chevrolet

If you’re in the planning stages of building your car, or even if you have finished and are driving it, there are lots of free or inexpensive things you can do to make your ride faster and/or more efficient. This month, The Auto Builder gives you 25 of those ideas. Most of these free tips simply involve putting your car on a diet. Every 100 pounds of weight removed from your car equals dropping 1/10th of a second at the strip. Even though you may not be racing, the same theory applies to the street, and also to the extra weight you must lug around.

Eyes wide open, with faces up against the glass, kids on a passing school bus wondered what it could be. Amazed by the size of this land yacht, some must have wondered what it was like to pilot such a gas-guzzler, while a few couldn’t help but smile at the resounding roar of the mighty L72 427 underneath it all.

Let’s face it, most of us are working within the confines of a set of unwritten, yet clearly defined, rules of hot rodding. Stance, engine choice and wheels are for the most part selected from a menu of items that come “pre-approved” by our peers. Sure these rules work most of the time, and they provide a degree of certain acceptance when you’re building a traditional pre-’49 hot rod. But all in all, it also makes us a group of conforming nonconformists. However, for some hot rodders (and they are in the minority) building hot rods is about pure ingenuity, a total lack of peer pressure and joy of mixing parts from various sources and making it all work.

Is a love for fast cars—specifically those that are Chevrolet-powered—hereditary? If you were to ask C.A.T. Operations Engineer Kevin Christensen of Castaic, California, he would definitely say that it is.

Sitting slightly nose-high and looking that much more restrained with dog dish hubcaps framed in bias-ply blackwalls, this ’62 Chevy bubbletop is as sinister as it is subdued. In fact, as smooth as these panels are, one has to wonder if this car has ever broken a sweat or even turned a wheel with aggression since it rolled off the showroom floor.

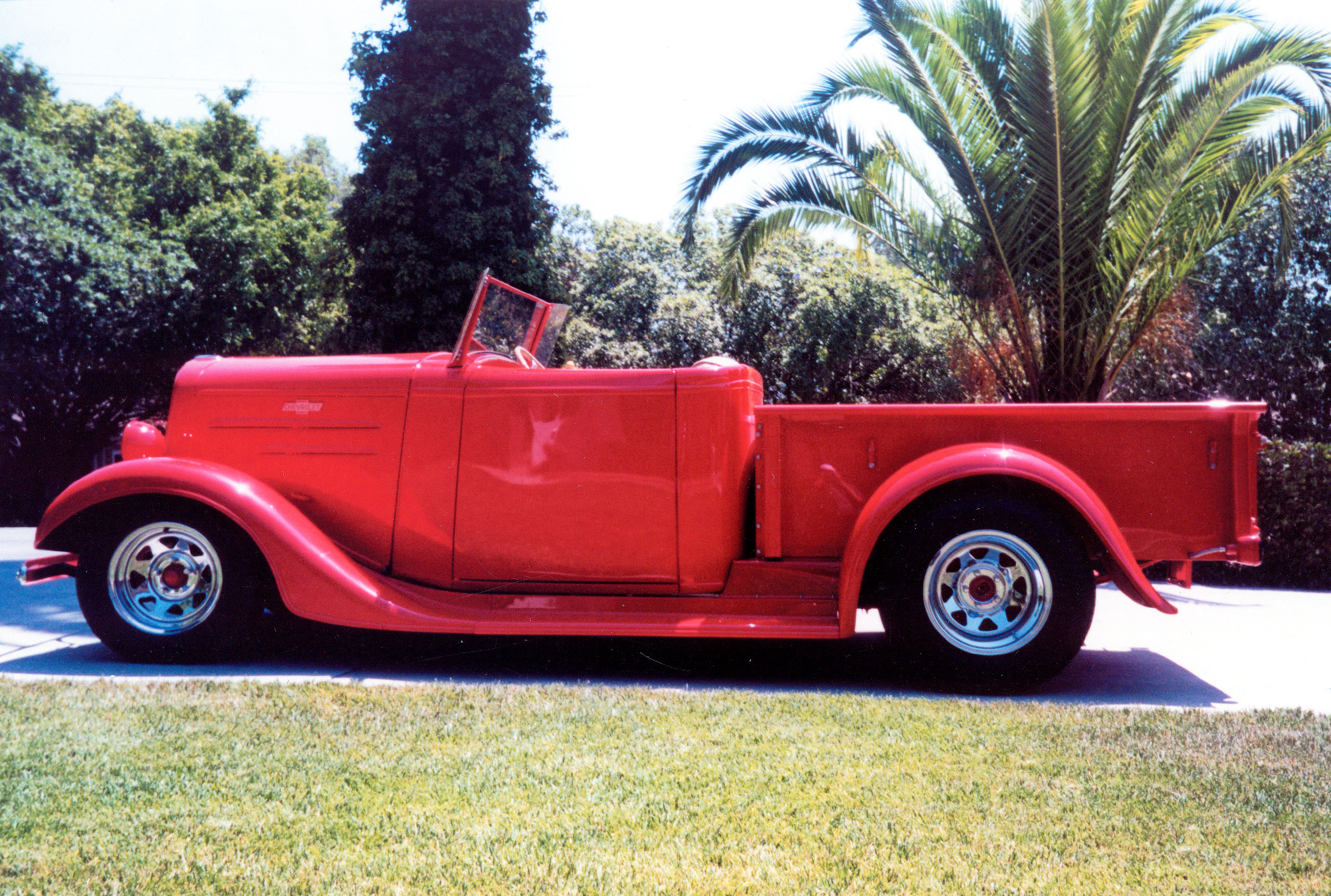

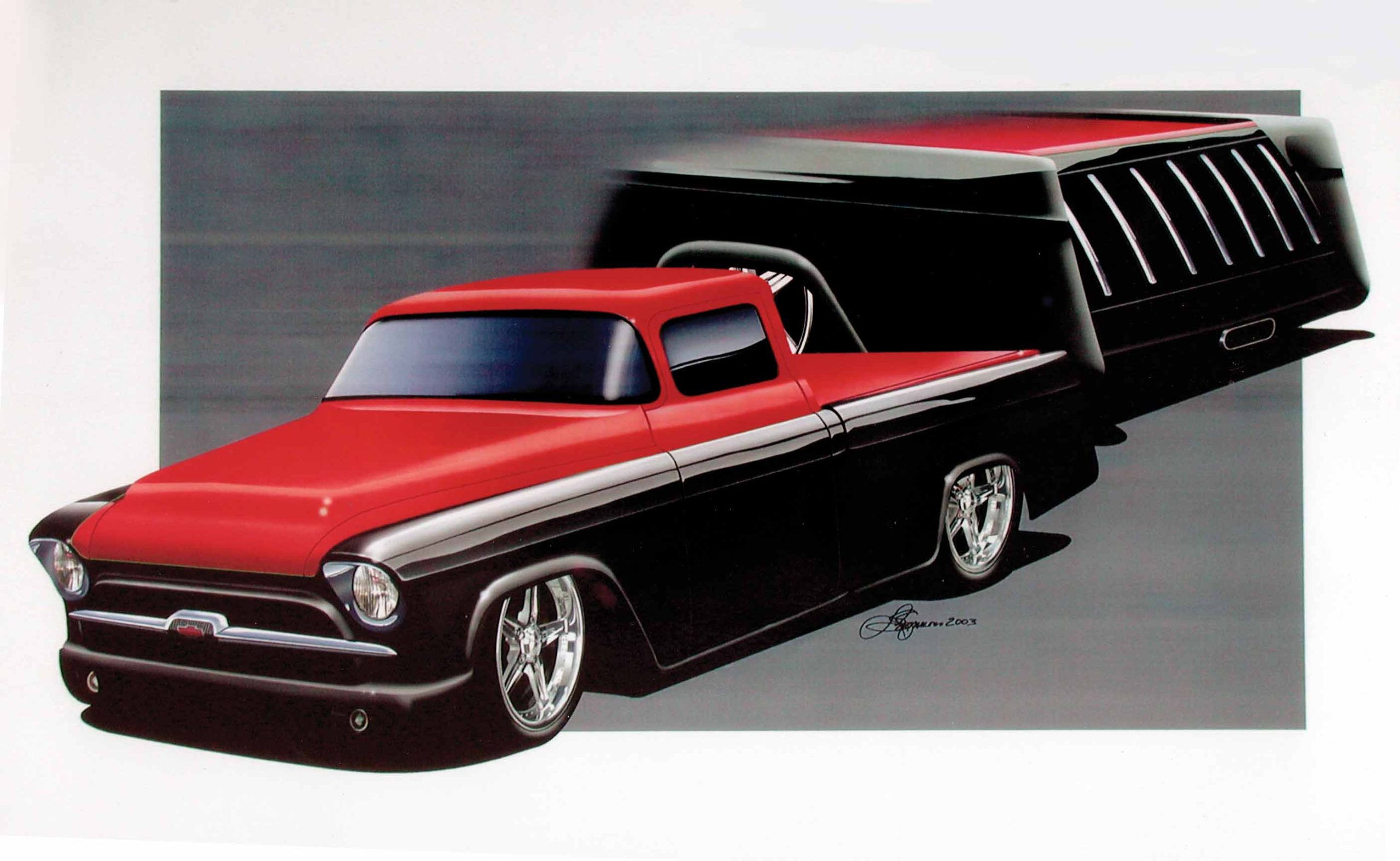

“I started building this car a little over 15 years ago after completing a Pro Street ’70 Camaro RS for my then-16-year-old son, Brad,” says overhead door installation specialist Jim Meltzer of Ventura, California. “I always had the urge to build a ’59 Pro Street Chevrolet El Camino (hence the nickname “U.S. Pro-1”), having owned one of those cars when I was just 21 years old,” he says. “Forty years later, the ’60 came along, and I figured that was close enough. The El Camino project was a joint collaboration with my sons Brad and Rod, and it got off to a great start. We made plans for a big motor and even built a full rollcage for that huge hunk of steel with the intentions of actually racing it.”

These tips are performance-oriented in nature because no matter how good-looking a matching-numbers Chevy might be, getting there and back is vital, as is prepping the car properly and inexpensively with little trouble. While six-figure projects and high-tech billet products flood the market, finding a good deal at the local salvage yard or a worthwhile part left over from a project can be just as exciting and much easier on the wallet.

First-generation Camaros are all the rage these days, and no wonder. With so many ways to bring them into a new era, they make great selections. So, while the big-block power and a five-speed trans served owner Gary Johnson well over the years, rocketing gas prices led him to a more efficient LS2 option.

Simplicity is the key here, as this ’55 Chevy perfectly embodies the sleeper theme with a no-frills look and monster power. It doesn’t even feature all the stainless Bel Air or 210 trim you normally find on most tri-5 models; but even though this is a plain-Jane 150 devoid of trim, Ernie Lankford’s all-black ’55 certainly doesn’t get overlooked.

In part nine of our Cimtex Rods Super Cameo Buildup Series, we covered the installation of the Classic Industries Parts and Accessories reproduction ’55-’59 Chevrolet/GMC lower door hinge panels, doorsill rocker panels, upper and lower door hinges, new right- and left-side front floor pans, inner and outer lower cab patch panels, and right- and left-side truck cab supports. To put it in a nutshell, the crew at Cimtex Rods in Jarrell, Texas, basically rebuilt the whole bottom end of our Super Cameo ’56 Chevrolet big window truck cab from stem to stern. Now, with a rock-solid truck cab firmly bolted onto our Cameo’s highly modified C4 Corvette-suspended truck chassis, we closed with the promise that we would be installing a new set of Dynacorn International Inc. ’55-’59 Chevrolet/GMC reproduction truck doors, followed by angle-chopping the top on our ’56 big-window a total of 3-1/2 inches in the front and 3 inches in the rear. Unfortunately, things didn’t exactly go according to plan.