THE AUTO BUILDER

Featured

Road Warrior Tips for Surviving Bad Weather Driving

CHECKING AND CONTAINING FLUIDS

- All Post

- 20 High Priority - SR Super Rod

- Builds

- 25 High Priority - FB Ford Builder

- Cars

- 30 High Priority - AR American Rodder

- 01 Post Status

- 35 High Priority - RD Rodders Digest

- 40 High Priority - OTR On the Road

- 45 High Priority - SRB Street Rod Builder

- 50 High Priority - TB Truck Builder

- 55 High Priority - BSCENE Buckaroo Scene

- 60 High Priority - FPB Family Power Boat

- Trucks

- Swaps

- Performance Boats

- _000 Home Sliders

- Modern/Future Tech

- Builders

- 00 Sidebars

- Manufacturers

- 05 High Priority - HCI Hot Compact Imports

- 05 Publications

- 10 High Priority - CR Chevy Rumble

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Back

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Back

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Back

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Back

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- Steering

- Interior

- Accessories

- Power Adders

- Exterior and Hull

- Engine

- Fuel System

- Electrical

- Outdrives

- Back

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Back

- Chrysler

- Mercury

- Subaru

- Volvo

- Volkswagen

- Chevrolet

- Cadillac

- Pontiac

- GMC

- AMC

- BMW

- Oldsmobile

- Buick

- Jeep

- Acura

- Lincoln

- Mitsubishi

- Ford

- Dodge

- Honda

- Nissan

- Toyota

- Plymouth

- Back

- 05 Pub HCI Hot Compact Imports

- 15 Pub 4x4 4x4 Builder

- 20 Pub SR Super Rod

- 25 Pub FB Ford Builder

- 30 Pub AR American Rodder

- 35 Pub RD Rodders Digest

- 40 Pub OTR On the Road

- 55 Pub BSCENE Buckaroo Scene

- 10 Pub CR Chevy Rumble

- 50 Pub TB Truck Builder

- 60 Pub FPB Family Power Boat

- 45 Pub SRB Street Rod Builder

- Back

- Steve Sellers

- Bobby Alloway

- Chip Foose

- Boyd Coddington

- Rad Rides by Troy

- Cal Auto Creations

- Ring Brothers

- George Barris

- Jesse James

- West Coast Customs

- Jack Fuller

- Carl Casper

- Bob Cullipher

- J.F. Launier

- Jerry Nichols

- Back

- Street Rods

- Hot Rods

- Late Model

- Drag Race

- Handling

- Compact Cars

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Power Adders

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Power Adders

- Electrical

- Exhaust

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Power Adders

- Steering

- Exterior

- Accessories

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Power Adders

- Chassis

- Engine

- Electrical

- Exhaust

- Fuel System

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Engine

- Fuel System

- Electrical

- Power Adders

- Exhaust

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Back

- 05 Post Imported

- 20 Post Missing Images (All)

- 25 Post Missing Images (Partial)

- 15 Post In Progress

- 30 Post Internal Review

- 40 Post On Hold

- 27 Post Missing Content

- 50 Post Approved

- 10 Post Images Imported

- 17 Post Missing TXT Files

- 18 Post Missing PDF Files

- Back

- Chassis

- Engine Swaps

- Interior Swaps

- Driveline

- Back

- Street Trucks

- OffRoad Trucks

- Fuel System

- Electrical

- Exhaust

- Transmission / Drivetrain

- Power Adders

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Transmission / Drivetrain

- Suspension

- Steering

- Brakes

- Wheels and Tires

- Power Adders

- Interior

- Exterior

- Accessories

- Chassis

- Engine

- Fuel System

- Electrical

- Exhaust

- Back

- 01 Sidebar Left

- 01 Sidebar Right

Spotlighter

POPULAR READS

-

Product Spotlight: Bill Mitchell Products Aluminum LS Engine Block

-

Product Spotlight: Pyramid Optimized Design Sequential Aurora Taillight for 1964½–1966 Mustang

-

PRODUCT SPOTLIGHT: 60-66 Chevy C10 Fresh Air Vent Block Off Plate

-

PRODUCT SPOTLIGHT: Cam Covers for GEN/3 Coyote from Pyramid Optimized Design

Shoot ‘Em Up

Story and Photography by Matt Emery

Installing a Barry Grant Six-Shooter

There is probably no engine component that draws the eye more than the fuel intake system. And throughout automotive history there are two examples that seem to hold a magical place for rodders; one is a huge blower and the other is a multiple-carburetor setup.

It was way back in the early days of rodding that multiple-carb setups were in the limelight. Even today there is a certain aura surrounding an engine equipped with six Strombergs. The only problem was that it was nearly impossible to get all of the carbs in sync and working as a team.

Sure, they looked great and worked pretty well if the performance gods were on your side, but more often than not the setup left at least one cylinder fuel starved, while another was overly rich. As a result, the multiple-carb setup fell by the wayside for serious power seekers. This was especially true with the evolution of the four-barrel carb.

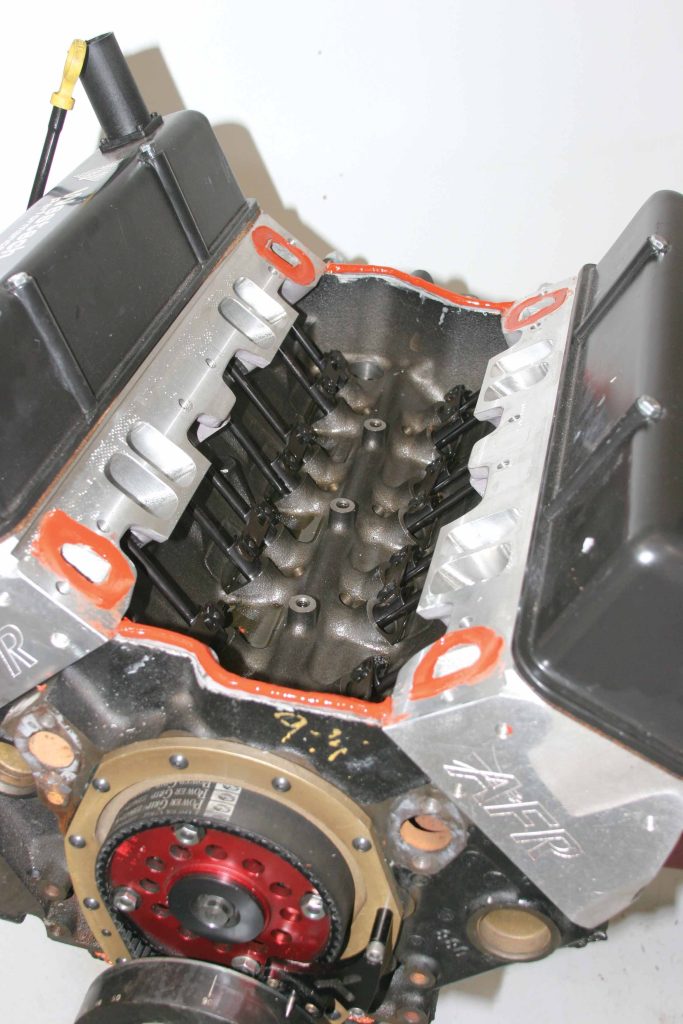

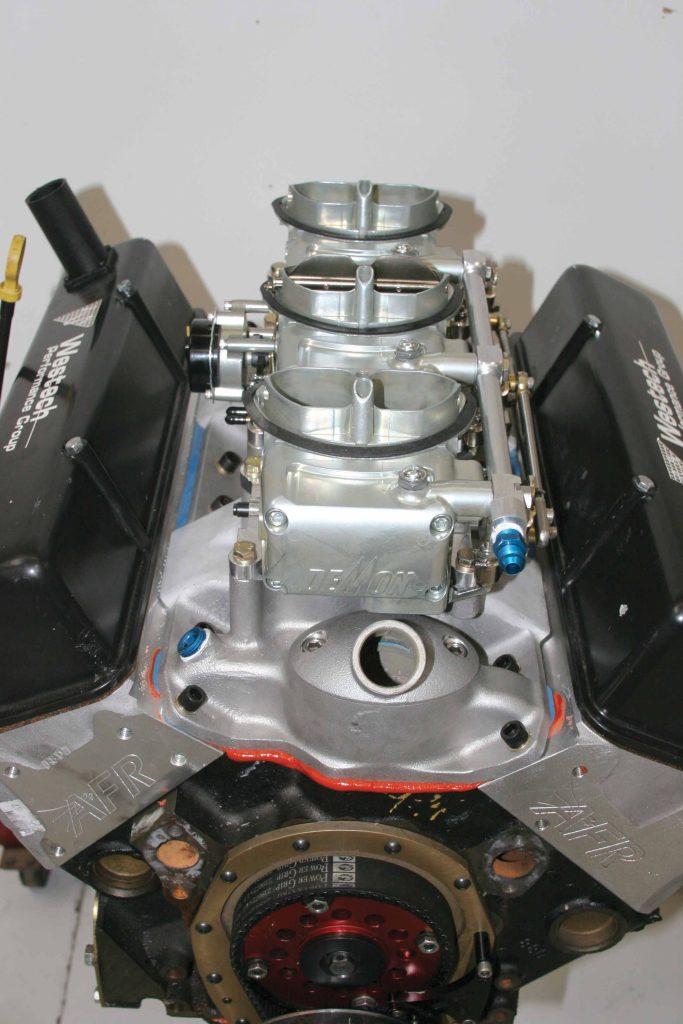

But all that has changed with the introduction of the Barry Grant Six-Shooter. Taking the best of the old and new, Barry Grant has worked his magic and turned the multiple-carb theory into not only a system that looks great but one that actually works great, too. He has done this by using three 250cfm two-barrel carbs, connecting them with a well-designed throttle linkage system (another big problem in past multiple-carb setups) and installing them onto a dual-plenum aluminum intake manifold. The result should bring tears of joy to those who love the look of the multiple systems, without bringing tears of frustration from trying to get them to work.

For many years now, Barry Grant has been building carbs that are performance driven but also provide superior looks. His line of Demon (Road Demon, Speed Demon and Mighty Demon) carburetors feature high-flow characteristics with ease of operation and jetting changes. They even have sight glasses in the side of the float bowls to make it easy to see if the proper fuel level is present. And there is no denying that the look of the Demon carbs is superior to anything out there. The smooth, sculpted look of the carbs is one that is appreciated by those who spend many hours and dollars smoothing the rest of their trucks.

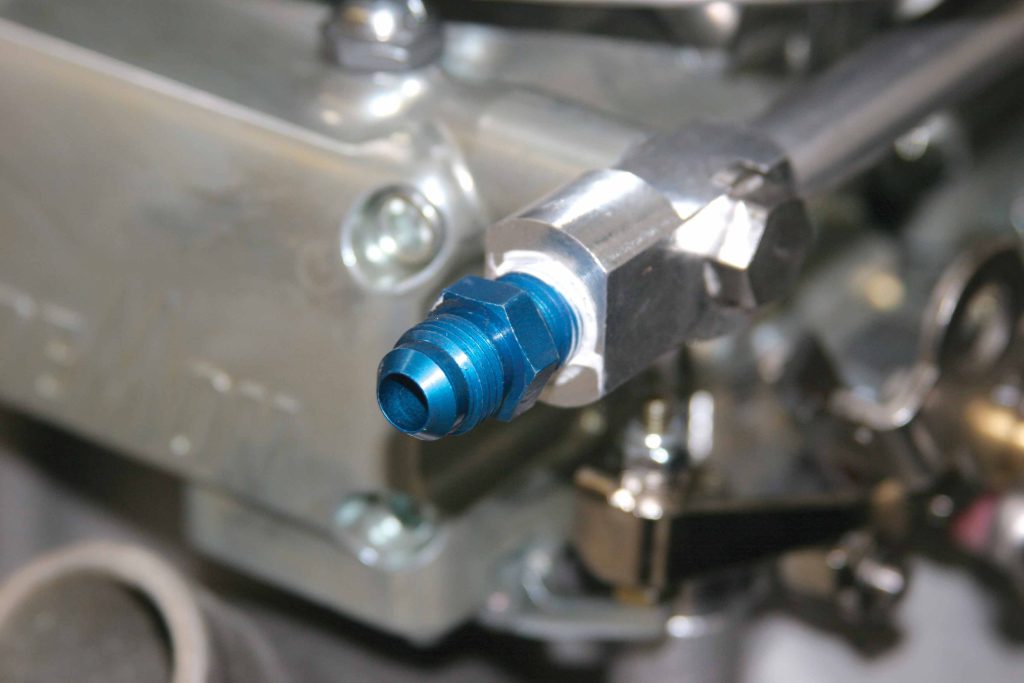

Now with its Six-Shooter, Barry Grant has taken the great aspects of the multiple-carb setup (the looks) and engineered out the problems associated with them (the hassles of actually getting multiple carbs to work with each other). He has done this by tasking the center carburetor with 90 percent of the operating parameters, while the two outside carbs only kick in when extra fuel and air are required, such as during high-speed runs. The carbs are made from zinc but have been finished in silver chromate to give them a polished look, while other pieces, such as the baseplate and metering blocks, are made from billet aluminum. The fuel log is a combination of billet aluminum/stainless steel and features a dual O-ring design to ensure that no fuel can escape.

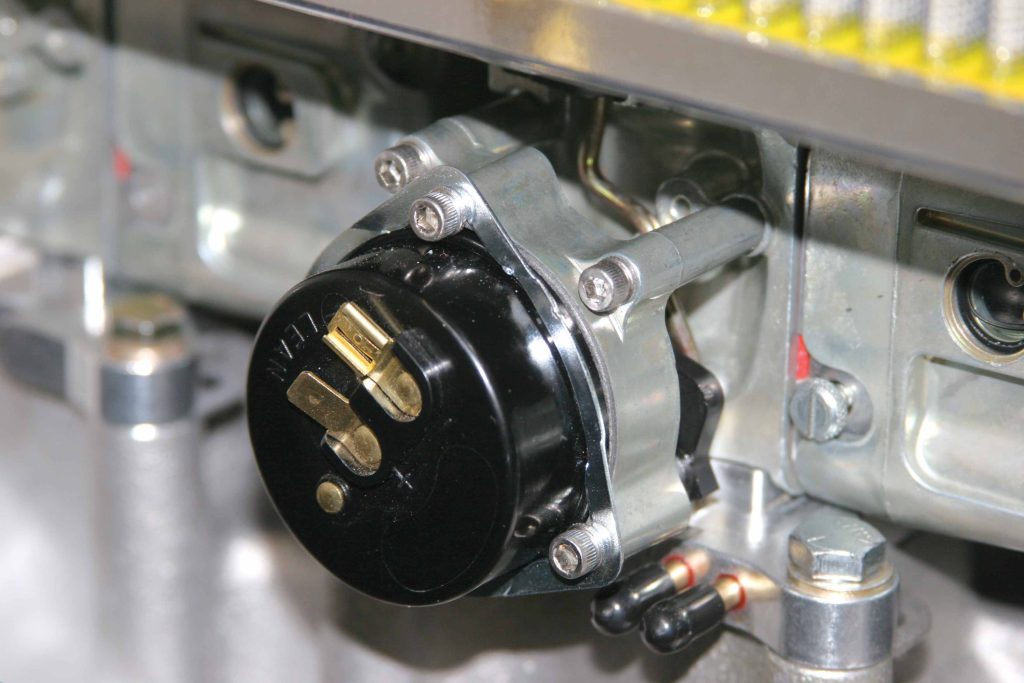

To ease starting, the center carb is equipped with an electric choke, as well as a vacuum-operated power valve. The power valve is a fuel-enrichment device that operates only when the vacuum is low (such as when the throttle is down and speed is high). During these times, the power valve adds additional fuel to the main circuits of the central carburetor. The valve becomes inactive when the engine is at idle and the need for fuel is decreased. Speaking of idle, another feature associated with the center carb is that it is the only one of the three to control idle characteristics. There are two idle-mixture adjusting screws found on the center unit, and since they have no bearing on the idle, the two outboard carbs are preset at the factory. The float-bowl height is adjustable on all three carbs.

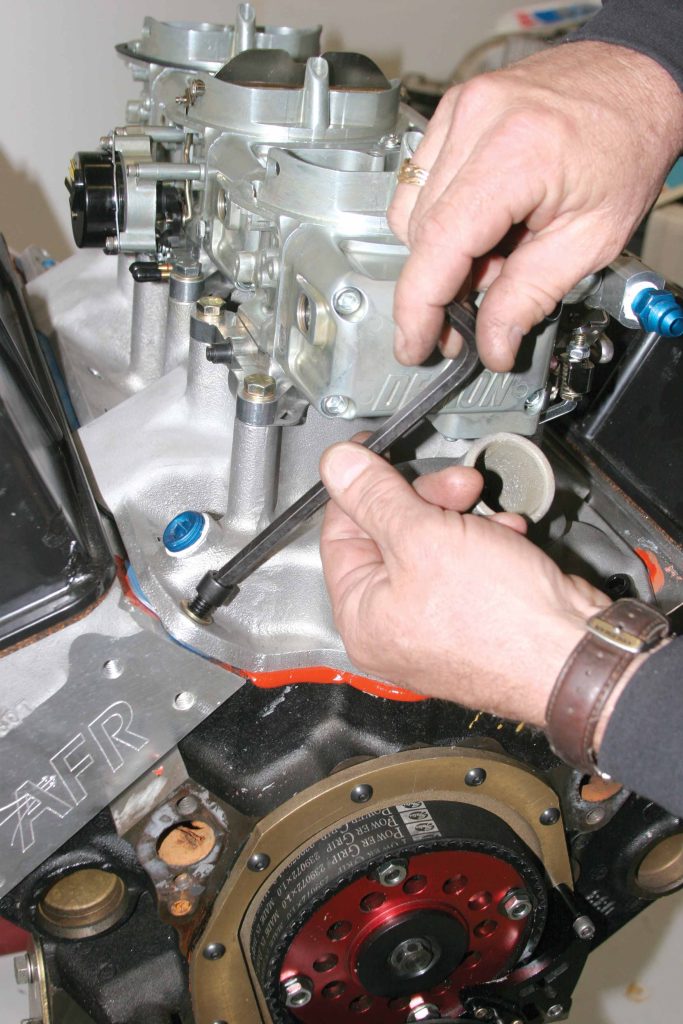

For those vacuum needs such as transmission modulation or distributor advance, the central carburetor has those connections, while the rear carburetor is equipped with a port to connect to a PCV valve or brake booster. The guys at BG have truly thought of everything to make installing and running a Six-Shooter easy.

It is especially easy to do when someone else does it. That is why we were on hand when the guys at Westech Performance Group in Mira Loma, California, installed the Six-Shooter on one of the engines they have been building. Headed up by ex-moto journalist John Bechtel, Westech has gained the reputation of being a top-notch engine testing and product development facility, as well as having both an engine and chassis dyno on site. They like to say, ÒIf you saw it in a magazine, chances are it was tested at Westech.

So, how did the Six-Shooter do on the dyno, you ask? The Westech crew said that after testing the Barry Grant Six-Shooter on a small-block Chevy, the combination even gained a few horses over the same engine compared to when it was equipped with an Edelbrock Performer intake manifold and four-barrel carb. And as you all know, the Performer is a great manifold itself and usually gains 15 to 20 horses over a stock intake manifold! So, the Six-Shooter will give you both great looks and an increase in overall horsepowerÑtruly the best of both worlds.

Follow along as Westech employee Rick Stoner makes quick work of installing the Barry Grant Six-Shooter.

Author

Matt Emery

ARTICLE SOURCES

Barry Grant, Inc.

Dept. TB

1450 McDonald Rd.

Dahlonega, GA 30533

706/864-8544

Westech Performance Group

Dept. TB

11098 Venture Dr., Unit C

Mira Loma, CA 91752

951/685-4767