THE AUTO BUILDER

Featured

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

BLUE OVAL IN A BOW TIE

Bill Ayers' Exercise in Ingenuity

Author

Gerry Burger

Photography by Bill Ayers

The Rules of Hot Rodding

Let’s face it, most of us are working within the confines of a set of unwritten, yet clearly defined, rules of hot rodding. Stance, engine choice, and wheels are for the most part selected from a menu of items that come “pre-approved” by our peers. Sure these rules work most of the time, and they provide a degree of certain acceptance when you’re building a traditional pre-’49 hot rod. But all in all, it also makes us a group of conforming nonconformists. However, for some hot rodders (and they are in the minority) building hot rods is about pure ingenuity, a total lack of peer pressure, and the joy of mixing parts from various sources and making it all work. Bill Ayers is just such a hot rodder. With virtually no rules to encumber him, he goes about building things that work and look good doing it, often simply using what is available at the moment.

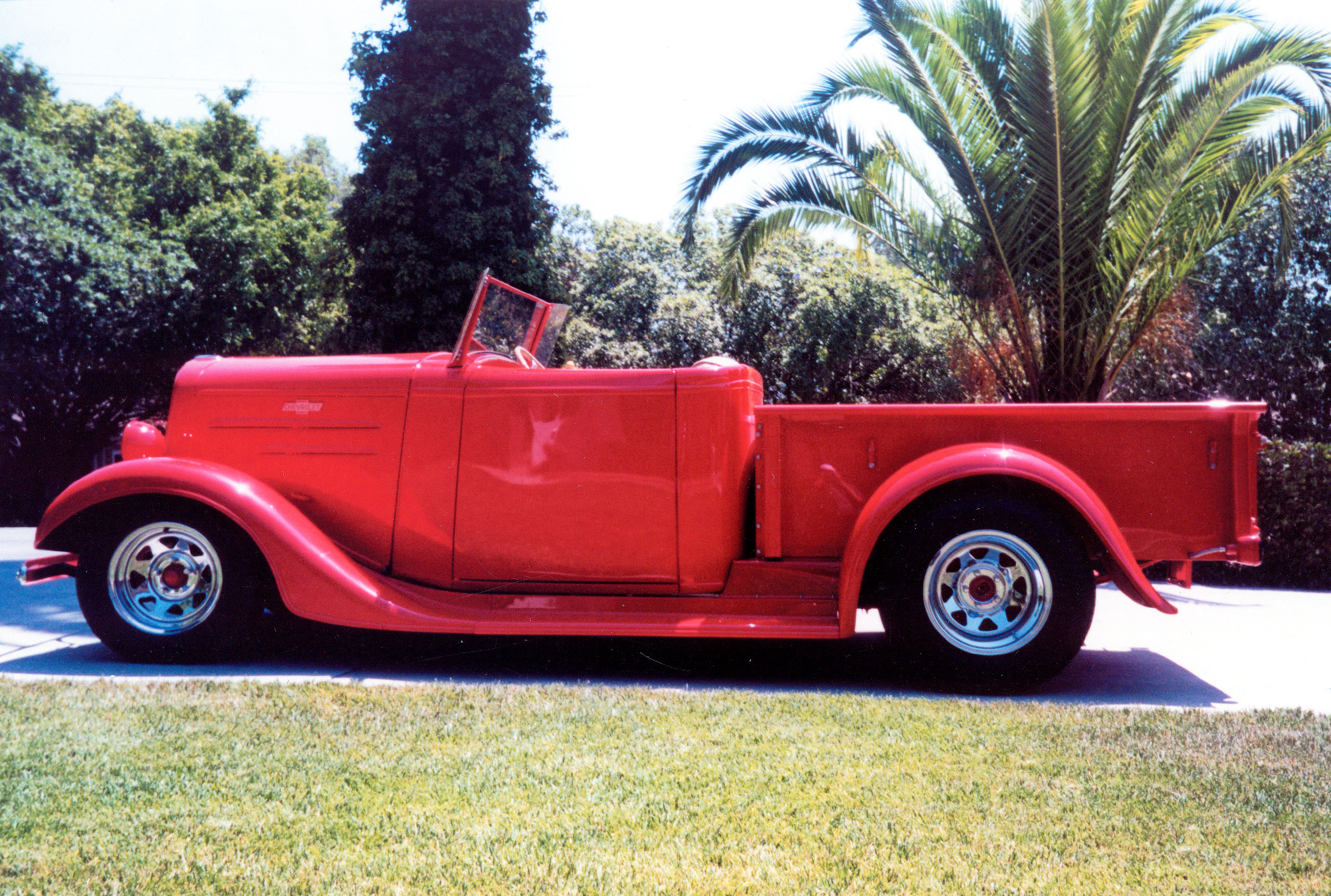

A ’36 Chevrolet Transformation

His latest project is the ’36 Chevrolet pictured here. The roadster pick-up began life as a ’36 Chevrolet pickup truck, but when Ayers decided he wanted a roadster pickup, he had no reservations about systematically removing the roof from the cab. Sure, the interior was braced with box tubing first, and the door opening was braced prior to the roof opening. Yet in the end, he had rolled the top edges, added suicide doors with Porsche 914 door latches and had a neat roadster, but we’re getting ahead of ourselves here.

A Serendipitous Discovery

You see this project actually began one day when Bill Ayers was lying underneath his ’81 Toyota pickup truck, installing a new muffler. Now Ayers couldn’t help but notice the striking similarity between this Toyota frame and the one under his ’34 Chevy truck street rod. A quick session with the tape measure proved his eye was sharp, the overall dimensions and shape were almost identical. Next, he measured a ’36 Chevy truck cab he had behind the garage, and once again it was clear that a mid-’30s Chevy cab would fit nicely on a Toyota chassis.

Acquisition and Initial Modifications

The next day, he ran an ad in the local paper. Within a week, he was towing home a rollover-damaged ’79 Toyota pickup truck. The body and bed were removed and scrapped, leaving Ayers with a bare chassis. After some measuring and skillful fabrication, there were new mounts on the Toyota frame. Lifting the ’36 Chevrolet cab onto the frame confirmed the chassis would work just fine with the Chevy sheet metal. It was at this point the cab was rolled inside and relieved of its roof.

Customizing the Dashboard and Windshield

The dashboard was filled and then an opening was cut in the dash to accommodate the Opel GT instruments he had on hand. Windshield stanchions were formed from pieces of box tubing, and after rolling the tops of the doors and the rear of the cab, it was time to fit a top to his roadster pickup. Way back in ’65, Bill Ayers was working on a Victress fiberglass sports car and needed a windshield. He bought a rusted-out Austin-Healey 100-6 just to get the windshield. He parted the rest of the car out, saving only the folding top assembly. Everything else was long gone. Digging around he found the assembly and mounted it to the rear of the cab and built a new header for the windshield area. Voilà! A full folding top in record time. Wondering what the top might look like upholstered, Ayers simply covered the bows with duct tape to simulate top fabric. Sure enough, the profile was just fine, and work now turned to mounting the front sheet metal.

Fitting the Front Sheet Metal

The stock ’36 Chevrolet front fenders, hood, and grille shell were mounted to the Toyota chassis, making mounts similar to stock ’36 items that would fit the imported chassis. In the process, however, the front of the frame had to be trimmed off for sheet metal clearance. Because these Toyota trucks are front-steer suspensions, that meant the front strut rod mounts, idler arm, and steering box were cut off, too!

Solving Steering Issues

As it turns out, a ’78 Pinto power rack and pinion that Ayers had “lying around” was the perfect solution. After making mounts, the steering problem was solved. The original front strut braces were then shortened and modified to fit new mounts on the shortened Toyota chassis.

Rearend Modifications

The rearend was mounted by cutting the spring mounting pads from the Toyota rear axle and locating them on a ’65 Falcon 8-inch rear. After welding the pads in place, the Falcon rear was bolted to the Toyota springs (minus two leaves per side) with factory hardware. An adjustable panhard bar was fabricated, and in just a couple of quick weeks, Ayers had a rolling chassis and a ’36 Chevrolet Roadster pickup cab. Next, he rolled the car in the corner of the shop and took a few years off!

Installing the Engine and Transmission

When he got back to work on the project, it was time to mount the motor and transmission. Because he was adamant about keeping the torsion bar front suspension, the engine bay was narrow, as was the center of the chassis. A C-4 Ford automatic transmission proved to be narrow enough to fit in the frame. So, he bolted a ’70 351 Windsor to the front of the transmission and proceeded to mount the Ford motor and transmission between the Toyota frame rails and under the Chevrolet sheet metal. (We told you there were no rules on this one!) Factory Mustang GT headers cleared everything, and a shortened Falcon driveshaft now passes the power rearward.

Fitting the Pickup Bed

It was time to mount the pickup bed to the frame. The Chevy and Toyota frames are shorter than the beds they hold; however, this time Ayers decided to shorten the stock ’36 Chevrolet bed to match the end of the Toyota frame. To mount the bed to the Toyota chassis, the bed would have to be channeled a bit to provide room for the higher kick-up of the Toyota frame. Ayers turned the bed over and built a subframe from 1 X 1 box tubing; this subframe was then adapted to the chassis and the bed bolted in place.

Finishing Touches

A new tailgate was fabricated from tubing and sheet metal, and a set of Poli-Form Model A fiberglass rear fenders were narrowed 1 inch and mounted to the Chevrolet bed. Smoothie running boards were then mounted between the Chevrolet front fenders and the Model A rear fenders with owner-fabricated brackets.

Taking a Break

Ayers now had a full-bodied, driveline-installed, ready-to-run hot rod Chevy Roadster Pickup. So, he took a couple of years off.

Final Assembly

When the truck next rolled out of the corner, Bill Ayers vowed to finish it. The Toyota truck seat had been saved, and after stripping off the upholstery and tweaking the frame, the Toyota truck seat fit the stock ’36 Chevrolet seat box perfectly. After doing his own bodywork, the truck was painted bright red and his daughter Denise brought a sewing machine over to the house and did the upholstery.

Conclusion

Bill Ayers finally had his Ford-powered, Toyota-suspended, Chevrolet-bodied, Model A-fendered street rod on the road. The car embodies the very essence of hot rodding, with the main ingredient being liberal doses of ingenuity and hard work. The results are a good-looking, good-driving car that is a true reflection of its 72-year-old owner. Building great street rods isn’t easier when you throw out the rules—but it sure can be very rewarding.