THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Products That Caught Our Eye at PRI 2025

The performance products and engineering that made us stop and take notice

The 2025 PRI Show in Indianapolis was a full-throttle showcase of performance automotive products, from street-ready upgrades to extreme race tech. We hit the floor to highlight the booths, parts, and builds that really stood out—gear that makes engines breathe better, weld stronger, and deliver reliable horsepower with precision.

Aeromotive

Aeromotive rolled into PRI like the fuel-system authority they are—quietly confident, laser-focused, and zero interest in chasing trends. Their philosophy is simple: OEM-level durability, race-level performance. Every fuel system is engineered in-house, stress-tested with aerospace precision, and built to survive street miles, dragstrip abuse, and daily driving without flinching. No gimmicks, no shortcuts—just components that deliver consistent fuel flow, long-term reliability, and total confidence every time you fire it up.

Diesel Performance Fuel Systems

Aeromotive brings that same aerospace mindset to diesel, building systems that survive heat, contamination, and heavy loads. From high-flow lift pumps to in-tank modules and complete fuel cells, every component is engineered to run cooler, quieter, and longer than conventional diesel components. Flow-through pumps, brushless motors, and serious filtration protect injectors and fuel systems mile after mile, making these diesel setups as dependable under towing or performance duty as their gas counterparts.

CLICK HERE TO LEARN MORE & LEVEL UP YOUR DIESEL’S PERFORMANCE.

PerTronix Ignition – Ignitor Series

PerTronix Ignitor modules upgrade tired points systems with a clean, reliable spark while eliminating mechanical wear, constant adjustment, and inconsistent timing. From the original Ignitor to Ignitor II with adaptive dwell control, up to Ignitor III with multi-spark pulses and an integrated rev limiter, these modules improve cold starts, throttle response, and high-RPM stability. Paired with Flame-Thrower coils, they deliver scalable spark energy, reduced misfire under load, and dependable street-and-strip performance for classic and modern performance engines alike.

VaporWorx Fuel Pump Controllers

A new addition to the Aeromotive family, VaporWorx adds intelligent control to high-horsepower fuel pumps by regulating output based on real-time engine demand. Using advanced PWM modulation, VaporWorx reduces excess heat, electrical load, and pump wear during cruise and idle while keeping fuel delivery instant and rock-solid at wide-open throttle. The result is quieter operation, longer pump life, improved street manners, and OEM-like drivability—without giving up the fuel volume required for serious power.

CLICK HERE TO LEARN MORE & TAKE CONTROL OF YOUR FUEL DELIVERY.

Aeromotive

Committed to designing and manufacturing the highest quality delivery systems in the market.

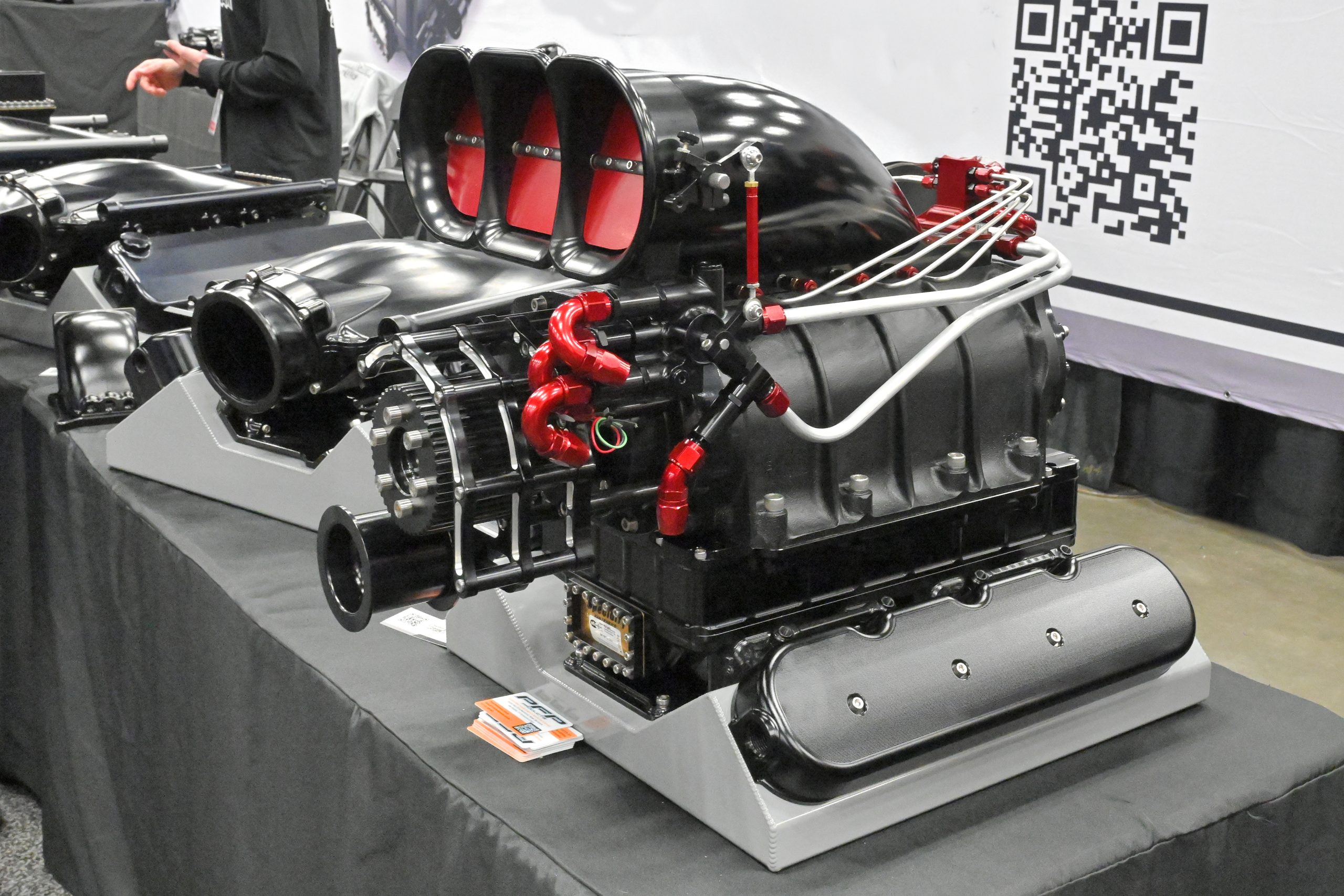

Crower & Compressed Air Supercharging

Crower Cams & Equipment has long been trusted for precision valvetrain components and race-proven engine hardware, and at PRI they paired with CAS (Compressed Air Supercharging) to showcase a radically different approach to boost. Instead of belts or turbines, CAS delivers instant power using high-pressure compressed air—eliminating lag and parasitic loss while delivering dense air on demand.

Putting that technology to the test was Tina Pierce’s Nova, a big-block 509ci combination feeding compressed air to consistently run deep into the 4-second range in the eighth mile. A proven competitor across Street Outlaws, no-prep, and radial racing, Pierce’s car proved CAS isn’t a science project—it’s a competitive, repeatable system backed by real on-track results, and one of the most talked-about displays on the PRI floor.

Crower Cams & Equipment Co.

With decades of engineering prowess behind high-performance valvetrain components, camshafts, lifters, and specialty engine hardware, Crower has long been a trusted name for builders who demand precision, durability, and proven results. Their products are engineered to extract every ounce of power and reliability from serious engine builds, whether it’s for bracket racing, hot rods, or all-out competition cars. Hosting CAS inside their booth felt like a natural fit, as both companies share a passion for pushing performance boundaries through smart engineering, not hype.

CAS (Compressed Air Supercharging)

CAS is exactly the kind of outside-the-box forced induction technology that turns heads. Instead of spinning rotors or turbines to create boost, CAS stores high-pressure compressed air (up to 3,300 psi) in lightweight cylinders and uses a sophisticated boost control unit and regulators to meter air into the engine on demand. The result is instant throttle response, zero turbo lag, and no parasitic loss from belt-driven blowers—delivering cool, dense air straight into the combustion chamber. It’s a radical reimagining of forced induction systems, refined with race-ready components specifically engineered for drag racing and high-performance racing applications.

Miller Electric Mfg. LLC

Miller Electric is a name almost every fabricator, builder, and welder knows on sight. For nearly a century, Miller has been at the forefront of arc welding and cutting technology, earning its reputation on innovation, durability, and field‑tested performance across industries from construction and transportation to custom automotive fabrication. Their gear isn’t just for the shop — it’s built to handle real work in demanding environments, backed by rigorous engineering and thoughtful design that’s kept them relevant and respected year after year.

Miller Venture 150 S Battery Powered Welder

One product that really stood out at PRI was the Miller Venture 150 S Battery Powered Welder, a portable, battery‑powered stick/TIG machine built for modern mobile welding. This welder breaks the traditional power tether by using swappable lithium‑ion batteries engineered specifically for welding, letting users ditch long leads, generators, and breaker woes — and save up to 250 hours per year on setup alone. Weighing in at under 27 lbs with an intuitive interface and features like 100 % duty cycle at max output, Lift‑Arc™ TIG starts, Hot Start™, and thermal overload protection, it delivers stable, professional results whether you’re on a roof, in a remote jobsite, or tackling structural steel.

What makes the Venture 150 S particularly compelling is how it reimagines portability without sacrificing capability. With solid stick welding performance up to 150 A, TIG capability up to 160 A, and batteries that charge fast while delivering consistent arc quality, it’s a smart tool for welders who need power in places where traditional machines just can’t follow.

Whether you’re out on a trail rig fab session, working maintenance in a tight spot, or just want to cut downtime and trip fatigue, this welder puts true on‑the‑go welding in reach — a living example of how Miller continues to innovate for the people who make things happen.

Miller Electric Mfg. LLC

Building the quality welding products you need to help build our world.

Pedal Commander

Pedal Commander Throttle Response Controller and its vehicle‑specific variants are some of the most talked‑about throttle response upgrades on the market, and the company behind them has a story that resonates with enthusiasts worldwide. Pedal Commander is engineered by Vitalen Auto Performance Inc., a performance tech company that started building its throttle controller in Turkey back in 2011. After early success across Europe, the brand moved its headquarters to Southern California in 2015 to better serve the U.S. enthusiast market and expand globally. Since then, Pedal Commander units have been sold on six continents and have earned certifications like CARB, FCC, ISO, and TÜV, as well as multiple recognitions from SEMA, which speaks to both their engineering quality and industry acceptance.

At its core, Pedal Commander exists to solve a common frustration with modern vehicles: throttle delay. Most drive‑by‑wire systems built today soften the connection between your foot and the engine, which can result in a sluggish, disconnected feel off the line. The Pedal Commander device intercepts and remaps the throttle signal to remove that delay, giving drivers a more direct and engaging response without modifying the engine or voiding warranties. Installation is simple and non‑invasive, and the controller comes with multiple modes—Eco, City, Sport, and Sport+—each with a range of 36 customization levels so drivers can tailor throttle sensitivity to their preference or driving environment.

On the PRI floor, what caught a lot of attention were the performance‑focused units like Pedal Commander for Ford F250 and Pedal Commander for Jeep Grand Cherokee. These models highlight the versatility of the system across vehicle types—from trucks to SUVs—delivering quicker throttle response and a more confident driving feel whether merging onto a highway or getting on it hard at the light. With Bluetooth connectivity and app‑based control on many versions, users can tweak settings on the fly, helping make Pedal Commander not just a performance accessory but a customizable driving enhancement tailored to individual styles and vehicles.

Pedal Commander

The world’s most advanced plug-and-play Throttle Response Controller. Designed to eliminate the sluggish response from your engine when accelerating, the Pedal Commander turns any cars into a performance vehicle in minutes.

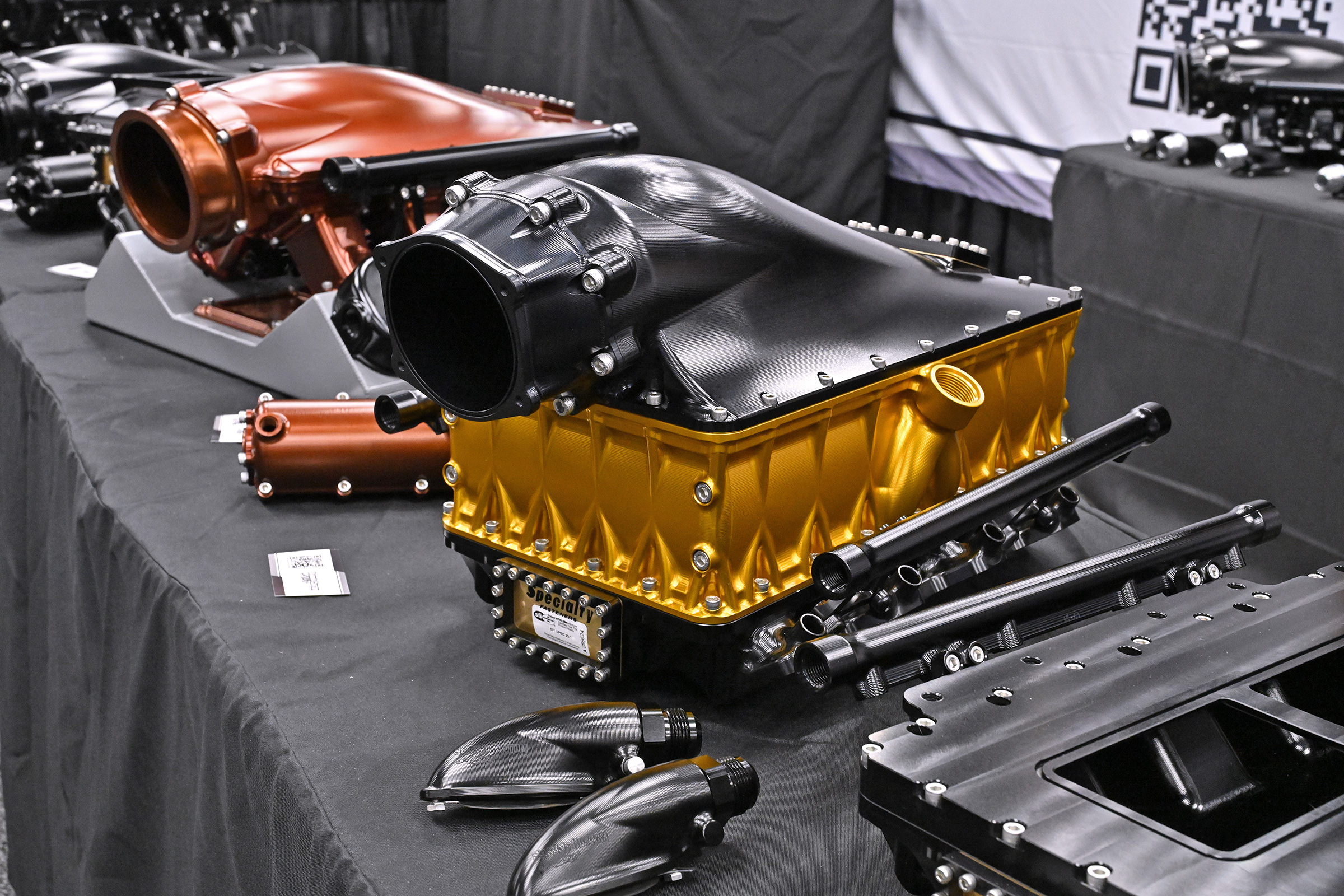

Shaun’s Custom Alloy

Shaun’s Custom Alloy is a boutique performance parts maker all the way from down under in Australia, with a clear mission: to deliver high-performance billet components crafted with precision and genuine quality. Hailing from the land of wide open roads and serious car culture, this passionate team of automotive experts builds parts from premium aerospace-grade aluminum, combining advanced machining techniques with real-world performance insight. From intake elbows and manifolds to timing covers and oil catch cans, every piece is engineered to meet the demands of serious enthusiasts and professionals alike. Their philosophy centers on doing things the right way: thoughtful design, rigorous testing, and uncompromising craftsmanship.

Quality isn’t just a buzzword at Shaun’s Custom Alloy—it’s woven into every step of their precision manufacturing process. Parts are designed using advanced CAD software, CNC-machined billet aluminum, and tested for strength, durability, and performance before ever leaving the workshop. This relentless focus on engineering refinement ensures each component enhances power, efficiency, and long-term reliability, even in high-stress performance applications. Looking ahead, Shaun’s Custom Alloy continues to invest heavily in research and development, pushing the limits of what precision-engineered billet components can deliver for modern builds.

At PRI, what drew immediate attention from builders and fabricators was Shaun’s lineup of LS intake manifolds. These LS-specific billet intake manifolds, machined from solid billet aluminum, offer superior airflow, strength, and thermal stability compared to cast alternatives. With smooth ports, clean transitions, and performance-driven design, the manifolds support everything from street performance builds to high-output race engines. Whether the goal is improved throttle response, increased peak horsepower, or a cleaner, more refined engine bay, Shaun’s manifolds stood out as solution-driven hardware with craftsmanship you can see—and feel.

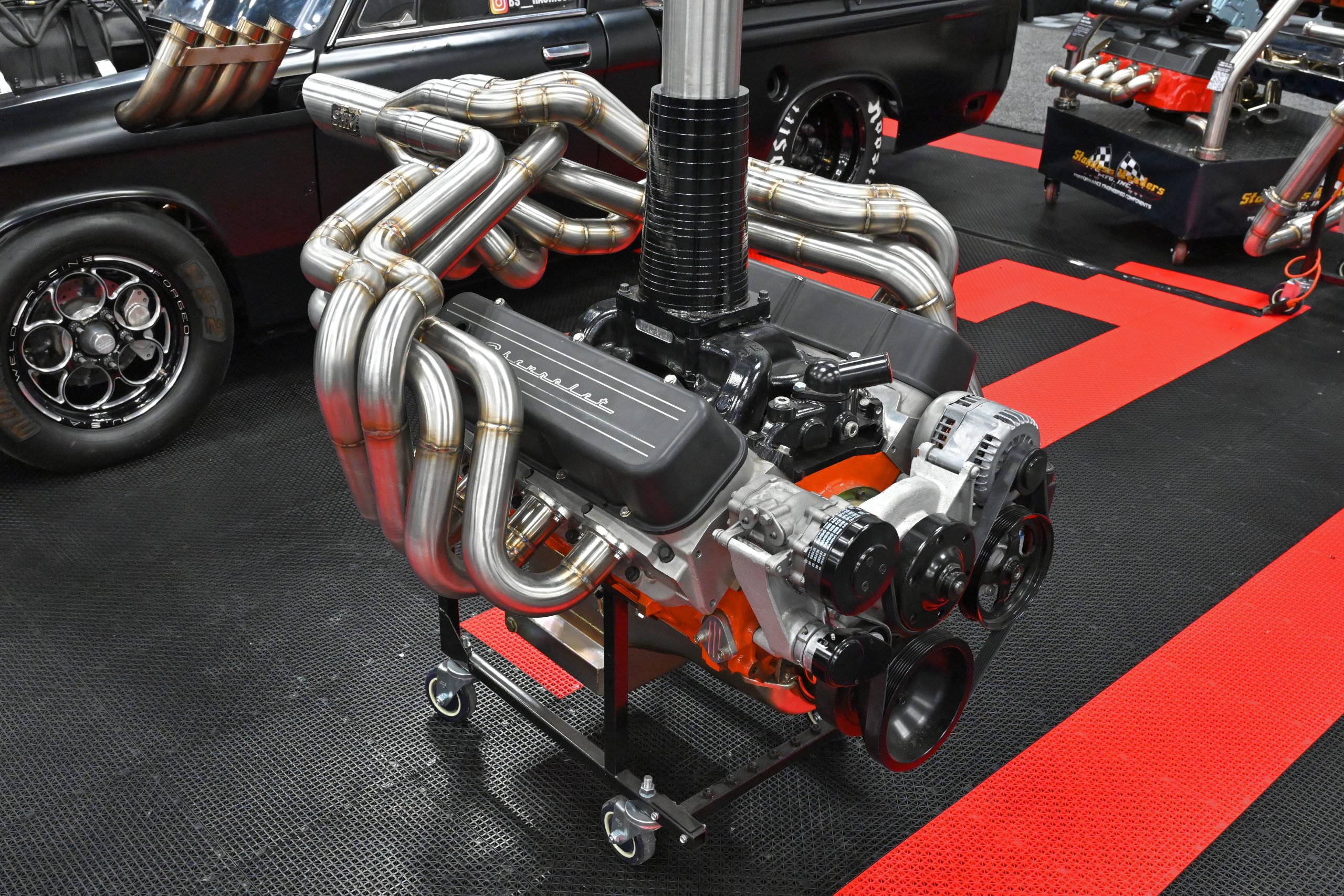

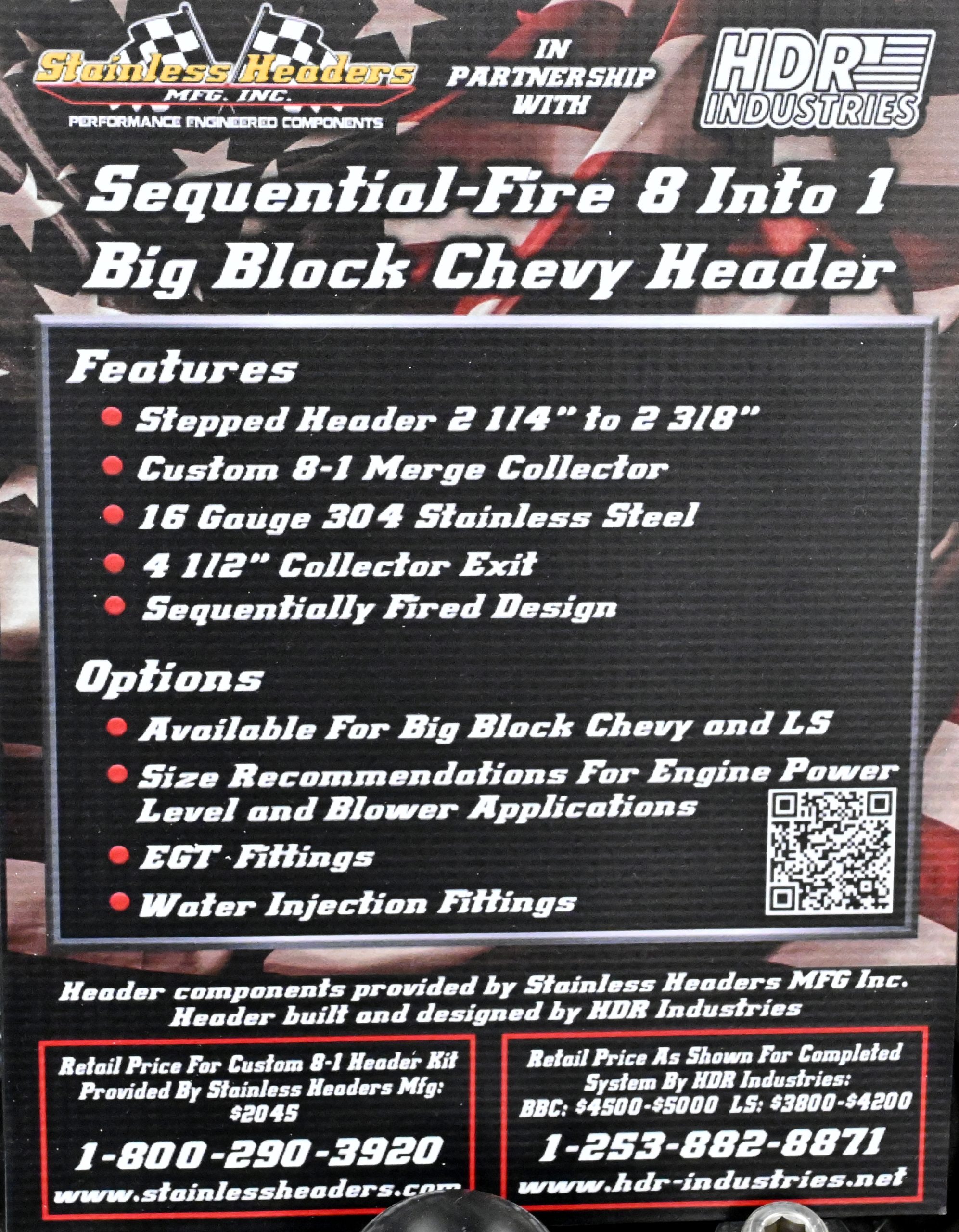

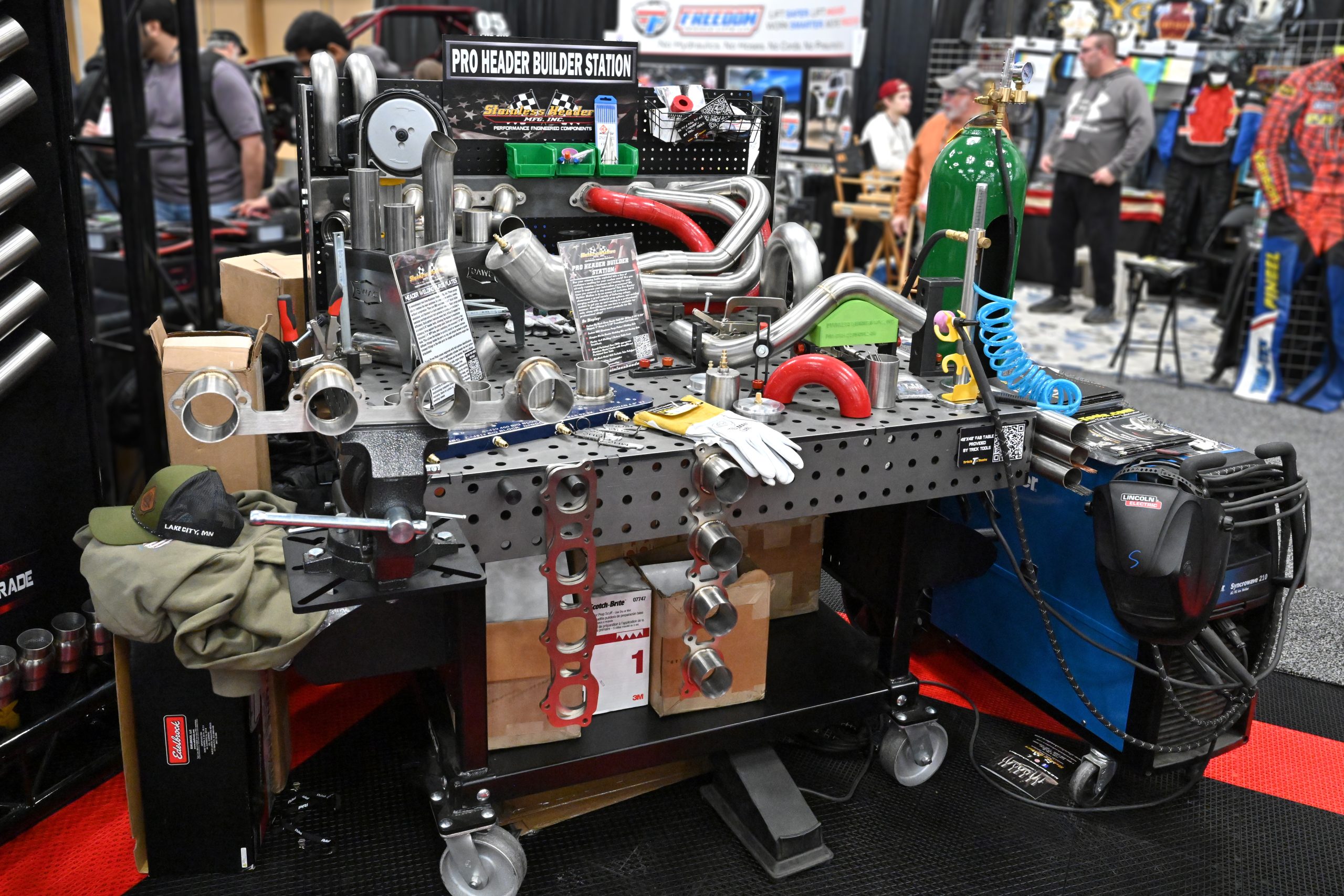

Stainless Headers Mfg., Inc.

Stainless Headers Mfg., Inc. has been a leader in high-end custom header and exhaust components since its founding in 2007 by Chris Stepp. With a foundation in aerospace and mechanical engineering, the company leverages decades of fabrication experience to deliver precision-built, USA-made headers that meet the exacting standards of serious enthusiasts and professional builders alike. Stainless Headers stands out for its ability to work with a vast range of materials—from 304, 316, 321, and 347 stainless steels to nickel alloys, titanium, and multiple series of aluminum—allowing nearly any custom collector-header combination to become reality. Their commitment to quality, craftsmanship, and innovation has earned them a loyal following, an extensive customer gallery, and even an industry-first Builder Locator Map connecting fabricators nationwide with their products.

At PRI, one of the most talked-about displays was the HDR Industries Sequential 8-into-1 Jet Boat Headers, a collaboration with Stainless Headers that brings custom marine exhaust solutions to builders without sacrificing performance. Handcrafted by HDR Industries and built to order, these headers feature TIG-welded 304 stainless tubing, thick header flanges, and fully customizable tube and collector sizing. Optional features include ceramic coating, mirror polishing, water injection fittings, EGT sensor bungs, and a variety of tip designs. This partnership shows how Stainless Headers’ engineering expertise can extend beyond cars and trucks into extreme, purpose-built applications.

Stealing the show on the truck side was Brandon Shannon’s 1976 Chevrolet Luv “Medusa”, a nitrous-fed, big-block Chevy Luv no-prep truck out of Greenville, SC. This beast packs a far big block engine, Powerglide transmission, Ford 9-inch rear end, and a full custom-fabricated cage, suspension, and headers all handled in-house by Brandon and his dad. Every inch of Medusa has been hand-built and welded by the duo, from the headers to the chassis, showcasing the type of extreme, high-performance build that Stainless Headers’ components are made for. The truck has earned its Medusa nickname thanks to the wild, eye-catching headers and aggressive stance, perfectly illustrating what’s possible when precision fabrication meets pure no-prep racing passion.

Whether it’s marine headers, billet exotic applications, or jaw-dropping street-legal no-prep trucks like Medusa, Stainless Headers continues to demonstrate why they are the go-to source for enthusiasts and builders who demand precision, quality, and uncompromising performance in every stainless-steel component they create.