Comparing a Shot of Nitrous and a Daily Driver’s Small-Block Nitrous Cam

By now, we all certainly know that nitrous oxide is a performance enthusiast’s best friend. Nothing can wake up a sleepy motor like a quick shot of nitrous.

Do you need to increase the power output of your motor by 50 hp, 75 hp or even 100 hp? Nothing combines the power potential, ease of installation and bang for the buck like a well-designed nitrous oxide system. In less than an afternoon, you can transform your mild-mannered machine into a serious street/strip terror. Even running a conservative amount of nitrous can easily increase the power output by 100 hp, which removes a solid second from your 1/4-mile times and offers a gain of nearly 10 mph, thereby transforming your 14-second stocker into a stout 13-second street machine, all with the push of a button.

While the power gains offered by nitrous are certainly impressive, even more power is waiting to be unleashed with the proper cam timing. Just like forced-induction applications, nitrous motors respond favorably to specific cam timing events. To illustrate the benefits offered by nitrous and a dedicated nitrous cam, we devised a suitable comparison test.

The idea behind the test was rather simple. We wanted to illustrate the gains offered by replacing a stock cam with a grind specifically designed for use with nitrous. Naturally, this would require a cam swap while on the dyno. To properly illustrate the power gains, we would run our test motor with nitrous using the stock cam, and we’d run it again after installing the nitrous cam. Naturally, the flow of nitrous would have to remain the same, as would things like oil, water and air temperatures, not to mention the air/fuel ratio and timing. It is imperative that these variables are fixed in order to avoid affecting the outcome of the cam swap. Keeping these variables constant was easy on the engine dyno since we had full access to all of the data. While performing the nitrous cam test, we could also demonstrate the power offered by the cam swap alone since the vast majority of the engine operation on a daily driver will occur without nitrous use. The question on the table was whether the cam swap would be as beneficial to the normally aspirated combination, or if we needed to be running the juice to take full advantage of the additional power gains.

Since the vast majority of enthusiasts don’t prowl the streets with dedicated nitrous motors, we decided that it would be prudent to test the effectiveness of the nitrous cam on a real street motor that could be used as a daily driver, one that would yield a delicate balance of performance, mileage and drivability, even in bumper-to-bumper traffic. Sure, we all want a 500hp stroker small block, but the reality is that while fast, they can be difficult to live with, especially during your daily commute. However, a mild small block will deliver endless miles of trouble-free service while offering acceptable fuel economy and impressive torque production.

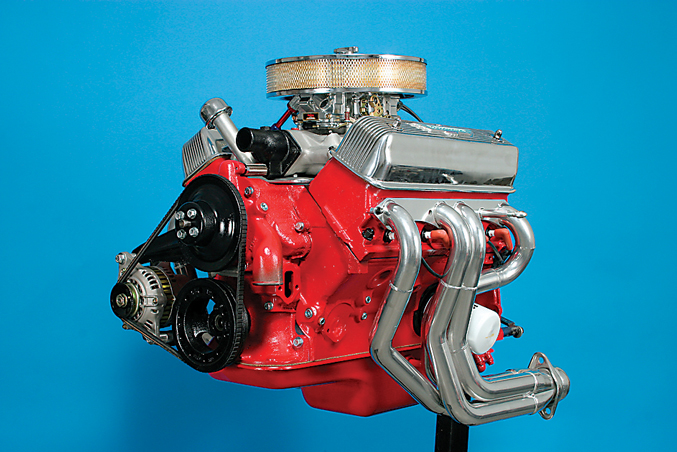

Our test motor certainly qualified as a daily driver, offering nearly 20 inches of vacuum thanks to the use of a production 200hp 350 hydraulic flat-tappet cam. A smooth idle is one quality offered by a stock cam profile, though the cam limited power production in the upper rpm range. In addition to the factory cam profile, the 350 small block featured AFR 190 heads, an Edelbrock Performer RPM Air-Gap intake and a Barry Grant Speed Demon carburetor. The static compression was less than 10.0:1, something that could easily be run on pump gas thanks to the use of the aluminum heads. Additional mods included an MSD distributor, Hooker headers and 1.6 ratio rockers.

The first order of business was to select a suitable cam profile and a matching nitrous system. For our cam needs, we turned to the Comp Cams catalog and went straight to the section for nitrous cams. Given the daily driver status of our test motor, we chose the smallest hydraulic flat-tappet nitrous cam listed for a small-block Chevy. The NX256H cam offered a 212/222 degrees duration split at 0.050 inch (compared to just under 200 degrees for the factory cam), a 0.434/0.464-inch lift split (calculated with a 1.5 rocker) and a 113-degree lobe separation angle. With our 1.6 ratio rockers, the NX256H cam actually provided 0.463-inch lift on the intake and 0.495 inch on the exhaust. Naturally, the stock cam also benefited from the additional lift offered by the 1.6 ratio rockers.

For the nitrous, we selected a ZEX adjustable-plate nitrous system that allowed us to dial in the power gains by changing the jets. Once again, we continued with the conservative approach and installed jetting to increase the power output by 100 hp, though jetting was available to more than double that power gain if our motor could withstand the additional cylinder pressure.

With our cam and nitrous ready, we installed the test motor on the engine dyno and dialed in the combination with the stock cam. After tuning the 350 Chevy with jetting and timing, we were rewarded with peak power numbers of 343 hp and 397 lb-ft of torque. Even with the stock cam, the 350 managed to produce over 350 lb-ft of torque from 2,500 rpm to 5,100 rpm. Adding the nitrous resulted in a jump in peak power from 343 hp to 429 hp, a gain of 86 hp. The nitrous improved the power output with the stock cam by as much as 110 hp at 4,100 rpm, but the gains fell off to 84 hp at 5,300 rpm. Part of the drop in power can be attributed to the 4-degree drop in timing that was recommended by ZEX for the 100hp nitrous shot. Retarding the timing by 4 degrees was done to minimize the chance of harmful detonation. The drop in timing would have more of an effect on the power at higher engine speeds. The torque gains were impressive as the ZEX system increased the torque production by 140 lb-ft, from 397 lb-ft to 537 lb-ft. And believe us, an instant gain of 140 lb-ft is anything but subtle.

After running the nitrous with the stock cam, we swapped in the Comp NX256H cam. Swapping the cams required the removal of the carb and intake, along with the rockers, pushrods and lifters. We replaced the used hydraulic lifters with the new set provided with the cam. The new lifters were pre-lubed using Lucas 30W oil before assembly. The cam received a liberal dose of assembly lube, as did the entire valvetrain before reassembly. One trick new product we employed during the cam swap was Comp’s Valve Train Assembly Spray. This made lubricating the valvetrain a snap. After adjusting the valves, we were ready for the 20-minute break-in procedure. After we were sure that the cam and lifters were happy in their new home, we were safe to make full-throttle runs.

The new cam profile required only minor jetting, but the power difference was certainly impressive. Equipped with the NX256H cam, the 350 test motor now produced 399 hp and 407 lb-ft of torque. You will remember that the motor produced just 343 hp and 397 lb-ft with the stock cam. Despite being designed specifically for nitrous use, the cam improved the power output of the normally aspirated motor by more than 50 hp! In fact, the largest power gain was nearly 65 hp at 5,600 rpm. While a wilder cam will usually yield big top-end power gains, the gains are usually accompanied by a tradeoff in power in the low end. This particular cam swap was the exception to that rule, though, as the impressive top-end power cost little power, if any at all. There was a slight drop in power at 2,500 rpm, but the bigger cam kept pace with the stock cam from 2,700 rpm all the way to 4,300 rpm, where the nitrous cam literally took off power-wise. Where the torque curve fell rapidly with the stock cam, it continued strong for another 1,000 rpm before starting its decline. The result of this shift in the torque curve was a sizable jump in power production.

We were quite pleased with the power gains offered by the nitrous cam on the normally aspirated combination. We could enjoy the extra power on a daily basis without having to suffer any loss in low-speed power. Now we wanted to see if the gains would continue once we engaged the nitrous. Using the same 100hp jetting and 4-degree timing drop, we activated the nitrous with the NX256H cam installed. The results were quite impressive, as the peak power numbers jumped from 399 hp and 407 lb-ft of torque to an even 500 hp and an amazing 567 lb-ft of torque. The nitrous kit improved the peak power by 101 hp and the peak torque by 160 lb-ft. The nitrous offered gains ranging from 133 hp at 4,200 rpm to 100 hp at 5,300 rpm. The power gains offered by the same 100hp shot of nitrous were greater with the nitrous cam profile than with the stock cam, indicating that cam timing does, indeed, play a part in an effective nitrous motor. The fact that the nitrous cam also works well without the nitrous makes this type of cam swap a no-brainer for a mild, real-street 350, but it’s an even greater surprise once the nitrous is employed.

While testing the mild small-block 350, we compared the stock 200hp 350 hydraulic flat-tappet cam against the Nitrous HP NX256 with and without the nitrous. We were concerned about how the motor would respond to the dedicated nitrous cam when it was not running the juice, which is 99.5 percent of the time. Replacing the mild factory cam with the NX256 resulted in a significant jump in power. The larger cam profile lost little (if any) power down low but showed significant power gains past 4,300 rpm. The peak numbers jumped from 343 hp at 5,100 rpm and 397 lb-ft at 4,000 rpm to 399 hp at 5,400 rpm and 407 lb-ft at 4,600 rpm. The power curve indicated that the motor would now pull strongly to 6,000 rpm, where the power was falling off badly with the stock cam. This was one of those rare occasions that the cam upgrade showed improvements everywhere without the tradeoff in power that is usually associated with wilder cam timing.

Before we performed the cam swap to the NX256H, we ran the ZEX plate nitrous kit on the small block equipped with the stock cam. Running the nitrous system on the small block with both cams would help to illustrate the power gains offered by the cam swap, both normally aspirated and with the nitrous. Running a 100-shot (46 nitrous jet and 43 fuel) through the ZEX plate system resulted in a jump in peak power to 429 hp and 537 lb-ft of torque. The torque gains exceeded 100 lb-ft mostly because the nitrous was engaged low in the rpm range (3,500 rpm). The nitrous kit improved the peak power output by 86 hp, but the power gains ranged from a high of 110 hp at 4,100 rpm to a low of 84 hp at 5,300 rpm. Additional tuning could have possibly unearthed a few more horses, especially in the upper rpm range, but some of the power difference can be attributed to the drop in ignition timing by 4 degrees, which is recommended by ZEX at this power level.

After replacing the stock cam with the NX256H, we once again installed the ZEX plate nitrous kit and ran the identical jetting and timing with the nitrous cam. Results were impressive as the nitrous system increased the power output of the 350 test motor from 399 hp to 500 hp, a gain of 101 hp. The torque gain was even more impressive as the nitrous-equipped small block thumped out 567 lb-ft of torque, a gain of 160 lb-ft. As was the case with the stock cam, the power gain offered by the nitrous system varied from a high of 133 hp at 4,200 rpm to a low of 100 hp at 5,300 rpm. Obviously, the results show that the same nitrous system applied to the motor equipped with the dedicated nitrous cam offered a larger power gain, indicating that the nitrous cam profiles are definitely beneficial. The fact that the nitrous cam showed impressive power without the nitrous activated was just icing on the cake.