Putting a Stop to Our Project ’67

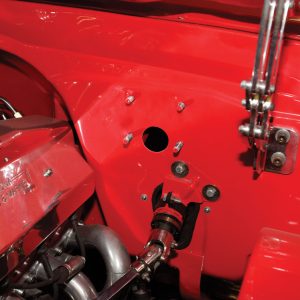

In the long continuation of our Project ’67, the 1967 Chevrolet C10 buildup, several major components and systems have been previously addressed, most notably the Goodwrench LQ4 6.0-liter 366ci Escalade engine buildup by Arizona Speed & Marine. This included the versatile Magnuson Radix supercharger, 4L60E transmission and numerous performance parts and accessories. Continuing along those performance lines and all-out fashion, we would need to contend with the great amount of power this engine package would deliver. Initially, we can’t say that the stock brakes on the C10 were ever designed for the shear torque that would be applied to these assemblies, so it would eventually be necessary to address the stopping performance as well as the go performance. And, after all, brake upgrading was a part of this project plan from the beginning.

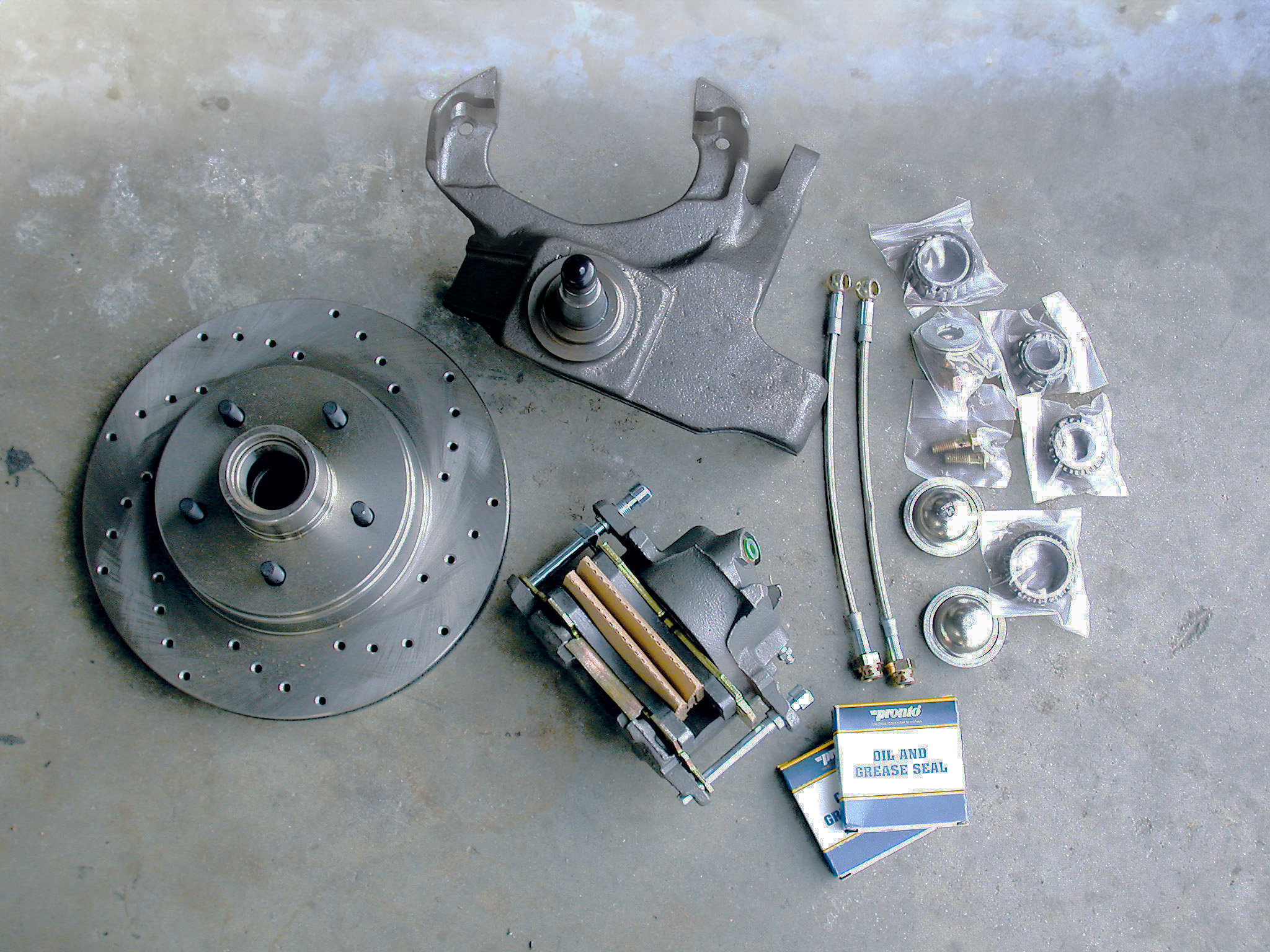

Baer Racing in Phoenix is known for its beefy solutions to all matters of braking considerations. In our case, the recommended solution was a complete set of brakes, including the Baer Track Plus system for the front and rear. Baer Racing has been developing brake upgrade kits for well over a decade now, and it has easy-to-install kits for any number of applications. Starting with a replacement kit for the Fox Mustang chassis, Baer soon increased the number of manufactured systems to over 150 different kits, making it one of the largest selections available for parts, complete systems, rotor replacements and other related options. Each of Baer’s kits is designed for installation with no welding or fabrication of any kind.

For our C10, both the front and rear brake kits feature Baer Claw Track PBR two-piston aluminum front calipers with PBR one-piston Pin Drive rear calipers. Matching large-diameter drilled and slotted rotors—13-inch front and rear—replace the 11.6-inch (front) and 11-inch (rear) OE units. For the standard ’67 GM pickup (available in six-lug or five-lug), the Baer brake kit increases the front track by 0.375 inch on both sides and more on a drop spindle. The standard increase on a typical Mustang II front suspension, as our truck is so equipped, is 0.300 inch. Due to the larger diameter and contact pattern of the rotor/caliper, there is an increase in the amount of braking force generated, and the larger rotors are able to absorb and shed more heat, which keeps the brake system working correctly under difficult driving conditions. This is just what we were searching for in this demanding application. So, with the selection of parts complete, the Chevy was taken to Baer’s facility for the installation of the brakes. Hal Baer and his team quickly equipped our project with the required upgrades, and we were on hand to follow this installation along so that you could see exactly what is involved in getting this job done. Keep in mind that your Chevy pickup doesn’t need to be modified as much as this one is for you to enjoy the benefits of these brakes. Check out this installation to see just how straightforward it is, and then you can decide how much brake you need to give your Chevy real stopping power.