THE AUTO BUILDER

Featured

Triple Crown of Muscle Cars 2024

Triple Crown of Rodding 2025: Top 30 Review

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

34 Expert Restoration Tips for Classic Car Enthusiasts

Pro techniques to elevate your car build while saving time and avoiding costly mistakes.

Author

Jeff Lilly

Words & Photography

1. Sealing Body Seams Before Paint

Just before paint, you will need to caulk the seams on your project’s body. Any visible seams should be done to give a smoother appearance and keep water and rust stains from appearing, especially if you tend to drive in the rain. Apply 3/4 masking tape on the lap side or higher edge about 1/16th from the drop-off edge. On the overlapped portion or lower side, move the tape back 1/8th to 3/16th of an inch. Using 3M 8300 sealer, cut the tip to allow a 1/8th bead. This product flows smoothly and can be finger-stroked with lacquer thinner to make it extra slick. Peel the tape away after one foot at a time is finished. After one hour, you can prime/paint over it.

As seen, the seams are all sealed, providing a very smooth transition from each panel. Once all is sprayed and assembled, it will look great.

2. Preventing Mess with Dynamat

When installing Dynamat to sound-deaden your ride, place aluminum tape on all the overlaps “available from any hardware store.” This will keep the sticky black butyl from getting on your clothing/skin while working inside the vehicle, especially if it will be several weeks before the carpet is installed.

As seen, the seams are all sealed, providing a very smooth transition from each panel. Once all is sprayed and assembled, it will look great.

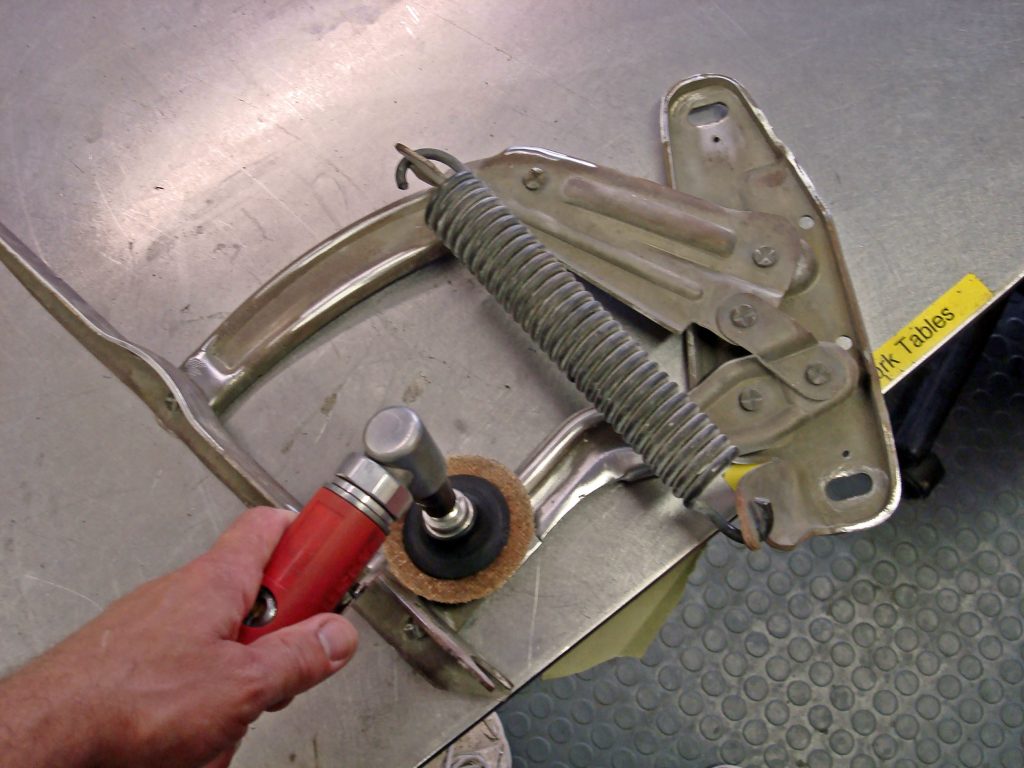

3. Protecting Inner Panels During Paint Stripping

During paint stripping, use aluminum foil tape to seal off the inner panel from the outer. This will keep the old paint and stripper from entering the inner structure and becoming trapped, causing a big problem later on during refinishing. In addition, place it over any holes. Simply take a Scotch-Brite disc on an angle grinder to clean all the paint off the edges down to the bare metal where the tape covered it to finish the process.

6. Ensuring Wheel Opening Perfection

As seen on this body-worked fender, masking paper was taped behind it. This not only provides cleanliness during priming but allows you to see how perfect your wheel opening is when standing back 5-10 feet. It eliminates your eyes from trying to focus on too many areas at once for the ultimate inspection.

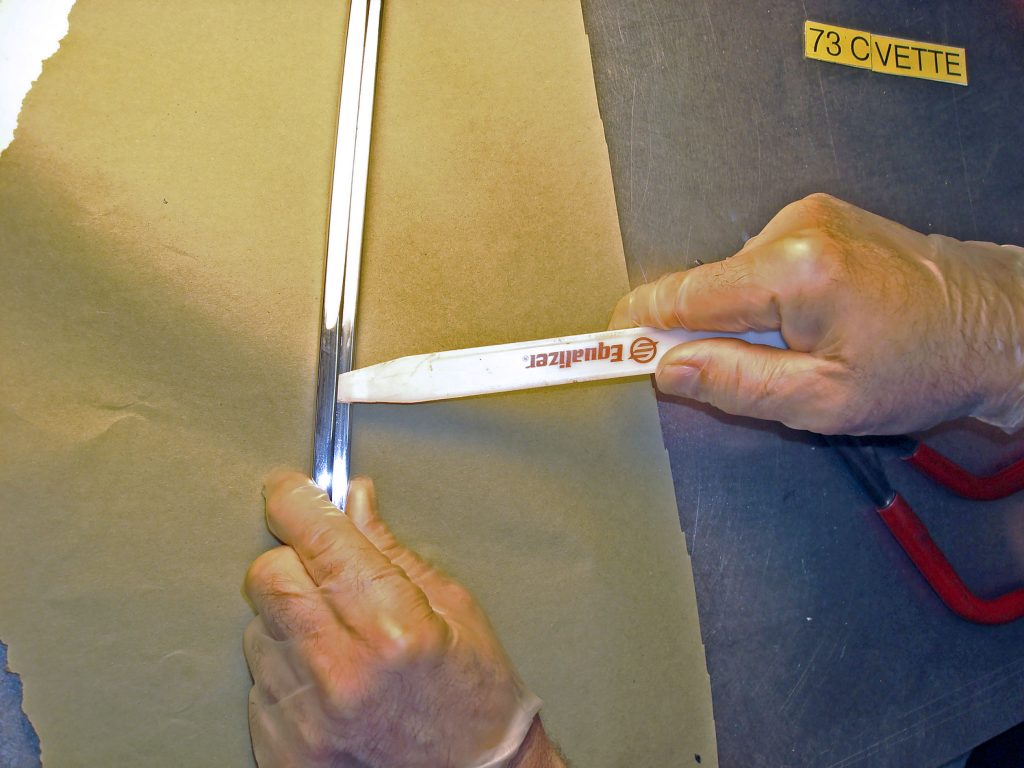

7. Fitting Metal Trim Before Chroming

It is best to fit all the metal trim in its copper state before final nickel and chrome is done. This is the last time you will be able to correct any fit problems. Most platers over-grind and tend to tweak the parts a bit during preparation, and being they do not have the car in front of them to check the fit, you can correct any areas you are not happy with at this time.

10. Strengthening Wavy Panel Edges

Often, the edge of a panel will be wavy or unstable compared to the center, especially on open panels that are not folded back. The use of a MIG welder to spot a few areas and then cool with a wet rag will stiffen the panel just enough. Simply grind them back down slowly to the surface before bodywork and priming.

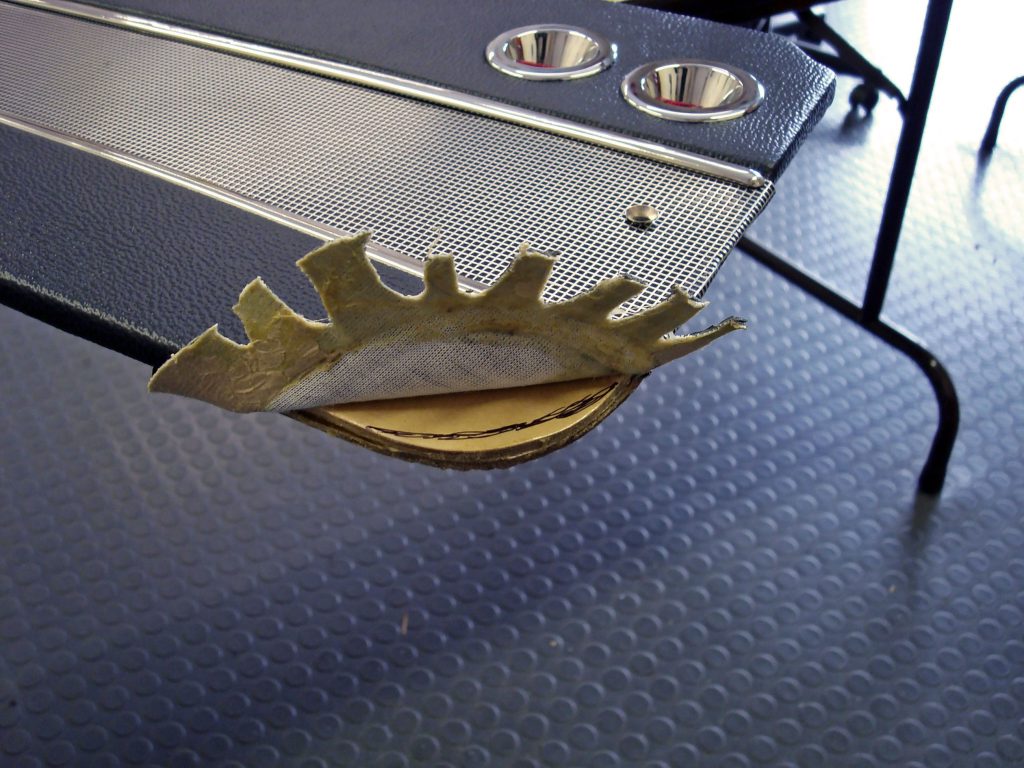

13. Custom Fitting Factory Door Panels

When installing factory parts such as this interior door panel, they will more than likely not fit well. Hold the panel up to your door and simply mark the panel where it needs trimming, then pull back the material from around the backside and trim off the excess. Then rewrap and glue for a custom-fit door panel.

15. Converting Pot Metal Studs for Trim

Some trim, such as this stainless steel molding, came with pot metal studs that accepted thread-cutting nuts, which often slip when tightened. Using the proper thread-cutting die, you can change them over into a regular threaded nut to avoid snapping off the studs during assembly if they were too tight and also avoid a loose molding when the thread-cutting nuts have already cut too many grooves on the stud.

16. Shipping Rare Parts Safely

During shipping of rare parts, always use wooden crates with foam and peanuts to keep them safe. I am not going to insinuate or call anyone by name, but those people wearing brown shorts can ruin irreplaceable parts, so be extra cautious and spend the money to transport right.

24. Polishing and Painting Moldings

On this two-step tip, polish the outer edges of the moldings as needed. For the centers that need painting, perform any required bodywork because neither glossy nor satin paints will cover dings.

Use Slick Sand primer by Evercoat and brush it onto the spots. Allow it to dry for 45 minutes, then block sand all ripples out. Mask the moldings off, and they will be ready to paint. Apply Ditzler’s epoxy primer for adhesion, followed by the desired topcoat.

As seen, the seams are all sealed, providing a very smooth transition from each panel. Once all is sprayed and assembled, it will look great.

28. Breaking in Rubber Seals During Final Assembly

To break in rubber seals at final assembly, use a small binder strap between the doors. Install J-hooks to the door by drilling a small 1/4-inch hole at the bottom or top of the door, depending on where the rubber is tightest. Attach the binder and adjust it incrementally every two to three days. Remove the striker during this process to eliminate restrictions. Once the doors close easily, reinstall the striker.

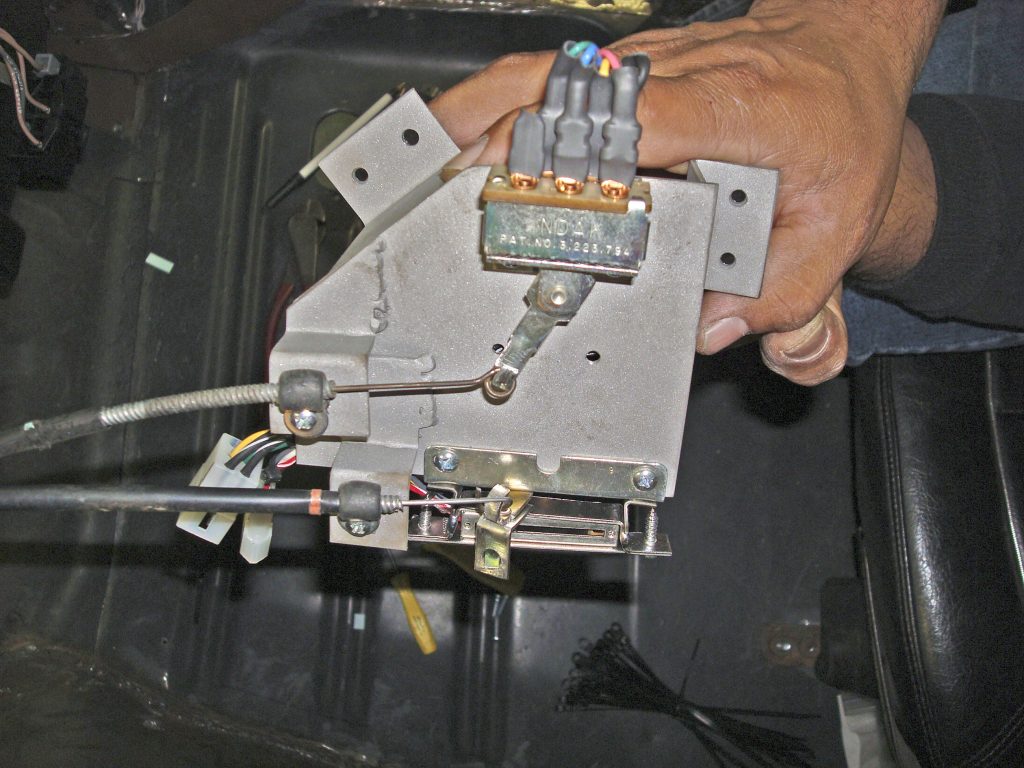

30. Adjusting Heater Plenums and Air Vents

If a heater plenum hits an upgraded speaker system, cut away the interfering section.

Use a piece of ABS plastic cut to fit and shape it with a heat gun.

ABS adheres well to the old box, forming a clearance while maintaining airflow to the defroster.

31. Reshaping Plastic Trim

Most plastic on a car or truck’s body can be reshaped using a heat gun. For example, overly curved kick panel wind lace can be tweaked. Heat it, place it within 30 seconds, and hold it in place while it cools for a precise fit.

32. Correcting Header Fitment

Headers often do not fit correctly. Check them with a straight edge before coating and installation. If needed, weld on the lower bead and file it to level. Ensure the gasket matches the header and the heads. Tighten the headers, remove the gasket, and check alignment to avoid sealing issues.

33. Trimming Side Dash Pieces for Perfect Fit

Above the dash pad on each corner, side trim often doesn’t fit well. Mark the area and use a mini belt sander to remove the excess metal for a precise fit.

34. Verifying Cable Thickness

With rising copper prices, be selective when choosing large cables for battery and stereo leads. Some manufacturers use extra-thick plastic coatings to make the cable appear correct, but the copper inside may be undersized. Always ask for a sample or ensure the cable is gauged correctly before purchasing.