Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

TheAutoBuilder

15 Tech Tips

here are a few tips to help you out with some common Boating Maintenance problems you may run into.

Author

TheAutoBuilder Staff

I have been working as a marine tech for about five years now, and one thing I have learned is that you have to be somewhat of a contortionist to deal with some boats. I have learned many things that can make the job a lot less painful. If you find yourself in a situation with your own boat that seems impossible, try calling your local marine shop. Chances are that the experts there will be able to give you some advice to help you through the problem. Meanwhile, here are a few tips to help you out with some common problems you may run into.

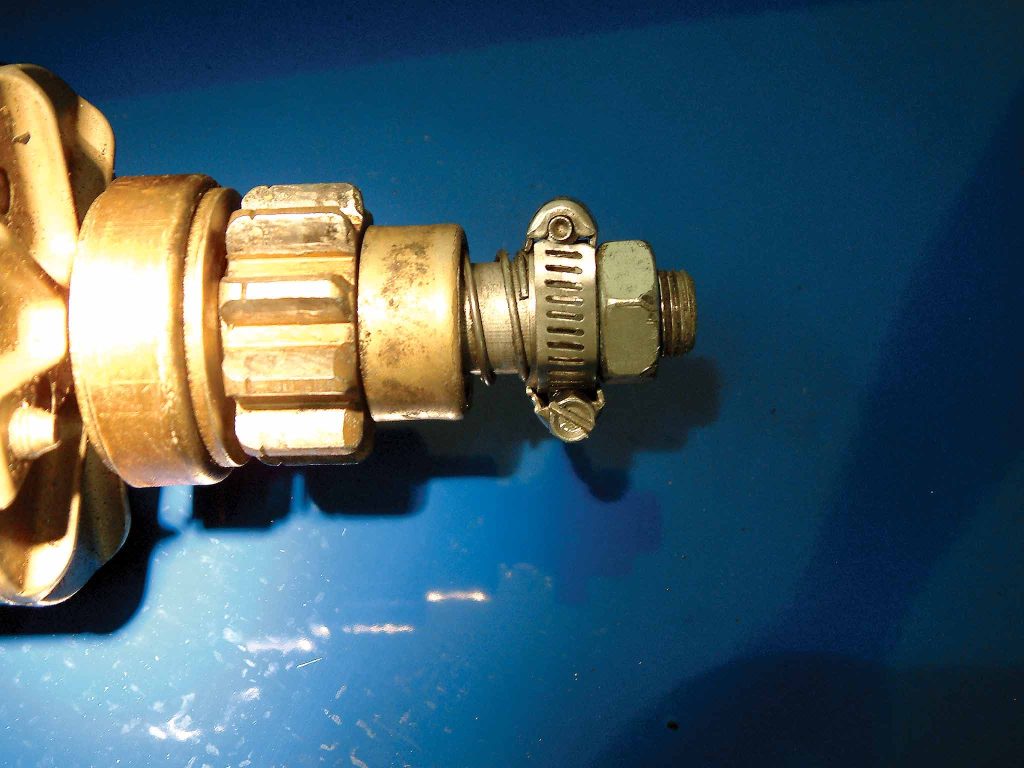

1. Connecting Two or More Hose Clamps Together to Fit Larger Diameters

2. Keeping Fuel Stabilizer Off the Gel Coat

Fuel stabilizer can stain gel coat, so it is important to keep it in the tank and off the boat. An easy way to do this is to punch a small hole in the seal of the stabilizer bottle.

3. Drilling Gel Coat

One mistake that is easy to make is cracking gel coat when drilling or setting a screw into it. The best way that I have found to drill into gel coat is to run the drill in reverse. This way, the bit won’t grab and crack the surface. When setting a screw, the threads cannot grab the gel coat or it will crack it. A clean way to deal with this problem is to start with a bit the size of the screw to thread into, then use a bit slightly larger than the outside diameter of the entire screw to drill through the gel coat. This way, the screw will only thread into the fiberglass or wood that is underneath the gel coat

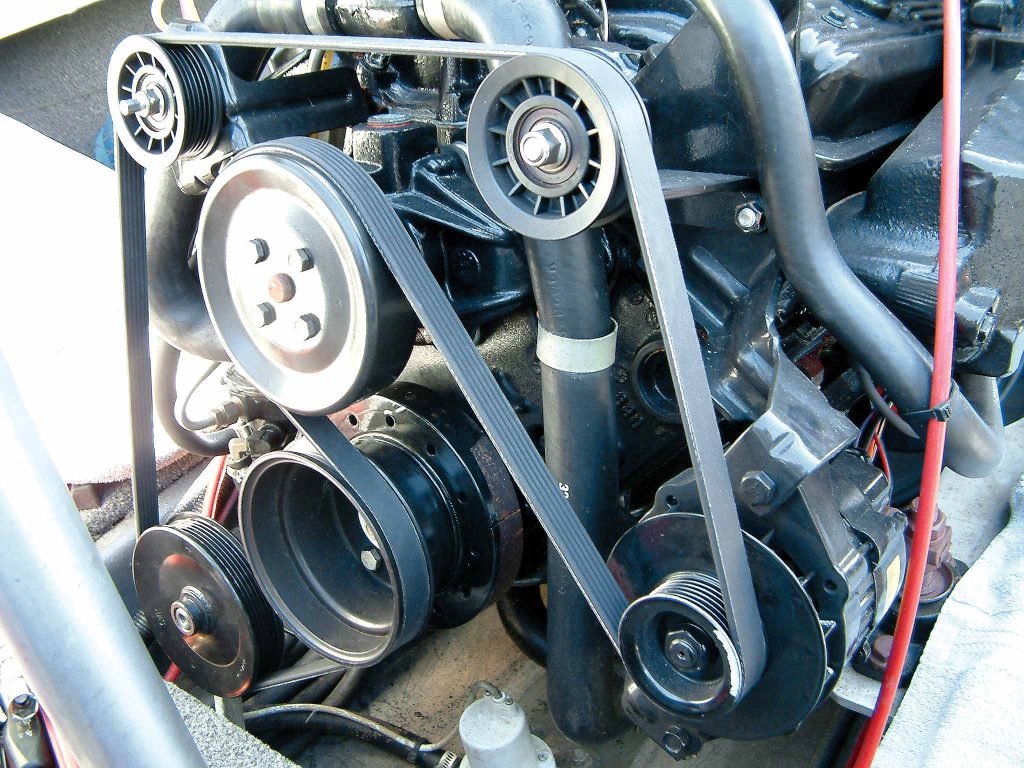

4. Serpentine Belt Routing

When you have to remove a serpentine belt, the fun part is figuring out how it was routed. Most serpentine systems are just a big loop that has a break to turn the circulating pump. You just have to remember where the break is. On this motor, the break is between the alternator and the crankshaft.

5. Installing Spark Plugs

Since the plugs are located under the exhaust on a boat, it can be fun getting them started when installing them. It helps to take a small piece of heater hose and push the plug into the end, using it to turn the plug into its threads. This also eliminates the danger of cross threading the plug, as you could with a ratchet. Even though the plug will sit with the heater hose, it still needs to be torqued.

6. Removing a Stubborn Drive

Make sure you read the manual on how to remove your outdrive before trying this; the procedure for removing some drives is very important. With that said, if you put a piece of 2×4 between the top cap of the drive and the gimbal ring and pull up on the drive, it should break free.

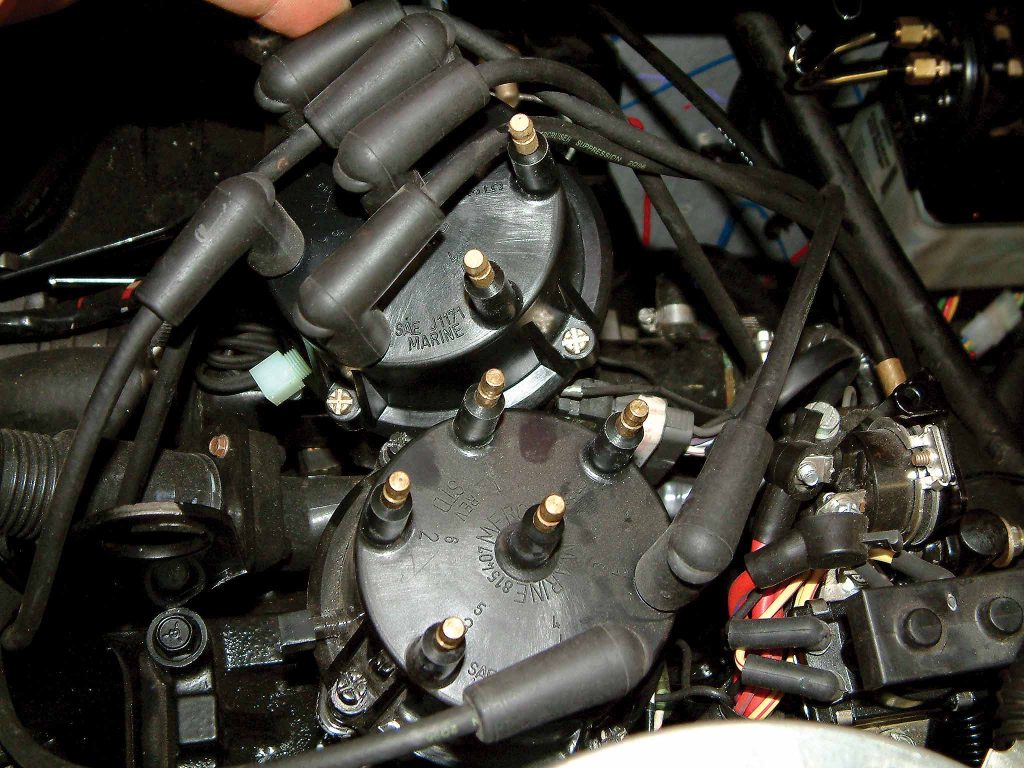

7. Keeping Plug Wires in the Right Place

A simple way to keep the wires in order when you replace the distributor cap is to leave them attached to the old cap and then switch them over to the new cap one by one.

8. Removing Stuck Rotors

On boats where corrosion has set in, the distributor shaft is one of those parts that feels the wrath. If you have to pull on the rotor too hard to get it off, it can be a real knuckle buster. (I know because I have used a few choice words in the past.) A great way to get around this is to grab the rotor with a pair of pliers and turn it to break the plastic key. Then it will just twist off. Make sure you remove the key from the shaft before trying to install the new rotor. Also keep all debris out of the distributor.

9. Keeping the Oil Out Out of the Bilge

An old antifreeze bottle cut to make a pan is a really clean way to catch an oil filter.

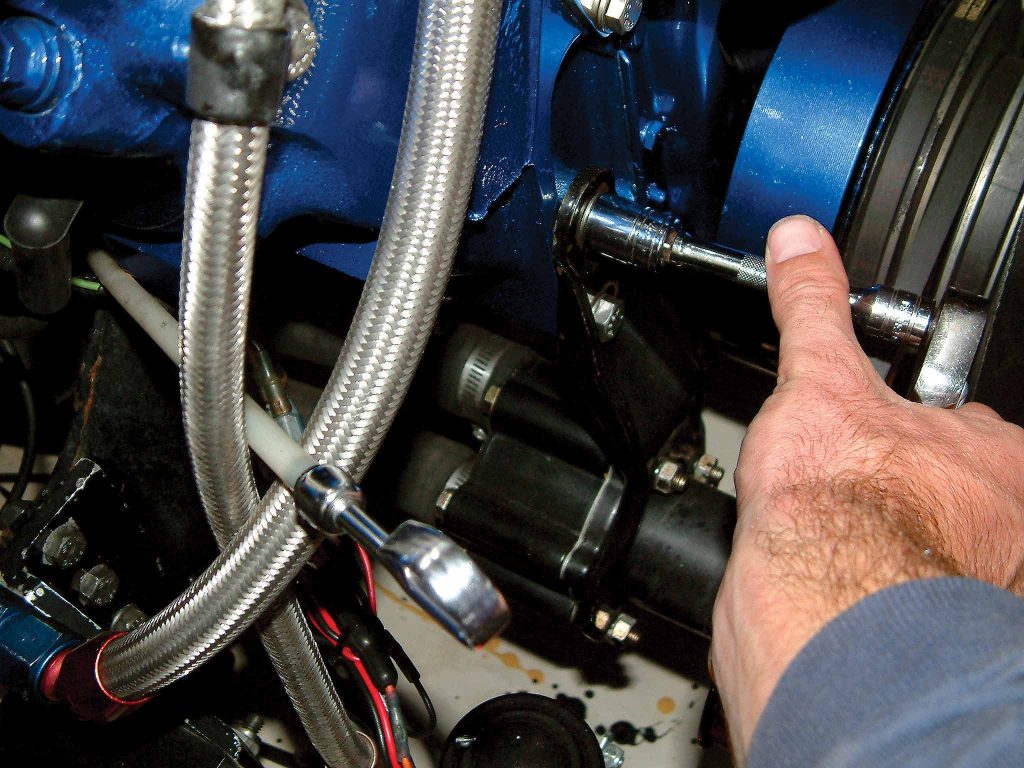

10. Removing Seawater Pumps

A lot of times, it is easier to remove the entire pump and mounting bracket than just the pump. And it is really easy to get the pump off the bracket on a workbench instead of hanging upside down in the bilge. This applies to many things, not just seawater pumps.

11. Upside Down Oil Filters

If you are like me, the first time you see one of these, you will wonder what you did to deserve this mess. Well, it turns out that this style is easier to keep from making a mess than other styles. All you have to do is break the filter loose so that air can get in the filter and the oil will drain into the oil pan where it belongs. When you have it just loose enough, you should be able to hear it gurgle.

12. Corrosion Protection for Bolts

If you have spent any time with a saltwater engine, you will see why this is important. As you reassemble things, such as circulating pumps and thermostat housings, just put some gasket sealing compound on the threads of the bolts. This could save you from spending too much quality time with your tap and die set next time the job needs to be done.

13. Clogged Speedo Pickups

Most of the time the clog does not go past the pickup itself. Simply find a drill bit that is the right size for the pickup and twist it by hand to remove the clog. Do not use a power drill. If the bit drills too deep, you will be purchasing a new gearcase.

14. Keeping Tab Washers In Line

It is hard to just run a prop nut down and keep it aligned with the tab washer. If you pull the prop and tab washer against the nut while tightening, the tab washer will turn with the nut and stay aligned. You might want to wear a glove to keep from cutting your hand on the prop.

15. Torquing the Prop Nut

The safest way to torque the prop nut is by putting a piece of 2×4 between the prop and anti-ventilation plate and torquing to proper specs.