Engine Checking and Geometry Tips, Plus Useful Cam Choices

While explaining to engine builder Joe Sherman that the Crane 1.60-ratio roller rocker arms on our ’70 Monte Carlo have lasted over 60,000 miles and are still in fine operation today, Sherman asked if it still had the stock heads. We replied, “original L48, 300hp 350,” and his reply was just as quick: “That’s very good; gotta be a record. Bet you checked your valvetrain geometry years ago.”

His comments did capture our attention, but they also made us ask ourselves what he was talking about. We turned on our tape recorder and asked him to explain so that we could bring the information to you. Here are Joe’s comments, and he covers a lot of useful information.

COMMENT #1: AFTERMARKET HEADS

“Stock-length pushrods work correctly on any aftermarket heads only about 10-percent of the time. Most of these heads have raised ports for better cylinder filling. This usually means that the screw-in stud base is now higher. You now need to install an adjustable pushrod with a dial indicator and find out where maximum lift is. Many past stories say it should be right in the middle of the valve stem. This is okay, but if it’s slightly higher–toward the rocker arm stud–that’s even better. It’s called finding the ‘sweet spot.’ There should be a pattern on the dial indicator where maximum lift will show up over .050-.060 thousandths of a rotation. Both before and after this sweet spot, the lift will get smaller. If maximum lift is below the middle of the valve stem, this is very bad. The valve guides will wear out in nothing flat.”

COMMENT #2: LIFTER BUTTON HEIGHT

“Mechanical lifter to mechanical lifter, or hydraulic lifter to hydraulic lifter, the height of the button (where the pushrod makes contact) can be as much as 100-thousandths of an inch different. That’s a bunch. Again, you have to take exact measurements and write down everything for comparison.” We asked Sherman if this could be a reason why one engine puts out 5-10 more horsepower than another. His reply: “Could be.”

COMMENT #3: ROLLER ROCKER ARM DEPTH

“The pushrod seats in the roller rocker arm button: Do not assume that different brands are all the same (dimensionally). Actually, don’t assume anything. Check the static lift, so you know you aren’t leaving anything on the table. Also note that an adjustable pushrod can be used only for static testing, where you turn the engine over by hand (using a ratchet or breaker bar). It cannot be used in a running engine.”

COMMENT #4: USE THE SAME LIFTERS

“Work like this often drives people crazy. If they do a mockup and do not use the same lifter in checking as in the running engine, lift numbers can change. People who degree cams with solid lifters to figure out their geometry, then switch to a hydraulic lifter for operation, can be completely out to lunch.”

COMMENT #5: “CORRECT GEOMETRY” DEFINITION

“Finding the correct geometry means getting maximum lift, but moreover, it also means you won’t wear out the valve guides prematurely.”

COMMENT #6: HORSEPOWER BENEFIT

“Besides normal-wearing valve guides, the biggest benefit is power gained. Major race shops have tested for this. It is both theoretical and possible to gain 5-10 horsepower. That’s .5 to 1.2 horsepower per cylinder–good geometry versus bad geometry. A shorter pushrod will open the valve a bit sooner than one that measures up right in the middle of the valve stem.”

COMMENT #7: SUPPLIED PUSHRODS

“Companies once supplied stock-length pushrods with everything. They’re okay with factory stock heads, but not with aftermarket heads. There are so many different aftermarket heads that rocker arm positioning is going to be different. This requires a different-length pushrod.”

COMMENT #8: MANDATORY CHECKS

“Nobody uses stock heads in serious performance and race applications, other than where it’s mandatory per the rules. So valvetrain geometry checks are mandatory.”

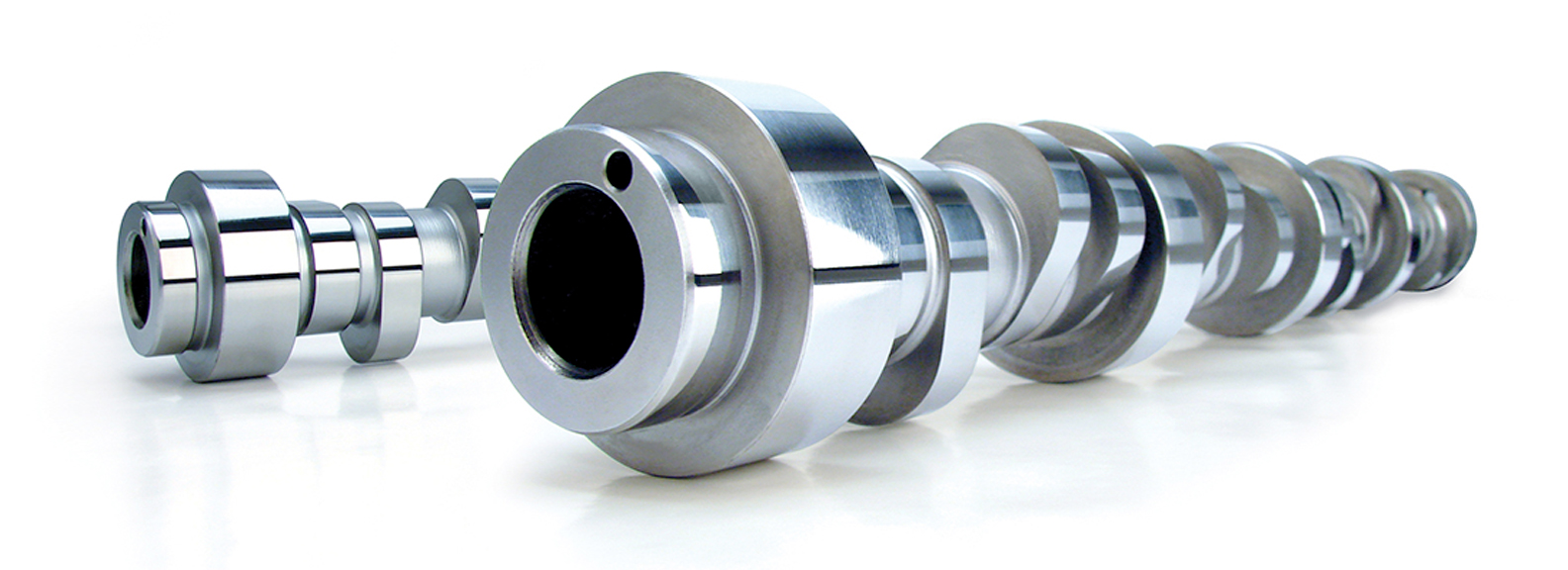

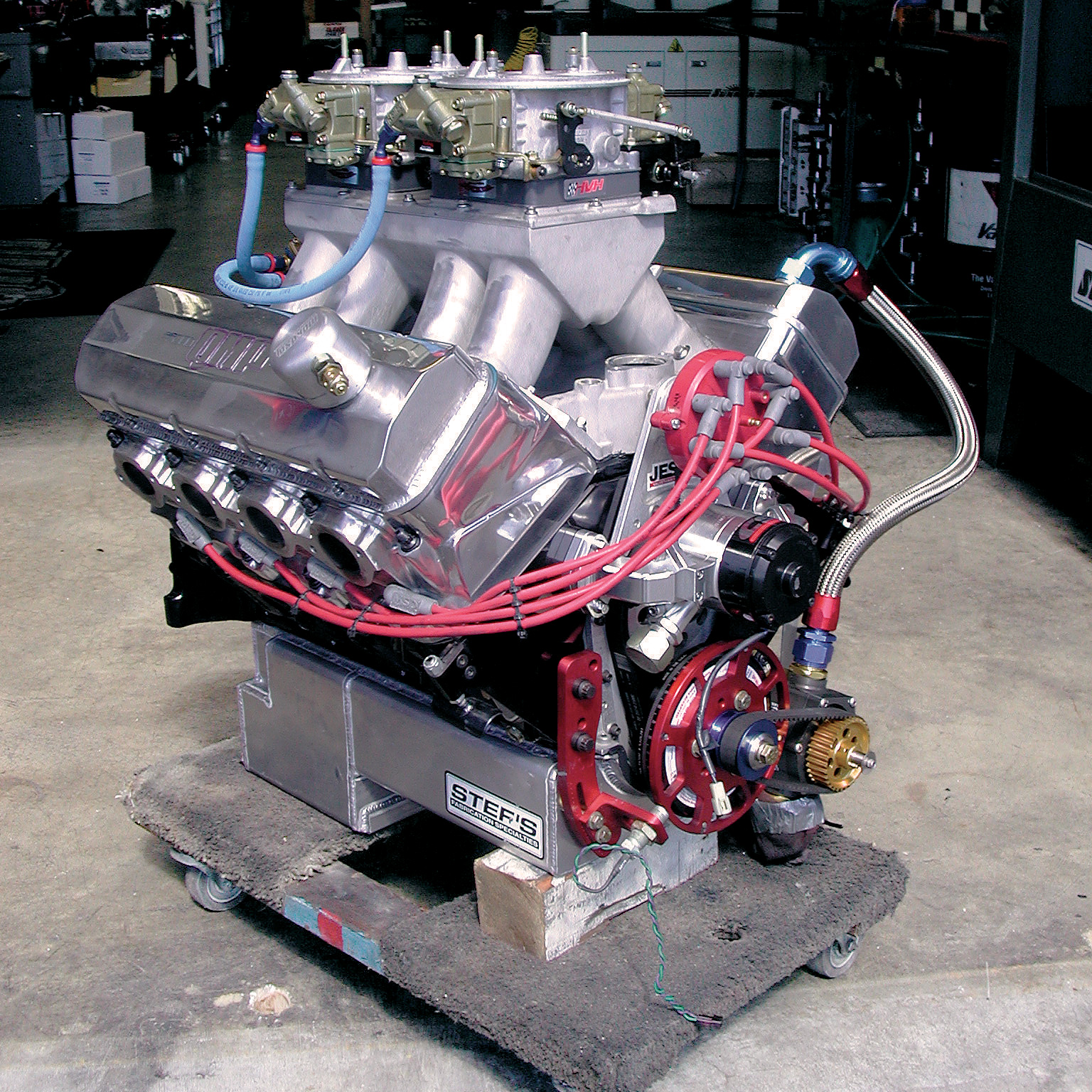

MULE ENGINE CAMSHAFT TESTING

-

Subject: 11.0:1 compression 357

Top engine shops indeed test their wares repeatedly. Such is the case with Joe Sherman. Never have we asked him for secret data. We’re happy with the good ol’ hardcore stuff that will benefit you for free! Sherman’s secrets are generally buried in his one-off, built-to-spec engines.

His “mule” engine is a 0.040-inch oversize 350 (357) with 11.0:1 compression ratio (pump gas friendly). The pistons, connecting rods and piston rings are “sophisticated.” Factory pieces they are not, but neither are they out of line financially. He recently tested five camshafts to see where the horsepower and torque numbers plotted on an rpm scale for each profile.

The drill is not to see how much horsepower you can make at a high rpm. It’s what numbers you can post every few hundred rpm, from 3000 to 8000 rpm. Why? It’s this kind of powerplant that propels the car ahead by a few car lengths through the quarter-mile. All those numbers from 3000 to 7800 rpm are far more important than what the digital number reads at 8000 rpm.

Each camshaft tested had a lift of about 0.540 inch. The heads were aluminum angle-plug 2.02s. An open-plenum race manifold with a Holley 850cfm annular discharge carburetor served as the induction.

When the testing was completed, Sherman was most positive in talking about the smallest camshaft. It was a 262-264-degree cam at 0.050 inch. He thought his overall combination was right-on, and he expected to see 550 horsepower at 7500 rpm. We could certainly live with that. Well, at 6500 rpm, the Superflow dynamometer read 530 horsepower. At 7700 rpm, it was 585 horsepower! Subsequent runs produced a peak of 590 horsepower at 7700 rpm. We’ll be “peaking” over Joe Sherman’s shoulder for more dyno test engine combos in future issues.