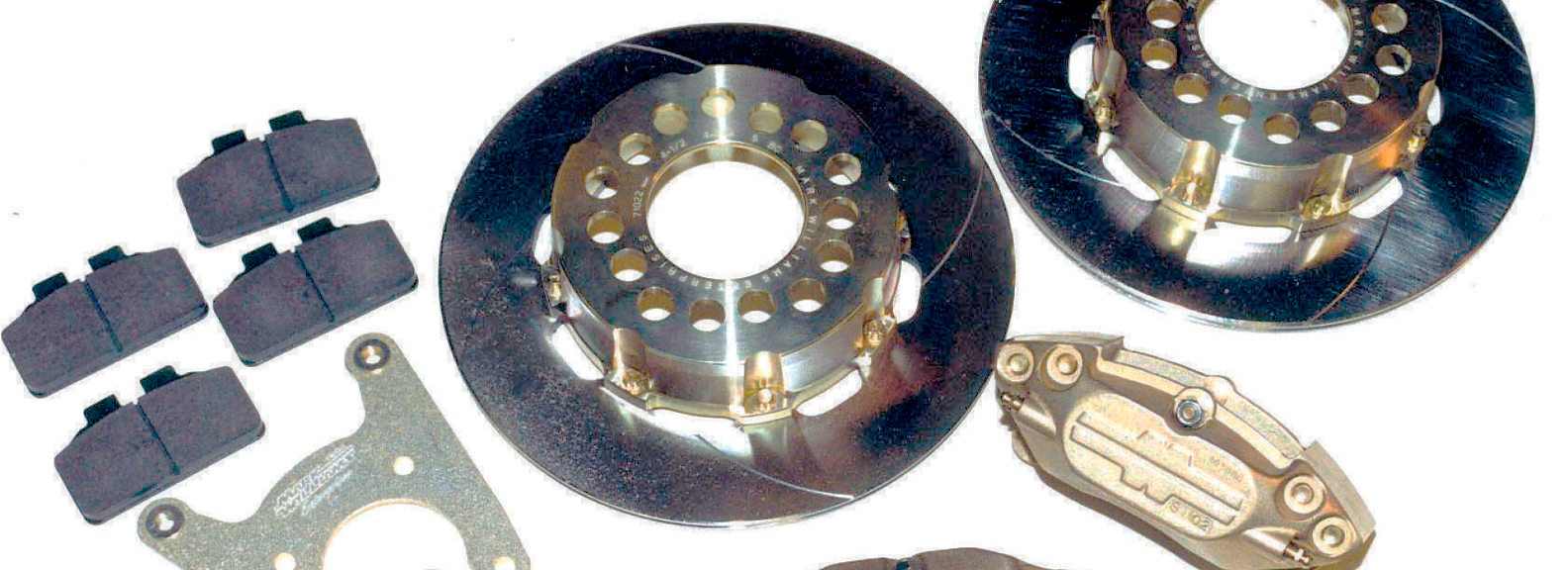

In the eyes of the Chevy enthusiast, ultimate acceleration reigns supreme. Everything plays second fiddle in the performance-oriented minds of many enthusiasts, including handling, comfort and so on—besides, those things are tough to quantify. Acceleration and top speed are what we are into and unfortunately, all too often, last on the performance priority list is braking. Remember, no matter how quick or fast a particular Chevy is, and no matter how well that Bow Tie handles, no matter how plush it is, no matter how straight the body panels are or how crafty it’s built, eventually you have to get the thing to stop.

Wheel choice is probably the single biggest factor in determining the direction of your project. Just as the thought of installing stock steel wheels on anything other than a restoration seems absurd, the idea of installing race-styled wheels on a restoration may be just as absurd. Or is it?

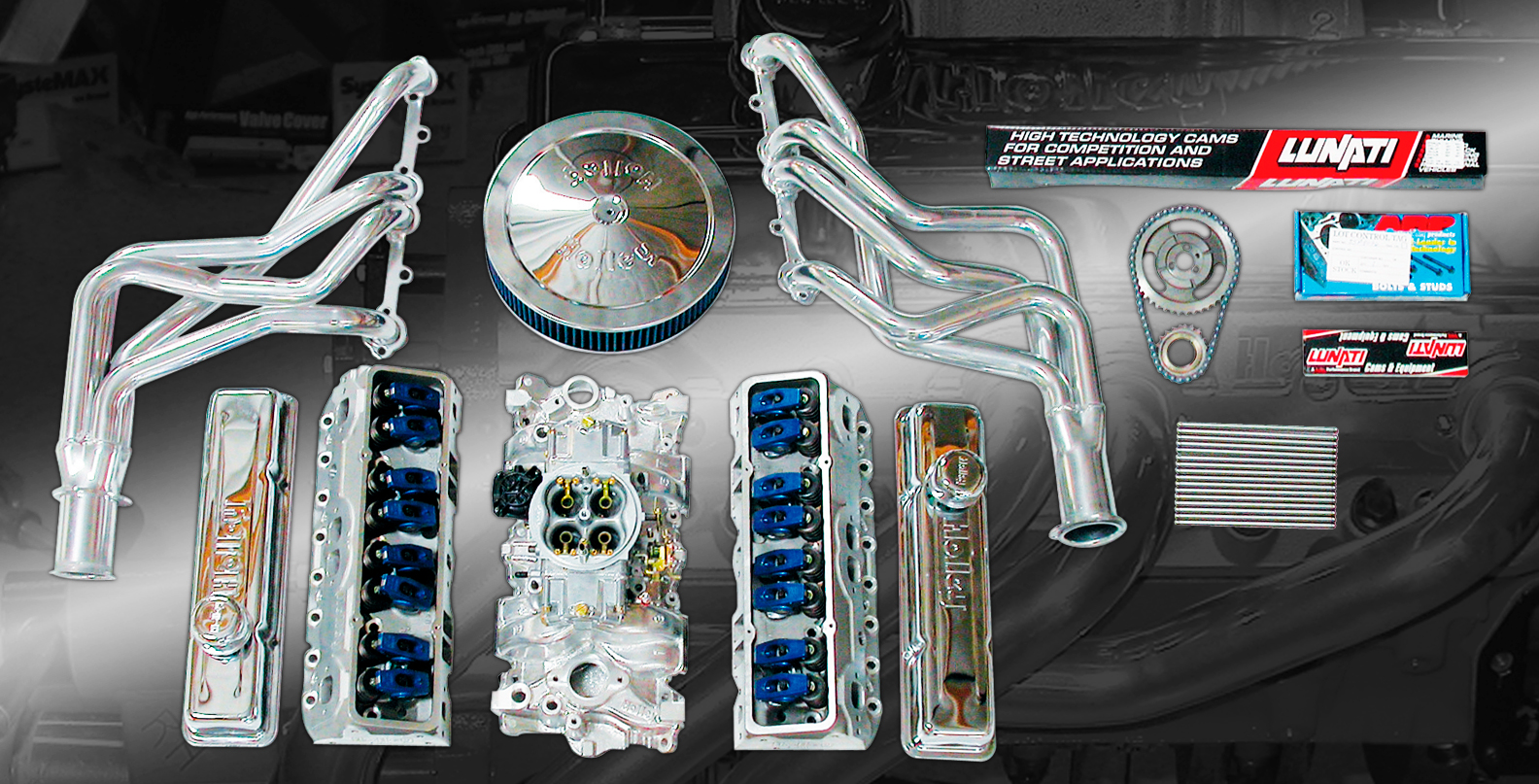

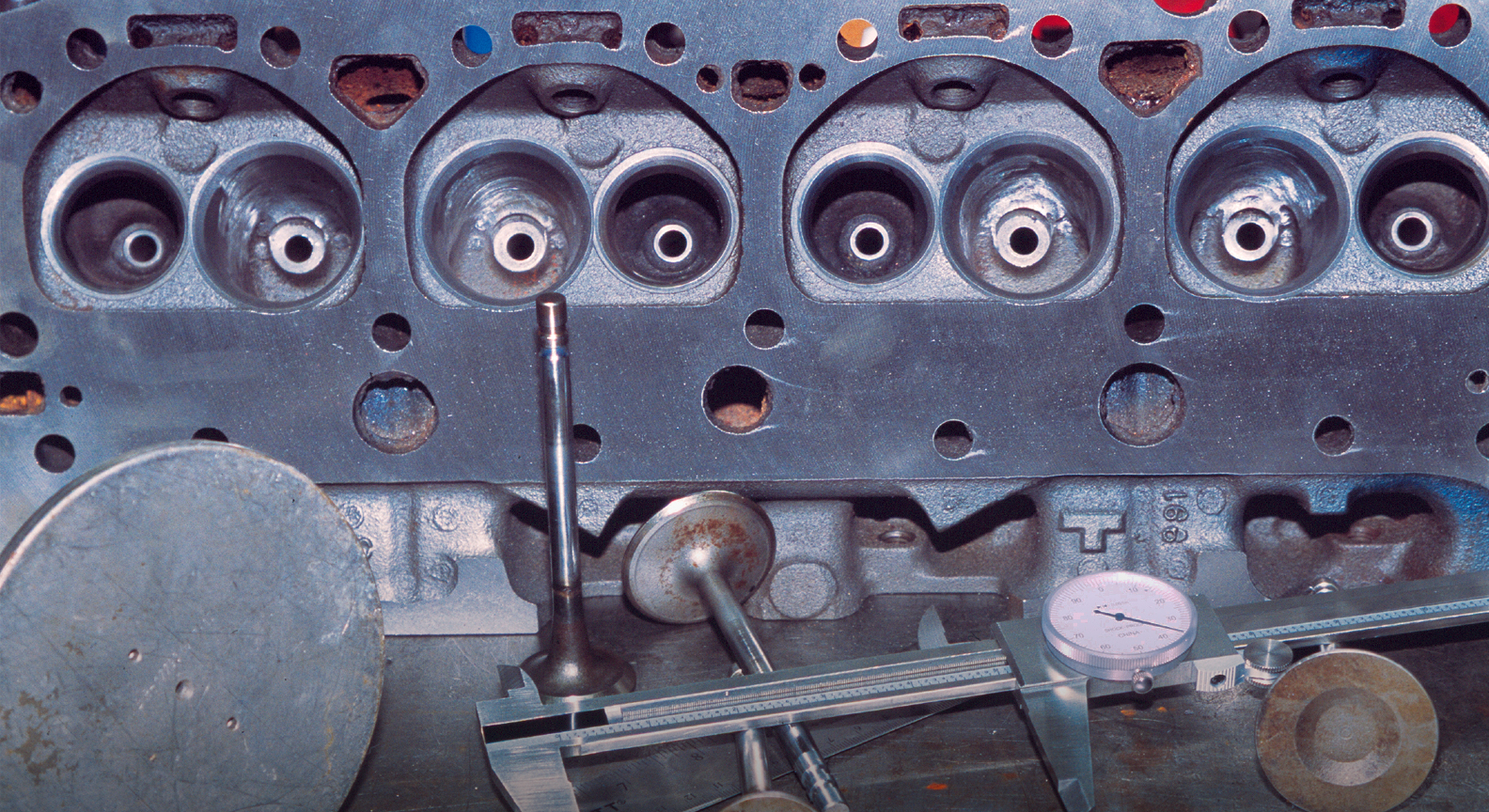

You can’t throw a stone these days without hitting an aftermarket aluminum cylinder head. They perform as good or better than anything the factories put out, and then some. They are much lighter than iron heads, and they’re now extremely affordable. Thanks to competition in the aftermarket, it could easily be said that for the performance and price benefits of a new set of aluminum heads, why would anyone bother refurbishing a set of iron castings?

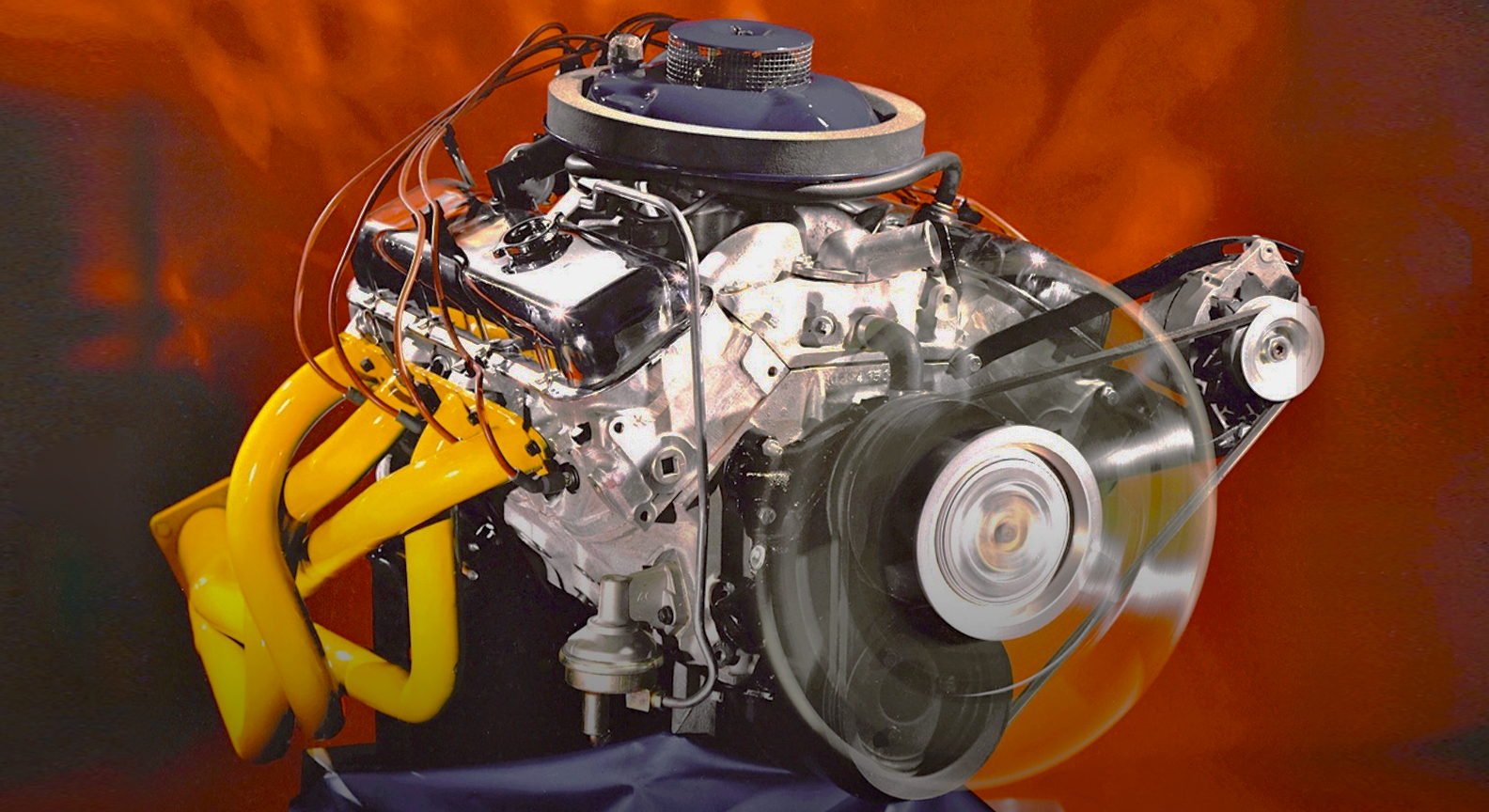

Some Years Ago, Chevrolet Began Lowering Engine Compression (To 8.50:1) In An Effort To Meet Tailpipe Emissions Numbers. It Also Retarded Camshaft Timing In An Effort To Lower NOX (Nitrides Of Oxygen/Unburned Particulates). By 1974, Horsepower, Torque And Overall Engine Efficiency Had Dropped Some 30 Percent To 50 Percent. Chevy’s RPO L48 And LM1 350 Small-Block V-8s Then Got A Flow-Restrictive Catalytic Converter In 1975, And Finally In 1985, A New Monolith Catalytic Converter, As Well As Direct-Port Fuel Injection And Improved Camshaft Timing, Boosted Horsepower, Torque And Engine Efficiency.