THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Pyramid Optimized Design: The Builder’s Secret Weapon

The Quiet Partner Behind Custom Automotive’s Biggest Victories

Their Work Wins — At the Highest Level

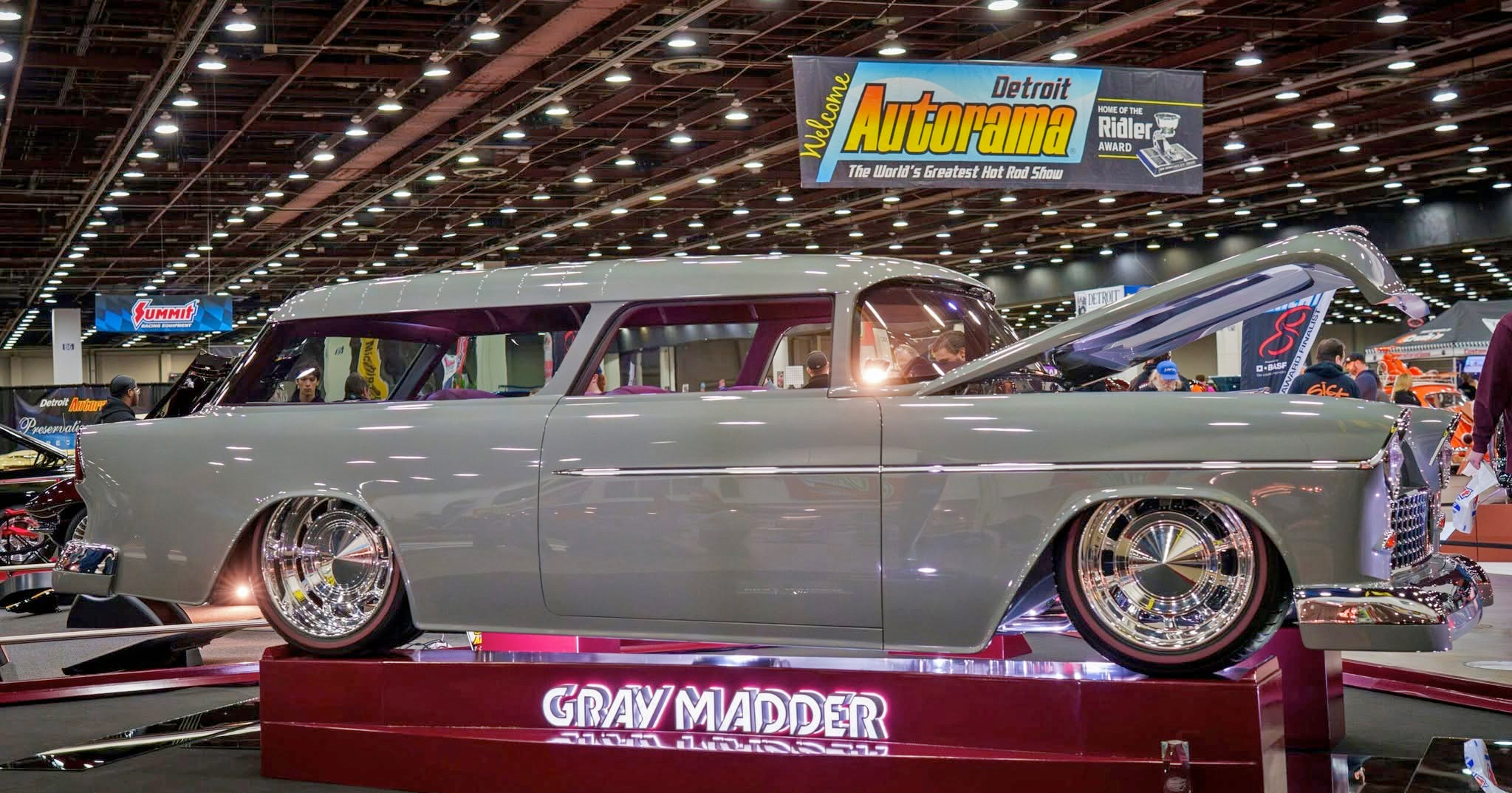

You don’t land in the winner’s circle by accident. Pyramid helped craft the headlights and taillights on the 2025 Ridler Award–winning ’55 Chevy Nomad “Gray Madder.” When the top award in custom car building is on the line, builders choose Pyramid — because their design, engineering, and execution deliver championship-level results.

And it’s not just cars. Pyramid even fabricated the Big Oak Garage Celebrity Pick trophy for the Triple Crown of Rodding, proving their talent scales from precision components to industry icons. If it needs to look incredible and function flawlessly, they’re the ones trusted to build it.

The RMS Camaro goes Commando

On the RMS Customs ‘69 “Commando” Camaro, Pyramid didn’t just contribute—they helped define the car’s identity. Their custom full-housing taillights are engineered with precision: no LED bleed, crisp illumination, and a plug-and-play fit that looks factory-born but unmistakably modern. RMS trusted Pyramid not only for the part, but for how the part integrates into the Camaro’s aggressive redesign. That’s what Pyramid Optimized Design does best: they create harmony between vision, function, and form.

Full-Service Design That Goes Beyond Parts

What sets Pyramid apart is their broad suite of custom automotive design services. They can step into any stage of a build and elevate it. Sketching, scanning, engineering, prototyping, production — everything driven by deep technical chops and creative horsepower.

Whether you need carbon fiber bodywork, intricate lighting, a complete interior redesign, or a one-off component that’s never existed before, Pyramid’s process blends art and engineering in a way few shops can match.

Capabilities That Turn Dreams Into Reality

Pyramid’s capabilities read like a dream wish-list for any serious builder. They leverage industry-leading 3D scanning, advanced reverse engineering, and full CAD development, backed by both 3-axis and 5-axis machining for precision component creation. Their 3D printing arsenal covers FDM, resin, and metal printing, giving them unmatched flexibility in prototyping or producing final parts. When a project calls for production-grade materials, they offer injection molding, plastic casting, sand casting, and investment casting, allowing them to engineer components in whatever medium the build requires. And when things need to be welded, shaped, or handcrafted, their TIG and MIG welding, wheel design and manufacturing, suspension engineering, chassis design, and full in-house fabrication ensure that even the wildest concept can be brought to life with precision and style. This isn’t just a parts shop — it’s an entire innovation ecosystem.

Bring Your Vision to Life

Got something in your head that feels “too crazy” for most shops? Perfect — that’s where Pyramid Optimized Design does their best work. Their blend of 3D scanning, CAD engineering, precision machining, 3D printing, casting, welding, and fabrication gives them everything they need to take napkin sketches all the way to award-winning hardware.

Whether you’re crafting custom lighting, rethinking a chassis, engineering a suspension system, or developing a bespoke part that only exists in your imagination, Pyramid has the technology and the talent to turn it into reality.

Your build deserves more than off-the-shelf solutions. It deserves a partner that can dream with you — and then engineer the dream into metal.

Ready to make your vision real?

CLICK THE BANNER BELOW!

Visit Pyramid Optimized Design to explore their full range of services and get in touch with the team behind some of the biggest builds in the game!

Pyramid Optimized Design

A contract design firm focused on manufacturing custom automotive parts, products, and solutions.

Collaboration beyond the status quo.