A HIDDEN ALTERNATOR CHARGING SYSTEM THAT ONLY LOOKS LIKE A GENERATOR

Story and Photography by Jay Harden

The relentless progress of technology is a difficult topic for those of us captivated by the cars and lifestyles of a bygone era. As technology advances at an exponential rate, we now find ourselves clamoring to keep up with the latest and greatest products that simultaneously render many of our old favorites obsolete. Just about the time you figure out how to use your new digital camera and multifunction cell phone, you find out that someone decided it was necessary to combine the two. The struggle to balance the conveniences of modern technology with our nostalgia is especially difficult for many street rodders.

Technology offers a seemingly endless supply of daily conveniences, but convenience is not necessarily what street rodders want. Many want their cars as they once were, only faster, louder and more controllable. Then there are those who would much prefer to watch the faces of admiring passersby from their massaging leather seats with solid-state sound systems and the A/C blasting. New technology does that to people, even street rodders, but it also provides other advantages: reliability, better performance and comfort. However, these new advantages can come at a great expense. The very character, that all-important and irreplaceable element of rodding that drew most of us in to begin with, is often sacrificed for convenience and progress. Many attempt to balance form and function with the new and the old, and they often conclude with a universal “What the….?” But there are those times when the right technology finds its way into the right hands, like computer-controlled direct-port Hilborn setups and three-bbl electronic-controlled intake systems. That’s not as much a convenience as it is performance progress with style.

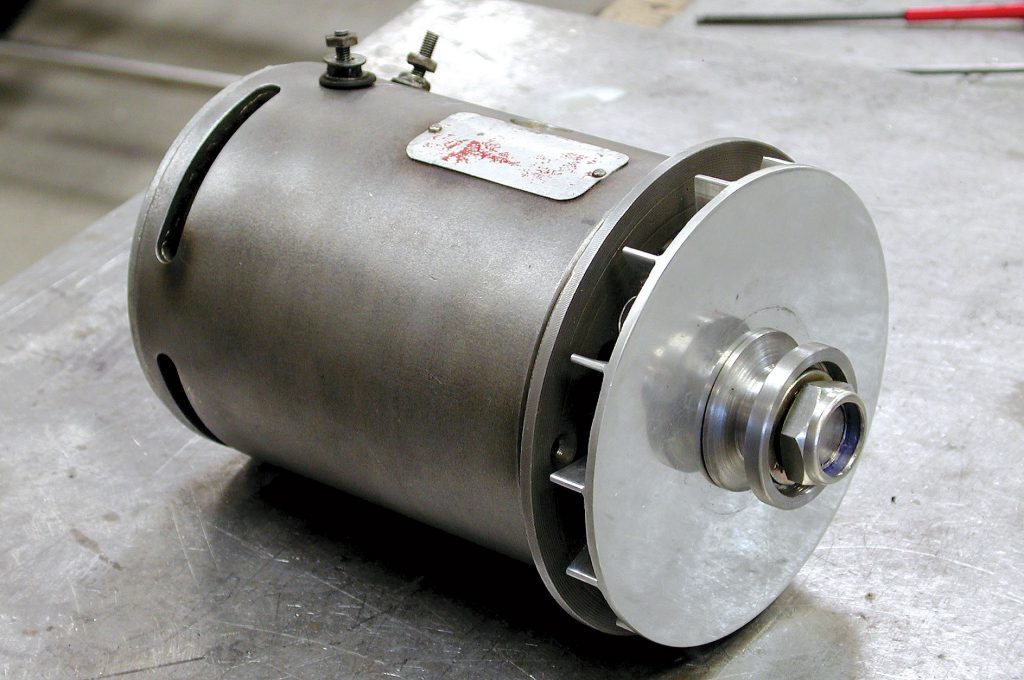

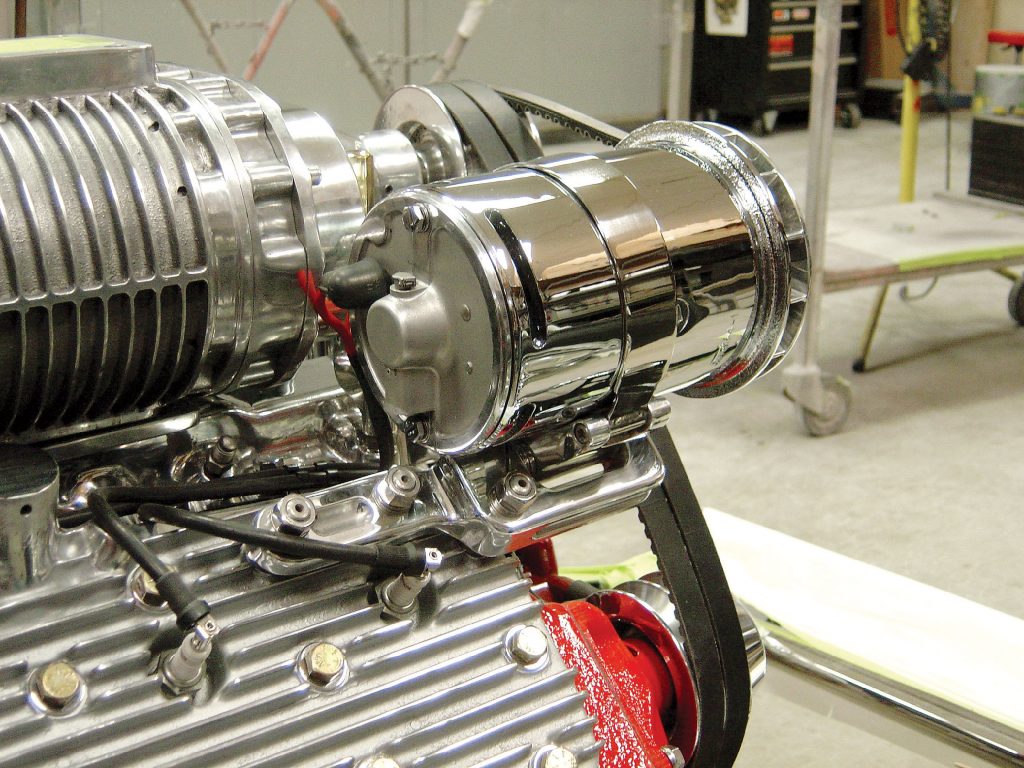

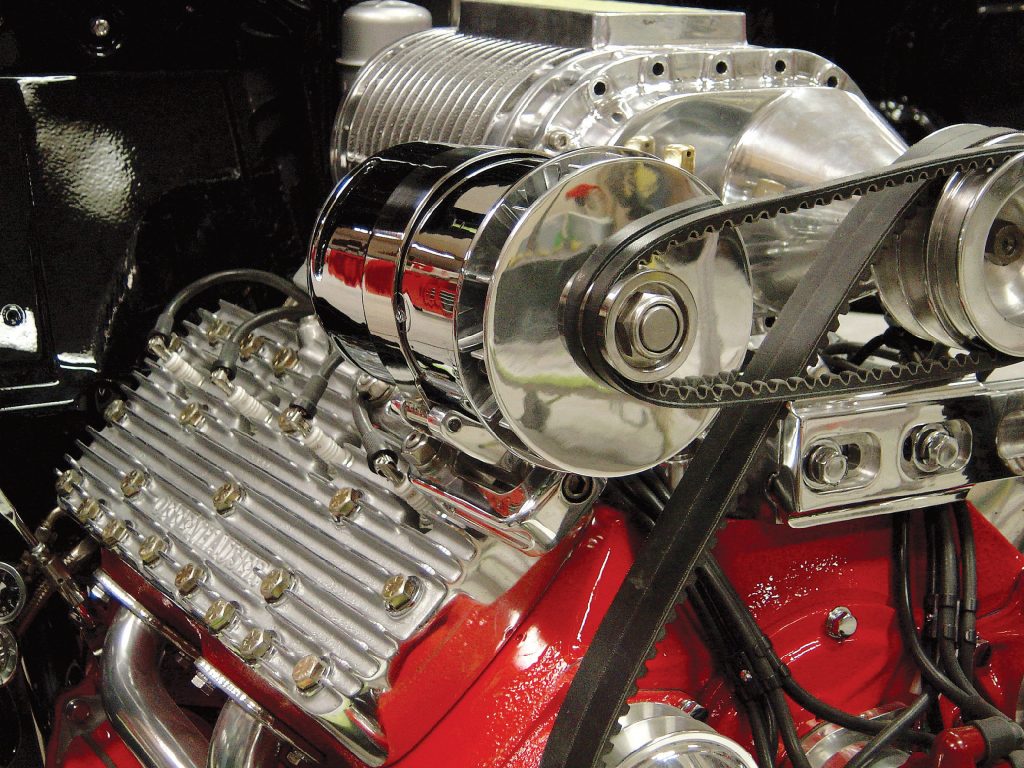

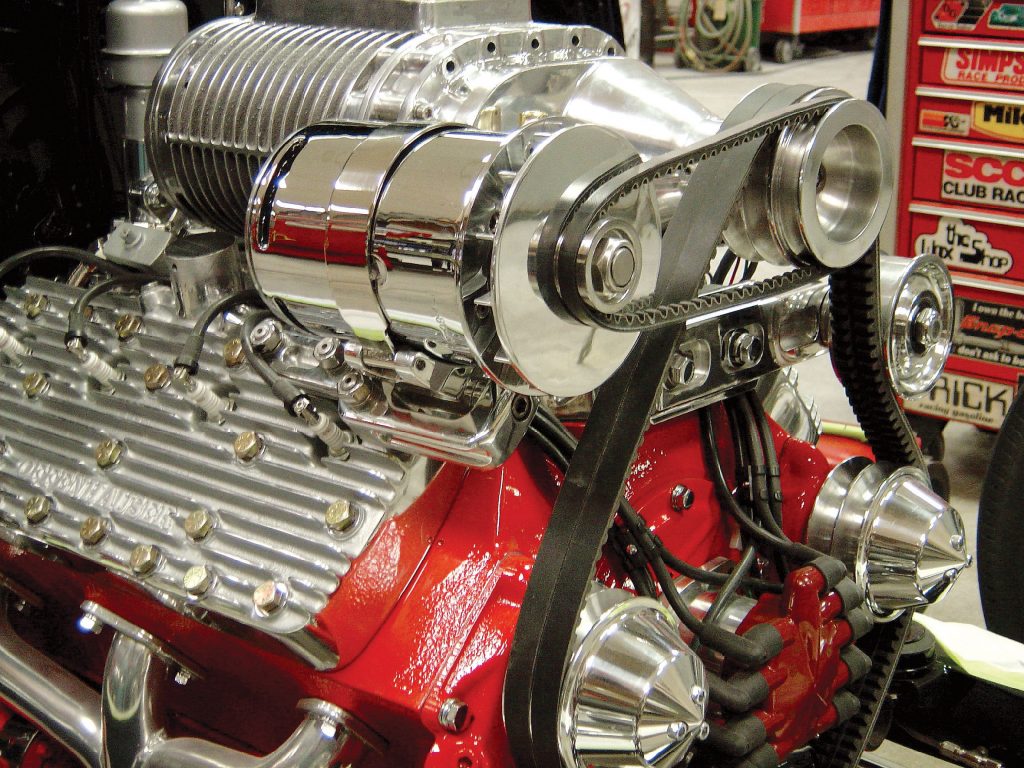

Another example of how to correctly combine the advantages of modern technology and the irreplaceable character of nostalgia can be found on a little ’32 Ford three-window coupe being built as a period-perfect ’50s hot rod at Steve’s Auto Restorations (SAR) in Portland, Oregon. What makes this car a little different can be found in several modern upgrades hidden well enough not to reveal its true “authenticity.” One of the most interesting details of this build is the generator that sits atop the blown Flatty. Although most admirers would probably never notice the difference unless they were told, the generator simply acts as a clever housing for the alternator. The authentic appearance of the car undermines several upgrades that necessitated a more efficient charging system than an old generator could provide. With halogen headlights brightening the way and an electric fuel pump feeding the Flathead, the decision was made to hide the new within the old. We thought it was trick enough to show you how those clever guys at SAR pulled this off.

Although most of us would waste little time pondering the necessity of matching a purse with shoes, we would question the importance of appropriate engine accessories. For many traditionalists, plopping a new alternator on top of a detailed and SCOT supercharged Flatty would best serve as an invitation for a fight. The crew at SAR wasn’t interested in starting any trouble, but an alternator was deemed necessary because of its superior charging capabilities and efficiency. So they decided to mix the old with new to satisfy the customer’s desire to achieve a period-specific appearance without the headaches of decades-old technology. The stock generator produces about 15 amps at idle and around 30 amps at full steam. This does not compare favorably to the 40 amps at idle and 70 amps at speed provided by the alternator; the generator simply cannot keep up. Although the generator and alternator cases have been machined specifically for this application, the alternator internals are easily replaceable. Rather than relying on specialty parts and service for a near-century-old generator, the alternator is much more reliable and cheaper to service.

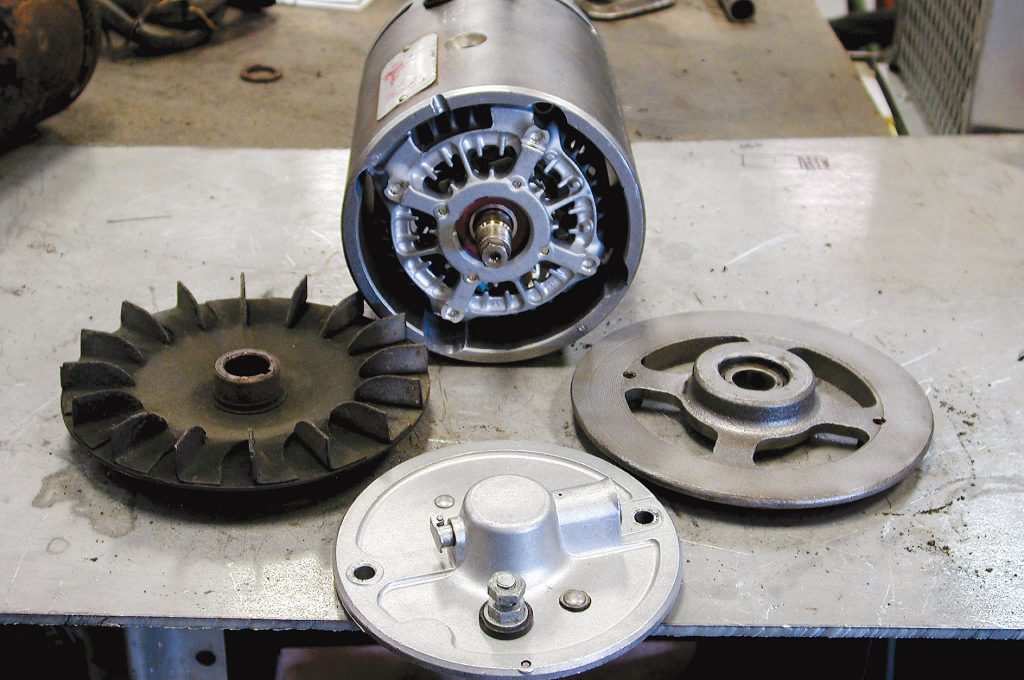

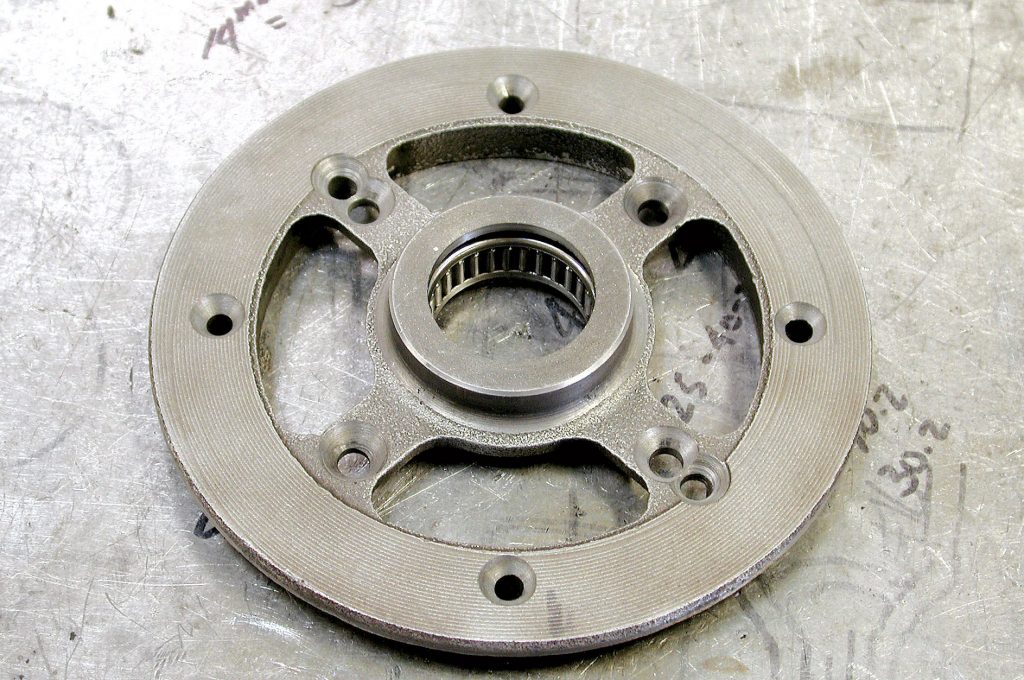

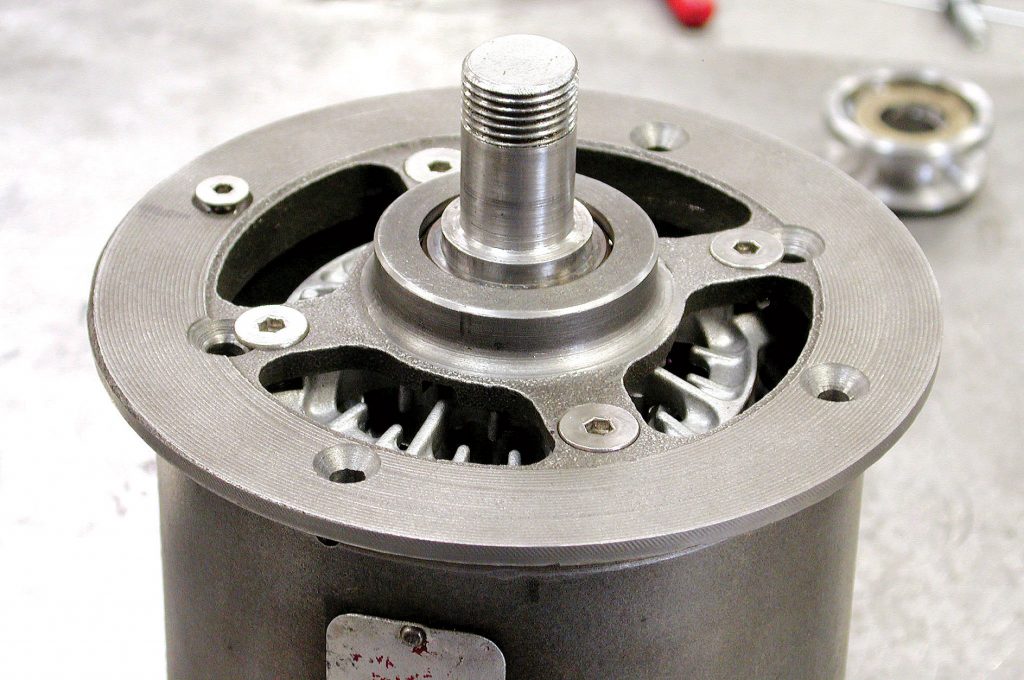

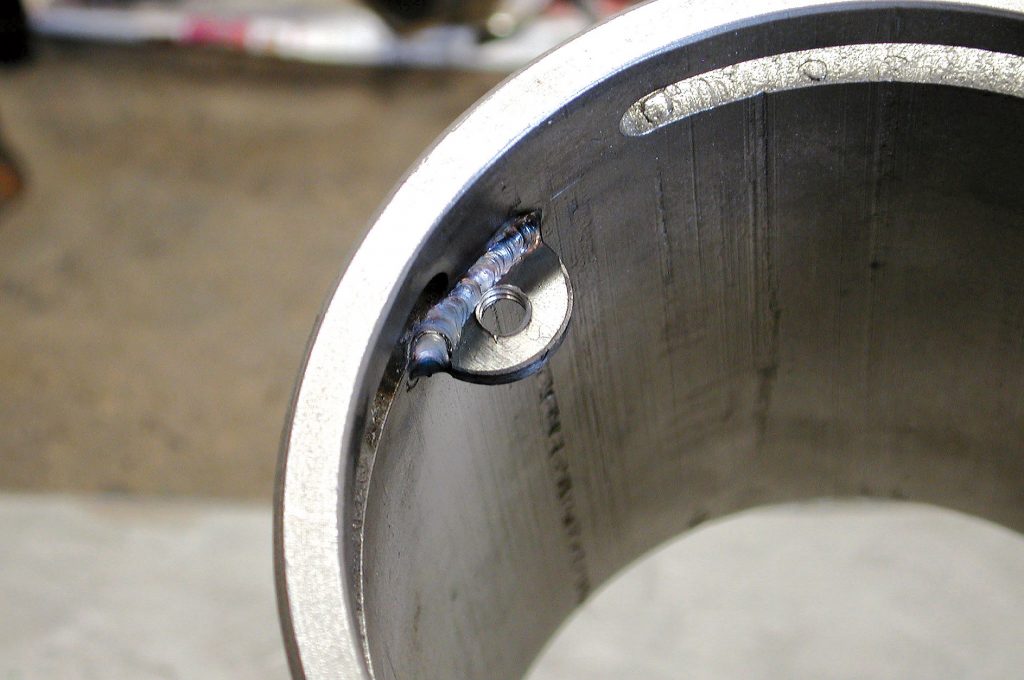

The first step involved gutting the generator and machining the housing to accept the smaller alternator. The alternator is actually a small industrial tractor unit, but it provides plenty of charging for the deuce. The real work began after the alternator housing was machined to slip inside the generator case. Because the alternator shaft was too short, a longer one had to be machined as an extension. The front cover was also machined to accept a new bearing to help support the load of the shaft extension. If the required machining process seems complicated, you are correct, but the greatest testament to the expertly assembled piece is that it is virtually indistinguishable from a stock unit.

Make no mistake, the ingenuity and skill required to combine new technology with nostalgic character is not always easy or simple to pull off. When it is, though, it blends the best of two worlds: an era we love and one we can’t live without. Thanks to shops such as SAR, which continue to prove that we can still put technology to good use, even when it is well hidden within the belly of ages-old technology, we get to enjoy the old with the new.

Article Sources

Steve’s Auto Restorations

www.stevesautorestorations.com

503/665-2222

4440 S.E. 174th Ave. Portland, OR 97236