THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

THE DODGE BROTHERS

Their Name Is Peck, But They Have Mopar In Their Blood

Author

Roger C. Johnson

Photography & Words

Tony Peck’s Challenger Transformation

Tony and Phillip grew up in a family that already had its allegiance with Mopars, so it should be no surprise their daily drivers have roots in Highland Park, Michigan. Older brother Tony drives the Challenger he bought from the family of its original owner, back in 1992. Unfortunately the car was parked under a pine tree for a number of years and had rusted considerably. Eventually, Tony, younger brother Phillip, dad Frank and uncle George began a complete restoration on the E-body. When it was practically finished, a friend’s trailer somehow escaped from its hitch, rolled down Tony’s driveway and smashed into the Challenger denting up the front and pushing the car into its engine, which was sitting on a stand behind it. Tony was so distraught, so he let the car sit unfinished for five long years.

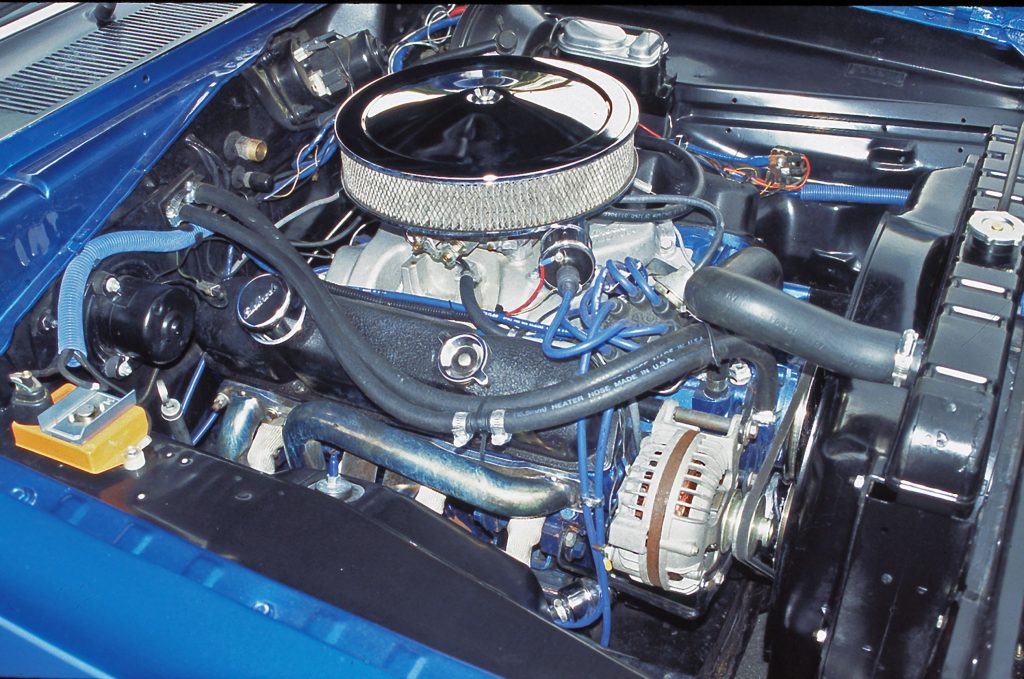

The good news is, he re-thought the entire project during this time, and decided a resto rod, with a road-racing flavor, was more to his liking than a restored stocker. So, he towed the Challenger to his dad’s shop, E&R Transmissions in Atlanta, and began the transformation. It didn’t hurt that this facility also happens to have expertise in body and chassis work as well as engine building. At the same time, the original 318 was retired from active duty and a fresh big block replaced it. The new Challenger engine is a 0.030-inch over 440, utilizing forged six-pack pistons and forged factory rods that were resized, shot-peened and secured with ARP fasteners. A factory crank operates in the oversized block that was also decked and aligned bored. To keep the engine’s weight in check, Edelbrock aluminum heads were used after being CNC ported and polished. Further dietary supplements include an Edelbrock RPM intake, and one of Vic’s 800 cfm aluminum carbs.

Challenger Powertrain and Performance

A Comp Cams XE274 hydraulic cam and lifters orchestrate the valvetrain with the help of 1.6:1 roller rockers, and pushrods from mother Mopar. Mom also supplied the aluminum water pump and housing, high volume oil pump and 6-quart Hemi oil pan with windage tray. Hedman ceramic coated headers, MagnaFlow 3-inch X-pipe and a 3-inch exhaust system from TTi expel exhaust gases like cannon fire.

As you might imagine the rebuilding and upgrading of the Challenger’s Torqueflite was a walk in the park for the Peck family. Tony chose a Mancini converter with a 2500 rpm stall speed, to harness the engine’s power and deliver it to a 8.75-inch Chrysler Sure-Grip rearend spinning 3.23 gears.

Stopping and Handling Upgrades

To make this Mopar stop as well as it goes, factory 12-inch ’cop car’ rotors from a B-body, 4-piston calipers and proportioning valve from Wilwood, and a Stainless Steel Brakes rear disc conversion kit join forces to thwart forward motion as required. Polymatrix pads at all corners help guarantee the intended results.

The car’s suspension and steering systems were completely rebuilt or replaced with more modern equipment including a fast ratio steering box and polyurethane bushing throughout. Even the sway bars were upgraded with units from Addco and measure 1-1/8-inch diameter up front and 7/8-inch out back. Putting all this energy to the ground is the responsibility of 17×8-inch front Center Lines with 225/50X17 Nitto tires and 17×9.5-inch rears with 275/50X17 Nittos, along with gas charged shocks all around.

Final touches to the Challenger include re-chromed bumpers, all new interior including reupholstered late-model Nissan seats (for lateral support), new weatherstripping, new carpet and replacement headliner.

The E-body Mopar was actually a shortened B-body chassis. This was the easiest way for Chrysler to quickly develop a brand new pony car that could handle all the engines in the Mopar family line up—including the massive Hemi. The Challenger’s wheelbase was 2 inches longer than that of Plymouth’s E-body Barracuda.

It was said the Challenger was the one car in the Mopar product line that could actually entice Camaro lovers to jump off the GM bandwagon. Some have even described them as Camaros on steroids.

The body on this Challenger was lovingly massaged by the entire Peck family to produce its laser straight sheetmetal. Only the paint was contracted out during the rebuild process.

Build-Up

Phillip Peck’s Dodge Dart Build

To round out the family portrait, younger brother Phillip picked up this little Dart in May 2004, for a user-friendly price of $600. The car originally belonged to a mechanic who moved away and left it at the garage he worked for, and never returned to claim it. Phillip loaded up the Dart on a trailer and took it to the usual sanctuary—his dad’s transmission and restoration shop.

The Dart was stripped to bare metal and required some floor pan replacement before reconstitution began. Phillip even widened the rear quarter panels one inch on each side to make room for a 17×9.5-inch rear wheel and tire package. This car’s original 318 was sacrificed to the god of doorstops, and was replaced with a low deck 400cid B-block. This is actually the engine Tony was going to install in his Challenger before he located the 440. And most of us only get old clothes from our big brothers.

Dart Powertrain and Performance

The 400 incorporates 9.5:1 Keith Black flat top pistons, rebuilt factory rods and a polished Mopar crankshaft. The 452 heads operate in conjunction with a Comp Cams X284 bumpstick, an Edelbrock Performer intake and an 800 cfm Edelbrock carb. Another “Peck Special” Torqueflite with a manual valve body and 3000 rpm stall converter are the last things the horsepower remembers before it is spit out to the rear wheels through the 8.75-inch Mopar rear and Auburn limited slip turning 3.55 gears.

Handling and Community Effort

Phillip had no intention of taking a back seat to his big brother in the ride department, so his Dart has also undergone a complete steering and suspension upgrade that includes urethane bushings, larger front torsion bars, a one inch front sway bar and a rebuilt quick ratio steering box. Phillip also tapped friend and parts guru J.J. Davis who donated much of his time, some of his parts and all of his enthusiasm to the completion of this project.

Continuing the Dodge Brothers’ Legacy

Like the original Dodge brothers, Tony and Phillip grew up in a family obsessed with all things mechanical. They possess an impressive knowledge, if not reverence, of Mopar history that can be traced to their dad and grandfather. They also display a bulldog determination to get the job done regardless of the obstacles in their path. It looks like John and Horrace can rest easy.

Like on the Challenger, all bodywork except for the paint was handled in house by the talented Peck family. The ’Intense Blue Pearl’ paint comes from the Dodge Dakota R/T pallet and is even carried over to the interior. Since Dodges have always been billed as more upscale and slightly larger than their Plymouth counterparts, it should be no surprise the Dart rides on a wheelbase of 111 inches compared to 108 inches for the Plymouth equivalent body styles. Phillip chose Center Line’s “Cruising Custom” wheels and surrounded them with Fuzion tires. Up front are 17×7’s with 225/45×17’s, with 17×9.5’s supporting 275/40×17’s out back. Notice the wheel centers have been powdercoated silver to match the bumpers and door hands.