THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

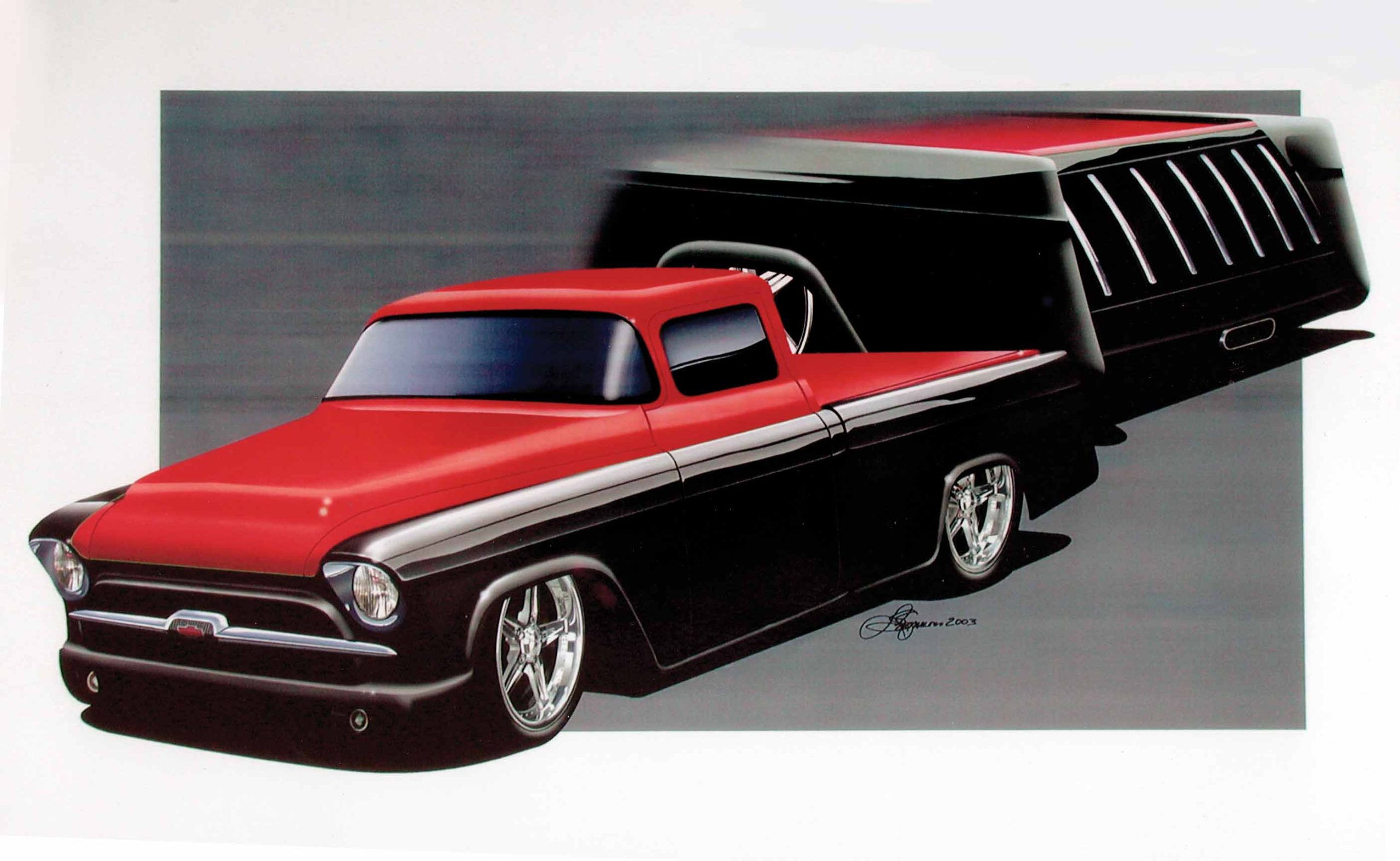

CIMTEX RODS SUPER CAMEO: PART 3

It’s Time to Bring Up the Rear With the Installation of a Modified 1986 Corvette IRS

Cimtex Super Cameo Buildup: Part III – Rear Frame Rail Modifications

In Part III of our Cimtex Super Cameo buildup, we’re going to follow along as the guys from the Jarrell, Texas, crew modify the rear framerails on this ’56, “kicking it up” a full 8 inches. In the process, Tim and Darrell will also narrow the Corvette C4 IRS half shafts to achieve the much desired rear tire clearance they need in order to be able to run a set of humongous 20×10 billet wheels wrapped with a set of BFGoodrich radial T/A rubber.

Measuring and Cutting the Frame Rails

First the Cimbanins made certain that in the process of all their hammering and welding on the front of the ’56’s chassis, the rear framerails did not warp or shift their position. Once satisfied that things were in order and the framerails were as intended, the brothers constructed a pair of 45-degree, 2×3-inch box tube kickups measuring 8 inches tall. Next the ’56’s wheelbase was measured from the centerline of the Corvette C4 front spindle to the rear of the chassis, and a reference mark was scribed on the stock rear kickup at exactly 114 inches. With the truck’s wheelbase set in stone, our installers were also able to arrive at the correct centerline for the new rear kickups. “When we made our measurements, we also set the kickups at three degrees positive angle, which maintains the built-in rake of the chassis,” said Darell.

Once those measurements were made, the crew used a Craftsman plasma cutter to remove the stock rear centersection of the ’56 chassis, leaving only a small portion of the rear frame section temporarily intact for future reference. Then they tack welded the new kickups to the main rails, and once again they checked and rechecked their measurements prior to final welding these new pieces in place. Then they discarded the remaining portion of the back rails and fashioned new ones made out of 2×3-inch mild steel box tubing. “That pretty much takes care of the back half of the chassis,” commented Darrell. “Our next step was setting up the Corvette rear suspension!”

Installing the Corvette Rear Suspension

After removing the stock Corvette truss work, the Cimbanins placed the aluminum inspection cover from the Corvette C4 gear carrier in a mill and milled off the mounting bosses. From there, the guys trial fit and centered the Flat Out Engineering Corvette C4 rear crossmember, setting it at a neutral pinion angle. Then it was tack welded into place. Note that there is a welded-on bracket on this crossmember that centers and supports the C4/C5 gear carrier.

Once the Cimbanins had achieved the correct suspension geometry using the stock C4 Corvette trailing arms, they custom fabricated a set of adjustable upper and lower control arms to replace the bulky OE units. These arms are manufactured from 4130 chromoly and measure 11 inches top and 13 inches bottom in length. Once completed, these new arms were outfitted with Energy Suspension polyurethane suspension bushings and bolted to the Flat Out Engineering control arm mounting brackets and hub carrier. At this juncture, Darrell scribed a cut line at the top of the C4 hub carrier where the mounting tabs originally held the truss work in place, and they, too, will be milled off.

Fabricating Adjustable Torque Arms and Coilover Shocks

Next our installers began fabricating a set of four adjustable 4130 chromoly rear torque arms, which will replace the former truss work. These units measure 18 inches in length and feature Energy Suspension polyurethane suspension bushings. Along with the torque arms, the Cimbanins also fabricated a set of 3/8-inch cloverleaf mounting plates, using 1-3/4×1-7/8-inch aluminum spacers that bolt directly to the Corvette gear carrier. “Everything was made adjustable to within 1/2 to 1 inch in either direction, positive or negative camber,” said Darrell. “That way we can set camber and toe-in on the rear suspension without any problems.”

Cimtex Super Cameo Buildup: Part III – Completing the Rear Frame Rails

Finally the guys at Cimtex installed a pair of Aldan Eagle No. 659 coilover shocks using a pair of 12-1/2-inch-long, 400 lbs-in coil springs offset at 25 degrees. Of course, when the final suspension is up and running, this setup will also include a pair of four-piston, Baer Racing Pro Touring disc brakes along with Chisenhall/Russell Performance stainless steel brake and fuel lines, which will be hidden inside the chassis. A length of 1-inch-diameter Romex electrical cable was run through both sides of the Cameo’s framerails prior to completely boxing the remainder of the chassis in 3/16-inch flat stock. That way, all brake and fuel lines will enter/exit through the driver’s side of the chassis, and all electrical lines will run through and exit on the passenger’s side.

Installing Driveshaft Loops

In the process, Team Cimtex also fashioned a pair of driveshaft loops out of a piece of 3x6x3/8-inch sectioned steel pipe. These loops are kicked up a total of 4 inches on the rear crossmember and 2 inches at the front crossmember. Of course, installation was as easy as locating dead center on both OE crossmembers and then measuring the outside diameter of the pipe. With that done, an angle cut was made to correspond to the circumference of the pipe. Then both pieces were welded in place.

Finishing Touches on the Chassis

At last the brothers Cimbanin welded up all the superfluous holes, as well as all the mounting brackets (both OE and custom) on Super Cameo’s chassis. Then everything will be bodyworked to perfection prior to being painted a bright red.

Up Next: Engine and Drivetrain Installation

In our next installment, we’re going to mount the ZR1 Corvette engine, as well as build the engine and transmission mounts, install the Jimmy G./racetrans.com-assembled GM 4L80E electronic overdrive transmission and hook up our custom-fabricated driveshaft. We’ll also install the Baer four-wheel disc brakes, the pedal assembly, the master cylinder and the power brake booster, as well as all of the brake and fuel lines, so stay tuned!

ARTICLE SOURCES

Aldan Shock Absorber Co.

22015 S. Avalon Blvd.

Carson, CA 90745

310/834-7478

Baer Brakes

3108 W. Thomas Rd., Ste. 1201

Phoenix, AZ 85017-1411

602/352-1411

Cimtex Rods

P.O. Box 205

Jarrell, TX 76537

512/746-2707

Energy Suspension

1131 Callejon

San Clemente, CA 92673

949/361-3935

Flat Out Engineering

633 W. Katella Ave., Unit K

Orange, CA 92867

(714) 639-2623