THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Firewall Mayhem

Crankshaft Triggers for Chevy Ignitions

Author

Wayne Scraba

Story & Photography

Crankshaft trigger mechanisms have been used in racing applications for a considerable length of time. In truth, they’ve actually been in service for decades. It’s a simple known fact that one of the best ways to improve engine performance is to ensure that the ignition timing is stable. That’s the whole purpose behind such a system, and that’s why racers regularly use them.

So far, so good, but what does that have to do with Chevy street machines and super rods, many of which could easily be described as daily drivers that never get within 1,000 yards of a race track of any sort save for the spectator parking lot? Well, that’s simple. In today’s automotive world, the unpretentious old distributor is disappearing. It’s a fact that fewer and fewer engines use them. Instead, late-model engines actually lack distributors, meaning that the onboard engine management system (computer, ECU and so on) runs everything from spark to fuel to ignition advance curves. A bank or two of coils are typically mounted somewhere on the engine or strategically close by in the engine compartment. The engine management system tells the respective coils when it is their turn to fire, so say goodbye to the distributor.

There’s more, however. Many years ago, it was pretty common to whack at the firewall of your Chevy to make room for a big hulking HSI distributor. In fact, it wasn’t at all uncommon for folks to “engineer” a firewall with a 10-lb sledgehammer. The sledgehammer ultimately fixed the distributor clearance problem in many cases, but it wasn’t aesthetically pleasing. The same applies to the old setback arrangements on firewalls. Let’s face it; if you peel 2 inches or more out of the firewall by way of engine setback, you could make room for the engine and help to better distribute the weight balance. If the entire firewall was moved as opposed to just boxing it, then you were eating up 2 inches (or more) of foot room, which generally led to an equal amount of seat setback just to get your knees where they belonged. Besides, some homebrewed setback firewalls eliminated the toe board, and without a toe board, driving any distance became downright fatiguing. Those Chevys found their way onto the dragstrips until someone with restoration aspirations began putting it all back together the way it came. Sound familiar?

Enter the crank trigger system. Here, you can use a crank trigger to fire an EFI/ignition system (or a much simpler ignition system) with no distributor. On a typical Chevy application (likely the most common offender when it comes to firewall clearance issues due to the rear-mount distributor), you can also switch to a front-drive distributor for which there are a number of options. In some of these systems, the distributor still provides a place for distributing spark, but a more accurate crank trigger arrangement does the harder job of figuring out when that spark is timed.

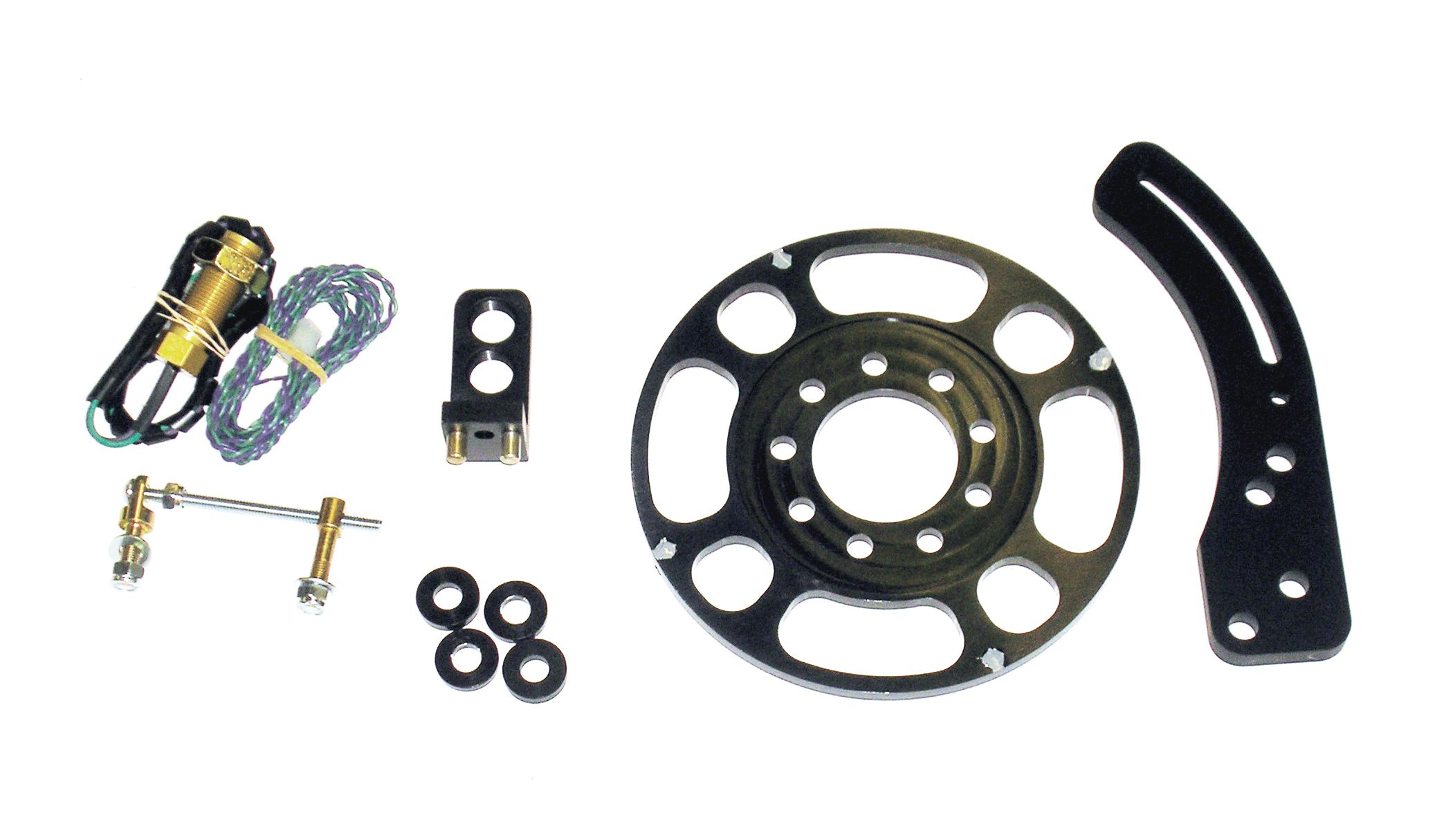

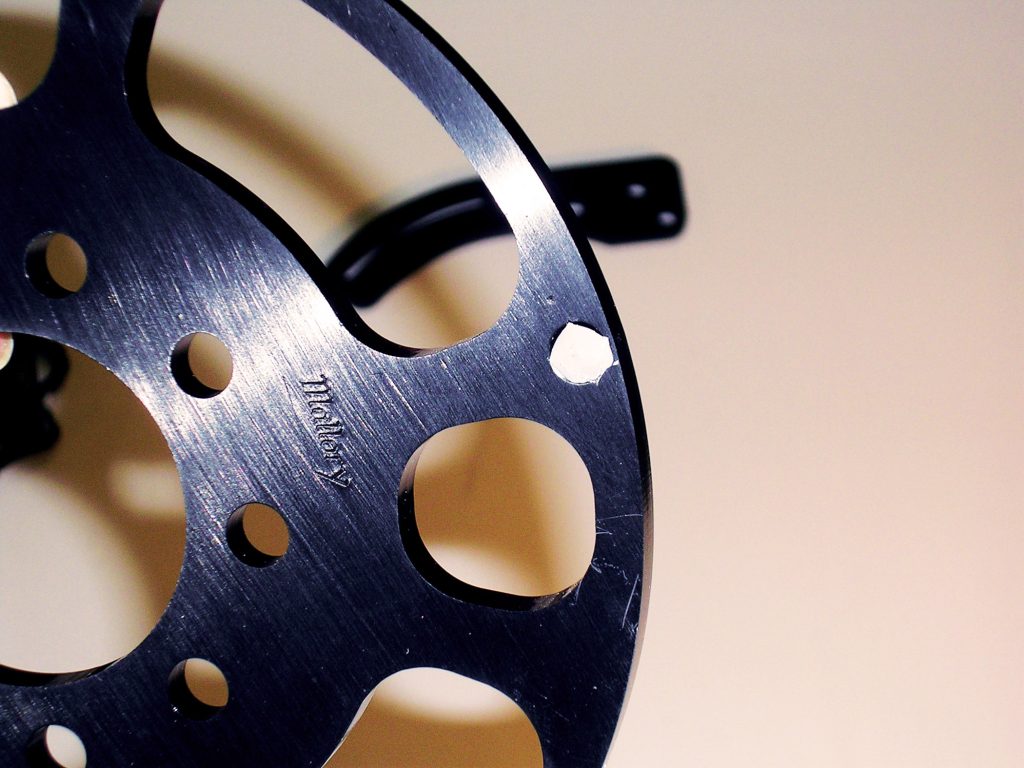

Although the Mallory crank trigger shown in the accompanying photos looks very much like a conventional crank trigger, there are considerable differences. Many of the older crank trigger mechanisms incorporated a wheel with steel studs protruding from the circumference. The wheel, in turn, was bolted to the harmonic damper. In those systems, as the crankshaft turned, the steel studs passed by a stationary magnetic pickup. From this point, the trigger signaled the ignition system to fire. In contrast, the current Mallory configuration incorporates four special magnets that are secured inside an aluminum wheel, which is also bolted to the harmonic damper on the nose of the engine. As the wheel turns with the crank, the magnets pass by a stationary nonmagnetic pickup that actually tells the ignition to fire.

What’s the difference between the two types of triggering devices? The newer flying magnet configuration produces extremely accurate timing, but unlike the old stationary magnetic trigger system, it can’t be accidentally triggered by a bolt or even an irregularity on the trigger wheel or damper. Only the rotating magnets can trigger the ignition. Aside from preventing false triggering, the flying magnet configuration produces a signal with a considerably higher voltage than a conventional pickup.

By design, the CNC-machined aluminum mounting bracket is slotted to provide a healthy range of timing adjustments. Essentially, you move the pickup to advance or retard timing in non-computer-controlled applications (more details are shown in the accompanying photos). Spacers are included so that the pickup bracket can be installed on engines with or without front motor plates (usually 1/4 inch thick). Mallory’s crank trigger system is available for small-block Chevys (6-1/4-, 7- and 8-inch damper), big-block Chevys and Chevy odd-fire V-6 applications.

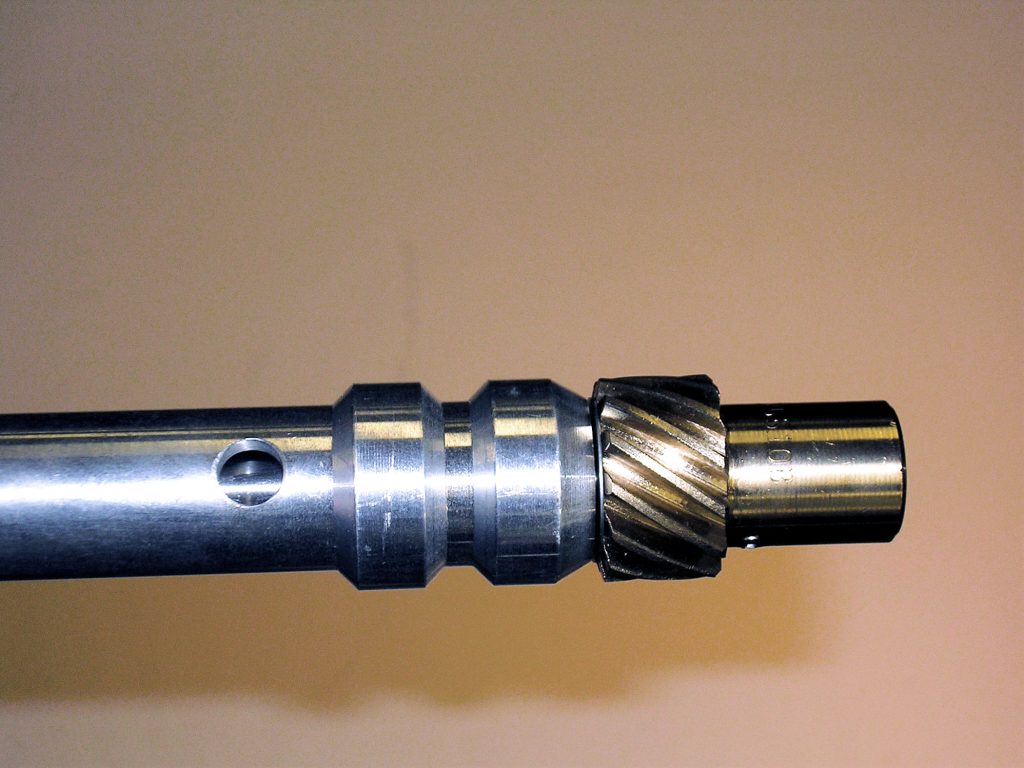

So far, so good, but what happens to the distributor hole and the internal oil pump drive inside the Chevy engine? Let’s look at the oil pump drive first since it’s the most likely scenario you’ll encounter for a street-driven Chevy application. Mallory offers a special oil pump drive for Chevrolets that is designed specially for applications with an internal (wet-sump) oiling system. This drive comes complete with a shaft and aluminum/bronze drive gear so that it will plug the distributor hole and drive the oil pump. In the event that the engine has a dry-sump or external wet-sump oil pump and there’s no need for a pump drive, you can simply use a Mallory distributor hole plug. This piece is machined from T6/6061 billet aluminum and plugs the distributor hole when an external dry-sump or external wet-sump oiling system is used on the engine.

As you can see, crank triggers aren’t all smoke and mirrors or hocus pocus, and they have plenty of uses outside of motor sports; in fact, they work terrifically well on high-horsepower street applications and should be considered as there are a number of brands to select from. With today’s technology, the need for big engine setbacks, severely notched (or…ahem, “mildly modified”) firewalls isn’t really necessary. By thinking outside the box and incorporating a crank trigger setup into your game plan, there’s more than one way to slide a bigger engine into a short engine compartment or to gain a little engine setback for better road manners. For a closer look at Mallory’s crank trigger components and other manufacturer hardware, check out the accompanying photos.

ARTICLE SOURCES

Mallory Racing

A Division of Holley

1-866-464-6553

MSD Ignition

A Division of Holley

1-866-464-6553

Summers Brothers Racing

4747 Brooks St., Suites D & E

Montclair, CA 91763

909/399-5121