THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Buxtosaurus Rex

Another Killer, Classic Pickup From the Minds and Talent at Buxton Motorsports

Author

Matt Emery

Story & Photography

Some of you out there might think that this writing stuff is easy and that we can whip up a story at a moment’s notice. But it is always tough to come up with a good hook on which to build a worthwhile feature.

Some features are all about the vehicle, while others include related stories about the owners, how the vehicle was located or if it had been some sort of family heirloom, and some are about the builder and how the vehicle was conceived and constructed. This is the case particularly if the builder is someone who has built a killer ride out of a forlorn hulk, especially if it is also a one-of-a-kind ride that has features of special interest for others to follow. This is one of those features.

Rex Buxton, who heads up Buxton Motorsports in Irvine, California, is a guy who has taken luck, mated it with education and experience, and then tossed in a serious dose of hard work and determination to become one of the premiere builders on the West Coast. While he is well known within the muscle car and hot rod worlds, he also dabbles in well-turned-out vintage trucks. Not long ago, he and his crew built this 1951 Chevy pickup for longtime customer Kirk Heintz, who hails from San Clemente, California.

Buxton got the bug as a 10-year-old kid, when a friend of the family stored a Gasser at their place. Buxton, being a kid, would sit in the car and take in all of the sights and smells. This friend would also take Buxton to the now-defunct Lions Drag Strip to watch the races and work on the car between runs. Buxton says that he knew at this time that he was bound to be a car dude. He says that he used to draw pictures of Funny Cars doing big burnouts, but it was later and this is where the luck comes in that Buxton got his first car, a 67 Shelby Mustang. The husband of a friend of his mom’s had passed away and she wanted to sell the car. Neither the lady nor Buxton knew what it really was, and the price was set at $900. It wasn’t until he showed the car to his shop teacher (whom Buxton says freaked out) that he understood what he had. Buxton says laughingly that he thought then that all cars had two carbs the Mustang was equipped with a 289 with dual quads.

The teacher helped him rebuild the engine with a few new goodies, and Buxton says that he had the fastest car in the school for a year or two. That was, until he and his buddy with a 70 GTO started to experiment with nitrous injection. They had learned through reading history books that the Army Air Corps had used it in an attempt to outrun Zeros. The pair promptly went to the hardware store and bought copper tubing and compression fittings and used old solenoids from a soda fountain to jury rig a system. They also promptly melted the Goat’s engine. But with trial and error (and a few engines), Buxton says, we kicked ass at the local street races by turning in high 11-second passes. This was pretty fast for a street car back in 1978.

Soon after taking welding classes, Buxton was working at welding up FMF motorcycle pipes and BMX bicycle frames. He then got a job in aerospace at age 20 and quickly got his green paper and government certificates. Soon he was building space shuttle parts.

Even with this success he still had the racing bug, and he opened his own shop in 1987. Still seeking knowledge, Buxton attended the Alston chassis school in 1988 and 89 and joined the dealer program. Buxton soon had five guys building up to 12 cars at any one time, and says: People thought I was the up-and-coming chassis builder at 27 years old, but it proved to be too much!

A combination of marital and personal problems led to the demise of that shop, and my first marriage. I worked for another car builder until I once again started my own shop in 1997. This was in a small shop in Laguna Hills that grew into the purchase of our own building in Irvine in 2003. I now have three employees and build an average of two cars a year. One of those was this Chevy pickup.

When the owner brought this truck to Buxton in late 04, it was an old farm truck with a straight-six engine, three on the tree and studded snow tires.

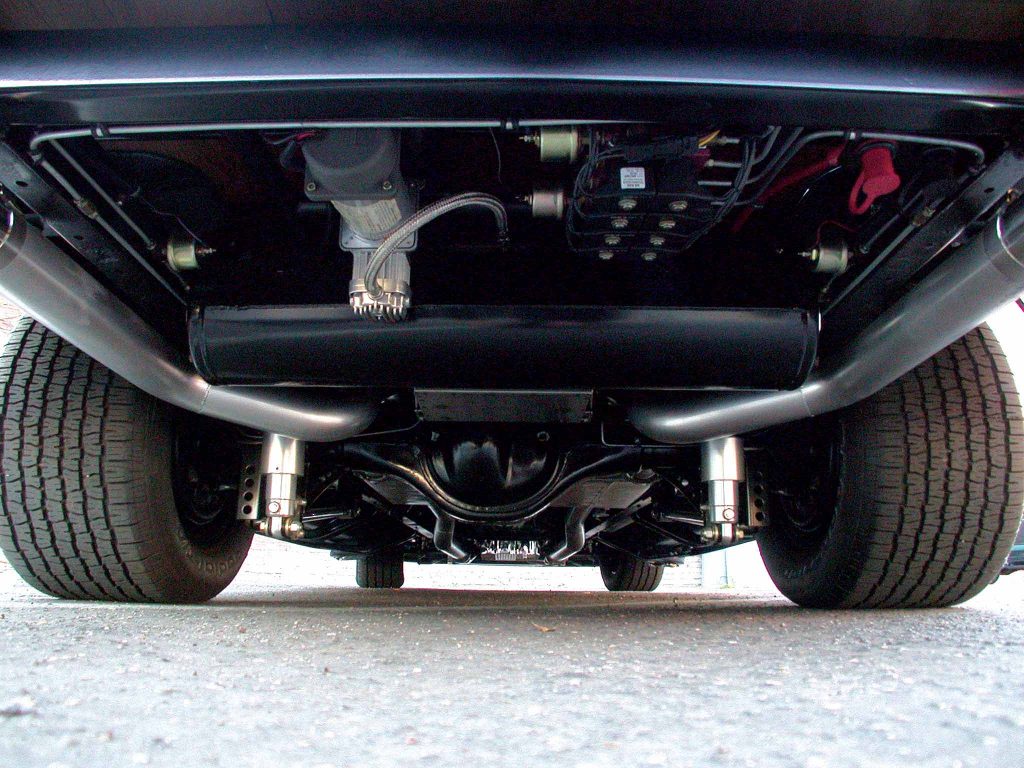

Buxton began by boxing the frame and adding an IFS unit. With Air Ride Technologies airbags and 2-inch dropped spindles, the front end of the Chevy was able to go very low. In the rear, a Currie Enterprises 9-inch rearend was suspended with ART airbags on a four-link system. Speaking of the rearend, it has been equipped with Strange Engineering 3.73 gears. As the Chevy would obviously come across a few bumps, aluminum QA1 adjustable shocks are used on all four corners. Speaking of the corners, a set of Wheelsmith smoothie wheels adorns this Chevy, giving it a very cool retro look.

Decidedly not retro but very cool just the same, a ZZ430 crate engine sits between the Chevy’s framerails. Buxton used a thinner head gasket to raise the compression ratio to an estimated 10.2:1. Equipped with a Holley 4150 780cfm, the carb was built by Sean Murphy of SMI Fuel Systems of Huntington Beach, California. It sits upon a show chromed Street & Performance aluminum high-rise intake manifold, while Bitchin Products valve covers and air cleaner housing were also used. A Vintage Air front-runner accessory drive system show chromed, of course was added. A set of Sanderson full-length headers gets the burnt fuel to the TTI stainless steel tips via mandrel-bent, ceramic-coated tubes.

A 4L60 trans with upgraded internals to handle the 430 hp the engine produces gets the power to the rearend with a little help from the B&M trans cooler. A custom driveshaft by Drivelines Inc., of Lake Forrest, California, puts a nice spin on things.

With the frame, suspension and powertrain finished, Buxton turned his attention to the body. As stated, the truck had spent its time on the farm and was in pretty rough shape. Buxton and his crew hand formed a majority of the body pieces they needed. Items such as the floor and tunnel are handmade, and Buxton said that there were over 50 holes in the firewall that needed to be welded. The bed is new, but the rear fenders are the real thing according to Buxton, though he did have to search a little for good ones one of them actually came from Canada. He did, however, modify the bed so that the fenders are now in line, heightwise, with the front units. Buxton says that while he and his crew did most of the work, he did have metalwork specialists GMT in Huntington Beach do some of the mods. Other tricks include using 43 Ford taillights that feature custom billet brackets to fit the Chevy bed.

When all was ready, the truck was trucked over to Eagletons Custom Paint, also in Huntington Beach, which applied the PPG Tuxedo Black paint. When the time came for the truck to be reassembled, Buxton used So-Cal Speed swan-type side mirrors to go along with the show-chromed grille and bumpers.

The interior is also show quality while still retaining the feel of the original truck. Gone is the stock bench seat, and in its place is a Glide Engineering unit covered with black and gray leather with cool cloth houndstooth inserts. The leather and houndstooth motif is continued in the door panels and headliner, all of which were done by the award-winning crew at Gabe’s Street Rod Interiors of Bloomington, California.

Though the gauge cluster is original, it was refurbished by US Speedometer, but the Billet Specialties Banjo steering wheel is definitely new. A Vintage Air climate control system provides cool air while the Pioneer stereo system provides hot tunes. The MP3-capable head unit is found in the glovebox, while the 10-disc CD changer and the twin 1,000-watt Premier amps are hidden beneath the seat. This wattage is sent to Polk Audio speakers hidden around the cab. The DVD player is also beneath the dash, as is the monitor screen it powers. To get power to all of these components, as well as the rest of the truck, Buxton used a Painless Performance 18-circuit wiring system.

In the time since the truck was completed and has been on the scene, it has garnered class wins at such prestigious events as the Grand National Roadster Show, as well as the Sacramento Autorama, and it received a Boyd’s Top Ten pick at Goodguys Del Mar Nationals. It is little wonder that this Chevy has done so well, as it is as clean and finished as any truck we have ever seen. Though Buxton’s heart may be at the racetrack, taking home the winner’s hardware, his talent sure seems to lie in picking up trophies at the showgrounds as well.