THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

CIMTEX RODS SUPER CAMEO: PART 1

The Auto Builder Documents the Build of One of the Trickest Tri-5 Chevrolet Pickups We’ve Seen

Author

Bob McClurg

Story and Photography

While attending the 2003 SEMA Show, we ran across Darrel and Tim Cimbanin from Cimtex Rods in Jarrell, Texas. The Cimbanin brothers were there to drum up support and showed us some sketches of their latest truck building project, and what a project it is!

Of course, the Cimbanins are renowned for building some of the neatest street rods, street machines and custom street trucks in the Southwest. In 2002 and 2003, they were the talk of the custom street truck industry with their candy tangerine, angle-chopped ’55 Chevrolet stepside pickup.

Predictably, other competing truck enthusiast magazines clamored to feature the little Chevy stepside, which goes by various nicknames such as “Fast Orange,” the “Texas Tangerine,” and the “Killer Tomato.” In fact, the ’55 was selected as one of the top 10 out of “The Top 100 Trucks Built in the Past 30 Years” by “Truckin’’ magazine, and it was also one of “StreetTrucks” magazine’s top 50 trucks built in the last decade. Among the seemingly endless procession of awards and notable distinctions, the Cimbanins’ tangerine ’55 was also the recipient of two Boyd’s Picks awards and, more important, was voted the Goodguys Truck of the Year for 2002-2003! Okay, so that pretty much sums up the capabilities of the Cimbanins and brings us up to speed on the ’55. Now on to the Super Cameo.

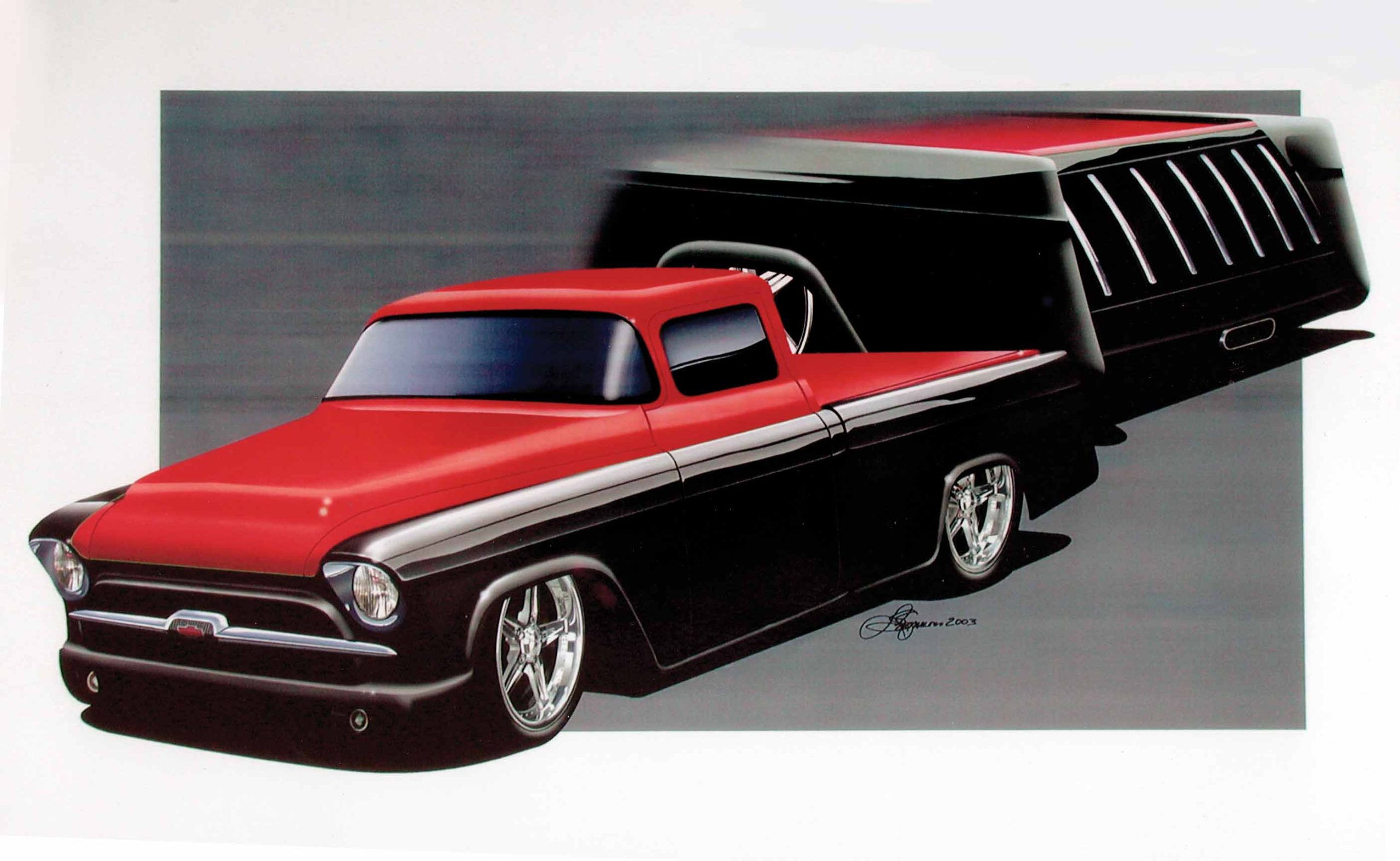

We were standing in front of the Buckaroo Communications display on the main floor of the SEMA Show, and Darrel Cimbanin dropped the bomb. Reaching into his briefcase, he produced a series of Todd Emond’s sketches for one of the coolest-looking ’55 to ’57 Chevrolet tri-5 Cameo pickup trucks we’ve seen in a long, long time. “What do you think of this?” he asked. “This is our latest project. It’s called the Cimtex Rods Super Cameo, and if you think the ’55 was killer, you aren’t ready for this one!” By that time, Darrel had our undivided attention, and he and brother Tim proceeded to outline the parameters of the build. First came the actual truck itself.

“We found a partially restored, 1956 Chevrolet half-ton, big-window 4×4 stepside pickup locally that’s had most of the cosmetic bodywork already done to it. With tri-5 Chevrolet Cameos being so valuable, we figured that nobody would get upset with our using a standard shortbed Chevy and [making] it look like a genuine Chevy Cameo. However, we’re not going to use standard Cameo fiberglass rear fenders…no sir! Since the entire bed is basically going to be handmadet, we’re going to use a set of Mar-K reproduction side panels, and we’ll fashion the Nomad-style tailgate ourselves. Then we’re going to use the rear skins from a 1955 Chevrolet panel truck,” Darrel continued.

“Of course, we’re not going to know exactly how good the previous bodywork is on the cab until we take it over to Hutto, Texas’ True Grit Paint Removal and have the body sandblasted. I mean, you can’t expect much for $2,400, which is what we paid for the darned thing, but from what we’re able to tell so far, we’re fairly optimistic.” Once the ’56 is all sandblasted, it can be bolted up to the shop’s Longhorn Manufacturing Company body rotisserie and the Cimtex crew can get down to business. “Sears Craftsman is one of our associate sponsors on this project, and we’re going to be using a number of its bodyworking tools and saws, like the new Craftsman dual disc cutter, the new air nibbler, a rotary cut-off tools an air saw and a plasma cutter, among a host of other items.”

Darrel went on to say that the Cimtex Super Cameo will feature an angle-chopped top that’s 3-1/2 inches at the front and 3 inches at the rear, along with a pancaked, forward-tilting ’57 Chevrolet half-ton hood. There will also be some creative repositioning of the front well openings and a number of other subtle treatments, like the center-mounted rear exhaust. As you can see from Emond’s rendition, the new truck will be painted red, white and black, which coincidentally happens to be both Buckaroo Communications’ and Sears Craftsman’s official corporate colors. Not bad for starters.

“This thing’s going to feature a pretty radical chassis. Very little of the original ’56 Chevrolet half-ton framerails are going to be left when we’re finished. We’re going to install a Flat Out Engineering Corvette C4/C5 to ’55-’59 Chevrolet truck front and rear crossmember setup, which will bolt up to an ’84-’87 Corvette C4 or an ’88-’96 Corvette C5 independent front and rear suspension system. We’re going to set an overall ride height of 6 inches in front and 8 inches in the rear, which will give the truck a nice rake. Of course, the rear of the frame will feature a custom-fabricated 8-inch kickup, and the rear half-shafts on the Corvette rearend will be narrowed a total of 3 inches (1-1/2 inches per side) so that we can run some fairly sizeable rubber.”

Other modifications to the C4 Corvette IRS will include the elimination of that bulky cast-aluminum truss work, and in its place the Cimbanins will fabricate a set of dual rear control arms featuring Energy Suspension polyurethane bushings. Team Cimtex also intends to use a set of Aldan Eagle coilover shocks, front and rear, as well as a set of Baer Racing 13-inch cross-drilled and slotted Pro Touring rotors and four-piston Baer Racing PBR disc brake calipers. Working in conjunction with the Baer Claw brake system will be one of Stainless Steel Brakes Corporation’s (SSBC) billet-aluminum master cylinders and power brake boosters. Also along for the ride are Edelbrock/Russell Performance brake line fittings and Chissenhall Company’s stainless steel brake and fuel lines, which will be run inside the boxed Chevy framerails.

As of this writing, wheels and tires are not certain, but the builders are deciding between either a set of Boyd Coddington or Intro 18×9-inch and 20×10-inch billet wheels rolling on Bridgestone Potenza radial rubber.

Now here’s the real kicker. The Cimbanins are going to be using a brand-new, 350cid, ’98 Corvette ZR-1 engine for power! At present, there’s talk about installing some kind of a forced induction system on the engine, but whether that’s a centrifugal supercharger such as a Paxton or a Vortech or some kind of turbocharger remains to be seen. The other news regarding the engine is that it will be backed up by a Jimmy G. Galante-prepared (www.dragtrans.com) GM 4L60E, which is a fairly radical departure for a ZR-1 application. In order to do this, it will require a specially fabricated and balanced eight-hole ZR-1-to-4L60E ring gear, which was originally fabricated by Rick Kirk at Ripley, Oklahoma’s RK Machine for the Mercury marine ZR-1 engine Wet Vette project. As far as the actual engine management system and related electronics are concerned, the Cimbanins will be using a Fuel Air Spark Technologies (FAST) Microsoft Windows-based system, along with a Painless Performance wiring harness.

Other participants in the project include MagnaFlow (mufflers and stainless exhaust), Royal Purple (racing oil), ididit (billet steering column) and Air Mobil (polished aluminum radiator). Plans for the interior call for a Corvette-inspired dash, along with the ididit six-way tilt shift steering column, a Kicker audio system, Vintage Air climate control and a Vernon McKean-stitched interior featuring SoftTrim leather.

ARTICLE SOURCES

Cimtex Rods

P.O. Box 205

Jarrell, TX 76537

512/746-2707