THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

4/7 SWAP

Changing Cam Lobes and Firing Order Can Add Power

Author

Mike Petralia

Story and Photography

However, we wanted to make more without making any radical changes to the engine. In fact, we decided to make essentially zero changes to the engine and see if we could still make more power. Confused? Well, it gets better.

We did actually change one part, namely the cam. But we consider that actually not a change at all. You see, if you were building a motor from scratch and hadn’t already bought a cam, the “new” cam we installed would be the only cam to buy. Get it?

Oh, and one more thing. The new cam changed the engine’s firing order, too, and it’s what you might call the 4/7 swap. Racers have been doing this for quite some time. Swapping lobes 4 and 7 on the cam and distributor cap yields better power in most Chevrolet engines. Why is that, you ask? Here are the basics of the reasoning.

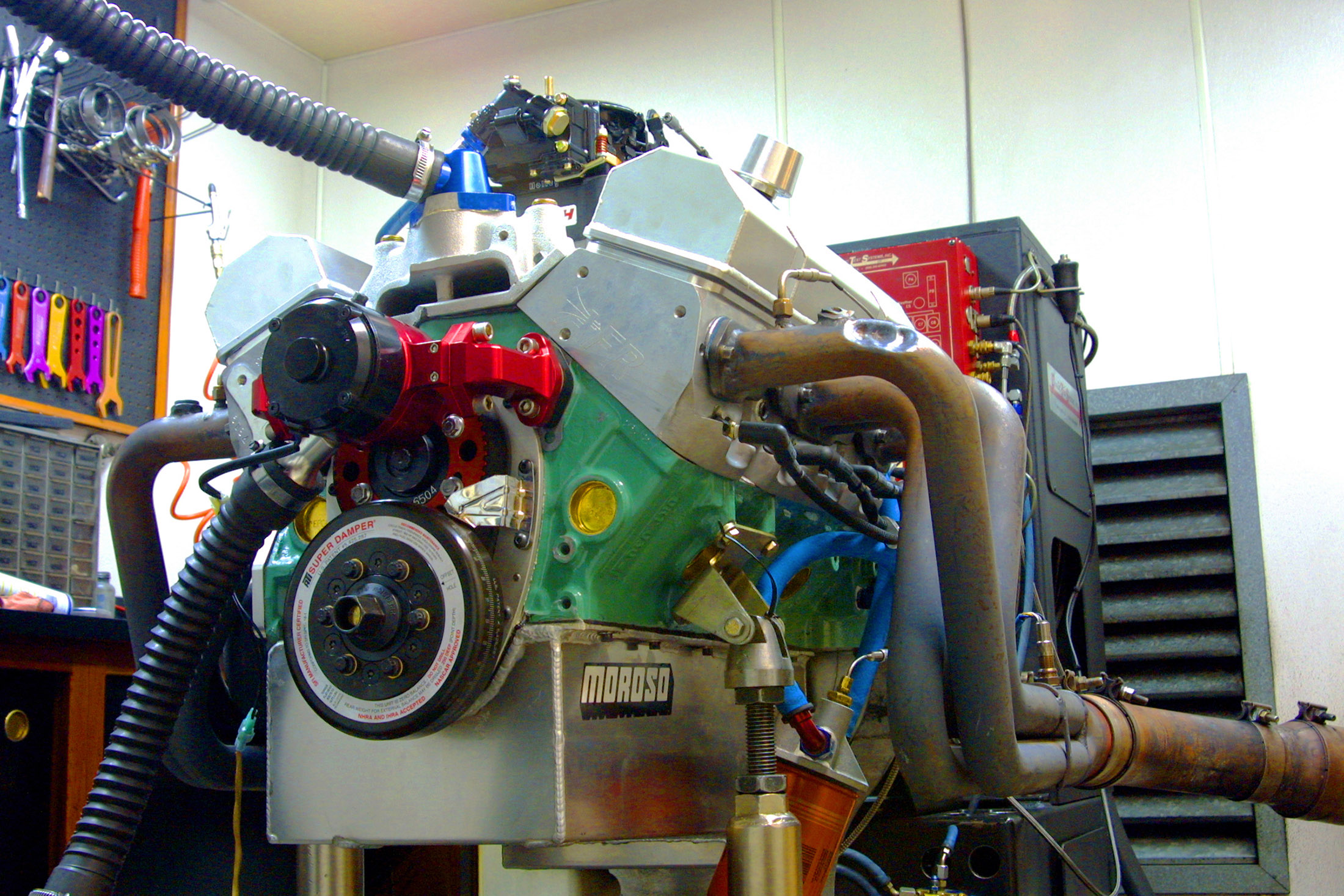

87-OCTANE ENGINE REVISITED

To make this kind of power, you need some cubic inches, so we started with a Dart Iron Eagle four-bolt block that had a standard 9.80-inch deck height. The bottom end carries an Eagle Specialties Pendulum Undercut 4340 forged crank. Eagle’s undercutting process strategically lightens the crankshaft, improving the engine’s ability to accelerate.

Connected to the crank are Eagle’s 5.850-inch H-beam rods floating JE pistons that were custom-made to take heavy abuse. Since we expected this engine to possibly detonate at some time in its lifespan (very hot days, long hauls and uphill driving, for example), we had Speed-O-Motive in West Covina, California, apply their specialized coatings to reduce friction on the piston skirts and reject heat from the piston tops (they also handled the block machining). A JE Pro Seal ring pack was selected because it’s designed to take abuse from heat and detonation.

The Airflow Research CNC heads have 180cc intake runners with extremely good cylinder filling capabilities and an awesome exhaust port. AFR’s standard 68cc chambers put the engine below 9:1 compression (8.77:1). Comp Cams 1.6:1 aluminum roller rockers are used in conjunction with the 2.02/1.60-inch valves.

CAM SPECIFICS

Since they greatly reduce friction, hydraulic-roller cams are the only way to go if you want to make great power with the least amount of heat buildup inside the engine. Lazer Cams ground a cam for this engine that works as well in a strong street car as it would in a high-performance truck or perhaps a racecar. It’s radical because of how much power it helps to produce without causing any noticeable detonation on 87-octane unleaded. It’s still mild because of the engine’s large displacement (409 ci) and because it could easily be driven every day. This cam, while considerably bigger than a stocker, will outrun many bigger cams in smaller motors, so it makes for a happy combination in this 400-inch-plus engine.

Other than the 4/7 lobe swap, the cam’s design is fairly straightforward. The guys at Lazer formulated that the lobe swap, especially when combined with a single-plane intake manifold, can improve cylinder filling over the stock firing order. Think of the engine as a big vacuum pump under the carb. Now, draw a picture in your head of the normal firing order at the intake manifold (1-8-4-3-6-5-7-2). After cylinder 1 draws in its mixture, the column of air/fuel in the intake manifold must switch directions and move to the back of the engine (8). Then for the next intake pulse in the old firing order, the column switches back up toward the front again (4), and then it moves directly across the engine to cylinder 3 and so on. With the 4/7 swap (1-8-7-3-6-5-4-2), note how after cylinder 8 draws its mixture, the column of air/fuel, which is already heading toward the back, now more easily slides across to cylinder 7. Then it gets a little better still after it moves up through the middle of the engine at cylinders 3, 6 and 5 and finishes at cylinders 4 and 2, which are right next to each other. It’s theorized that less momentum loss in the air/fuel column is why the 4/7 lobe swap adds power.

4/7 SWAPPING FOR POWER

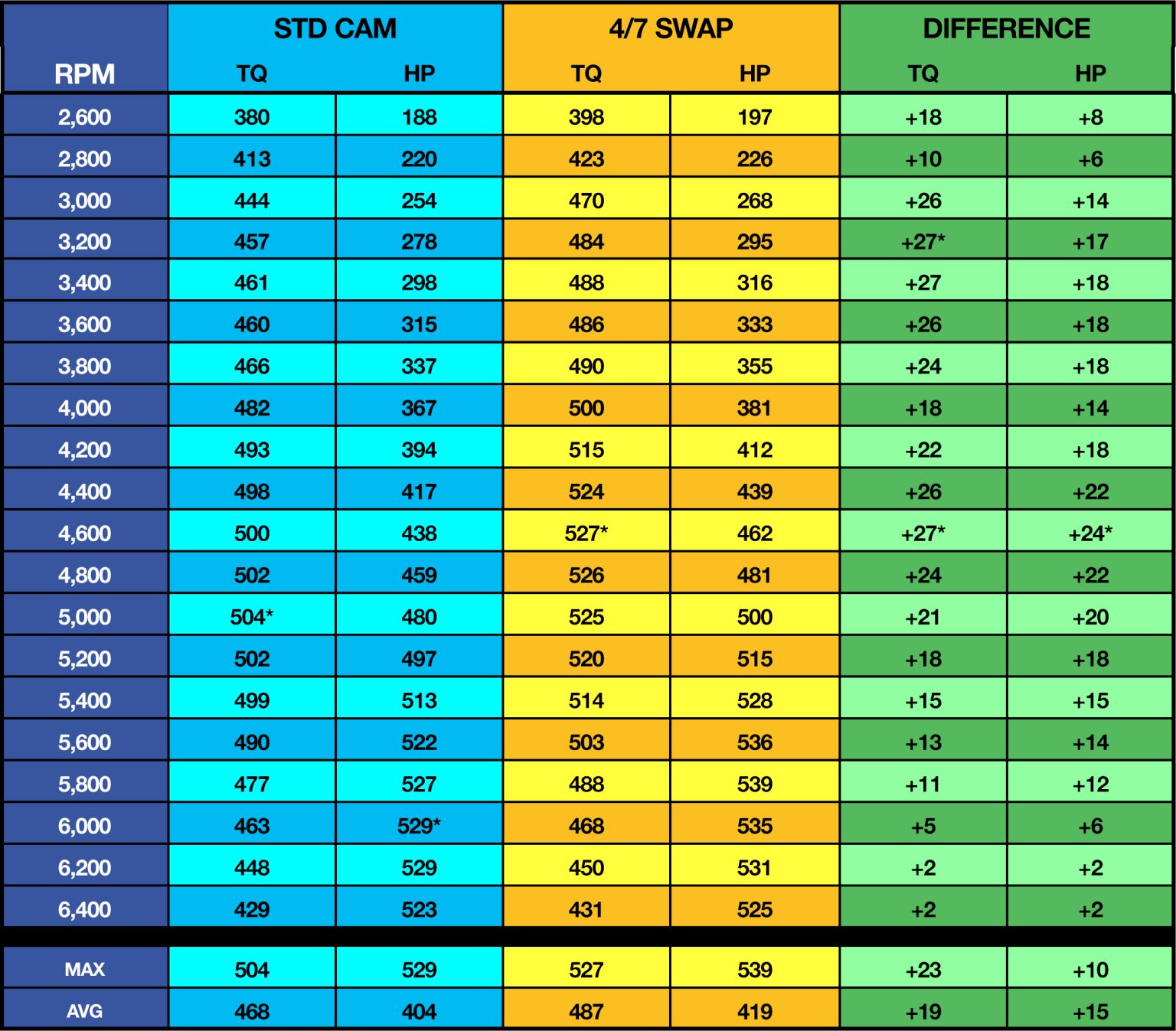

The biggest gains were at the torque peak, where the 4/7 swap cam picked up 27 lb-ft and 24 hp. Also check out how there was a 27 lb-ft torque increase at 3,200 rpm, even though it dipped slightly after that before regaining its momentum again at 4,400 rpm.

ENGINE COMPONENTS

This is a list of the pertinent pieces for this 409cid,

- 87-octane SBC buildup.

- Bearings: Clevite H-series

- Block: Dart Iron Eagle (PN 31121211)

- Bore/Stroke/CID: 4.165-inch/3.75-inch/408.74 cid

- Cam: Lazer HR custom 4/7 swap

- (240/246 degrees at 0.050 inch, 0.596/0.588-inch lift, 108 LS, 104 ICL)

- Cam Drive: Comp Cams belt (PN 6504)

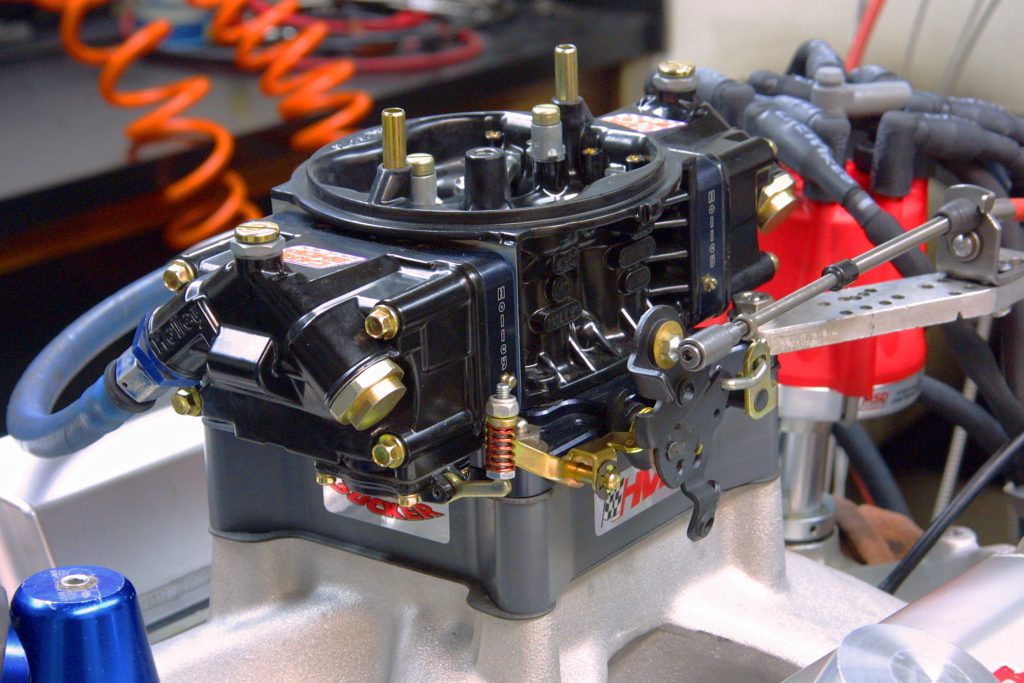

- Carb: Holley HP950 (modified by The Carb Shop)

- Carb Spacer/s: HVH Super Sucker 1- and 2-inch

- Compression Ratio: 8.77:1

- Connecting Rods: Eagle H-beam, 5.850 inches (PN CRS5850B3D2000)

- Crank: Eagle 4340 (PN 4350375057AU)

- Dampener: ATI

- Distributor: MSD

- Gaskets: SCE

- Heads: AFR L-98 180 CNC (68cc chambers)

- Headers: 1-3/4-inch Hooker dyno headers

- Ignition: MSD

- Intake Manifold: Edelbrock Victor Jr., CNC port-matched (PN 2900)

- Lifters: Lazer HR

- Pistons: JE custom (coated by Speed-O-Motive)

- Plug Wires: Performance Distributors

- Pushrods: Comp Cams 5/16-inch diameter, 6.900 inches long (PN 7933-16)

- Rings: JE Pro Seal (0.024-inch top gap, 0.026-inch second gap)

- Rockers: Comp Cams 1.6:1 (PN 1002-16)

- Spark Plugs: Autolite (PN AR3932)

- Water Pump: CSR electric

2-INCH CARB SPACER

Any time we’re on the dyno, we like to search for more power using different parts. Sometimes we don’t find any, but in this case, the 4/7-swap cam liked a little more breathing in the form of a taller carb spacer. To keep everything fair and correct, we first tested the engine using the same 1-inch tall HVH carb spacer that we ran back in the Feb. ’06 engine dyno tests, which are the dyno results shown in the dyno test. Then while tuning the carb, it seemed likely that the engine might respond to a little more air, so we installed a 2-inch tall HVH spacer, which effectively increased plenum volume in the manifold and moved the carb a little further above the runners, allowing more time for the air/fuel column to transition from vertical motion to horizontal motion. In doing so, the engine picked up power over nearly the entire rpm band, but the biggest disadvantage to this test was that the carb would sit too high to clear most hoods without some kind of hood scoop. This is, of course, why many horizontally designed manifolds have been developed over time. In all, the less the air has to transition, the more power that can be made.

New peaks with 2-inch carb spacer: TQ: 530 HP: 540

ARTICLE SOURCES

Lazer Cams - CLOSED

Division of Campower, Inc.

2839 Sanderwood Dr

Memphis, TN 38118

(901) 795-3992

Vrbancic Bros Racing

1461 E. Philadelphia

Ontario, CA 91761

(909) 947-3575